Our custom padel rackets with a round design deliver a balanced combination of power, control, and extensive customization options. This design, supported by advanced production techniques1 and superior materials like carbon fiber2 and glass fiber3, provides a reliable solution for distributors who demand both performance and brand differentiation.

In today’s competitive padel market, procurement managers are tasked with selecting high-performance gear that meets rigorous technical standards while still allowing for unique branding. At NEX Padel, we have honed our production process to ensure that every custom padel racket, especially our round design, is manufactured with precision and speed. This article examines the benefits of a round racket design, explores technical details and customization options, and compares it with other design types to support your sourcing decision.

The market offers a variety of padel racket shapes such as Diamond, Teardrop, and Round. Among these, the round design consistently stands out in terms of balance and ease of production. Here’s why:

• The round shape provides enhanced balance, leading to a more forgiving sweet spot that is ideal for players of all skill levels.

• It ensures a uniform distribution of mass, which improves both control and stability during vigorous play.

• From a production perspective, the symmetry of the round design allows for consistent replication, ensuring that every racket meets strict quality standards.

This design is particularly attractive to sports equipment distributors because it translates into a more universally appealing product. Whether end users are beginners or seasoned players, a round padel racket often delivers the performance attributes that enhance their overall play experience. By standardizing production with advanced techniques, we can customize every facet—material composition, shape nuances, and even graphic detailing—to meet market demands.

When evaluating custom padel rackets, material selection plays a crucial role in performance and durability. At NEX Padel, our manufacturing incorporates various materials including glass fiber, 3K carbon fiber, 12K carbon fiber, and 18K carbon fiber to cater to different performance niches. Here is a closer look at how these materials contribute to the final product:

• Glass Fiber3: Known for its cost-effectiveness and excellent vibration dampening4 properties, glass fiber is ideal for achieving a balanced feel. It is often incorporated into the round design for players who value comfort and consistence in ball response.

• Carbon Fiber (3K, 12K, 18K): Our high-performance carbon options are preferred when maximum power and precision are required. The different fiber weaves provide varying degrees of stiffness and resilience. A 3K carbon fiber configuration, for instance, offers a versatile build suitable for a wide range of playing styles, while 12K and 18K configurations are engineered for players seeking elite performance, improved rigidity, and enhanced durability.

This attention to material detail ensures that buyers receive rackets that not only meet industry benchmarks for performance but also offer flexibility in design—be it through a classic round shape or through custom modifications based on specific customer needs.

Procurement managers often face the challenge of choosing between different racket designs. Below is a comparative table that highlights the key features of the Round, Diamond, and Teardrop designs:

| Feature | Round Design | Diamond Design | Teardrop Design |

|---|---|---|---|

| Balance & Control | Uniform weight distribution; larger sweet spot | Forward balance; favors offensive play | Slightly balanced; versatile performance |

| Production Consistency | High due to symmetry and ease of replication | More complex production requiring precise weight distribution | Intermediate; requires specialized tooling |

| Customization Options | Extensive: shape, print, hand grip, and handle customization | Limited; focus on performance orientation | Moderate; available in selected customization areas |

| Material Compatibility | Excellent with glass fiber and various carbons | Often emphasizes high-end carbon fiber usage | Can combine multiple materials flexibly |

| Target Player Profile | All-level players, ideal for broad market appeal | Advanced players, typically niche competitive markets | All-round performance, bridging beginner to intermediate play |

This table illustrates that while each design type has its distinct advantages, the round design is uniquely positioned to offer a combination of balanced performance, production reliability, and extensive customization features. For sports equipment distributors, this means that a round padel racket is more likely to appeal to a broader market segment, ensuring consistent demand and ease of stock management.

Our advanced production techniques set us apart in the manufacturing realm. At NEX Padel, we understand that timely delivery and precise customization are critical for your business operations. Here’s how we excel:

-

Rapid Prototyping5 and Sampling: We offer fast sampling processes to validate design elements early. This ensures that any modifications, whether in terms of color, print, or shape, are incorporated without delay. Our ability to quickly produce a sample enables you to verify the design specifications before proceeding with large-scale orders.

-

Customization of Components: Beyond the racket frame, we offer full customization for accessories such as hand grips and handle covers. This means your branded logo can be integrated across the product, enhancing overall brand visibility.

-

Tailored Material Usage: Depending on the target player profile and market segment, you can choose from an array of materials. With options ranging from glass fiber to different grades of carbon fiber, we ensure that the final product aligns with both performance expectations and budget considerations.

-

Efficient Production Lead Time: By leveraging state-of-the-art production techniques and rigorous quality control measures, we consistently meet stringent lead times. This reliability minimizes inventory risks and aligns with your production schedules, thereby securing a competitive edge in the market.

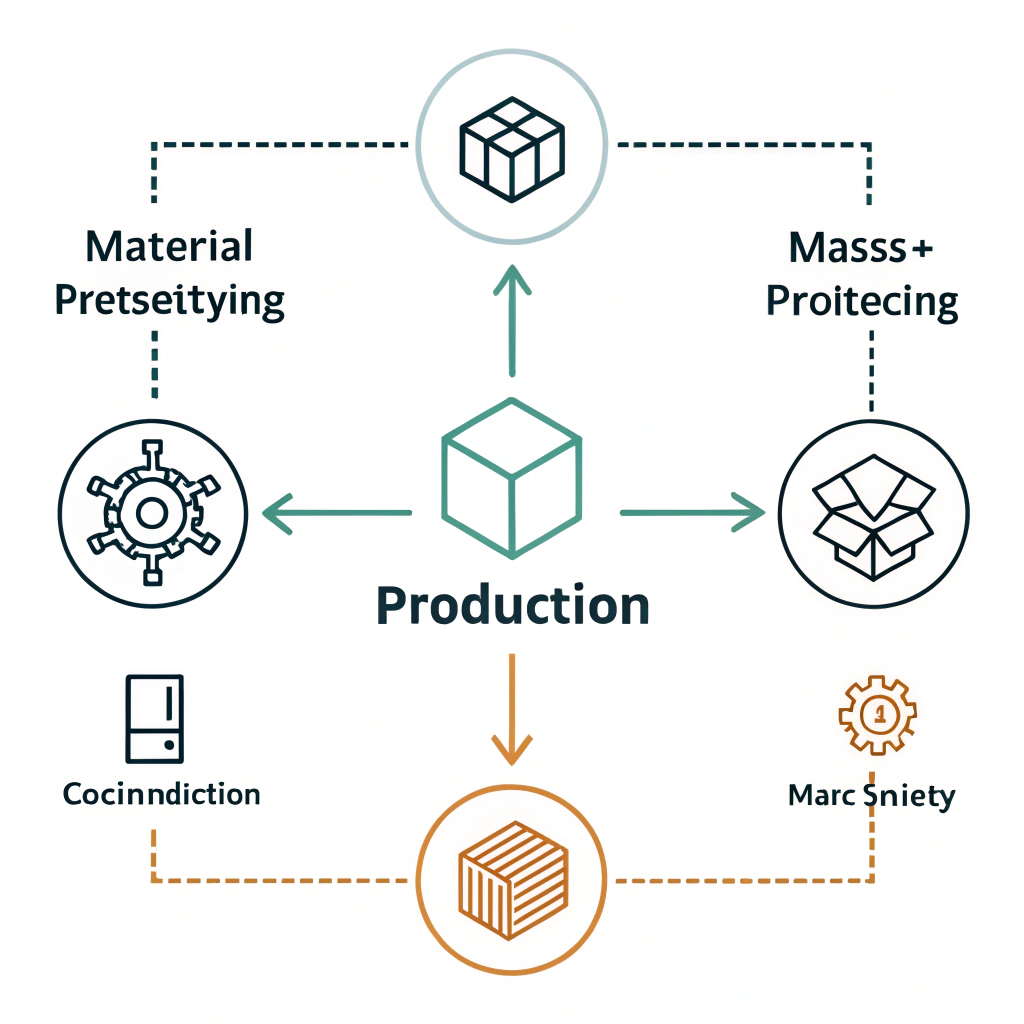

Below is a simplified flowchart that outlines our production process from concept through to delivery:

| Stage | Key Activities | Outcome |

|---|---|---|

| Concept & Design | Initial design consultations | Customized design blueprint |

| Material Selection | Choosing optimal carbon/glass alternatives | Material specification sheet |

| Prototyping | Fast sampling and quality testing | Validated prototype |

| Mass Production | Precision manufacturing & quality control | Full-scale production run |

| Customization | Print, logo, and accessory integration | Branded final product |

| Delivery | Timely logistics and supply chain management | Delivered as per schedule |

This structured approach guarantees that every custom padel racket you purchase from us not only meets industry standards but is also tailored to your specific market requirements. The advanced production capabilities at NEX Padel mean fewer delays, superior product consistency, and ultimately, a more rewarding procurement experience.

For procurement managers and sports equipment distributors, selecting the right padel racket can influence both competitive advantage and customer satisfaction. The round design offers several strategic benefits:

• Wide Market Appeal: The balanced nature of round rackets makes them suitable for a wide range of skill levels. This universality is crucial when servicing clubs, multi-level tournaments, and casual play alike.

• Customization for Branding: With full customization options, you can align each product with your brand identity. Whether it’s through unique color schemes, custom prints, or personalized accessories, these rackets serve as a canvas for your brand.

• Consistency and Reliability: The inherent symmetry in a round design reduces production variability. This consistency translates into reliable performance for end users, ensuring that your clientele receives a product that lives up to their expectations every time.

• Operational Efficiency: Simplified production processes associated with the round design lead to better uptime, effective cost management, and a short lead time, all of which are vital for maintaining a streamlined inventory management system.

In a competitive marketplace, the round padel racket not only meets but exceeds performance standards while offering flexible customization options. This can set you apart in a fast-paced industry where end-user satisfaction significantly drives repeat business.

The choice of a custom padel racket is not merely about selecting a product—it is about adopting a strategic asset that can amplify your brand’s appeal in the sports equipment market. The round design, with its superior balance, wide range of customization, and dependable production process, stands as a clear frontrunner for distributors and padel clubs aiming to cater to diverse player profiles.

At NEX Padel, we combine the latest manufacturing technology with a deep understanding of market needs to deliver products that are both innovative and reliable. By choosing our custom padel rackets, you embrace a solution that is technically sound, highly customizable, and engineered for consistent excellence. We invite you to explore our range of padel rackets and discover how our round design can become the cornerstone of your product lineup.

For more detailed discussions on material choices, customization options, or production timelines, feel free to reach out to our team. Your strategic advantage in the competitive padel market starts with the right partnership—and with NEX Padel, quality and innovation are always in play.

People Also Ask

Q1: What makes a round padel racket design ideal for customization?

A1: A round design offers uniform weight distribution and a larger sweet spot, which not only improves performance but also simplifies production consistency. This facilitates extensive customization, such as personalized prints and grip designs, ensuring the racket meets both technical standards and brand identity needs.

Q2: How do advanced materials like carbon fiber improve the performance of a round padel racket?

A2: Advanced materials like carbon fiber enhance rigidity and durability while reducing weight. This results in a racket that delivers powerful shots with controlled precision. The round design further benefits from these materials by maintaining balanced performance across different play styles.

Q3: What production advantages does NEX Padel offer in manufacturing custom padel rackets?

A3: NEX Padel uses state-of-the-art production techniques and rigorous quality control measures to ensure consistent product quality and fast lead times. Our ability to rapidly prototype and incorporate extensive customization—ranging from material selection to branded accessories—gives distributors a reliable and competitive edge in the market.

-

[advanced production techniques]: Discover how these modern manufacturing methods optimize consistency, efficiency, and quality control in the production process. ↩

-

[carbon fiber]: Learn about the unique strength-to-weight ratio and durability characteristics of carbon fiber that make it a popular choice in high-performance sporting goods. ↩

-

[glass fiber]: Explore the cost-effective benefits and material properties of glass fiber, including its role in enhancing balance and overall racket performance. ↩ ↩2

-

[vibration dampening]: Find out how vibration dampening properties improve comfort and stability in sports equipment, reducing fatigue and enhancing playability. ↩

-

[Rapid Prototyping]: Understand how rapid prototyping accelerates product development, enabling speedy iterations and timely market entry. ↩