Padel rackets are made by carefully applying composite layers—commonly carbon fiber, fiberglass, or Kevlar—onto a mold, where temperature and pressure combine to shape, cure, and finish the frame and face of the racket. This article details the molding process, the materials used, and quality control measures to ensure that each padel racket meets precise performance and durability standards.

For technical production managers and manufacturing engineers, understanding the detailed phases of the molding process is crucial when optimizing production lines or benchmarking process innovations. In this article, we share a comprehensive breakdown of the molding process for padel rackets, exploring the selection of composite materials, layer application, curing in molds and presses, and the rigorous quality control measures conducted at each stage.

Our goal is to provide actionable insights and technical details that align with advanced production techniques, ensuring that manufacturing operations meet industry standards while driving production efficiency and cost-effectiveness.

The molding process for padel rackets can be divided into a series of distinct phases. Each phase is critical to achieving a high-quality final product. Below is an overview of the process stages, along with a table summarizing key steps, required equipment, and materials.

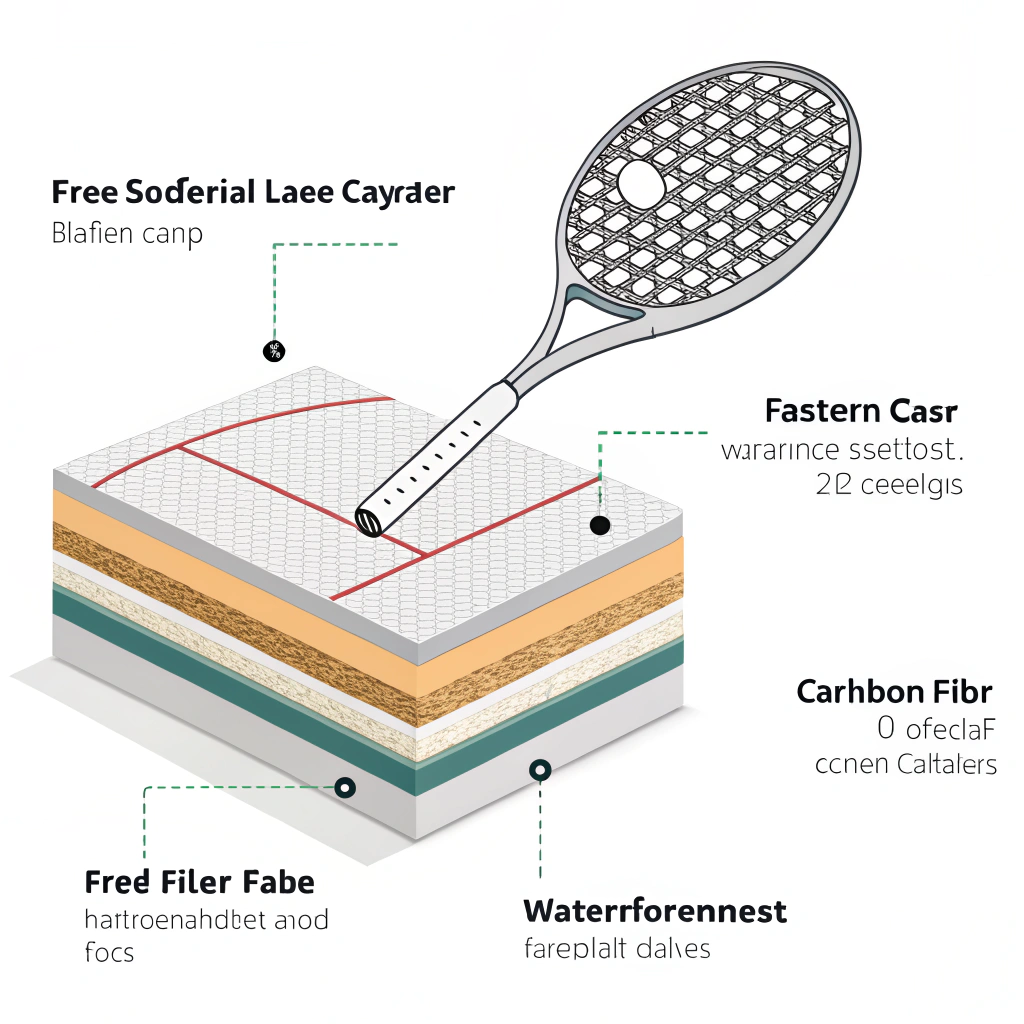

The foundation of every padel racket is its composite materials1. Typical materials include:

- Carbon fiber (3k, 12k, 18k variants): Chosen for their excellent strength-to-weight ratio.

- Fiberglass: Valued for its flexibility and ease of manufacturing, particularly in models meant for beginners.

- Custom materials: Sometimes, combinations or enhanced composites are selected based on customer specifications.

Each raw material undergoes quality checks to ensure consistency in properties. The fibers are pre-cut to specific dimensions and pre-treated to remove any impurities or moisture that might affect the curing process.

Control of the composite fibers, including tension and fiber alignment, is critical at this stage. Adopting advanced measurement techniques minimizes waste and ensures that the material performance is maximized in the final product.

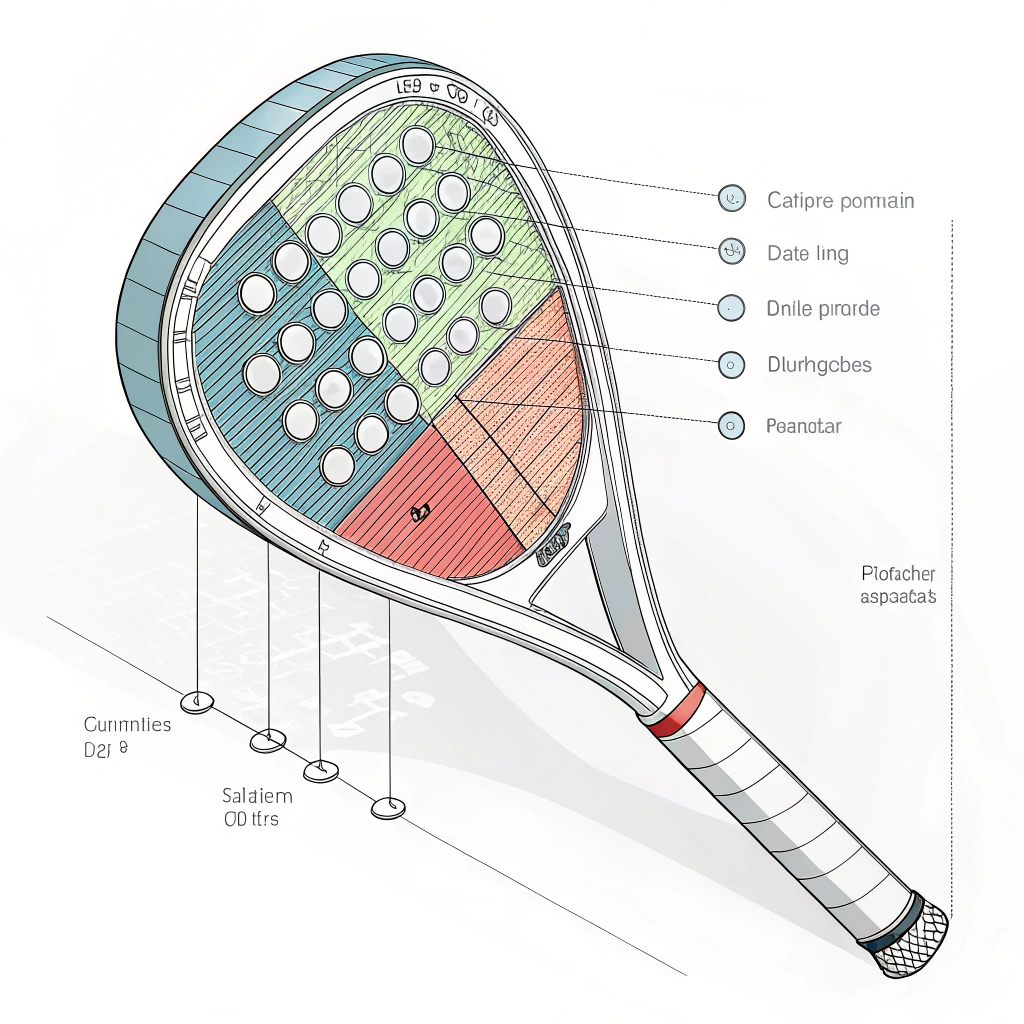

The lay-up process2 involves the precise placement of composite layers on a tooling3 surface or mold. This stage is essential to ensure that the final racket has optimal structural integrity and balance.

a. Base Layer Application: A base layer of composite material, often fiberglass, is applied first. This forms the internal foundation.

b. Core Fiber Integration: For padel rackets requiring high performance, multiple layers of carbon fiber are subsequently added. Each layer is carefully oriented to maximize strength in critical stress areas.

c. Reinforcement Layers: Additional coatings may be applied to areas expected to experience high impact.

- Temperature and Humidity: Controlling environmental factors is essential, as they influence the adhesion and flow of the resin.

- Tooling Precision: The mold design must accommodate custom shapes like Diamond, Round, or Teardrop forms. Any deviation can result in structural weaknesses.

During the lay-up stage, continuous inspection is conducted to verify layer uniformity and eliminate air pockets. This step is vital for maintaining both performance and durability.

The molding stage is where the padel racket begins to form its final shape. This phase involves transferring the lay-up into a pre-heated mold equipped with pressing equipment.

a. Mold Preparation: The mold is heated to the required curing temperature. For instance, carbon composite materials typically cure at high temperatures to activate chemical bonding in the resin.

b. Transfer to Molds: The layered composite is then carefully placed into the mold.

c. Application of Pressure: Hydraulic or pneumatic presses apply uniform pressure to ensure that the material conforms precisely to the mold shape. Proper pressure distribution eliminates any residual stress and gaps.

d. curing process4: The assembly stays in the mold for a predetermined time, allowing the resin to cure while the shape is fixed in place.

- Press Molds: Highly engineered to provide even pressure distribution.

- Temperature Monitors: To ensure constant heat levels.

- Pressure Sensors: To maintain predefined pressure limits throughout the curing cycle.

- Safety Margins: Too little pressure or incorrect temperature can lead to incomplete curing, while too much can cause warping.

- Mold Design: Customized molds are essential to produce the required racket shapes precisely. Our production supports fully customized shapes along with printed colors and logos.

Once the curing process is complete, the padel racket exits the mold ready for finishing touches.

a. Demolding: The cured product is carefully removed from the mold, ensuring not to introduce any damage or stress.

b. Trimming and Cleaning: Excess resin or composite material is trimmed off and any surface imperfections are polished.

c. Attachment Procedures: Handles (complete with custom hand grips and handle covers) are attached. Additionally, custom logos or designs may be printed onto the racket frame.

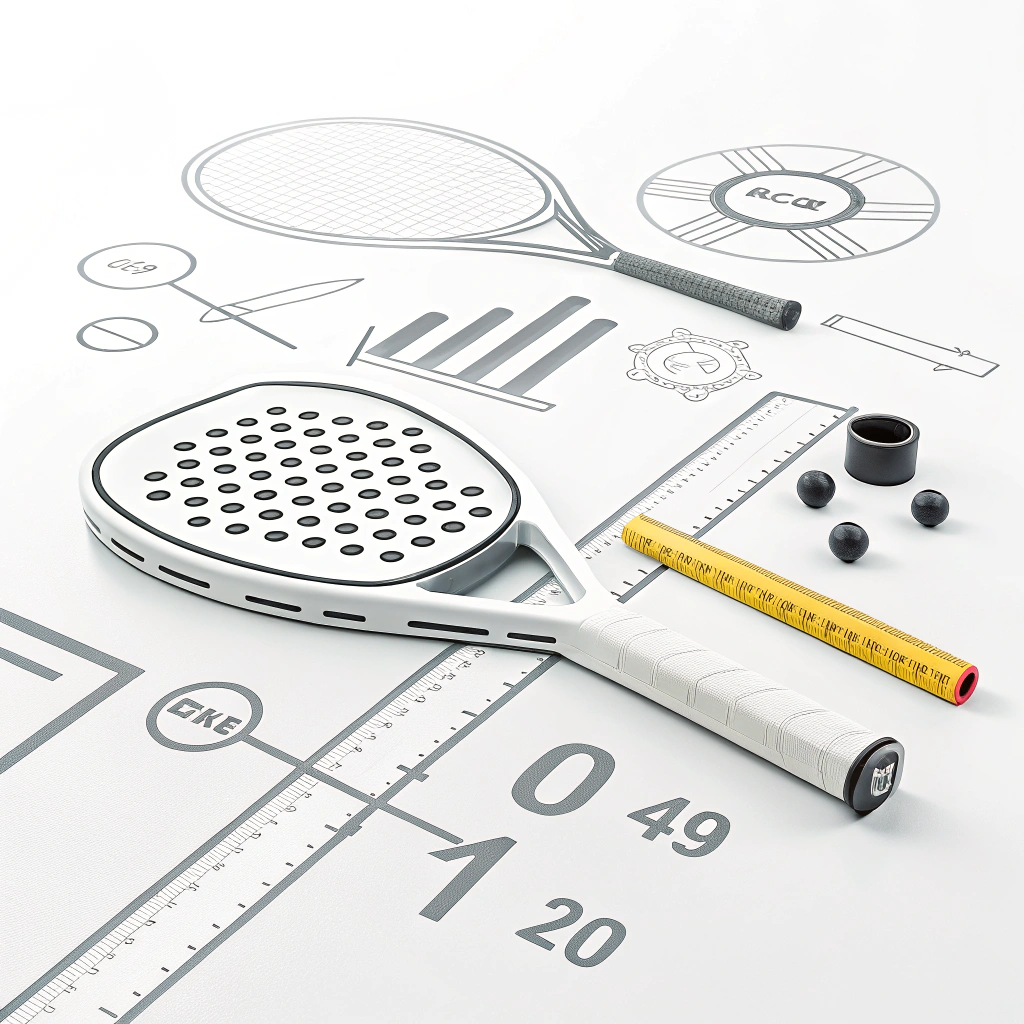

- Shape Customization: Options include Diamond, Round, and Teardrop shapes.

- Printing and Logo Integration: Custom printing ensures that brand elements are incorporated seamlessly.

- Accessory Integration: Options for custom hand grips and handle caps add personalization without compromising on quality.

The finishing stage involves final quality checks:

- Visual Inspection: To ensure the aesthetics meet brand and quality standards.

- Dimensional Accuracy: Measurement tools verify that the racket conforms to design specifications.

- Performance Testing: Basic performance tests are conducted to ensure structural integrity and balance.

Quality control is integrated into each phase of the production process to ensure that every padel racket meets high-performance standards and customer specifications.

| Phase | Key Inspection Points | Testing Method |

|---|---|---|

| Material Preparation | Fiber quality and pre-treatment | Visual & Mechanical testing |

| Lay-Up Process | Uniformity of layers and absence of air pockets | Ultrasound & Optical Scan |

| Molding Operation | Accurate curing, shape conformity | Temperature & Pressure Logs |

| Finishing | Trim accuracy, logo placement, surface finish | Caliper Measurement & Visual Inspection |

- Benchmark Testing: Rackets are compared against performance benchmarks to assure consistency.

- Feedback Loop: Data from quality tests is fed back into the production process to continuously improve procedures.

- Documentation: Each racket undergoes extensive documentation for traceability, essential for B2B compliance.

To achieve cost-efficiency and enhanced product quality, manufacturers are encouraged to focus on:

- Optimizing Molding Parameters: Fine-tuning the temperature, pressure, and curing time can lead to significant improvements in product performance.

- Investing in Advanced Sensor Technology: Real-time monitoring equipment ensures that deviations in process parameters are detected early.

- Regular Calibration of Equipment: Maintaining equipment calibration minimizes production defects and enhances repeatability.

- Supply Chain Quality: Using premium-grade raw materials from verified sources contributes to the reliability of the final product.

Manufacturers must balance between innovation in production techniques and maintaining stringent quality control. Embracing smart manufacturing and Industry 4.05 principles can further enhance process performance by integrating IoT sensors and data analytics for continuous process monitoring.

A leading OEM in the sporting goods industry recently integrated advanced molding techniques into their production line to address issues such as structural inconsistencies and increased defect rates. Key steps undertaken in their process improvement plan included:

- Data-Driven Process Control: Implementation of IoT-based sensors helped capture real-time data on mold temperature and pressure. This allowed for minor adjustments during the curing process, leading to better adhesion and uniformity.

- Training Programs: Technicians received in-depth training on handling composite materials and operating advanced molding equipment. This reduced human error and ensured consistency across shifts.

- Enhanced Inspection Routines: Adoption of ultrasound and optical scanning devices during the lay-up and curing stages meant that any defects were flagged early. This led to a significant reduction in rework and scrap rates.

- Feedback Loops: By incorporating customer feedback and performance data from finished products, the manufacturer was able to adjust the process parameters in real-time, ensuring that each production batch met the exact requirements for performance and durability.

The success of this implementation was evident in a 25% reduction in production downtimes and a 15% increase in overall product quality, confirming that even established production processes could benefit from incremental changes and technological integration.

The padel racket molding process is a detailed blend of high-precision material handling, advanced manufacturing techniques, and rigorous quality control measures. It involves multiple phases—from raw material preparation to launching the finished product—that must be carefully integrated to produce a quality padel racket.

Manufacturing engineers looking to optimize their production should consider:

- Ensuring stringent control during the lay-up process to achieve consistent layer uniformity.

- Leveraging advanced molding technologies that offer precise temperature and pressure control.

- Investing in detailed post-production quality control methods to validate the integrity and performance of the product.

By understanding and adopting these advanced manufacturing techniques, companies can not only improve the quality and durability of the final product but also achieve significant cost savings and operational efficiencies. For decision-makers, the insights provided here serve as a blueprint for benchmarking existing processes, exploring new methods, and ultimately fostering collaboration with specialized OEM manufacturers like NEX Padel—who offer both high-performance padel rackets and advanced custom manufacturing capabilities.

Taking action now on these recommendations may pave the way for enhanced production quality and operational excellence in your manufacturing processes. Whether you are fine-tuning an existing line or setting up a new production workflow, staying updated with the latest advancements in composite molding can provide a competitive edge.

Q: How are padel rackets made?

A: Padel rackets are typically made by layering composite materials such as carbon fiber or fiberglass, followed by precision molding in a press. The process involves applying layers, transferring them to a heated mold, pressing for an optimal shape, and completing fabrication with finishing touches like handle attachment and custom printing.

Q: What is the construction of a padel racket?

A: The construction includes a composite face and frame, made primarily from high-strength materials like carbon fiber and fiberglass. These components provide excellent durability and performance, with the composite layers carefully arranged to optimize power, control, and balance.

Q: What is the life of a padel racket?

A: While padel rackets are engineered to deliver consistent performance, their optimal lifespan in terms of maintaining ball output, control, and power is typically around one year under ideal conditions.

-

composite materials: Reading this article will provide insights into the makeup and benefits of composite materials, which combine two or more constituents to produce enhanced material properties—crucial for achieving lightweight durability. ↩

-

lay-up process: This resource explains the lay-up process in composite manufacturing, detailing how layers are methodically arranged to optimize strength and balance in high-performance products. ↩

-

tooling: Discover how tooling design and surface preparation affect production quality, ensuring precision in forming complex shapes and maintaining structural integrity. ↩

-

curing process: Learn about the curing process in composite manufacturing, including temperature, pressure, and chemical reactions that solidify resin and secure the final form of the product. ↩

-

Industry 4.0: Explore the principles of Industry 4.0 and how smart manufacturing, IoT integration, and data analytics are revolutionizing production processes for enhanced efficiency and quality. ↩