Introduction

Padel has rapidly grown from a niche sport to a global phenomenon in recent years 3D Printing and Padel: Sports and technology revolution for professionals and amateurs] With its blend of elements from tennis and squash, the game’s soaring popularity has driven innovation in padel equipment, especially rackets. Modern padel rackets (also known as pala in Spanish) are highly specialized pieces of sports gear. They differ from tennis racquets in that they have a solid, perforated hitting surface instead of strings, and they are typically shorter and thicker. As the sport expands, players and brands alike seek customized padel rackets that cater to specific playing styles, aesthetic preferences, and emerging values like sustainability.

(

Customization in padel rackets can range from tailoring the racket’s shape and weight balance to selecting advanced materials and personalized graphics. For manufacturers, producing custom rackets requires mastery over the entire production process – from design and material selection to fabrication and quality testing. It is a complex endeavor that blends cutting-edge technology with skilled craftsmanship. Each stage must be carefully controlled to ensure that a racket not only meets the client’s specifications but also adheres to high performance and safety standards.

This article provides a comprehensive, step-by-step exploration of how padel rackets are made and what goes into creating customized designs. We will delve into the complete production process, discussing everything from raw material selection (with a focus on eco-friendly options) to advanced manufacturing techniques and strict quality control measures. Throughout each major section, we will highlight the advantages that NEX Padel – a leading padel racket manufacturer – brings to the table, such as its use of sustainable materials, state-of-the-art equipment, and rapid prototyping capabilities. By examining both general industry practices and NEX Padel’s specific approaches, readers will gain insight into what makes a high-quality custom padel racket and why OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) partnerships are so valuable for sports brands today.

Padel Racket Design and Components

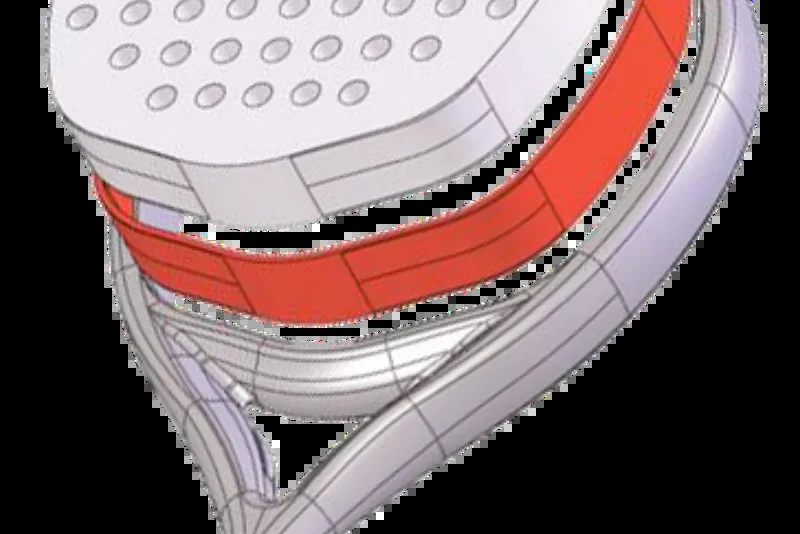

(China Padel Racket Manufacturers, Suppliers, Factory - nexpadel.com) An exploded 3D model of a padel racket, illustrating its internal parts: the core (shown in red) and the surrounding frame and face layers (in grey). This visualization highlights each component's position and role in the racket’s structure. Understanding the racket’s anatomy is crucial when planning customizations.

Before diving into manufacturing, it’s important to understand the basic design and components of a padel racket. A standard padel racket consists of several key parts: the core, the surface (face), the frame, the grip, and the drilled holes on the face. Each of these elements can be tuned or customized to achieve certain performance characteristics:

- Core: The interior of the racket is made of a foam material that provides the racket’s bounce and feel. This core is usually EVA (ethylene-vinyl acetate) foam or a similar polymer foam, which can vary in density and hardness. A harder core yields more power but less comfort, whereas a softer core offers more control and shock absorption.

- Surface: Covering both sides of the core are layers of composite material (typically fiberglass or carbon fiber) that form the racket’s hitting surface. This surface, often called the face or “planes” of the racket, must be rigid enough to transfer energy to the ball but also durable against impacts.

- Frame: The perimeter or frame around the racket gives it structure and protects the core. In many modern designs, the frame is integrated with the surface material as a single piece (a unibody construction), often reinforced with carbon fiber for extra strength.

- Grip and Handle: The racket’s handle is attached to the frame and is covered with a grip. Inside the handle, some rackets include a wrist strap for safety. The handle’s length and thickness can vary slightly, and it usually contains a plastic cap at the butt (end cap) which can also be customized (e.g., with a logo or specific shape).

- Holes: Padel rackets have an array of holes drilled through the face. These holes reduce air resistance and weight, and they also influence how the racket swings and how it contacts the ball. The number, size, and pattern of holes can differ by design, affecting the sweet spot and aerodynamics.

One of the most significant design considerations is the shape of the racket head. Padel rackets generally come in three primary shapes: round, teardrop, and diamond. Each shape offers distinct playing characteristics:

- Round rackets have a centrally located sweet spot and offer superior control. They are usually balanced (evenly weighted) and forgiving on off-center hits, making them ideal for beginners or players who prioritize control over power. However, round shapes typically generate slightly less power for smashes.

- Teardrop rackets are a hybrid shape between round and diamond. They provide a balance of power and control, with a sweet spot that is slightly above the center. Teardrop designs give a moderate boost in power while still maintaining good control, suiting intermediate players or all-round players seeking versatility.

- Diamond rackets have a more top-heavy distribution with the sweet spot higher up on the face. This shape is geared toward advanced players who want maximum power in their shots; the head-heavy balance allows strong smashes and volleys. The trade-off is that diamond-shaped rackets are less forgiving and harder to maneuver for less experienced players.

Besides shape, other design parameters include the racket’s weight (most padel rackets weigh roughly between 350 and 380 grams) and balance point (whether the weight is more towards the head or handle). A head-heavy racket (higher balance point) can increase power in smashes but may feel less nimble, whereas a head-light racket (lower balance point) can be easier to maneuver at the net but might sacrifice some hitting power. Manufacturers and custom designers consider these factors to tailor a racket to a player’s style – for example, a defensive player might prefer a lighter, head-light racket for quick reactions, while an aggressive player might opt for a heavier, head-heavy racket for maximum ball speed.

Another design feature often customized is the surface texture of the racket face. Some rackets have a smooth glossy finish, while others have a sandpaper-like gritty texture or patterned surface. A textured surface can enhance spin on the ball by “grabbing” it upon contact, which is useful for players who utilize a lot of slice or topspin. The choice of a glossy versus sanded finish thus can be a performance customization: glossy surfaces tend to swing a bit faster through the air (less drag) and may provide a tiny power boost, whereas rough surfaces trade a bit of speed for more spin control (Our Materials - nexpadel.com).

Finally, aesthetics play a role in customization. Brands or individual customers often want specific color schemes, logos, or graphics on their rackets to reflect their identity. The cosmetic design does not generally affect play, but applying these designs involves its own processes (painting, decals, etc.) during production.

NEX Padel’s Design Expertise: At the design stage, NEX Padel leverages both its experienced engineers and rapid prototyping tools to refine racket concepts. Years of manufacturing know-how have given NEX Padel insight into which shapes and constructions best suit different player profiles. For instance, the team can recommend an optimal balance and frame shape based on whether a client brand is targeting professional tournament players or casual enthusiasts. NEX Padel uses advanced CAD (computer-aided design) software to create 3D models of custom racket designs, allowing precise adjustments to dimensions, weight distribution, and hole patterns before any physical prototype is made. In fact, rapid prototyping technology – such as 3D printing for grip molds or CNC machining for sample molds – enables NEX Padel to produce functional prototype rackets quickly for testing. This means a brand collaborating with NEX Padel can go through several design iterations in a short time, testing each prototype’s feel and performance on the court. By shortening the development cycle and fine-tuning designs early, NEX Padel ensures that the final custom racket will meet the intended specifications and performance criteria. The ability to iterate quickly on prototypes is a major advantage that speeds up innovation and allows bespoke designs to be perfected before mass production.

Material Selection: Choosing the Right Materials (and the Eco-Friendly Alternatives)

The choice of materials is fundamental to padel racket performance. High-quality materials can make a racket lighter, stronger, and more responsive, whereas poor material choices could result in a racket that feels dead or breaks under stress. In this section, we detail the materials commonly used in each part of a padel racket and highlight how manufacturers like NEX Padel are incorporating eco-friendly materials into the mix.

Surface Materials (Faces and Frame)

Carbon fiber fabrics, like the 3K woven pattern shown above, are a common surface material in padel rackets. Such composites offer an exceptional strength-to-weight ratio. This characteristic translates into powerful shots and a durable racket face.

Most premium padel rackets use composite laminates for the surface – primarily fiberglass, carbon fiber, or hybrids of the two:

-

Fiberglass: Fiberglass (woven glass fiber) is a popular choice for the outer layers in many rackets, especially intermediate-level ones. It is more flexible and elastic than carbon fiber. This flexibility can give the racket a slightly softer feel and larger sweet spot, which is forgiving for recreational players. Fiberglass is also generally cheaper than carbon fiber. However, it’s slightly heavier and less stiff, meaning rackets with fiberglass faces may not generate as much power as full carbon ones.

-

Carbon Fiber: Carbon fiber is a stiffer and lighter material compared to fiberglass. Rackets that incorporate carbon fiber (in part or fully) tend to be more expensive but offer superior performance for advanced players. Carbon fiber’s high strength-to-weight ratio means that a racket can be made very rigid without being heavy. This rigidity provides greater power on smashes and volleys because less energy is lost to deformation. Carbon fiber faces also tend to be very durable. Different grades of carbon fiber are used:

- 3K, 12K, 18K Carbon: These numbers (3K, 12K, 18K) refer to the number of filaments in each tow (bundle of fibers) in the weave. 3K is a common standard weave (3000 filaments per tow) producing the classic small checkered pattern. 12K and 18K have larger, flatter weaves. Generally, a higher tow count can slightly increase the flexibility of the face (since the fibers are spread out more) and adjust the weight. Brands sometimes market higher-K carbon as a premium feature for improved feel or power. Ultimately, all are forms of carbon fiber, and the performance differences come down to the specific racket construction and layering.

- Graphite/Graphene: In racket sports terminology, “graphite” often refers to carbon fiber composites. Some manufacturers (like HEAD with its Graphene technology) incorporate graphene or other nano-materials with carbon fiber to further strengthen the frame without adding weight. These advanced materials are part of the evolution of carbon composites, yielding even better rigidity and durability.

-

Kevlar/Aramid: A few rackets include Kevlar (an aramid fiber) reinforcement, usually in the frame or in a hybrid with carbon fiber. Kevlar is very tough and handles impacts well, which can improve the racket’s shock absorption and durability on the edges. It’s less common but is another material option for customization, especially if a brand wants a racket known for extra durability.

-

Hybrid Composites: It’s common to see combinations, such as carbon fiber surface with fiberglass underneath, to blend characteristics. For example, some designs use a layer of carbon for stiffness and power, backed by a layer of fiberglass for added flexibility and comfort. This way, the racket can cater to a wider range of playing characteristics (power + control). Some high-end models also use new fibers or mixes like basalt fiber or aluminum-carbon weave to tweak performance.

The frame around the edge is typically formed by the same composite layers wrapping around, especially in a one-piece construction. In older or budget designs, sometimes the frame might be a separate molded piece attached to the faces, potentially made of carbon fiber or even plastic. But modern high-end padel rackets, like those produced by NEX Padel, are often made as a one-piece thermoformed unibody, meaning the frame and face are cured together in one mold. This unibody approach using carbon fiber or fiberglass composites ensures a stronger structure (no weak glue joints) and more consistent performance across the racket head (Our Production Techs - nexpadel.com).

From a customization standpoint, a brand can choose the surface material layup to target certain player segments. For example, a brand might request: a full carbon fiber racket (for pro-level stiffness and power), a fiberglass-carbon hybrid (for intermediate players needing some flex and comfort), or even 100% fiberglass (for entry-level affordability and easier playability). NEX Padel advises its partners on these choices by sharing detailed comparisons of materials. For instance, they highlight that fiberglass offers more flexibility and a higher fault tolerance, suitable for beginners, while carbon fiber (especially high-modulus carbon) provides the rigidity and responsiveness for powerful hitting that advanced players demand (Our Materials - nexpadel.com). By selecting the appropriate combination of surface materials, a custom racket can be tuned to the target users’ needs.

Core Material

Inside the padel racket is the core foam, which significantly affects how the racket feels and responds on ball impact. The two primary types of foam used are EVA foam and PE (polyethylene) foam, though EVA dominates the market.

- EVA Foam (Ethylene-Vinyl Acetate): EVA is a closed-cell foam known for its resilience and relative stiffness. Most padel rackets use EVA in one form or another. EVA cores come in different densities/hardness levels. Manufacturers often classify them broadly as hard, medium, or soft EVA.

- A hard EVA core (sometimes called “High Density” or branded with terms like EVA “High Memory”) will rebound quickly and not compress much on ball impact. This yields more power (because the ball spends less time on the racket, a more explosive rebound) but gives a harder feel and can transmit more vibrations to the arm. Hard cores are favored by players who hit aggressively and want maximum power, often in warmer climates where the foam naturally softens a bit during play.

- A soft EVA core compresses more on impact, providing a longer contact time which can increase control and reduce vibration (thus more comfort). Soft cores make the racket feel gentler and can help with precision and with players who have arm injuries or need more absorption. The downside is that very soft cores can lack power, especially in cold conditions (where the foam can become too stiff). Many modern rackets use medium or “multi-density” EVA, sometimes with multiple layers of different hardness (e.g., a harder outer layer and softer inner layer) to try to provide both power and comfort depending on the shot.

- PE Foam (Polyethylene Foam): Some rackets (particularly older models or certain brands) have used a foam referred to simply as “foam” which is often a polyethylene-based foam. PE foam is generally softer and offers great elasticity and ball rebound, giving a very cushioned feel and excellent vibration dampening. Rackets with a PE core tend to be very comfortable and have good “ball output” (the ball springs off the racket easily). However, PE foam cores can be less durable (they may break down or lose resilience faster than EVA) and can feel overly soft for players who want more crispness. Over time, the trend has moved toward EVA for most performance rackets, sometimes with PE used in beginner rackets.

For most custom padel rackets, choosing the right foam is about balancing power and control. NEX Padel provides options for core hardness when clients order custom models. In fact, they note that EVA foam is the standard core material for nearly all padel rackets, ensuring consistent performance and durability. Within EVA, they offer harder or softer variants to match the racket’s intended purpose. A successful example is how some brands label their rackets: a “Power” model might come with a Hard EVA core to maximize speed on the ball, whereas a “Comfort” model might use a Soft EVA to reduce vibrations and improve control on touch shots.

Besides EVA and PE, the industry is also exploring innovative core structures. Some companies experiment with 3D-printed cores or foam injected with small beads for different damping effects. For instance, additive manufacturing has enabled the creation of complex lattice structures in a core, aiming to improve control and feel. While such experimental designs are not yet mainstream, they represent the cutting-edge possibilities for customization in the future.

Resin and Surface Coatings

The composite layers of a padel racket are impregnated with resin (usually epoxy) during manufacturing to bind fibers together. The type of resin and any coatings on the surface also form part of the material selection discussion:

- Epoxy Resin: The majority of rackets use epoxy, a thermoset resin that hardens to bind the carbon or glass fibers. The quality of the resin and the curing process can affect racket durability (poorly cured or brittle resin could lead to delamination or cracks). Manufacturers often have proprietary resin formulas or curing cycles to optimize strength and flexibility. Some are now exploring more eco-friendly resins (bio-resins) that incorporate renewable ingredients.

- Surface Finish/Coating: After the racket is formed, the surface might be coated with an additional layer for protection and playing characteristics:

- Glossy Finish: A smooth glossy clear coat can be applied, which seals the surface and gives a shiny look. It can slightly reduce air resistance and is preferred by players who like a bit more speed through the air.

- Sandpaper/Grit Finish: To create a rough surface for spin, manufacturers paint or lacquer the face with a gritty coat (often silica sand mixed into a clear resin). This rough texture helps grab the ball to impart spin, which is valuable for players who rely on sliced or topspin shots. Over time, this sanded texture might wear down, so quality of the coating matters for longevity.

- Matte/Soft-Touch Finishes: Some rackets have a matte finish or even rubberized feel; these are mostly cosmetic but can also slightly affect how the racket moves through the air or how it feels to the touch.

The coatings need to be durable (padel rackets often scrape walls or turf) and also safe (compliant with regulations on chemicals). High-quality paints and clear coats resist chipping and UV degradation, ensuring the racket looks good and performs consistently over its life.

Embracing Eco-Friendly Materials

An important trend in material selection is the push towards sustainable and eco-friendly materials. Traditionally, padel rackets use materials that are not particularly eco-friendly – carbon fiber production is energy-intensive, and epoxy resin is a petroleum-derived product that isn’t biodegradable. However, the industry is changing:

-

Recycled Carbon Fiber: Initiatives are underway to use recycled carbon fibers in rackets. For example, a collaboration between Decathlon (a major sports brand) and a materials company called Fairmat introduced padel rackets made with recycled carbon fiber composites. The recycled fibers come from repurposed industrial carbon composite waste, reducing the need for new carbon production. This collaboration resulted in rackets that are lightweight, robust and eco-friendly, achieving a significant reduction in environmental impact while maintaining exceptional performance.

-

Bio-Based Resins: Companies are experimenting with bio-resins (resins derived partly from plant-based sources) as an alternative to traditional epoxies. These bio-resins can cure and perform similar to conventional epoxy but have a lower carbon footprint. In the Fairmat-Decathlon project, for instance, they mentioned using bio-sourced resins along with recycled fibers (Recycled carbon for Kuikma rackets in 2024 | Padel Magazine), showing that high-performance rackets can be made more sustainable.

-

Natural Fibers: Some racket manufacturers have looked into natural fibers like flax or hemp as a partial replacement for carbon or glass fibers. Natural fibers can offer excellent vibration damping. For example, a few concept padel rackets have incorporated flax fiber layers to advertise a “green” angle. While these are not yet widespread, they point to a future where racket layups might include a mix of synthetic and natural fibers.

-

Recycled Plastics and Polymers: Even outside the core structural materials, there are opportunities to use recycled materials – e.g., recycled plastics for bumper guards or handle caps, or recycled foam for the core (though performance consistency is key here). Some brands have also looked at more recyclable thermoplastic composites, where the racket could theoretically be melted down and reused, unlike thermoset epoxies which cannot be remolded once cured.

-

Eco-Friendly Manufacturing: Beyond materials, eco-conscious brands work with manufacturers that implement environmentally friendly practices – such as efficient energy use, waste reduction (recycling excess carbon fiber cuts, reusing foam off-cuts), and safe disposal of chemicals. NEX Padel, for instance, emphasizes reduced material waste in its thermoforming production, contributing to a more eco-friendly process , and continuously looks for ways to reduce energy consumption in manufacturing.

Consumers are increasingly aware of environmental issues, and there is a rising demand for sustainable products. A market report highlighted that companies like Enebe Padel and Adidas have launched eco-friendly padel rackets made from recycled materials and biodegradable components, which have attracted environmentally conscious players (Padel Racket Market Size, Share, Trends [2032]). Thus, incorporating eco-friendly materials is not only good for the planet but can also be a selling point that differentiates a brand.

NEX Padel’s Eco-Friendly Material Approach: NEX Padel recognizes the importance of sustainability in modern sports manufacturing. While ensuring top performance, they also explore materials and processes that reduce environmental impact. One of NEX Padel’s advantages is its efficient use of materials – through precision cutting and thermoforming techniques that minimize waste, they ensure that very little raw material is wasted in production. Any excess carbon fiber or fiberglass trimmings from the cutting stage are carefully collected, and waste foam is kept minimal by optimizing mold designs. NEX Padel’s adoption of the unibody molding process not only improves racket quality but also contributes to sustainability: by producing the racket in one piece, there are fewer scrap pieces and less adhesive usage compared to multi-piece assembly.

Moreover, NEX Padel stays abreast of new material developments. They have the capability to work with recycled carbon fiber fabrics if a client requests a truly green product, and they source high-grade, non-toxic resins for production. In terms of surface finishes, NEX Padel uses advanced coatings that are durable but also compliant with environmental and safety regulations (free of heavy metals and excessive VOCs). The company’s commitment to eco-friendly materials is also evident in their R&D; for example, they are investigating alternative resins and fibers that could further lower the carbon footprint of their rackets without compromising performance. By being proactive on this front, NEX Padel offers partner brands the option to market a racket as eco-conscious – a selling point that can resonate strongly in today’s market.

In summary, the material selection for a padel racket – from carbon fiber sheets to the foam core and finishing coats – is a critical step that defines the racket’s capabilities. Through thoughtful selection and innovation, including embracing eco-friendly alternatives, manufacturers craft rackets that meet specific performance goals and values. NEX Padel’s material expertise and willingness to incorporate sustainable practices give it a distinct edge in creating custom padel rackets that are both high-performance and aligned with modern environmental standards.

Manufacturing Process: From Raw Materials to Finished Racket

Once the design is finalized and materials have been chosen, the next challenge is to actually manufacture the padel racket. The production process for padel rackets is a sophisticated multi-step operation requiring precision at every stage. Unlike mass-producing a simple item, making a high-quality racket involves numerous labor-intensive steps – including cutting fabrics, molding under heat and pressure, hand finishing, and rigorous inspection (

What makes padel rackets expensive?

– Padel USA). In this chapter, we walk through the complete production process of a padel racket, focusing especially on how custom rackets are handled (which often requires extra attention for unique specs or branding). We will also highlight how NEX Padel leverages advanced equipment and skilled craftsmanship during manufacturing.

For clarity, we can divide the process into several key stages: Design & Prototyping, Material Preparation, Layup and Molding, Cooling & Demolding, Trimming & Drilling, Finishing (Painting & Grip Assembly), and Quality Control. Some of these stages overlap or iterate, but we will discuss them sequentially.

Design & Prototyping

Even after the initial design phase (covered earlier) is done on paper or computer, in manufacturing there is usually a prototyping step. When a new custom racket is developed, especially under an ODM arrangement, the manufacturer will typically create a prototype or sample racket. This prototype uses the chosen materials and intended construction method to ensure the design works as expected physically.

Creating a prototype involves:

- Making a prototype mold or modifying an existing mold to the new shape and specifications. Racket molds are typically metal (often aluminum or steel) tools that define the shape of the racket during molding. If the custom design has a unique shape or thickness, NEX Padel might CNC-machine a new mold or add inserts to an existing mold to match the design. Having in-house mold fabrication capability allows quick adjustments at this stage.

- Doing a trial run of the layup (layering of materials) and compression molding for one or a small batch of rackets. This test helps refine the process parameters: for instance, determining the optimal temperature (usually around 150–180°C) and pressure needed given the specific materials, and the curing time (how long to press and bake the racket in the mold).

- Evaluating the prototype racket’s weight, balance, and structural integrity. Measurements are taken to ensure it meets the target weight and balance point. The prototype might be play-tested by the designers or even by a player to gather feedback on feel and performance.

- If something is off (say the racket came out too heavy, or the balance is wrong, or a new material layering didn’t bond well), adjustments are made. This could mean tweaking the layup (e.g., using one less carbon layer to reduce weight), adjusting foam density, or small design tweaks. This iterative process may repeat for a couple of cycles until the sample racket satisfies all requirements.

NEX Padel’s rapid prototyping capability shines here. Thanks to in-house tooling and machinery, they can move from a 3D design to a physical sample very quickly. Their factory is equipped with advanced CNC machines that can carve out mold components with high precision, and they maintain a library of mold bases for standard shapes which can be adapted for new patterns to save time. This means that when a brand asks for a custom prototype, NEX Padel can often deliver a sample racket in a short timeframe (potentially within weeks, depending on complexity). Rapid sample turnaround is crucial for brands that want to test their products or start marketing them quickly.

As an example, if a client requests a racket similar to a popular teardrop model but with slightly more weight in the head and a different bridge design (the area above the grip), NEX Padel’s engineers would adjust the CAD model, perhaps 3D-print a portion of the mold to create that new bridge for testing, and then make a prototype. This agility in prototyping allows for experimentation and refinement before committing to mass production.

Material Preparation (Cutting and Layup Setup)

Once the design and prototyping stage has validated the racket structure, full-scale production can commence. The first step in manufacturing is preparing all the raw materials for each racket:

- Cutting Fabrics: Large sheets of reinforcement fabric (carbon fiber or fiberglass cloth, often pre-impregnated with resin or to be hand-coated with resin later) are cut into the required shapes and sizes. Each racket requires multiple pieces of fabric: typically, a few layers for each face, and strips that will form the frame. Factories use cutting templates or computer-controlled cutting machines to slice the fabric with minimal waste. For instance, a CNC cutting table might cut out dozens of oval shapes (for faces) from a roll of carbon fiber, as well as long strip pieces to wrap the edges. Precision here is critical – the pieces must fit the mold properly and have the correct fiber orientation (the angle at which fibers run) as specified by the design. Orientation matters because it affects how the racket flexes and how strong it is in certain directions.

- Preparing the Core: The foam core (EVA or other foam piece) is usually pre-cut into the approximate racket shape as well, slightly smaller than the final racket outline (to allow the composite layers to wrap around). In some processes, the core may come as a pre-molded foam piece of the right thickness and contour. In others, a foam block or sheet is cut using a die or CNC cutter. Some high-end rackets have the foam pre-drilled with the hole pattern before assembly (so that when layers are applied and cured, the holes are already there), whereas others drill holes after molding. NEX Padel’s typical process involves drilling the holes after the racket is molded and trimmed, to ensure clean, precise holes. Therefore, core pieces are usually solid during layup.

- Lining the Mold: The mold (which comes in two halves, one for each face of the racket) needs preparation. Often a release agent is applied so the cured racket will come out easily. If the racket design has any in-mold graphics or texture (for example, some rackets have the brand logo as a raised or recessed part of the mold, or a specific surface texture pattern), the mold is cleaned and set up accordingly.

- Layering (Layup): Now the actual layup is arranged in the mold. Manufacturers layer the materials in a specific sequence:

- First, the outermost layer of the racket face goes into each half of the open mold. If using pre-preg (pre-resin-impregnated fabric), it’s laid in directly. If using dry fabric, workers will apply resin to it (e.g., by hand rolling epoxy) either just before or as they lay it in. This first layer will form the striking surface. It could be a carbon fiber sheet or fiberglass, depending on the racket. It is carefully smoothed into the mold shape.

- Additional layers of fabric are added on top as needed (a high-end racket might have two or three layers of composite on each side, whereas a basic one might have one layer each side). Each layer’s fiber orientation might be varied (e.g., one at 0°, next at 45°) to strengthen the structure in multiple directions.

- The foam core is placed in the center of one mold half, fitting into the prepared fiber “basket.” Some layups include an extra fiber layer on either side of the core for better bonding (essentially wrapping the core).

- Strips of fabric or extra patches are laid around the edges (frame area) and the handle area. These overlaps from each side will fuse and form the frame. If the design includes any extra reinforcement (e.g., Kevlar at the throat or carbon rods in the handle), those are placed now.

- Once the material “stack” is complete, the mold is closed, sandwiching everything together in preparation for molding.

This layup process is often done by hand by skilled technicians, especially for custom designs. They must ensure everything is positioned correctly, without wrinkles in the fabric, and that the right amount of resin is used (too much resin makes the racket heavy and brittle; too little can cause voids or weak bonding). NEX Padel’s production line is well-optimized for this stage. They train their staff to cut and stack materials with precision, following detailed layup instructions for each racket model (essentially recipes that specify how many layers of what material go where). They also utilize tools like fiber preforming aids – for instance, pre-cut fiber pieces might be shaped slightly in a separate process to better conform to the mold, ensuring consistency from racket to racket. This is indicated by separate stages like “Preforming” and “Layering” in their factory tour.

Molding and Curing (Thermoforming)

With the materials arranged in the mold, the next step is to press and cure the assembly so that it solidifies into the final racket shape. This is typically done via compression molding with heat:

- The two halves of the mold, now filled with the layup (and with the core sandwiched inside), are closed together. High pressure is applied, usually by a hydraulic press. Molding pressures can be on the order of several tons of force. NEX Padel, for instance, uses large heated pressing machines that clamp multiple molds at once to ensure efficient production (About - nexpadel.com) In the image above, multiple green hydraulic press stations are shown. This equipment allows several padel racket molds to be heated and pressed simultaneously. It illustrates the scale of advanced padel manufacturing equipment.

- The closed mold is heated to the required cure temperature, often around 140–160 °C (284–320 °F) for typical epoxy resins, though some processes might go up to 180 °C. NEX Padel’s description suggests a range of about 150–200 °C for their thermoforming process. This heat softens the resin and also slightly softens the foam core.

- Under heat and pressure, the resin flows and impregnates all fiber layers thoroughly. The foam core may compress a bit to fill any gaps and to fuse with the surface layers. The pressure is crucial to ensure there are no air bubbles or voids – essentially it “squeezes” the layers together tightly. As noted in NEX Padel’s process steps, they make sure all air is expelled and the core and surface bond tightly during this stage.

- The assembly is held under pressure at temperature for a set time (maybe around 10–30 minutes, depending on the resin and materials) to allow the resin to cure (harden). Some manufacturing uses “B-stage” resins that partially cure quickly then fully cure with more time, while others fully cure in one cycle.

- After curing, heating is stopped and the mold is allowed to cool, still under pressure, which helps the racket retain its exact shape. Once sufficiently cooled and the resin has solidified, the mold is opened and the racket can be demolded. At this point, it’s a single solid piece – a rough padel racket that has excess material around the edges (flash) and no holes yet (if holes weren’t molded via pins).

This molding process is where the racket truly takes form, and it’s also where a lot of the quality is determined. A well-molded racket will have strong structural integrity – layers perfectly fused without internal voids or weak spots. If any mistake happens here (like wrong temperature, insufficient pressure, misaligned mold halves), the racket could be defective (warped shape, delamination, etc.). That’s why experienced manufacturers like NEX Padel put heavy emphasis on this stage. They use advanced molding equipment that precisely controls temperature and pressure. The efficiency of compression molding also allows them to produce at scale – for example, using a press that can mold multiple rackets at once (some presses stack molds in layers to cure several rackets in one press cycle). NEX Padel mentions fast processing times as an advantage of their thermoforming method, making it ideal for large-scale production while maintaining consistency.

Cooling, Demolding, and Initial Inspection

After coming out of the press, the freshly molded racket (often called a “shell” or “blank” at this stage) is inspected for any obvious issues:

- While still in a semi-raw state, workers check that the mold filled correctly — e.g., all edges are intact, the surface looks proper, and there are no glaring air pockets or separations. If a racket came out clearly faulty, it is scrapped or set aside for analysis rather than moving further.

- The solidified excess resin/fiber that seeped out around the mold’s edges (flash) is still attached around the racket’s perimeter. Usually, at demolding, large flash pieces are trimmed off by hand to make handling easier.

- The racket at this stage has a rough edge and an unfinished surface. It might be a tad overweight due to extra material on the edges and lack of finishing, which will be corrected soon. It also typically has no holes (if the design calls for holes to be drilled later).

Sometimes, manufacturers let the demolded rackets rest or post-cure (sit at room temperature or a lower heat) to ensure the resin has fully cured and the racket has stabilized dimensionally, before performing further operations on it.

Trimming, Grinding, and Drilling

Now comes the finishing of the shape:

- Edge Trimming: The excess material (flash) around the edges of the racket is removed. This can be done with cutting tools (knives or small saws) or by using a router bit. The goal is to cut the racket’s outline exactly to spec. Any small overflows of resin or fiber are trimmed so that the racket’s frame edge is smooth and even.

- Sanding and Shaping: After rough trimming, the edges of the racket are sanded to a smooth finish. This can be done by hand or using belt sanders or grinding tools. The aim is to achieve the final frame shape and thickness with a clean edge. NEX Padel’s factory process includes a Sanding & Polishing stage for this purpose. The sanding also helps prepare the surface for painting by making it slightly rough (for good paint adhesion) and removing any gloss from residual resin on the surface.

- Drilling Holes: If the racket’s design includes holes in the face (virtually all adult padel rackets do), those holes are now drilled. High-precision drilling is important for performance and aesthetics. Many manufacturers use multi-spindle drilling machines or CNC rigs that can drill all the holes in one setup for consistency (Padel Racket Multi-head CNC Drilling Machine AKM5030-6H) (Padel Racket CNC Router Machine AKM5030-6H drilling process). For example, a CNC drilling machine may handle 4–6 rackets at a time, drilling the pattern of holes in each automatically. These machines ensure each hole is perfectly placed and can even minimize defects by drilling from both sides or controlling speed to avoid fraying the fiber layers (A padel racket CNC drilling machine under debugging - Facebook). The typical padel racket has around 30 to 60 holes, usually arranged symmetrically. Drilling is a critical step because a slight misalignment can affect balance or create a weak point, and poor drilling can cause cracks. NEX Padel uses automated multi-head drills to achieve precise, repeatable hole patterns.

- Quality Check: After trimming and drilling, the racket is checked for dimensions (length, width, thickness) and weight. If needed, minor adjustments (like a touch more sanding) can fine-tune the weight. The balance point can also be checked now, since the racket is structurally complete (aside from final finish and grip). If a racket is outside the acceptable tolerance, it might be rejected or reworked (though usually issues are caught earlier).

At this point, the padel racket has its final shape, hole pattern, and base weight. It is structurally complete but not yet painted or gripped. The next steps will give it the final appearance and playability touches.

NEX Padel’s use of advanced cutting and drilling equipment means that even custom designs with unique shapes or hole patterns can be executed with high precision. They can program CNC machines for a new pattern when a brand requests a distinctive hole layout, ensuring the custom aesthetic doesn’t come at the cost of structural integrity.

Finishing: Painting, Decals, and Grip Assembly

With the “raw” racket structure complete, the final cosmetic and functional touches are applied:

- Surface Finishing & Painting: Rackets are usually painted to achieve the desired color and graphics. The painting process involves several steps:

- Primer/Basecoat: If the racket has exposed fiber, a primer might be sprayed to help subsequent paint adhere and to cover the dark color of carbon (if a light color paint is planned).

- Color Coats: The racket is sprayed with paint in the required colors. This could be a single solid color or multiple colors in different areas. Complex designs might require masking certain areas and painting in layers. For example, a racket might be mostly black but with a colored stripe or logo area. Professional paint booths and turntables are used to ensure even coverage.

- Graphics: Logos and graphics are often applied via decals (stickers) or silkscreen printing. Decals with the brand name or logos are placed carefully on the racket face and sealed under clear coat. Some companies use water-transfer decals or even laser printing on rackets for detail. NEX Padel’s Light OEM service specifically allows brands to send their logo and color choices to be printed on stock racket models, meaning their paint shop is adept at custom branding.

- Texture Coating: If a gritty surface is required, a layer of clear coat with sand is sprayed on the hitting surfaces.

- Clear Coat: A final clear varnish is applied (in glossy or matte finish as needed). This seals in the graphics and provides a layer of protection against scratches and UV light. High-end rackets often get multiple coats of clear for durability.

Paint is then cured, either by air drying or in a low-temperature oven. Quality control at this stage ensures there are no paint runs, dust, or blemishes. Each racket’s design is compared to the customer’s artwork to verify accuracy.

-

Handle Assembly: While painting concerns the racket head and frame, the handle must also be finished and assembled:

- The molded racket typically has a stub or shaft that forms the handle’s internal structure. Around this, a separate handle grip piece (often made of a strong plastic or foam) is fitted. This piece gives the handle its shape (usually octagonal cross-section like a tennis racket handle) and is glued securely to the racket shaft.

- The butt cap (the plastic cap at the end of the handle) is attached. This cap usually has a loop for the wrist strap and often features the brand’s logo. Custom brands can have personalized butt caps; NEX Padel’s OEM options include custom end cap shapes or logos.

- A grip is then wrapped around the handle. The grip is the padded, often tacky tape that players hold. Factories typically put a basic grip on (usually black or a color the brand specifies). Brands can request custom grips – e.g., embossed with their logo or in a specific color – especially if they have distinctive branding.

- The wrist strap is threaded through the butt cap or handle. This is the cord players loop around their wrist. It often has a branded tab on it. Ensuring it’s securely attached is important for safety (so it never snaps during play).

-

Final Touches: Sometimes rackets get additional elements like a transparent protective tape on the frame edge (to guard against wall bumps) – this might be applied at the factory or provided separately. For OEM orders, manufacturers often also handle packaging at this stage: each racket might be put in a plastic bag or have a hanging tag attached, depending on how the brand sells them.

At last, the racket looks complete with its colors, logos, and grip. It should also be at its final specified weight (grips typically add a few grams) and balance. A final weight/balance check and visual inspection happens here as part of quality control.

NEX Padel’s Advanced Manufacturing Capabilities: Throughout the production process, NEX Padel utilizes advanced machinery and a refined workflow to ensure efficiency and consistency. Their factory integrates modern equipment at key stages – from automated fabric cutting for precise material prep, to multi-racket hydraulic presses for molding, to CNC multi-head drilling machines for perfectly aligned hole patterns. This level of automation, combined with skilled hand craftsmanship (in layup and finishing), means NEX Padel can achieve high throughput without sacrificing quality. They can produce in bulk (benefiting brands that need large orders) yet still cater to custom specifications (benefiting brands with unique designs). Additionally, NEX Padel’s use of the thermoformed unibody process gives them an edge: as they highlight, it yields lightweight yet strong rackets with consistent performance, and it allows them to create complex shapes that meet professional performance needs. By investing in such advanced production tech, NEX Padel can offer not only top-notch quality but also faster turnaround times – an important factor for brands trying to get their products to market quickly. For instance, if a brand needs to tweak a design after initial feedback, NEX Padel’s integrated setup (with in-house mold making and flexible production stages) lets them implement changes relatively quickly, even in an ongoing production run. In summary, NEX Padel’s production process is a synergy of technology and craftsmanship, giving them the capability to manufacture customized padel rackets efficiently while upholding strict quality standards.

Quality Control and Testing of Padel Rackets

Even after a padel racket has been built and painted to spec, the journey isn’t over until it passes rigorous quality control (QC) and testing procedures. Quality control is critical because it ensures that every racket that leaves the factory is safe, durable, and performs as intended. Especially for customized rackets (which may have unique features or untested material combinations), thorough testing is necessary to validate the design. In this section, we discuss how padel rackets are tested and inspected, and what standards are applied to guarantee quality. We will also emphasize how NEX Padel implements quality control, leveraging advanced testing equipment and strict protocols to uphold their reputation for reliable products.

Dimensional and Visual Inspection

The first step in QC is often a careful inspection of the racket’s physical attributes:

- Weight and Balance Check: Each racket is weighed on a precise scale to ensure it falls within the specified weight range. If a racket is supposed to be 360 grams ± 10g, the QC staff verifies this. They also check the balance point (often by balancing the racket on a knife-edge device) to ensure it matches the design (e.g., balance at a certain distance from the butt). Significant deviations here could indicate a manufacturing anomaly (like missing material or too much resin) and such rackets may be rejected or reworked.

- Dimensions: The overall length of the racket (typically about 45.5 cm for adult rackets) and thickness (mostly 38 mm for standard models) are measured with calipers or templates. Custom rackets might have different thicknesses (some recreational ones are thinner, junior rackets may be smaller), so QC ensures those are correct. They may also verify handle length and width, especially if a custom mold was used.

- Hole Pattern Alignment: Visually or with a template, they check that the drilling of holes is correct – no missing or skewed holes. All holes should be clean with no fraying of fibers. A poorly drilled hole can lead to crack initiation, so inspectors pay attention to the finish around each hole.

- Surface Inspection: The racket’s faces and frame are examined under good lighting:

- Check for any delaminations or bubbles – areas where the layers didn’t bond or resin didn’t fill. This might show up as white-ish spots or bulges and is a serious defect.

- Look for cracks or splits, particularly around the frame, holes, or bridge (throat) area.

- Inspect the paint and graphics for scratches, chips, or misprints. Any cosmetic defect is noted. Minor blemishes might be acceptable for some brands (especially on unseen areas), but premium brands often require flawless cosmetics.

- Ensure the texture (if sanded) is evenly applied and not coming off.

- Frame Integrity: Inspectors often run a finger along the frame edge to feel for smoothness or any sharp protrusions (which could cut players or indicate a chip). They might also gently flex the racket or tap it to listen for any internal rattles (loose particles inside) or odd vibrations.

NEX Padel has a dedicated QC team (one stage in their process is explicitly Quality Control. They perform comprehensive checks for defects and adherence to specs. Because custom orders often have unique branding, NEX Padel’s QC also verifies that all branding elements (logos, colors, and text like model names or specifications printed on the racket) are applied correctly as per the client’s instructions.

Mechanical and Performance Testing

Beyond visual inspection, rackets undergo tests to ensure they meet performance and safety criteria:

-

Compression/Bending Test: One common structural test is to subject the racket to a simulated stress. For example, placing the racket face-up between supports and applying pressure at the center (or using a machine to press on the face) to ensure it can withstand a certain amount of force without cracking. NEX Padel shows a Compression Testing setup in their facility.

The image above shows a compression testing setup pressing the racket face. This test evaluates the racket’s structural strength and the bonding of the core and surface layers. It ensures the frame can endure significant pressure without damage.

In such a test, a machine might press the center of the racket face with a defined force to see if the racket deforms or breaks. Manufacturers define a safe threshold (e.g., able to withstand a 30 kg load without structural damage). If a racket fails (cracks or deforms) below that threshold, it’s a QC failure.

- Durability Impact Testing: Some labs perform repeated impact tests. They may use a swinging pendulum or a robotic arm to strike the racket face or frame repeatedly, simulating the effects of hitting balls (or accidental hits against walls/floor). For instance, a machine might fire a ball at the racket at high speed hundreds of times, or a weight might drop on the frame edge to test shock resistance. The idea is to ensure the racket can handle normal (and a bit of extreme) use without developing cracks or soft spots. If a racket is marketed for durability, it should survive far more impacts in testing than it ever would in actual play without failure.

- Frame Torsion Test: This checks how much the frame twists under load. The racket handle might be clamped and a torque applied to the head. High torsional rigidity is good for control (the racket face doesn’t twist on off-center hits). Too much torsion could indicate a weak structure. By measuring this, QC can ensure consistency – that each racket of the model has similar stiffness.

- Vibration and Frequency: Some testing involves vibration analysis. By tapping the racket and measuring its vibrational frequency or using sensors during an impact, the manufacturer can get data on the racket’s stiffness and vibration damping. This helps ensure each custom racket model meets the expected feel – e.g., a higher frequency might mean a stiffer racket. It’s also useful to ensure added vibration-damping technologies (like an anti-vibration insert) are functioning.

- Environmental Testing: To ensure rackets hold up in different conditions, samples may be exposed to high heat, cold, or humidity. For example, leaving a racket in 50°C heat for a few hours (to simulate being in a car trunk in summer) then inspecting for warping or softened glue. Or a freeze-thaw cycle to ensure no cracking. These tests are usually done in development rather than on every batch, but if a custom design uses a new material or glue, the manufacturer might test a sample this way.

For customized rackets, especially if new materials or processes are used, the manufacturer will do these tests on prototype samples to validate the design’s robustness. If a brand is concerned about a specific aspect (say they want a guarantee that the racket won’t break if hit against a fence post), they can ask the OEM to perform that test and provide results.

Quality standards in padel are not formalized by a global body, but top brands have their own internal standards. For example, a brand might require that “each racket must withstand at least 10,000 ball hits at 100 km/h” or “no frame should crack under a 25 kg static load”. QC testing is designed to verify those kinds of requirements on a sampling basis (not every racket is tested to destruction, obviously, but a few from each batch might be tested).

NEX Padel’s advanced equipment likely includes the compression and impact testing rigs needed to verify these parameters. They ensure each model meets its performance and design standards. Additionally, by complying with various certifications (CE marking for Europe, for example, which ensures no hazardous materials and general safety), NEX Padel demonstrates that their rackets have passed requisite safety checks.

Consistency and Batch Quality

Maintaining consistency is especially critical when producing custom rackets in batches:

- Batch Sampling: From each production batch, a few rackets may be pulled for more intensive testing (like a stress test or a weight/balance audit) to ensure the batch is uniform. If any issue is found (e.g., one racket is unusually heavy or a tested one cracks under slightly lower load), the whole batch may be scrutinized. NEX Padel prides itself on reliable consistency, which is one reason many brands trust them as a supplier.

- Record Keeping: Modern factories keep detailed QC records. Each racket or at least each batch might have an identifier. If a problem is later discovered (say a certain batch had a resin issue), they can trace which rackets are affected. NEX Padel, working with many brands, must also keep orders separate and clearly labeled. They likely provide their clients with batch numbers or even individual serial numbers if requested. This traceability is part of professional quality assurance.

- Packaging Inspection: Before packaging, QC also checks things like correct model labels or tags, any accessories, and cleanliness. Rackets are wiped clean so they look perfect out of the box. If a racket comes with a cover or case, ensuring the right one is paired, etc., is also part of final QC.

Validation of Custom Features

For rackets with custom features, extra attention is warranted:

- If a racket has an unusual hole pattern, QC ensures none of the holes caused structural weaknesses (they might do an extra stress test on that model to be sure).

- If a new material (like a flax fiber layer or a new foam) was used, the QC team might do additional lab tests on one unit – for example, microscopic inspection of a cut section to see fiber bonding, or chemical tests for resin cure.

- If a brand requested a specific balance or swing weight, the manufacturer might measure that using a swing weight machine (common in tennis industry) to verify the rackets meet the spec.

- User Experience Testing: Sometimes a sample racket from production is play-tested by in-house players to ensure it feels right (this is more common in development, but for a particularly important custom order, a quick play test might be done as a sanity check).

All these measures ensure that when the rackets reach players’ hands, they perform excellently and have no hidden flaws that could lead to breakage or injury. A padel racket breaking during play is rare, but it can be dangerous, so manufacturers aim for zero failures in the field.

NEX Padel’s Quality Assurance Excellence: NEX Padel implements quality control at multiple stages of production, not just at the end. Their approach is proactive – preventing defects rather than just catching them at final inspection. For instance, they inspect raw materials (checking that each batch of EVA foam has the correct density, each roll of carbon fiber meets required strength specs) before they enter production. During layup, supervisors verify that the correct number of layers and proper fiber orientations are being used for a given model. When a batch of rackets comes out of the mold, NEX Padel’s team performs intermediate checks (removing any obvious defects early). This in-line quality monitoring helps avoid a scenario where an entire batch fails at final testing.

At the final QC stage, NEX Padel uses both human inspectors and mechanical tests. They utilize devices like compression testers and vibration analyzers to ensure each racket model meets performance benchmarks. Their emphasis on quality is reflected in the trust shown by their clientele – being “Trusted by 20+ companies globally” is not just a slogan; it is supported by a track record of delivering consistent, high-quality rackets order after order. NEX Padel’s reputation is built on the idea that a racket with a brand’s logo on it should meet that brand’s promise to players, and they enforce strict QC rules knowing that any subpar product could harm the brand’s image (and their own).

In practical terms, when NEX Padel handles an OEM order, they often send sample rackets from the production batch to the client for verification before the entire shipment is delivered. This transparency and willingness to validate quality at every step gives brands confidence. Additionally, NEX Padel continuously seeks to improve their processes (for example, applying lean manufacturing principles to reduce variability and upgrading testing apparatus for more accurate results). By maintaining high quality standards internally, NEX Padel ensures that the custom padel rackets they produce not only pass their own tests but also delight end-users and stand up to real-world play.

The Value of OEM and ODM Customization for Brands

With the technical aspects of production covered, it’s important to step back and look at why OEM/ODM customization is so valuable for padel racket brands. In the world of padel, there has been an explosion of new brands and models, all vying for attention in a growing market. Many of these brands do not have their own factories; instead, they partner with specialized manufacturers to design and produce their rackets. This section explores the benefits that brands gain from OEM/ODM partnerships, and provides real-world examples and success stories of such collaborations.

Defining OEM vs ODM:

- An OEM (Original Equipment Manufacturer) in this context is a factory that manufactures products for other companies to sell under their own brand name. The product design might be provided by the client brand, or developed jointly, but ultimately the design is owned by the brand and the manufacturer simply executes the production.

- An ODM (Original Design Manufacturer) offers product design as well as manufacturing. In an ODM model, a brand can choose from existing design solutions or co-develop a design with the manufacturer’s expertise. The ODM might have some ready-made designs that can be slightly tweaked (also called white-label products), or they create a new design for the client and then manufacture it.

In practice, the line blurs – companies like NEX Padel handle both roles. They can take a completely custom design (pure OEM manufacturing) or they can provide a catalog of proven racket designs that a brand can customize (an ODM service).

Benefits for Sports Brands

-

Access to Expertise and Advanced Technology: Not every brand has deep engineering know-how in composites or access to manufacturing technology. By partnering with a seasoned manufacturer, brands tap into a wealth of expertise. Padel racket production incorporates advanced techniques and materials – something manufacturers have mastered through years of experience and innovation. An OEM partner like NEX Padel has already fine-tuned the recipes for strong, lightweight rackets and invested in the machinery needed. This means a brand can leverage advanced equipment and skilled craftsmanship without having to invest in it themselves. For example, a new padel brand might have great marketing and player connections, but not know the optimal layup for a diamond-shaped racket – the OEM can guide them to a solution that works.

-

Cost Efficiency and Scalability: Building a factory for padel rackets is capital-intensive (land, machines, labor, R&D). For many brands, it’s far more cost-effective to outsource production. Chinese manufacturers, in particular, have become popular for this reason, offering competitive pricing while maintaining high quality. As highlighted in industry analysis, China is home to many of the top padel racket factories producing for international brands. This allows brands to benefit from economies of scale – factories might produce rackets for multiple brands, keeping their lines busy and costs per unit lower than what an individual brand could achieve on its own. Additionally, OEMs can ramp production up or down as needed. If a brand suddenly sees a spike in demand (say their racket becomes popular after a pro player uses it), the manufacturer has the capacity to increase production quickly to meet that demand.

-

Faster Time-to-Market: In the fast-growing padel market, being quick to release new models or respond to trends is crucial. An ODM partner with rapid prototyping and flexible production can drastically cut down development time. Instead of spending a year or more in development, a brand can go from concept to finished product in a few months with the right partner. For example, if there’s a new material trend (like a certain surface texture or a novel core material), the brand can ask the OEM to incorporate it and deliver updated rackets swiftly. NEX Padel’s ability to do rapid sampling and its streamlined process from design to delivery is a big advantage here. They can provide a quick quote, produce a prototype, and move to mass production in a seamless flow, as evidenced by their clear step-by-step OEM process.

-

Focus on Core Competencies: By leaving manufacturing to the experts, padel brands can focus on what they do best: marketing, sponsorship, distribution, and customer engagement. Many successful padel brands operate more like marketing companies – they sign professional players, sponsor tournaments, create buzz on social media, and build communities around their products. Their strength is in brand building and sales channels, not necessarily in weaving carbon fiber or running presses. OEM arrangements free them from the complexities of production so they can concentrate on expanding their market presence and developing the next great design concept. It’s a symbiotic relationship: the OEM ensures the product quality and technical performance, and the brand drives demand and handles retail, which in turn generates more production orders.

-

Customization and Differentiation: In a crowded marketplace, having a unique product is key. Working with an OEM/ODM allows even small brands to offer something distinct. They can customize shapes, materials, cosmetics, and features to have a signature racket. Without OEM support, a small company might be limited to generic off-the-shelf designs. But firms like NEX Padel encourage meaningful customization – offering heavy OEM where “precise dimensions, custom designs for each part, and specified materials” can be chosen. This means a brand can essentially create a racket from scratch that embodies their philosophy (be it the most eco-friendly racket, the most power-oriented racket, etc.). For example, an emerging brand might target environmentally conscious players and work with an OEM to use recycled carbon fiber and a cork handle, making their product stand out as a “green” padel racket. Such differentiation is possible only by tapping into the OEM’s material sourcing and engineering capabilities.

-

Lower Risk and Investment: Launching a new racket or brand comes with risks – primarily, what if the product doesn’t sell as expected? Using an OEM, a company can start with a relatively low minimum order quantity (MOQ) (NEX Padel offers low-MOQ custom solutions to test the market. This drastically lowers the initial investment. If the rackets are a hit, they can reorder in larger quantities; if not, they haven’t sunk the cost of setting up production lines idle. Also, the consistent quality from a good OEM means there’s less risk of product failures or returns that could hurt the brand’s reputation. Essentially, the brand can start small and scale up without huge capital expenditure, which is ideal for startups or companies exploring padel as a new category.

-

Global Reach and Support: A strong OEM partner often assists with logistics and compliance too. Manufacturing in a place like China means dealing with international shipping, customs, and various regulations. Experienced OEMs help their clients navigate these – for example, ensuring rackets meet EU standards (like chemical safety regulations), providing certificates of origin, and packaging products securely for long transport. Some even help arrange shipping (by sea for cost efficiency, or by air if speed is needed). This support can save a brand a lot of hassle, effectively providing them with a supply chain service along with manufacturing.

Examples and Success Stories

The padel industry has numerous instances of fruitful brand-manufacturer collaborations:

-

Major Brands Outsourcing: Even the biggest players sometimes outsource production. Babolat, a renowned brand in tennis and padel, produces its high-end rackets in its own facilities in Europe, but many of its more affordable padel racket models are made in China. By doing so, Babolat offers a range of prices – keeping top-tier rackets premium (made in France or Spain) and mid-tier rackets cost-competitive via OEM manufacturing in Asia. This hybrid production strategy allows Babolat to maintain a strong market presence across all consumer segments. Importantly, it underscores that OEM manufacturing doesn’t equate to lower quality – Chinese factories produce Babolat’s rackets to Babolat’s stringent standards, highlighting trust in those manufacturers.

-

New Brands Rise: Consider a hypothetical but typical scenario: A former professional player decides to start his own padel brand to offer rackets that match his playing style. He has design ideas and credibility among players, but no manufacturing facility. By partnering with an ODM like NEX Padel, he can translate his vision into reality. He might explain to NEX that he wants a racket with, say, a slightly elongated shape and a softer core for more control. NEX Padel’s team could take an existing frame design from their catalog, tweak the mold dimensions, use a softer EVA, and create a custom graphic for him. Within a short time, he has a batch of rackets with his branding to test and sell. Let’s say he starts with 200 units. The launch goes well — players appreciate the feel and quality (thanks to the OEM’s solid production), and the brand gains a foothold. Over the next year, he expands the line (maybe adding a power model and a junior model), all developed and produced with NEX Padel’s help. This success story is directly enabled by OEM collaboration, which lowers the barrier to entry for new brands to innovate and compete.

-

Private Label for Clubs or Retailers: Some padel clubs or sporting goods retailers introduce their own branded padel rackets as a private label. They achieve this by working with OEMs to customize existing designs with their logos and colors. For example, a chain of padel clubs in Scandinavia might commission a batch of rackets featuring the club’s name and colors to sell to members. These typically involve light OEM work — selecting a proven racket model and giving it a custom paint job and grip color. It’s a win-win: the clubs get a unique product and additional revenue stream, and the OEM gets a steady smaller-volume client. Success here is measured by member adoption; often club players like using their club’s logo gear, so it fosters community identity as well.

Decathlon’s Kuikma racket developed with Fairmat’s recycled carbon fiber exemplifies a successful materials innovation achieved through collaboration . This partnership between a leading sports brand and a materials company shows how OEM cooperation can bring sustainable advancements to products while maintaining high performance. It also underlines that even global companies will partner with specialists to push the envelope of design and eco-friendliness.

-

Collaboration for Innovation: The earlier example of Decathlon and Fairmat is a case of a brand working with a partner to innovate through new materials. Decathlon’s Kuikma brand leveraged Fairmat’s recycled carbon technology to create a more sustainable racket without compromising on playability. In this scenario, Decathlon provided the market insight and distribution network, while Fairmat (effectively an ODM in materials innovation) provided the technical breakthrough. The result was a notable product that gave Decathlon a marketing edge (as one of the first eco-designed rackets) and Fairmat a proof of concept in sports equipment. It highlights that even very large companies will engage in OEM/ODM relationships when it comes to incorporating specialized innovations.

-

Multiple Brands, One Manufacturer: There are cases where one factory produces rackets for several different brands, even competitors. For example, a high-quality factory in Spain or China might be making rackets for Brand A, Brand B, and Brand C, each with their own specs and designs. Each brand’s formula is kept confidential, but the manufacturer’s expertise underlies all of them. If that factory develops a new technology (say a new mold design that enlarges the sweet spot), they might offer it to all their client brands (each brand then markets it with their own spin). This kind of arrangement can help diffuse innovations through the industry. A real-world parallel: in tennis, a few OEMs (like in Taiwan or China) produce frames for many famous brands; the brands then do their own graphics, minor custom tweaks, and marketing. Padel is similar in that regard. The success is that all brands involved get top-notch manufacturing, while the factory enjoys large volume and economies of scale.

NEX Padel itself has numerous success stories through its client partnerships. While specific brand names might be confidential due to agreements, NEX Padel’s claim of being “trusted by 20+ companies globally” indicates they have helped over twenty different brands develop and produce padel rackets. Some of these brands likely started small and grew significantly with NEX’s support. By providing low MOQs, design assistance, and reliable quality, NEX Padel has seen clients go from initial concept to becoming established brands.

One can imagine a scenario such as: Brand X, a new European padel brand in 2020, worked with NEX Padel to create three models — a round control-oriented racket for beginners, a teardrop all-rounder for intermediate players, and a diamond-shaped power racket for advanced players. Through NEX’s heavy OEM service, Brand X customized everything: the frame shapes, the material layups (perhaps choosing a fiberglass-carbon mix for the beginner model and full 12K carbon for the advanced model), and distinct color schemes. They started with a modest order of a few hundred units each. Players and coaches tested them and found that the rackets performed on par with big-name brands, which was a testament to NEX Padel’s manufacturing quality. As these rackets gained positive word-of-mouth, Brand X expanded distribution, and within two years was selling thousands of rackets across multiple countries. They continually fed player feedback to NEX Padel, and together they introduced refinements and new models (like adding an anti-vibration system in the next iteration). This illustrates how a reliable OEM partnership can be the backbone of a brand’s growth story, allowing the brand to focus on marketing and expanding its lineup while the manufacturer ensures product excellence.

How the OEM/ODM Process Works (Brief Overview)

To demystify the collaboration process, here’s an overview of how a typical OEM/ODM project unfolds with a partner like NEX Padel:

- Initial Consultation: The brand and NEX Padel discuss the project requirements. The brand shares its vision – for example, target player profiles, desired playing characteristics (power vs control), design ideas (shape, color, logo). They might reference existing rackets they like or specific technologies. NEX Padel provides feedback on feasibility, suggests materials or models from their catalog that fit the bill, and gives a rough cost and timeline estimate.

- Design Proposal: Based on the consultation, NEX Padel comes back with a proposal. For light OEM, this might simply be a chosen existing model with proposed graphics. For heavy OEM, it could include technical drawings of a custom racket shape, details on materials (e.g., “Frame: 100% carbon 3K, Core: medium EVA”), and visual mock-ups of the design. The brand reviews this and any adjustments are discussed (maybe they want a slightly lighter weight, or a different finish).

- Sample Production: Once the design is agreed upon, NEX Padel produces sample rackets (usually a small number, maybe 1–5 units). These prototypes are sent to the brand. The brand can then test these: have coaches or players play with them, assess the look and feel, and gather feedback. If the racket meets expectations, they approve it. If not, they request changes. For instance, the brand might say “the balance feels a bit too head-heavy, can we move 5 grams towards the handle?” – NEX Padel would then adjust the design (perhaps by changing the distribution of material or adding weight to the butt) and provide another sample. This step may iterate until the brand is satisfied.

- Mass Production Order: The brand places the production order, specifying quantity of each model and any size variants (if applicable). NEX Padel then procures all necessary materials and schedules the production in their facility. Because they likely have other orders, a slot is allocated for this brand’s batch.

- Manufacturing: NEX Padel manufactures the rackets according to the agreed specifications, following the processes described in the previous sections. Throughout production, their QC checks maintain consistency and quality. The brand might be given updates at milestones (e.g., “molding completed, now in painting stage”).

- Quality Inspection & Approval: Once the batch is produced, NEX Padel’s QC team thoroughly inspects it. Often, they’ll share the QC report with the brand. The brand may also request detailed photos of the finished product or even visit the factory for a final inspection (or hire a third-party inspector). Given NEX Padel’s standards, issues at this stage are uncommon, but if anything is off, this is the time to address it (for example, if a logo color came out slightly differently than expected, minor corrections can sometimes be made).

- Shipping and Delivery: NEX Padel then packs the rackets safely for transport. They arrange shipping according to the agreement – many shipments go by sea freight in large cartons, unless timing is critical. The brand handles import at their country’s port (unless other terms are arranged). Shipping can take a few weeks by sea, so timelines are planned accordingly.

- After-Sales and Reorders: After the brand receives the rackets, the partnership continues. NEX Padel is keen to hear if the brand has any feedback from the market. Maybe players love it (great, plan the next order), or maybe there are suggestions (e.g., “some players wanted a slightly rougher surface for more spin”) – this can be discussed for future batches. If any defects or issues are found in any racket (rare, but say a batch had a few with cosmetic flaws that slipped through), the brand communicates this and NEX Padel would typically compensate in some way (replacement or credit). For subsequent orders, the process is even smoother – often the brand can just place a repeat order via email, or tweak the colors for a new season’s look while keeping the structure same, etc.