3D printing revolutionizes padel equipment manufacturing by enabling rapid prototyping1, advanced design customization, and significant production efficiency improvements. In this article, we explore how additive manufacturing2 is reshaping the padel industry, addressing traditional production challenges and offering innovative solutions for high-performance sports gear.

Manufacturing padel equipment has traditionally relied on conventional processes, such as molding and manual assembly. Despite these methods delivering consistent products, they often lack the design flexibility and rapid turnaround required in today’s competitive sports market. 3D printing3 introduces transformative changes by combining speed, precision, and customization, all of which are critical for design engineers, product development managers, and innovation strategists.

In an era where advanced production techniques are redefining the possibilities of sports gear, integrating 3D printing into production lines is key. Companies like NEX Padel, renowned for their high-performance padel rackets, are exploring these new opportunities. By embracing additive manufacturing, manufacturers can meet the evolving demands of high performance, durability, and tailor-made designs that modern athletes require.

Traditional manufacturing methods, while proven over decades, come with inherent issues:

- Limited Customization: Conventional processes often restrict product personalization. Changes to designs typically mean retooling production lines, which is both time-consuming and expensive.

- Long Lead Times: Producing new prototypes or adapting to market trends can be slow with older manufacturing techniques.

- Complex Design Constraints: Achieving intricate designs or integrating advanced materials into a seamless padel racket structure is often challenging.

- Resource Intensive: The assembly and production procedures sometimes result in higher material waste and energy usage.

These limitations echo throughout the padel production process, affecting both innovation and profitability. Manufacturers are therefore tasked with finding a balanced approach that leverages the reliability of traditional techniques while embracing modern technological advancements.

3D printing, also known as additive manufacturing, offers a unique solution by building products layer by layer based on digital designs. This method drastically reduces the time from concept to prototype and allows for rapid iteration on new designs. For padel equipment manufacturing, this means:

- Enhanced Design Flexibility: Engineers can experiment with complex geometries and innovative materials that were traditionally impossible or prohibitively expensive.

- Rapid Prototyping and Testing: Quick production of prototypes aids in faster market validation and reducing time-to-market.

- Cost Efficiency: By minimizing the need for extensive tooling and reducing material wastage, 3D printing lowers overall production costs.

- Customized Performance: Additive manufacturing facilitates the integration of different materials (e.g., advanced carbon fiber alternatives) into singular components, enhancing performance without compromising on weight.

To better understand the impact of 3D printing, consider the following benefit highlights:

| Benefit | Traditional Methods | 3D Printing Advantage |

|---|---|---|

| Customization | Limited, requires retooling | High, digital tweaks for unique designs |

| Lead Time | Weeks to months | Days to a few weeks |

| Material Efficiency | Significant material waste | Optimized material usage through design |

| Design Complexity | Restricted by manufacturing limits | Freedom to innovate with complex shapes |

| Production Costs | High tooling and setup costs | Reduced due to minimal tooling |

With these key advantages, 3D printing is not just an alternative, but often a superior choice for experimental innovation and small to mid-scale product runs.

While the benefits of 3D printing are clear, integrating it into existing production lines requires thoughtful strategies. Below, we outline several steps to successfully navigate this transition:

-

Assess Production Needs:

Evaluate which components of padel equipment would benefit most from additive manufacturing. Components that require complex geometries, tight tolerances, or personalized design are ideal candidates. -

Invest in Hybrid Manufacturing4:

Combining traditional manufacturing with 3D printing can yield the best results. For instance, structural components of a padel racket may still benefit from high-strength carbon fiber composites produced through conventional methods, while ergonomic enhancements or add-on parts can be 3D printed. -

Optimize Digital Design Processes:

Using advanced CAD software5 tailored for 3D printing can streamline workflow and reduce errors. This step is crucial for ensuring that digital models translate accurately into physical products. -

Quality Control and Testing:

New technologies must meet industry quality standards. Implement rigorous testing protocols to ensure that 3D-printed parts achieve the required performance and durability levels of padel equipment. -

Training and Skill Development:

Equip your engineering and production teams with the necessary skills to operate and maintain 3D printing systems. This investment is critical for long-term success and innovation.

Several major sports brands have already showcased the capabilities of 3D printing in their product lines:

- Personalized Protective Gear: Companies like Adidas and Nike have successfully used 3D printing to produce sports helmets and customized gear. Tailored padding and specially designed protective elements highlight how additive manufacturing can enhance safety and performance.

- Prototype Development: By rapidly producing prototypes for testing, manufacturers have reduced product development cycles. This speed-to-market advantage is instrumental in industries where trends and performance innovations are closely watched.

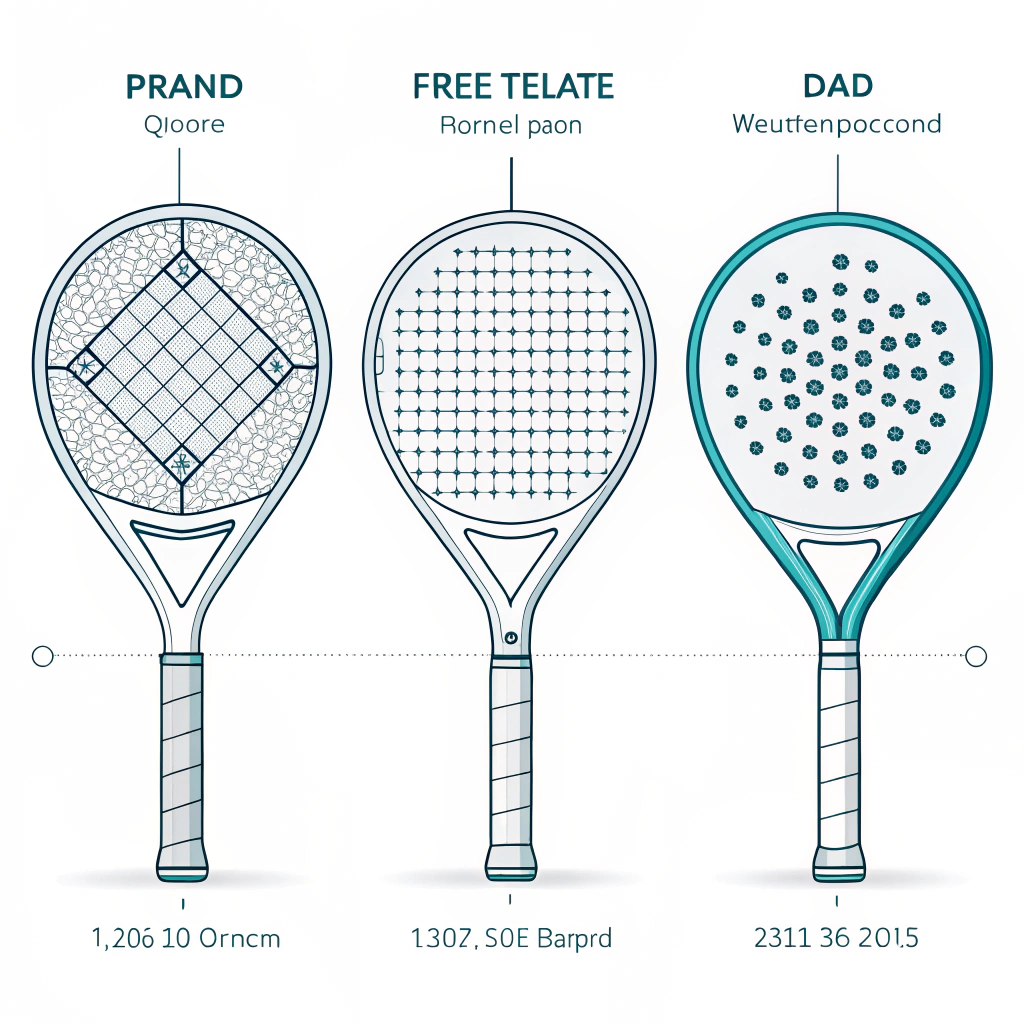

- Complex Racket Designs: In padel, manufacturers like NEX Padel are beginning to experiment with rapidly prototyping unique racket shapes (Diamond, Round, and Teardrop designs) that optimize player performance under various conditions. Additive manufacturing allows for quick adjustments and personalization that would otherwise be cost-prohibitive using traditional techniques.

Using a combination of data-supported insights and hands-on industry experience, these examples underscore how 3D printing is not merely a trend, but a viable solution for improving production efficiency and meeting modern design demands.

Transitioning to a hybrid manufacturing model that includes 3D printing also comes with challenges:

- Material Compatibility: Not all materials used in traditional padel production are suited to 3D printing. Manufacturers must carefully choose or develop printable materials that provide the necessary strength, flexibility, and durability.

- Initial Investment Costs: While 3D printing can reduce long-term production costs, the upfront expense for high-quality printers and training may be considerable. Evaluating return on investment (ROI) is essential.

- Process Optimization: 3D printing involves a new set of parameters, including print speed, layer resolution, and post-processing requirements. Fine-tuning these factors to harmonize with existing production strategies can be complex.

- Quality Assurance: Ensuring the repeatability and consistent quality of 3D printed components is paramount. Incorporating rigorous quality control measures is necessary to meet industry standards.

Despite these hurdles, many companies have successfully navigated the learning curve, resulting in enhanced product innovation and overall production agility.

For companies considering integrating 3D printing into their padel equipment manufacturing lines, the following step-by-step guide is recommended:

-

Conduct a Feasibility Study:

Evaluate your current production capabilities and identify areas where 3D printing can add significant value. Consider factors such as product complexity, customization needs, and market demand. -

Pilot Projects:

Start with controlled pilot projects that focus on a specific component or product line. Use these projects to gather performance data and refine your digital design-to-production process. -

Collaborate With Experts:

Partner with technology providers and industry experts who have experience in both 3D printing and sports equipment manufacturing. These collaborations can ease the transition and offer insights on best practices. -

Invest in Training:

Develop comprehensive training programs for your staff to ensure they are equipped with the skills needed to operate advanced 3D printing systems effectively. -

Monitor and Optimize:

Continuously analyze the performance of 3D printed components, adjusting processes as necessary to optimize efficiency, quality, and cost-effectiveness.

By following these strategies, companies can significantly reduce barriers to integration and enjoy the long-term benefits of an agile, innovative production environment.

3D printing stands as a pivotal technology that is transforming the sports equipment manufacturing landscape. For padel equipment, the benefits are compelling: rapid prototyping, enhanced design flexibility, cost efficiency, and the ability to quickly adapt to market trends. While challenges remain—such as material compatibility, initial investments, and process optimization—the potential for innovation and competitive advantage makes this technology indispensable.

At NEX Padel, our commitment to excellence in production is driving us to explore and integrate new techniques that maintain our leadership in high-performance padel equipment. We encourage design engineers, product development managers, and innovation strategists to consider 3D printing not just as a tool for prototyping, but as a catalyst for complete production transformation. With careful planning, collaboration, and continuous improvement, the integration of additive manufacturing can lead to groundbreaking advancements in the sports equipment industry.

If you're ready to explore how 3D printing can revolutionize your padel equipment manufacturing process, now is the time to take action. Embrace this technology to stay ahead of industry trends and deliver superior products that meet the dynamic needs of today's athletes.

-

How can 3D printing be used in sports?

3D printing in sports allows for the creation of fully customized protective gear and equipment. For example, personalized mouthguards or helmets with tailored 3D-printed padding can be produced, enabling enhanced comfort and performance. Major sports brands have begun adopting these techniques to improve athlete safety and product innovation. -

How is 3D printing used in soccer?

In soccer, 3D printing is used to produce customized protective face gear and other specialized equipment. By scanning athletes' features and using 3D design, manufacturers create gear that offers a precise fit and increased protection during play, addressing both performance and safety needs. -

What are the innovative uses of 3D printing?

Beyond sports, 3D printing is revolutionizing fields such as medicine by creating prosthetics, implants, and surgical tools. In sports equipment, it enables rapid prototyping, complex design creation, and personalized component manufacturing, leading to enhanced product performance and cost-efficiency.

-

rapid prototyping: Learn about rapid prototyping techniques and their role in accelerating the design and development cycle for innovative products. ↩

-

additive manufacturing: Click here to explore an in-depth article on additive manufacturing, covering its principles, benefits, and industrial applications. ↩

-

3D printing: Read more about the fundamentals of 3D printing technology and how it is transforming manufacturing processes across various industries. ↩

-

Hybrid Manufacturing: Discover how integrating traditional methods with 3D printing can optimize production efficiency and drive innovation in manufacturing. ↩

-

advanced CAD software: Find out how advanced CAD tools enhance digital design workflows and ensure precision in converting digital models into high-quality physical products. ↩