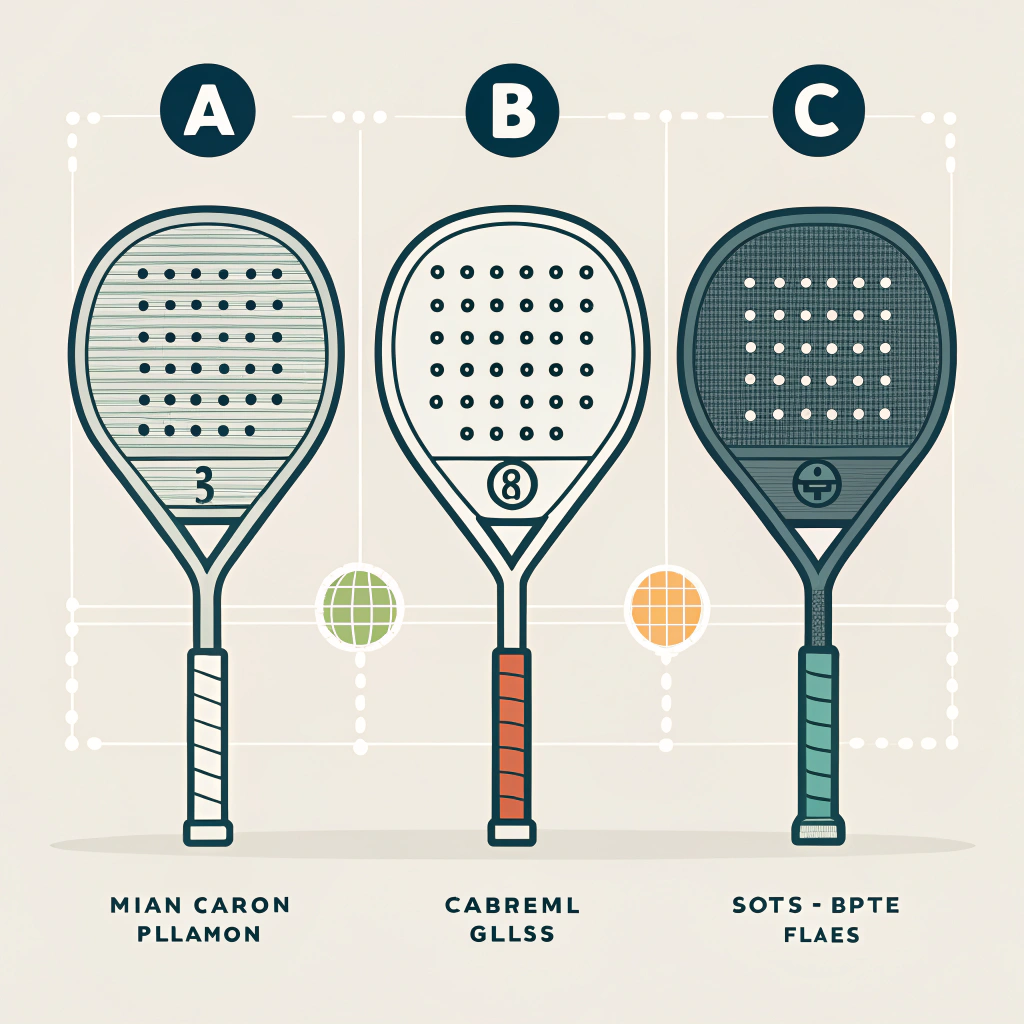

The quick answer: When selecting padel racket fibers, carbon fiber1 (particularly 12K and 18K) offers superior stiffness, durability, and weight reduction compared to glass fiber2, which, while more flexible and cost-effective, may not meet the high-performance requirements of advanced play. The choice depends on your specific performance goals, manufacturing techniques, and budget considerations.

For sports equipment manufacturers, the correct material selection in padel rackets is critical. Technical procurement managers and product development engineers need a detailed analysis of Padel Racket Fibers3—from Glass Fiber to various grades of Carbon Fiber (3K, 12K, 18K)—to optimize performance, durability, cost, and production efficiency. This guide explains the core differences between these materials, supported by technical data, comparative tables, and case examples from real manufacturing scenarios.

While designing high-performance padel rackets, manufacturers must balance several factors:

- Weight and maneuverability

- Structural stiffness and power transfer

- Durability under high-impact conditions

- Production complexity and costs

These fibers each have unique properties. Glass fiber, as one of the earliest composite materials in racket sports, offers cost efficiency and a forgiving nature. In contrast, carbon fibers, available in variants like 3K, 12K, and 18K, provide a rigid structure and lower weight, contributing to enhanced performance but typically at a higher production cost.

Glass Fiber2 is a well-established material known for its flexibility and moderate stiffness. Key features include:

- Flexibility: Offers more elasticity on impact, aiding in energy return and coupling a softer feel during play.

- Cost-Effectiveness: Generally cheaper than carbon fiber, making it a viable option in mid-range rackets.

- Production Tolerance: Easier to work with during molding and shaping processes, particularly for manufacturers aiming at rapid production cycles.

- Impact Resistance: Due to its composite structure, glass fiber provides high impact absorption, reducing shock during vigorous play.

These qualities make glass fiber an attractive option when manufacturers want to produce rackets that offer more rebound and a comfortable playing experience, particularly for players who may prefer a more forgiving hit.

Carbon fibers come in different grades, primarily defined by their tow count—3K, 12K, and 18K represent increasing stiffness and fiber density. Here’s a brief look at each:

-

3K Carbon Fiber:

- Flexibility vs. Rigidity: Compared to its higher-k counterparts, 3K carbon is softer, offering increased elasticity and shock absorption.

- Comfort: Provides a more comfortable experience for players who might have less aggressive playing styles.

- Manufacturing Possibilities: Its flexibility allows for easier customization and shape adjustments without sacrificing too much structural integrity.

-

12K Carbon Fiber:

- Enhanced Stiffness: A significant step up from 3K; the 12K variant offers a balance between stiffness and flexibility.

- Performance Boost: Delivers increased control and power. It is ideal for players who are already proficient and require more precision in their shots.

- Durability: Offers improved impact resistance, maintaining its shape under high pressure and repeated impacts.

-

18K Carbon Fiber:

- Maximum Rigidity: The highest tow count provides exceptional stiffness, which translates to greater power transfer and precision on ball contact.

- Performance Precision: Best suited for advanced players who demand high performance and can handle the less forgiving nature of a stiffer racket.

- Structural Integrity: Superior durability in competitive environments, ensuring long-lasting performance even under repeated high-impact conditions.

It is essential to appreciate that even though carbon fiber types, particularly the higher K versions, are more expensive and require more complex production processes, their performance benefits can be substantial, particularly in the premium segment of the market.

To simplify your decision-making process, the table below illustrates the differences and trade-offs between glass fiber and the various carbon fiber types commonly used in padel racket manufacturing.

| Material | Stiffness | Weight | Flexibility | Cost | Impact Resistance | Ideal For |

|---|---|---|---|---|---|---|

| Glass Fiber | Moderate | Higher | High (more elastic) | Lower | High shock absorption | Entry-level to mid-range rackets |

| 3K Carbon Fiber | Low to Medium | Lower | High elasticity | Moderate | Good for lower impacts | Comfortable play; customization options |

| 12K Carbon Fiber | Medium to High | Lower | Balanced between stiff and flexible | Moderate to High | Improved durability | High-performance, precision-oriented play |

| 18K Carbon Fiber | High | Lowest | Low (stiffer and less forgiving) | High | Excellent resilience | Professional competitive rackets |

This table can serve as a quick reference guide when discussing material choices with production teams, balancing performance trade-offs with cost constraints.

When moving from material analysis to production, understanding the manufacturing processes and the impact of each material on production timelines is essential. Manufacturers using advanced production techniques4 need to consider:

-

Molding and Lay-Up Processes:

Carbon fibers require meticulous lay-up and curing processes to optimize their properties. Variants like 12K and 18K need precision alignment to maximize their stiffness, while 3K can offer better versatility with slightly easier handling. -

Customization Capabilities5:

At NEX Padel, our capability for full customization—including custom shapes and printing—is significantly enhanced when using high-grade carbon fibers. The precision manufacturing used ensures that the performance benefits align with design specifics requested by our partners. -

Cost versus Batch Size:

Although glass fiber offers cost benefits, the choice of carbon fiber often depends on production volume and target market. In high-quality, performance-focused niche markets, the benefits of carbon fiber justify its higher cost. -

Quality Control and Durability Monitoring:

For any high-performance equipment, ensuring consistent quality is paramount. By implementing stringent quality control processes, manufacturers can minimize defects and guarantee the long-term durability of rackets, particularly when using the delicate and highly engineered carbon fiber lays. -

Integration with Other Components:

Padel rackets are not only about the frame; components like hand grips and handle covers also benefit from bespoke printing and design. Harmonizing the composite materials with these components is key to maintaining performance consistency.

A detailed production plan that addresses these areas ensures that material selection translates directly into superior end-product performance. Such diligence is especially critical for brands looking to position themselves as leaders in high-performance padel equipment.

Manufacturers working with NEX Padel have successfully leveraged these material insights in various production scenarios:

-

Case Study 1: Premium Racket for Professional Use

A well-known brand chose to integrate 18K carbon fiber in its premium racket series. The increased stiffness led to enhanced power and shot precision, which resonated well with professional players. Despite a higher production cost, the performance upgrade justified the selection leading to market success. -

Case Study 2: Mid-Range Customization for Versatile Play

Another sports equipment company opted for a hybrid design, using glass fiber in combination with 3K carbon fiber. This approach allowed them to balance flexibility with improved maneuverability. The resulting racket provided great energy return while keeping costs manageable—a perfect solution for a broader player demographic. -

Case Study 3: Targeting Beginners and Intermediate Players

For a brand aiming at entry-level players, using primarily glass fiber ensured a forgiving play experience and cost efficiency, while still enabling attractive design options through custom prints and color variations. Here, the more elastic nature of glass fiber helped reduce the risk of injury and improved overall player confidence.

These real-world examples showcase how material selection directly affects product performance, market positioning, and ultimately, customer satisfaction.

Selecting the correct fiber for padel rackets is not a one-size-fits-all decision. Consider the following summarized recommendations:

- Performance Focus:

For high-performance rackets, especially those intended for professional play, lean towards higher K carbon fibers such as 12K or 18K. They provide a combination of stiffness and lightweight characteristics that yield superior control and power. - Cost Efficiency and Flexibility:

If you aim for greater elasticity or must target a broader segment, incorporating glass fiber or a blend with 3K carbon can offer adequate performance with enhanced customization and a friendlier cost structure. - Manufacturing Considerations:

Evaluate your existing production capabilities—precise handling, quality control measures, and customization techniques are imperative when dealing with advanced carbon fibers. - Market Positioning:

Assess your target market’s needs. Premium segments that prioritize performance might justify the investment in higher-grade carbon fibers, while broader markets may benefit from a balanced approach using mixed materials.

By integrating these recommendations, product development teams can tailor materials and production techniques to match both technical performance demands and market expectations.

Q: Which is better carbon fiber or fiberglass padel racket?

A: In general, carbon fiber is lighter and provides higher stiffness compared to fiberglass, making it ideal for high-quality, performance-focused rackets. However, fiberglass offers more elasticity and cost efficiency, which may suit players who prefer a softer and more forgiving hit.

Q: Which is better carbon fiber or glass fiber pickleball paddle?

A: While carbon fiber delivers improved rigidity and power, glass fiber’s higher flexibility offers more rebound and energy return. The choice depends on the desired play experience—if greater energy return and a softer impact are priorities, glass fiber might be preferred.

Q: Which is better, 3K or 12K carbon?

A: The difference lies in rigidity—3K carbon is generally softer and offers more comfort and elasticity, whereas 12K carbon is stiffer, providing increased power and precision. The best option depends on the player’s technique and the intended performance characteristics of the racket.

-

carbon fiber: Reading this article will provide insights into the composite material properties of carbon fiber, including its stiffness, durability, and role in high-performance sporting equipment. Back ↩

-

glass fiber: Reading this article will help you understand the flexibility, cost-effectiveness, and energy absorption properties of glass fiber for sports equipment manufacturing. Back ↩ ↩2

-

Padel Racket Fibers: This article explains the technical aspects of padel racket fibers, detailing various material options and their impact on product performance. Back ↩

-

advanced production techniques: This resource details sophisticated production methods that enhance material performance and product consistency in sports equipment manufacturing. Back ↩

-

Customization Capabilities: This explanation covers how manufacturing customization can optimize product design and meet specific market needs in the sports equipment sector. Back ↩