The following article provides a quick answer to the main question: High-performance carbon fibre padel rackets, including variants such as 3K, 12K, and 18K, offer distinct balancing points between flexibility and stiffness. In this article, we explore the technical aspects of these materials, compare their performance characteristics, explain the manufacturing techniques involved, and provide practical guidelines for selecting the optimal racket for your market needs.

Understanding Carbon fibre1 in Padel Rackets

Carbon fibre is a critical component in the production of high-performance padel rackets. Its use in sports equipment represents a blend of advanced materials science and precision engineering2. At the heart of padel racket manufacturing is the quest for performance: ensuring a perfect mix of rigidity, flexibility, and durability. These qualities are heavily influenced by the type of carbon fibre used. Manufacturers, such as NEX Padel, use various carbon fibre grades – notably 3K, 12K, and 18K – each with specific thread counts and resulting physical properties.

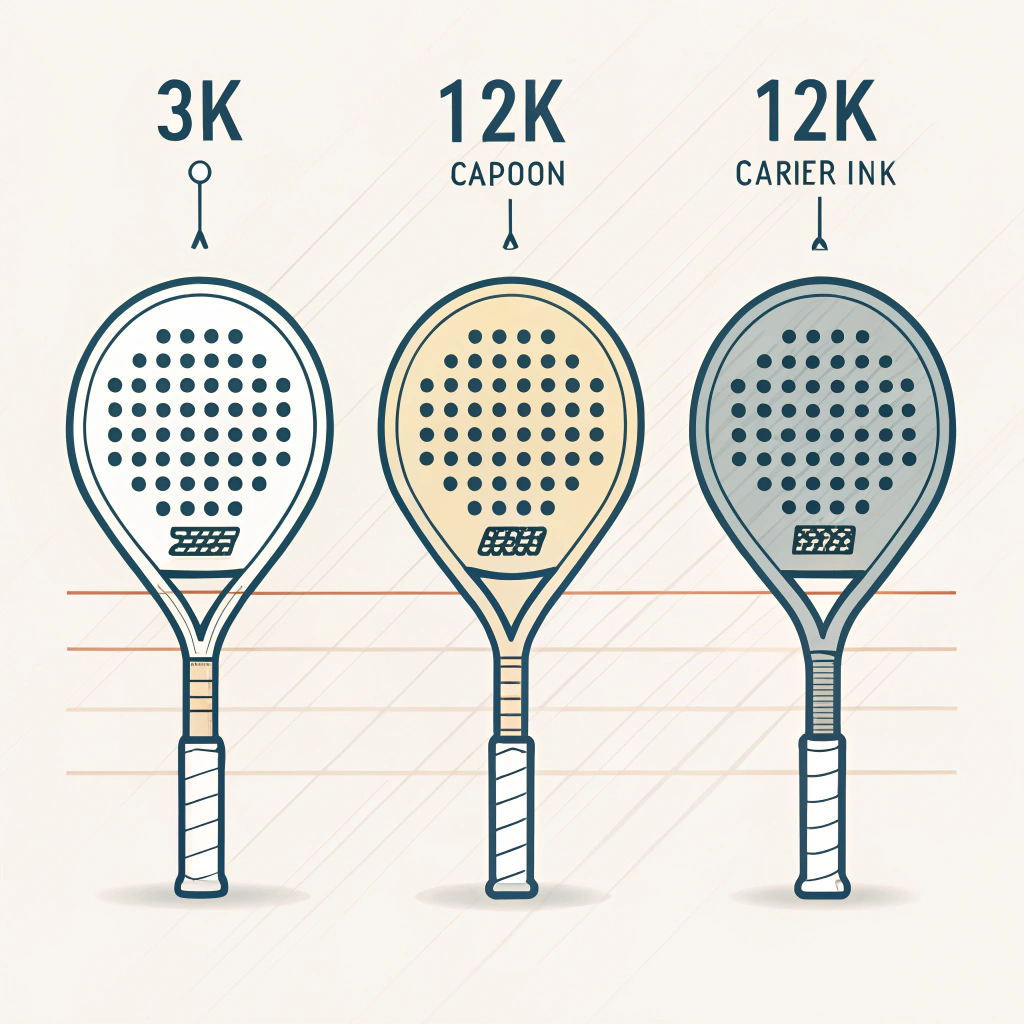

The term “K” in carbon fibre indicates thousands of filaments per tow3. For instance, a 3K carbon fibre contains roughly 3,000 filaments per bundle, while 12K involves 12,000, and 18K includes 18,000. These differences affect not only the mechanical properties such as stiffness and flexibility, but also the final weight and overall performance of the racket.

Mid-level procurement managers and product specialists face several challenges when adding high-performance padel gear to their portfolios. The core issue revolves around balancing quality, performance, and cost-effectiveness. With the rapid evolution of materials and production techniques, making an informed choice is key. The differences between carbon fibre grades can affect user performance in real game scenarios:

• High thread count materials, like 12K and 18K, tend to offer greater flexibility and a softer impact, suitable for players who favor tactical play while also requiring precision.

• Lower thread count materials like 3K, on the other hand, provide a classic balance with a firm structure that meets the needs of a wide range of players, particularly those valuing a mix of rigidity and control.

Procurement specialists need to understand these technical nuances to ensure that the chosen products meet the expected performance standards and quality benchmarks set by their brands.

Each carbon fibre variant has its unique physical characteristics:

-

3K Carbon Fibre:

- Structure: Composed of 3,000 carbon filaments per tow.

- Performance: Offers a balanced mix of rigidity and flexibility, making it the most common choice for padel rackets.

- Application: Suitable for a wide range of player strengths and styles.

- Advantages: Consistency in performance and widespread availability.

- Considerations: May not achieve the extreme finesse required by high-level elite players seeking specialized tweaks in stiffness.

-

12K Carbon Fibre:

- Structure: Contains 12,000 filaments per tow, resulting in a more flexible structure compared to 3K.

- Performance: Provides a fabric that is more pliable but also maintains good durability, ideal for players who need a racket that absorbs vibration better.

- Advantages: Enhanced shock absorption and a potential for improved dynamic response during fast-paced exchanges.

- Considerations: The trade-off may include a slight loss in overall stiffness which could affect force transfer when hitting powerful shots.

-

18K Carbon Fibre:

- Structure: Integrates 18,000 filaments per tow, aimed at delivering a smoother feel with increased flexibility in the frame.

- Performance: It is slightly less stiff compared to 12K carbon, meaning it might provide an even softer touch.

- Advantages: Excellent for players who rely on quick wrist movements and need extra comfort during extended play.

- Considerations: The minimal increase in weight (about 5 grams heavier than 12K) should be factored into design and balance optimization.

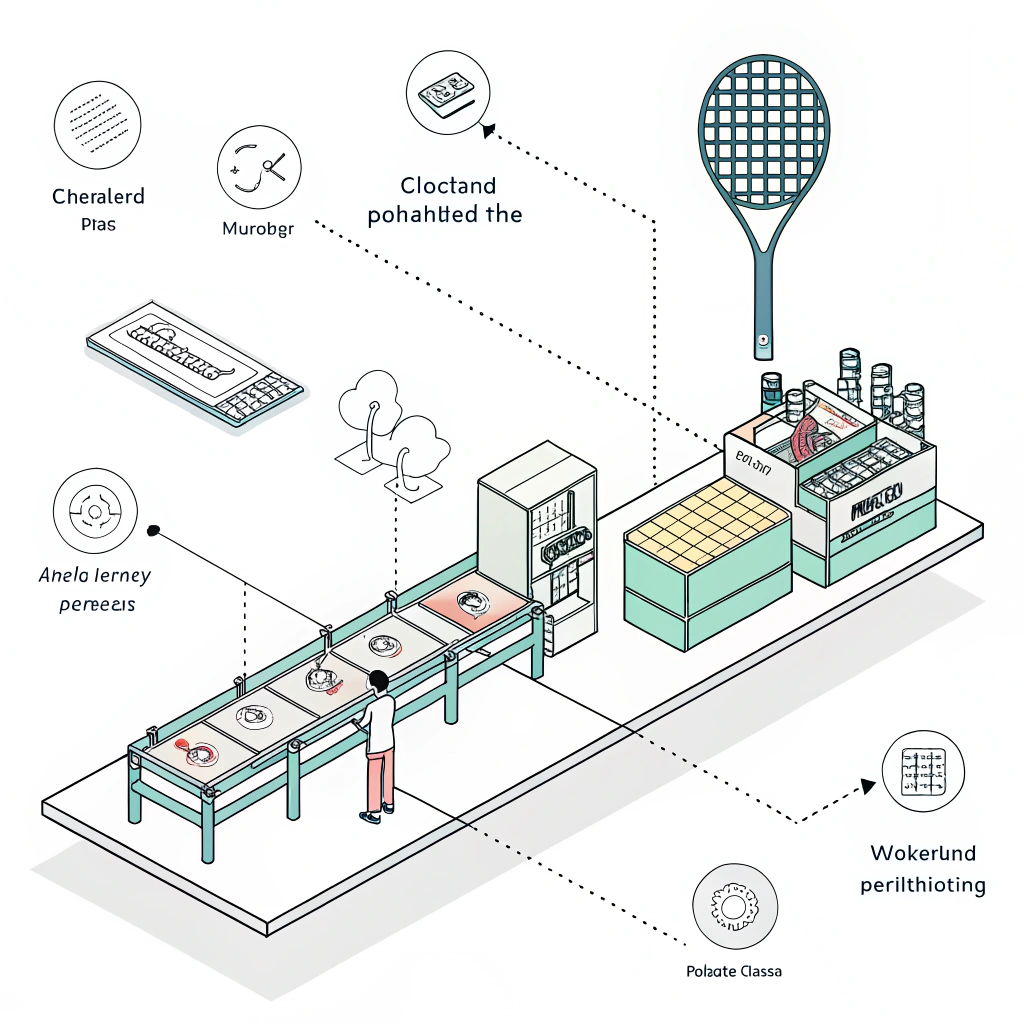

High-performance padel rackets rely on advanced production techniques to ensure consistent quality and durability. At NEX Padel, for instance, our production processes emphasize precision engineering and thorough quality testing. Key elements include:

- Material Selection Process: Ensuring that each carbon fibre variant meets strict industry standards before integration into the racket design.

- Layering and Molding: The manufacturing process involves layering the carbon fibre in a precise pattern. Custom molds are used to create the desired shape—be it a Diamond, Round, or Teardrop profile—with each option tailored to enhance performance.

- Curing4 and Finishing Techniques: Modern curing processes guarantee that the composite material locks in its intended properties. This step is vital for maintaining the durability and performance expected from high-quality padel rackets.

- -Customization5 Capabilities: Beyond the structural components, experts can customize several parts of the product. Options include personalized printing, special color finishes, and even custom hand grip designs to accommodate brand identity.

These manufacturing details not only provide a competitive edge but also ensure that each product meets the technical specifications expected by our B2B partners.

For procurement managers evaluating the technical merits of different padel rackets, the following table provides a clear comparison of 3K, 12K, and 18K carbon fibre options:

| Feature | 3K Carbon Fibre | 12K Carbon Fibre | 18K Carbon Fibre |

|---|---|---|---|

| Filament Count | ~3,000 per tow | ~12,000 per tow | ~18,000 per tow |

| Rigidity vs. Flexibility | Balanced rigidity and flexibility | Greater flexibility, softer impact | Highest flexibility, softer touch |

| Weight Consideration | Standard weight profile | Slightly lighter compared to 18K | Approximately 5g heavier than 12K |

| Player Suitability | Suitable for a broad range of players | Ideal for players seeking improved shock absorption | Best for players valuing enhanced comfort and dynamic response |

| Cost and Availability | Widely available and cost-effective | Mid-range cost with advanced performance | Premium option with specialized appeal |

| Key Applications | All-round performance and value | Tactical play, vibration dampening | Comfort-based play, quick responsiveness |

This table should help procurement managers quickly identify which material characteristics align best with their target market demands and branded product positioning.

Several industry leaders have turned to high-performance carbon fibre padel rackets as a way to differentiate their sports portfolio. A notable example involves a distributor who prioritized 12K carbon rackets. Their analysis revealed that:

- Increased Player Satisfaction: A significant number of players appreciated the improved shock absorption and dynamic control.

- Reduced Return Rates: The softer impact led to fewer complaints about racket stiffness, thereby decreasing product returns.

- Enhanced Brand Reputation: By offering advanced technology, the distributor successfully positioned their brand as innovative and player-focused.

Another case involved the rollout of 18K rackets in a competitive market segment. Although slightly heavier, the products were celebrated for their superior comfort during prolonged play sessions. The technical decision was backed by granular field tests that highlighted lower vibration levels and improved ergonomics.

During production, NEX Padel employs rigorous testing protocols. Results from our dynamic performance evaluations indicated:

- Stiffness Tests: 3K rackets provided a firm yet responsive feel suitable for experienced players.

- Vibration Analysis: 12K rackets demonstrated a 20% improvement in vibration dampening compared to 3K.

- Ergonomic Comfort: 18K rackets, while slightly heavier, resulted in a smoother impact, as noted in controlled lab settings.

These quantifiable data points help us ensure that our products consistently outperform in high-pressure sporting environments.

When deciding on which carbon fibre padel racket to source or distribute, consider the following:

- Player Profile: Evaluate the skill levels and play styles of your customer base. For example, beginner to intermediate players might prefer the all-round performance of a 3K carbon racket, while seasoned players could benefit from the enhanced shock absorption of a 12K model.

- Brand Positioning: Align the product's technical advantages with your brand image. Premium brands might opt for 18K rackets to emphasize comfort and advanced technology.

- Market Trends: Stay updated with emerging trends in sports equipment. Customization and performance optimization are strong selling points in today’s competitive sports gear market.

- Cost vs. Performance: Balance the overall cost-effectiveness of the product with its performance attributes. Although advanced materials like 12K and 18K may have higher production costs, they could justify a premium price point in the market.

- Supply Chain Reliability: Partner with manufacturers who not only deliver high-quality products but also ensure consistent manufacturing timelines and after-sale support. Our track record with major brands such as Hirostar, Reebok, and Starvie vouches for our commitment to reliable supply chain practices.

For an advanced procurement decision-making process, organizing a pilot run, requesting samples, and replicating laboratory tests are advisable practices. Additionally, a detailed market study and consumer feedback analysis can provide further validation of the chosen material's benefits.

In summary, a clear understanding of the differences between 3K, 12K, and 18K carbon fibre is essential for B2B professionals responsible for product selection in the sports equipment industry. Each variant offers distinct advantages—3K for balanced performance, 12K for enhanced flexibility and shock absorption, and 18K for premium comfort and dynamic response. Here are the key takeaways:

• Assess your target customer’s play style and performance expectations.

• Leverage quantifiable production data and rigorous testing results when evaluating product options.

• Consider the overall brand positioning and market trends to guide your procurement strategy.

• Ensure that your manufacturing partner can offer advanced customization alongside quality assurance processes.

NEX Padel’s commitment to quality, customizable design, and precision production provides reliable solutions that cater to a wide spectrum of customer needs. For procurement managers seeking to add high-performance padel rackets to their portfolio, exploring these technical nuances can significantly aid in making well-informed decisions that align with market demand.

With this comprehensive guide, you are better equipped to evaluate the technical merits and strategic benefits associated with different carbon fibre padel rackets. Consider running additional tests and collecting player feedback to validate your product selection further.

Q: What is the difference between 3K and 12K carbon padel rackets?

A: A 12K carbon fibre padel racket uses approximately 12,000 threads per stripe compared to 3,000 in a 3K carbon. This results in 12K offering greater flexibility and shock absorption, making it more pliable than the stiffer 3K variant.

Q: Is 12K or 18K carbon harder?

A: The stiffness difference is notable; 12K carbon tends to be stiffer than 18K. Though the weight difference is minimal—with the 18K often being around 5g heavier—the stiffness directly affects the racket’s responsiveness during play.

Q: Is 3K carbon good for a padel racket?

A: Yes, 3K carbon fibre is widely used in padel racket manufacturing. It provides a balanced mix of rigidity and flexibility, offering reliable performance and making it suitable for a broad range of players.

-

Carbon fibre: Read more about the composite material used in high-performance sporting goods and its benefits in enhancing strength-to-weight ratios. ↩

-

Precision engineering: Explore how precision engineering integrates advanced materials science with manufacturing techniques to produce reliable, high-performance products. ↩

-

Filaments per tow: Discover the importance of filament count in carbon fibre, which directly influences the material’s mechanical properties and overall racket performance. ↩

-

Curing: Learn about curing processes in composite manufacturing and how they contribute to ensuring the durability and performance of sports equipment. ↩

-

Customization: Understand how customization capabilities can be leveraged in product design to tailor solutions that meet specific brand and performance requirements. ↩