t

A padel racket built with 3K carbon fiber1 offers a reliable balance of performance and durability, making it a popular choice among manufacturers and sports equipment distributors. In this article, we compare 3K carbon with other carbon fiber variants, detail its manufacturing precision, and provide actionable recommendations for procurement managers seeking high-performance sports equipment.

Manufacturers face multiple challenges when selecting materials for padel rackets. Given the high demands of competitive play, the chosen carbon fiber must ensure durability, optimal stiffness, and performance that meets the expectations of both professional athletes and everyday players. Companies like NEX Padel leverage advanced production techniques to create rackets that excel in these areas. For procurement managers, it is important to understand the subtle differences between various carbon fiber grades, including parameters such as filament count2, density, and flexibility.

3K carbon fiber is extensively used in padel rackets, and its distinct properties make it highly attractive in the competitive sports equipment market. However, as carbon fiber technology evolves, understanding where 3K stands compared to others (like 12K, 18K, or even 24K) is essential to making an informed procurement decision.

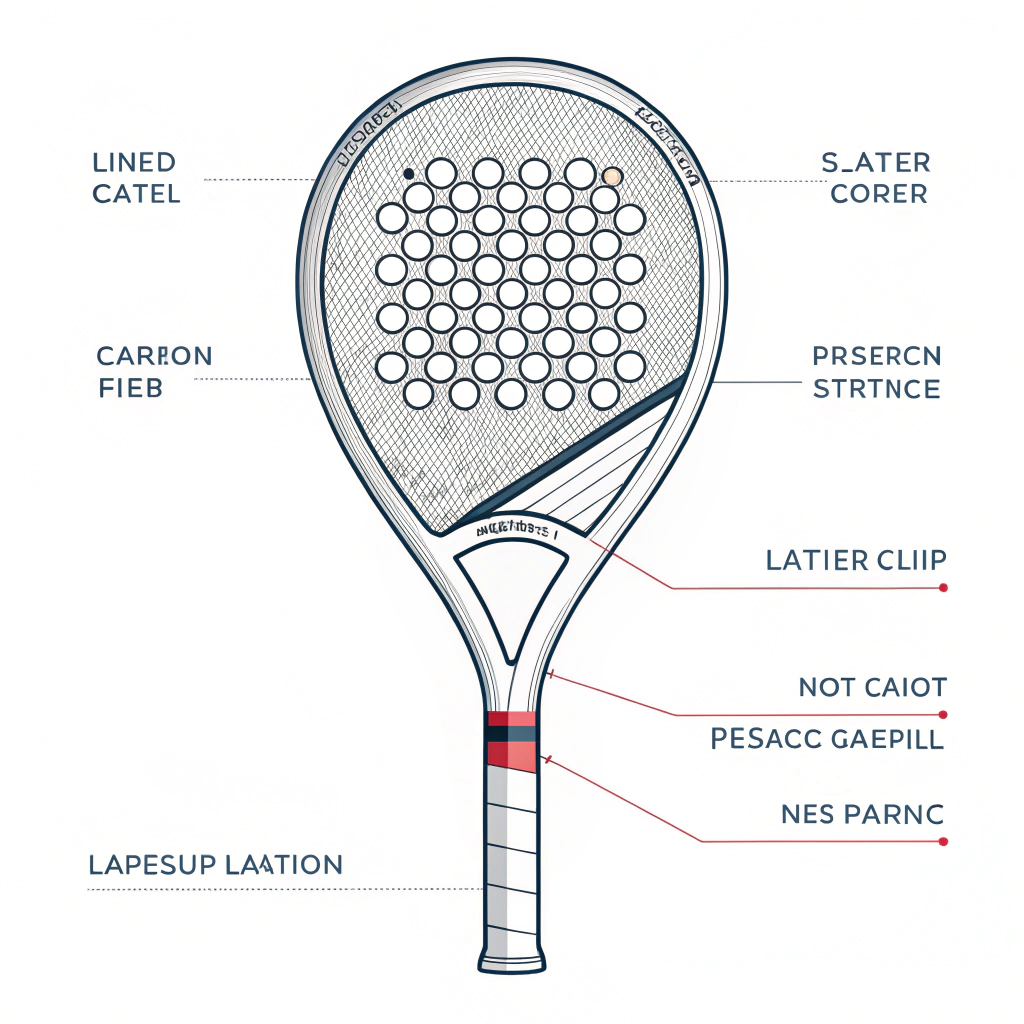

3K carbon fiber is defined by its filament count—roughly 3000 filaments per tow—which influences its density, stiffness, and overall behavior during play. Here are some key characteristics:

- Density and Flexibility: Although 3K carbon has a moderate density, it tends to exhibit a slight flex during impact. This flex can help in generating a controlled ball release, making it suitable for players who need both power and finesse.

- Manufacturing Precision: The production of 3K carbon allows for a precise application of resin and layering techniques. This results in a padel racket that maintains its form and performance consistency even under intense conditions.

- Cost-Effectiveness: Due to its widespread availability and balanced performance characteristics, 3K carbon fiber is a cost-effective option for brands and distributors looking to offer high-quality rackets without inflating production costs.

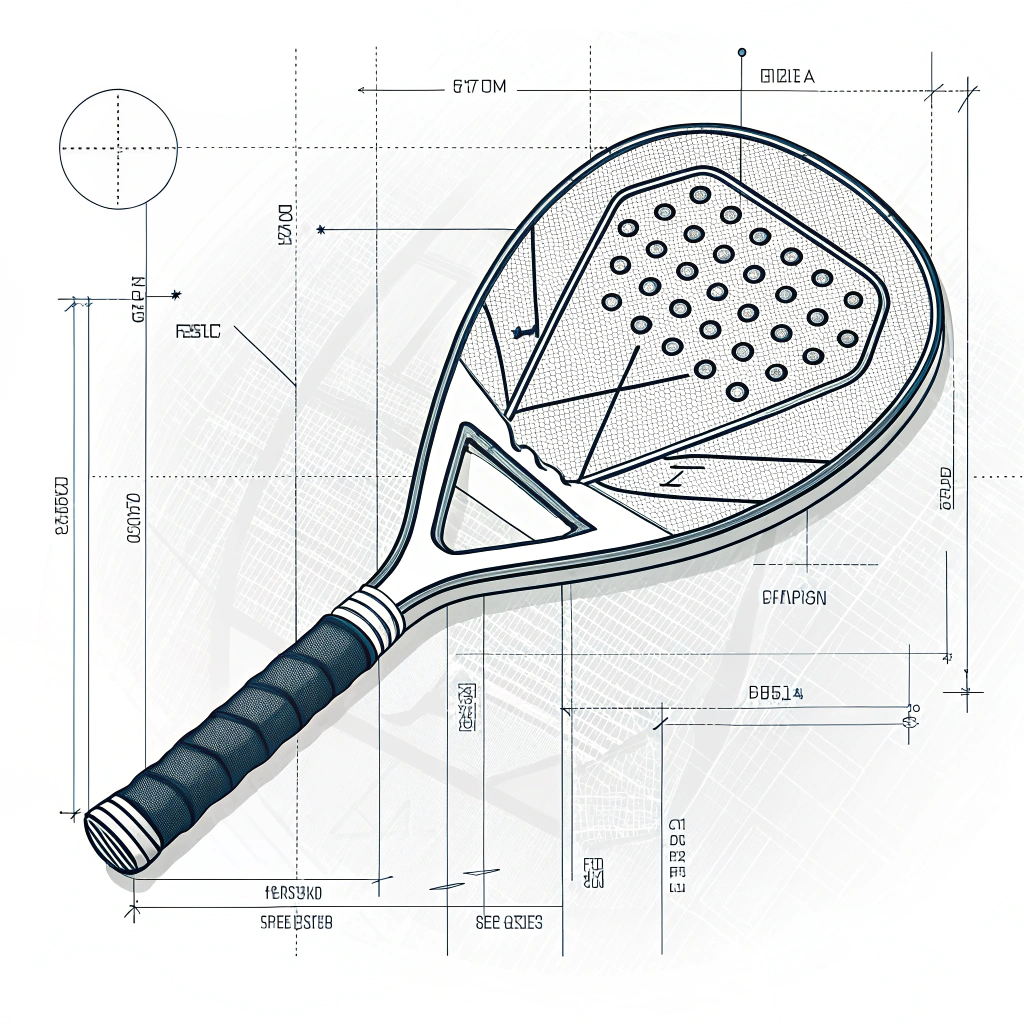

From an engineering and manufacturing point of view, 3K carbon fiber offers a predictable behavior pattern during stress and impacts. Precision manufacturing during production involves layering the carbon fiber in specific orientations to control racket stiffness and balance. For example, by adjusting the layup sequence, manufacturers can design rackets with advantages in ball control and impact resistance.

Below is a comparison table that highlights the differences between 3K and other carbon fiber grades often used in padel rackets:

| Feature | 3K Carbon Fiber | 12K Carbon Fiber | 24K Carbon Fiber |

|---|---|---|---|

| Filament Count | ~3000 per tow | ~12,000 per tow | ~24,000 per tow |

| Density | Moderate | Higher | Highest |

| Flexibility | Moderate flex upon impact | Greater flexibility; softer feel | Minimal flex; very stiff |

| Impact on Play | Enhanced control, predictable power | Softer ball release, less power | Ultimate durability and precision |

| Manufacturing Cost | Cost-effective and scalable | Higher cost due to specialized production | Premium pricing |

| Suitability | Widely used; excellent for balance | Suitable for players preferring a softer touch | Best for high-end, professional use |

This table helps illustrate how 3K carbon fiber strikes a balanced performance that appeals to a broad market segment, making it an attractive option particularly when compared to fibers that cater to more niche performance demands.

At NEX Padel, advanced production techniques ensure that our 3K carbon fiber padel rackets meet the highest standards of quality and performance. Our manufacturing process includes:

- Precision Layup: Using state-of-the-art machinery to control resin distribution and fiber orientation, ensuring each racket prototype is consistent.

- Rapid Prototyping3: Quick sample testing helps verify that modifications yield the desired performance characteristics before full-scale production.

- Customization Capabilities4: Our production lines support a variety of shapes including Diamond, Round, and Teardrop. Moreover, custom prints, colors, handgrips, and logo placements are available to meet specific client needs.

The ability to provide these high levels of customization not only benefits the end consumer but also lowers risk for the procurement manager by ensuring that the product meets both aesthetic and performance requirements.

Manufacturing sports equipment requires rigorous quality control measures. NEX Padel incorporates in-line testing and stress analysis to ensure that every racket produced exhibits consistent performance. Our quality control checks include:

- Dimensional Analysis: Ensuring that every racket meets the specified tolerances.

- Impact Tests: Simulating high-impact conditions to verify durability and performance during intense play.

- Material Integrity Reviews: Using non-destructive testing to detect any flaws in the carbon fiber layers.

Such practices not only confirm the performance benefits of 3K carbon fiber but also add significant value to the final product, ensuring that procurement managers can confidently acquire equipment that will stand up to competitive use.

Procurement managers and product developers typically select 3K carbon fiber for several practical reasons:

- Balanced Performance: 3K provides a combination of control and power that can satisfy both recreational and semi-professional players.

- Cost Effectiveness: It offers a high-performance solution without the premium price tag associated with higher filament-count materials.

- Customization Potential: Manufacturers can tailor the racket’s performance characteristics through varying production techniques, making it adaptable for different player profiles and market segments.

- Proven Durability: Extensive testing has shown that 3K carbon fiber exhibits sufficient durability for extended usage, ensuring reliability over the racket’s lifetime.

When evaluating padel racket options, consider the following points:

- Market Positioning: If your brand targets a broad audience, 3K carbon fiber’s balanced performance can appeal to a wide range of players. For specialized markets, other carbon variants might be considered.

- Production Lead Time: With rapid prototyping and quick sample approval processes as standard practice, 3K carbon fiber enables a more agile production cycle. This is particularly beneficial in markets where demand fluctuates seasonally.

- Total Cost of Ownership: Though higher filament counts like 24K offer excellent durability, their initial production cost is also higher. For cost-sensitive projects, 3K offers an ideal compromise between performance and budget.

A recent project at NEX Padel involved customizing a series of padel rackets aimed at mid-tier market players. The use of 3K carbon fiber was instrumental in achieving the following results:

- A 20% reduction in production costs compared to prototypes with 12K carbon fiber.

- Consistent performance metrics across multiple batches, verified through rigorous impact testing.

- Positive market feedback, with users highlighting the racket’s balance of control and power during gameplay.

This example underscores the value proposition of 3K carbon fiber as a material that meets market needs while optimizing production efficiency.

For procurement managers and product developers evaluating new padel rackets, 3K carbon fiber stands out as a reliable and cost-effective choice. Its balanced performance, combined with advanced manufacturing and customization capabilities, makes it an ideal option for brands aiming to cater to a broad range of players. By leveraging these properties, companies can ensure their product lines are competitive in both quality and price.

It is essential to consider your market position, production capabilities, and the specific demands of your user base when making a final decision. In many cases, the benefits of 3K carbon fiber in terms of performance and cost can lead to a strong return on investment, supporting both short-term and long-term brand strategies.

For companies like NEX Padel, which prioritize precision manufacturing and innovation, 3K carbon fiber is more than just a material—it is a core enabler of high-performance sports equipment that meets the evolving needs of the global market.

-

Is 3K carbon fiber good for padel?

Yes, 3K carbon fiber is commonly used in padel rackets due to its balanced characteristics. Its moderate density and controlled flexibility allow for a predictable ball release, making it an excellent choice for a wide range of players. -

What is the difference between 3K and 12K carbon padel racquets?

The primary difference lies in the filament count and resulting flexibility. While 3K carbon fiber offers a balance of power and control, 12K carbon fiber provides a softer feel with greater flexibility, which may result in a different impact on ball behavior during games. -

What is the highest carbon padel racket?

The highest quality carbon padel racket typically uses materials like 24K carbon, which promise superior durability and stability. These rackets are designed for high-end, professional use and are known for their consistent performance, albeit at a premium cost.

-

3K carbon fiber: Learn more about the unique properties, benefits, and applications of 3K carbon fiber in sports equipment manufacturing, including its impact on performance and durability. ↩

-

filament count: Explore how filament count affects the structural integrity and performance characteristics of composite materials used in high-performance sports gear. ↩

-

Rapid Prototyping: Discover how rapid prototyping accelerates product development cycles by allowing quick iteration and testing, ensuring that design modifications meet market demands efficiently. ↩

-

Customization Capabilities: Understand the benefits of customization in manufacturing, from tailor-made designs to scalable production solutions that cater to diverse consumer requirements. ↩