In a nutshell, the production process of a padel racket integrates modern automated technology, advanced composite materials1 and precise quality control measures to create a high-performance sports instrument. This article provides an in-depth look at each step of the process, from material selection to the final finishing touches, giving manufacturing managers and procurement specialists clear insights into how our factory ensures every racket meets the highest standards in durability, performance, and customization.

Manufacturing a padel racket is a complex process that requires careful planning, rigorous quality control, and the integration of advanced production techniques. At our factory, we use materials such as fiberglass and various grades of carbon fiber (3k, 12k, 18k) to craft rackets that meet diverse needs—from beginner comfort to professional-level precision. The process can be broken down into several key stages:

- Material Preparation and Selection

- Cutting and Layup Process

- Molding and Curing

- Assembly and Finishing

- Customization and Quality Assurance

Each of these stages plays a critical role in the final product and ensures that the padel rackets are not only well-balanced and durable but also capable of delivering top performance on the field.

Before any production begins, raw materials are carefully selected and tested. The ideal construction of a padel racket involves the use of high-strength composites. Our factory uses fiberglass for its flexibility and comfort for beginners, alongside high-grade carbon fiber for superior stiffness and durability required by professional players.

Key Material Types:

| Material | Characteristics | Applications |

|---|---|---|

| Fiberglass | Flexible, lightweight, cost-effective. | Ideal for entry-level and comfort-oriented rackets. |

| 3k Carbon Fiber | High precision, moderate weight balancing. | Suitable for a balance of performance and maneuverability. |

| 12k Carbon Fiber | Higher strength with reduced weight. | Used in mid to high-level performance rackets. |

| 18k Carbon Fiber | Superior stiffness and durability. | Best for professional-grade rackets requiring high responsiveness. |

During this stage, our expert technicians monitor the composite fibers to ensure they meet strict quality criteria. Precision in this step is critical, as any slight deviation in material integrity could affect the overall performance and longevity of the racket. This meticulous approach sets a strong foundation for the subsequent production stages.

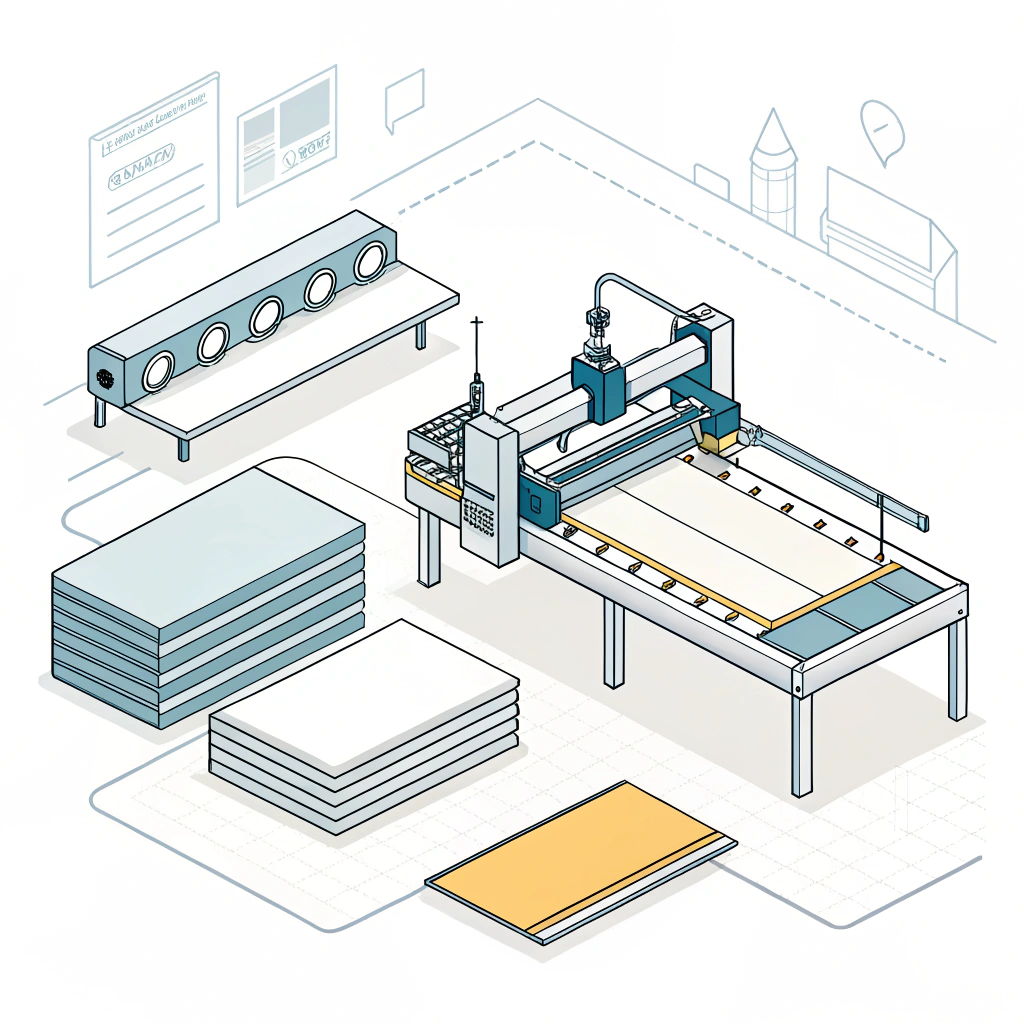

Once the materials have been selected, the next phase involves cutting and laying up the composite sheets. This process is highly automated, using computer-controlled cutting machines and laying systems that follow precise blueprints from our design engineers. The process typically involves:

- Precision Cutting: Automated machines cut the composite materials into specific shapes and sizes according to the racket design (whether it’s Diamond, Round, or Teardrop).

- Layering (Layup): Layers of composite materials are hand-placed or machine-laid in a pre-determined sequence to balance strength and flexibility.

- Adhesive Application: High-performance adhesives are applied between layers to ensure a strong bond during curing.

The care taken during the layup2 ensures that the structural integrity is maintained throughout the racket. Each layer supports the next, resulting in a product that provides reliable performance in terms of stiffness, shock absorption, and overall balance.

Key factors during layup include material orientation, fiber distribution, and accurate adhesive application. Any misalignment could compromise the racket’s performance. This step is supported by quality control checks both manually and through sensor-based automation systems that verify alignment and consistency.

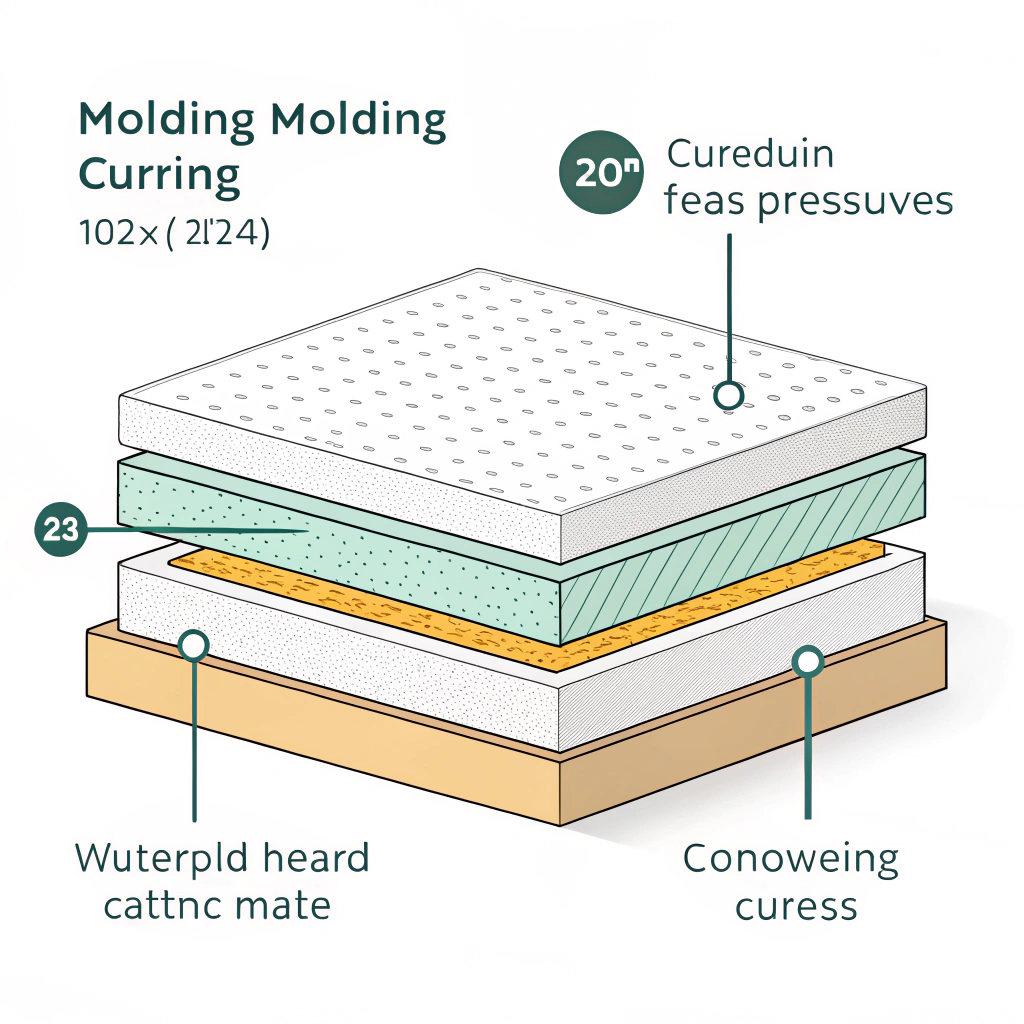

After the composite materials have been layered and prepared, the next step is to mold and cure the structure. The molding process involves placing the layup into a mold that gives shape to the racket. This is done under high pressure and temperature to ensure proper bonding and curing of the adhesives.

- Mold Design: Custom molds are created for each racket type (Diamond, Round, Teardrop) to achieve the desired balance and ergonomic grip.

- Pressurized Molding: The layup is placed into the mold where pressure is applied uniformly.

- Temperature Control: Controlled heating facilitates the curing process, enabling the resin to solidify and bind the composite layers effectively.

During the curing phase, our advanced ovens and curing chambers help in achieving the perfect structural properties of the racket. By carefully regulating temperature and pressure, the curing phase ensures that the composite materials achieve maximum strength and durability.

Quality checks are integral during this stage. Sensors monitor temperature uniformity and curing times to minimize the risk of defects such as voids or delamination. This rigorous process guarantees that each racket emerges from the mold with consistent performance characteristics.

Once the core and frame of the racket have been molded and cured, the assembly phase begins. This stage incorporates additional components and involves detailed finishing tasks to ensure the product is market-ready.

- Frame and Face Integration: The cured composite is combined with other structural elements to form the complete racket. This includes the integration of the frame and hitting surface.

- Surface Finishing: The racket undergoes trimming and sanding to remove any excess material or imperfections.

- Application of Protective Coatings: Advanced coatings are applied to enhance durability, aesthetics, and weather resistance.

The finishing process may involve additional customizations such as printed logos, color applications, and even special textures on the handle area. We offer extensive options for customization, including the use of different materials for the hand grip and handle cover. These customizations not only differentiate products but also provide branding opportunities for our partners.

Quality inspections are carried out at every step to ensure that each assembled padel racket meets stringent performance and safety standards. These inspections cover aspects like adhesive strength, surface uniformity, and overall finish quality.

Customization is one of the key selling points of our production process. We understand that different players and brands have unique requirements. Therefore, our production line is highly versatile, allowing for:

- Custom Shapes: In addition to standard profiles (Diamond, Round, Teardrop), we support fully customized shapes tailored to specific performance needs or aesthetic preferences.

- Custom Printing and Color Options: Brands can request personalized prints, logos, and specific color channels on the racket’s surface.

- Handle Customization: Beyond the racket’s body, hand grips and handle covers can be tailored with custom logos, textures, and material specifications.

To ensure satisfaction and performance, our quality assurance procedures are intensive. Here are some steps we take to maintain quality across every batch:

- In-Process Quality Checks: Throughout each stage—from material input to curing—our technicians and automated sensors verify key quality parameters.

- Post-Production Testing: Completed rackets undergo rigorous testing for consistency in balance, impact resistance, and durability.

- Customer Feedback Integration: We continuously monitor customer feedback and run field tests to ensure that our rackets perform as expected in various real-world scenarios.

| QA Measure | Purpose | Method |

|---|---|---|

| Material Verification | Ensure composite integrity | Visual inspections and material tests |

| Automated Alignment Checks | Verify proper layer alignment | Sensor-based monitoring systems |

| Curing Consistency | Prevent delamination or voids | Temperature and pressure sensors |

| Final Inspection | Validate overall product quality | Manual and instrumental tests |

Our commitment to quality does not end at the production line. Every product is tracked with detailed documentation so that in the rare event of any issues, we can quickly identify and address the root causes. These measures help us build confidence with our B2B partners and establish long-term, reliable supply chains.

Our factory integrates advanced production techniques to ensure high efficiency and precision. Key technologies in our production process include:

- Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM)3: These tools help design precise racket shapes and guide automated cutting and layup machines.

- Robotic Automation: Robots handle repetitive tasks such as material placement and adhesive application, increasing precision and reducing human error.

- Real-Time Data Monitoring: Sensors installed at each production stage collect data on temperature, pressure, and material alignment. This real-time monitoring allows for immediate corrections and ensures that all steps adhere to predetermined standards.

- Rapid Prototyping4: We utilize rapid prototyping techniques to test new designs and custom modifications quickly, accelerating the overall production timeline while maintaining quality.

These technologies not only boost production efficiency but also enhance the flexibility of our manufacturing process. This means faster turnaround times and the ability to cater to custom orders with varying designs and specifications.

Optimizing each step of the production process is essential for staying competitive in the sports equipment manufacturing industry. Our factory continuously evaluates and refines each stage of production. Key strategies for process optimization include:

- Lean Manufacturing Principles: We apply lean principles to minimize waste, reduce production time, and optimize resource usage while maintaining quality.

- Batch Production Techniques: For large orders, our batch production system allows efficient management of workforce and machinery, ensuring consistency and reliability.

- Feedback Loops: Continuous feedback from quality assurance teams and customer insights is integrated to refine both the product and the process.

- Predictive Maintenance5: Regular maintenance of machinery, guided by data analytics, minimizes unexpected downtime and keeps production flowing smoothly.

By honing these areas, we ensure that our production operations not only meet but often exceed industry standards. This commitment to efficiency and innovation allows us to offer competitive pricing and swift delivery, making us a trusted partner for brands such as Hirostar, Reebok, and Starvie.

The production process of a padel racket is a fusion of art and science, where careful material selection, cutting-edge automation, and stringent quality control converge to create a product that performs exceptionally on the court. Whether you are evaluating production capabilities for a potential partnership or seeking insights into modern manufacturing processes, understanding these stages can help you make informed procurement decisions.

Our factory’s approach is designed to provide maximum flexibility, enabling bold customizations while ensuring that every product meets the highest performance benchmarks. The investment in technology, rigorous quality checks, and continuous process improvements demonstrates our commitment to being a leader in the padel racket manufacturing industry.

For B2B procurement professionals, these insights highlight the intricate process that underpins every piece of equipment we produce. We welcome inquiries, detailed discussions, and opportunities to demonstrate how our advanced production techniques can be leveraged to meet your unique business needs. If you’re looking for precision, reliability, and customizable options in padel racket manufacturing, our facility stands ready to be your trusted production partner.

People Also Ask

Q: What is the construction of padel racket?

A: The construction of a padel racket involves a face and frame made from high-strength composite materials such as carbon fiber and fiberglass. Fiberglass is especially popular among beginners for its comfort and flexibility, while various grades of carbon fiber provide enhanced stiffness and durability for advanced performance.

Q: Where are padel rackets manufactured?

A: While some well-known facilities like QUAD Factory in Braga, Portugal are recognized for producing high-quality padel and pickleball rackets under advanced European standards, manufacturing can also take place in other leading regions. Our facility in Jiaxing, Zhejiang, China, leverages advanced production techniques to deliver exceptional quality and customization options in padel racket manufacturing.

-

advanced composite materials: Click to learn how advanced composite materials combine multiple constituents to achieve superior strength and lightweight properties, enabling higher performance in demanding applications. ↩ ↩

-

layup: Click to explore the layup process, which involves carefully arranging layers of materials to optimize strength, durability, and overall performance in composite structures. ↩ ↩

-

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): Click to discover how CAD/CAM technologies streamline design-to-production workflows, ensuring precision and reducing errors in manufacturing processes. ↩ ↩

-

Rapid Prototyping: Click to understand how rapid prototyping accelerates the testing and development of new designs, allowing for quick iterations and reducing time to market. ↩ ↩

-

Predictive Maintenance: Click to learn how predictive maintenance uses data analytics and sensor monitoring to anticipate equipment issues, minimize downtime, and optimize production efficiency. ↩ ↩