NEX Padel is a leading manufacturer of high-performance padel equipment offering customizable padel rackets engineered with advanced production techniques for maximum durability and precision. In this article, we explain how our solutions address common procurement challenges1 in the padel market, including quality consistency, rapid prototype production, and extensive customization options.

Procurement managers and sales directors in the sports equipment distribution industry face several challenges when selecting a B2B supplier for padel equipment. Many suppliers struggle with inconsistent quality, lengthy production cycles, and limited product customization. Additionally, the padel market continues to expand rapidly, making it increasingly competitive. The main issues include:

• Variation in quality control across suppliers

• Long lead times impacting inventory planning

• Limited options for customized designs, materials, and branding

• Inadequate information on technical specifications and manufacturing processes

These challenges can slow down supply chain efficiency and affect overall business performance for retailers and distributors.

Several factors lead to these challenges:

-

Material Complexity:

Padel rackets are crafted using various materials such as glass fiber and different grades of carbon fiber (3k, 12k, and 18k)2. Each material brings its own set of performance characteristics. The choice of material directly impacts weight distribution, durability, and power, and suppliers that cannot ensure precise material handling may fall short of buyer expectations. -

Design Versatility and Customization Needs:

Racket shapes like Diamond, Round, and Teardrop offer unique benefits. Many B2B buyers require customization not only in physical design but also in branding elements such as custom hand grips, handle covers with logos, and unique color schemes. Traditional manufacturing setups may lack the agile production process required to deliver these customizations without compromising quality. -

Supply Chain and Production Efficiency:

Beyond product design, timely delivery is crucial. In many cases, delays in production or shipping are due to inefficient prototyping and lack of rapid sample approval processes. In an industry where trends change quickly, a delayed supply chain can result in missed sales opportunities. -

Competitive Market Dynamics:

The padel sport’s rising popularity means that demand often outpaces supply. This imbalance pushes up costs and makes it hard for procurement professionals to secure high-volume orders at a reasonable price point while maintaining quality standards.

NEX Padel has developed practical, industry-proven solutions aimed at overcoming these challenges. Below is a comprehensive list of our strategic approaches that ensure quality, customization, and efficient supply chain management:

| Key Aspect | Challenge Addressed | NEX Padel’s Solution |

|---|---|---|

| Material Selection | Variation in quality and performance | Use of advanced materials including glass fiber and carbon fiber (3k, 12k, and 18k)2 ensuring consistency and precision in every product. |

| Racket Design Customization | Limited product variety and standard designs | Three core shapes (Diamond, Round, Teardrop) with full customization options. Custom printing, color options, and logo integration on both racket and accessories such as hand grips and handle covers. |

| Rapid Prototyping3 | Long lead times affecting market responsiveness | Fast sampling and prototyping processes allow for quick approval and iterative testing, ensuring that product design meets market trends and buyer expectations. |

| Supply Chain Efficiency4 | Production delays and inconsistent delivery | Streamlined production scheduling and strong logistic partnerships guarantee timely delivery even for custom orders. |

| Quality Assurance5 | Inconsistent product performance | Rigorous quality control protocols at every stage of production to ensure high durability and optimal performance in competitive padel play. |

These solutions not only resolve immediate challenges but are also designed to support long-term strategic growth for our partners.

Choosing the right material is fundamental to producing high-performance padel rackets. NEX Padel utilizes an array of advanced materials:

• Glass Fiber: Offers a reliable balance between flexibility and strength, suitable for intermediate to advanced players.

• Carbon Fiber (3k, 12k, 18k): Rackets made with carbon fiber ensure enhanced rigidity, durability, and a precise weight balance. The diverse options allow customization to match the varied skill levels and playing styles in the market.

These materials are rigorously tested under simulated play conditions to ensure that every padel racket delivers superior performance under the pressures of competitive play.

Modern padel players demand equipment that reflects both their playing style and personal brand. With our vast customization capabilities, NEX Padel offers:

• Shape Customization: Choose from Diamond, Round, or Teardrop designs to tailor the racket’s performance parameters such as center of gravity and swing balance.

• Design and Branding: Customers have the option to integrate corporate logos, custom prints, and color schemes directly into the racket design. Furthermore, accessories like hand grips and handle covers are customizable, ensuring that every detail reinforces brand identity.

• Prototype Rapid Production: Our advanced prototyping facility means that custom designs are converted to prototypes rapidly, allowing for quick market testing and validation before full-scale production.

These customization options are essential for distributors and retail companies looking to offer exclusive products that meet specific customer preferences and local market trends.

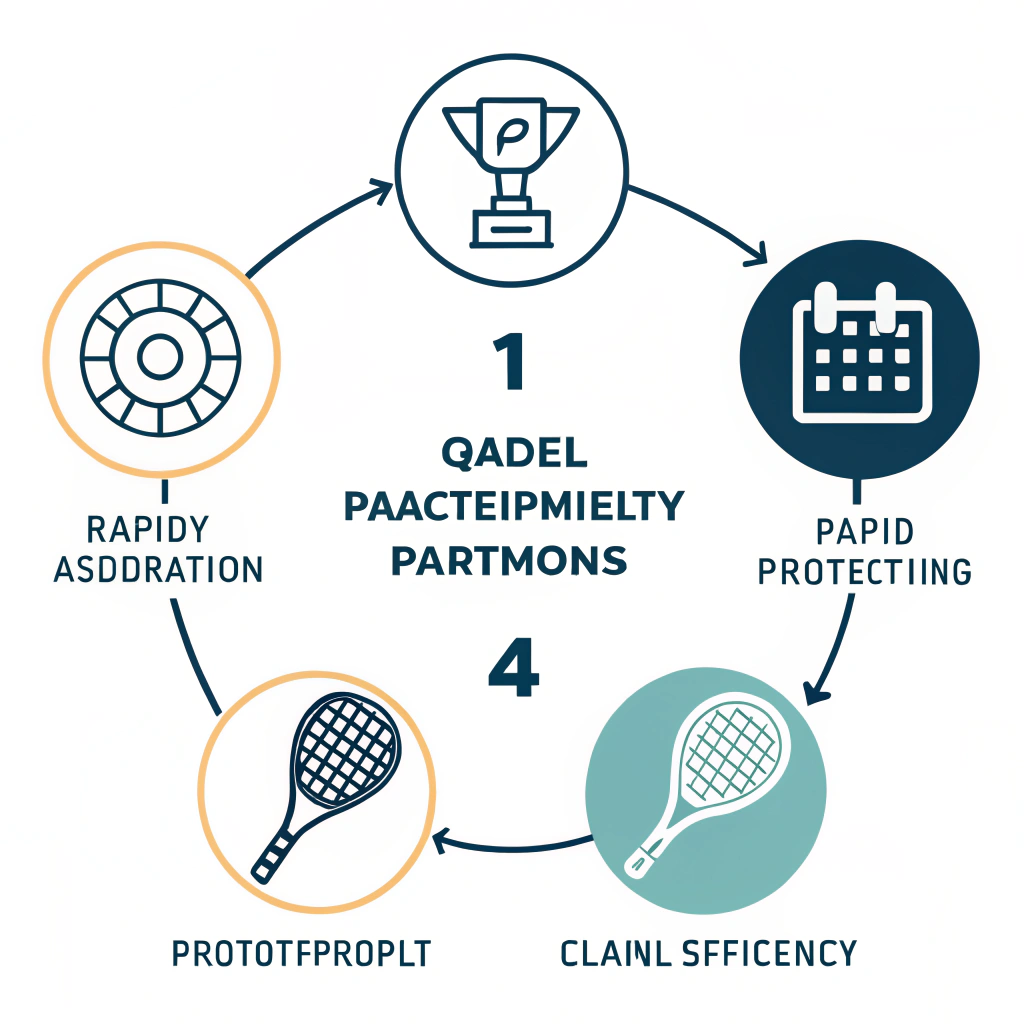

One of the most significant aspects for B2B buyers is the ability to rely on a supplier who can consistently deliver orders on time. At NEX Padel, we have implemented a robust production process that includes:

• Rapid Sample Approval: By shortening the prototype phase, we enable our partners to stay ahead of market trends with minimal delay.

• Integrated Manufacturing Process: Our tightly managed production lines ensure that every step from material selection to final packaging adheres to strict quality standards.

• Strong Partnership Ecosystem: We work in close collaboration with industry-leading brands such as Hirostar, Reebok, and Starvie, which reinforces our commitment to high standards.

• Supply Chain Management: Our logistics network is optimized for efficient handling of large orders. This reliability helps reduce risks associated with inventory shortages and market fluctuations.

Quality assurance is at the heart of our manufacturing process. Every product undergoes thorough testing stages to ensure performance consistency. Our quality assurance process includes:

• Material Testing: Each batch of materials is tested for durability, tensile strength, and resistance to impact.

• In-Process Inspections: Regular inspections during manufacturing to ensure adherence to design specifications.

• Final Product Evaluation: Comprehensive testing of the final product under simulated competitive conditions, ensuring that the padel rackets meet international standards and buyer expectations.

By continuously monitoring and refining our production techniques, we mitigate the risks typically associated with manufacturing high-performance sporting goods.

NEX Padel has a proven track record of successful partnerships with some of the best-known brands in the industry. For example, our collaboration with a leading sports brand resulted in a custom-designed line of padel rackets that combined superior materials, advanced manufacturing techniques, and exacting branding standards. Key performance indicators from this collaboration included:

• A reduction in prototype-to-production time by 30%

• Increased product durability as evidenced by extensive field testing

• Higher customer satisfaction ratings due to the level of product personalization

These results not only underscore our ability to meet rigorous B2B requirements but also highlight why many industry leaders choose NEX Padel as their trusted manufacturing partner.

For procurement managers looking to evaluate and adopt a high-performance padel equipment solution, consider the following checklist:

- Verify the spectrum of materials offered (especially carbon fiber grades and glass fiber).

- Assess the customization capabilities including shape, design, and accessory personalization.

- Evaluate the production cycle, with emphasis on rapid sample approval and scale-up capabilities.

- Review quality assurance protocols and third-party certifications or testing results.

- Confirm supply chain efficiency, particularly lead times and reliability in delivery.

- Examine case studies or testimonials from known industry partners.

- Consider overall value in terms of cost, quality, and long-term supplier reliability.

Incorporating these checkpoints into your procurement process will ensure that you select a supplier who not only meets but exceeds your performance and customization needs.

In today’s competitive padel equipment market, suppliers must offer more than just competitive pricing. Quality, customization, and delivery reliability are the pillars upon which successful B2B partnerships are built. NEX Padel excels in these areas with our state-of-the-art manufacturing, rapid prototyping, and flexible customization options that meet the precise needs of distributors and sports equipment retailers worldwide.

To move forward with confidence:

• Schedule detailed consultations with NEX Padel to understand our production processes.

• Request a prototype tailored to your specifications to witness firsthand the quality and customization capabilities offered.

• Explore our comprehensive quality assurance processes and discuss how they integrate with your procurement requirements.

Embracing these steps will ensure that your business stays competitive by offering high-performance, customizable padel racket solutions to your customers, ultimately leading to higher customer satisfaction and stronger brand loyalty.

Q1: What is the 40-40 rule in padel?

A: At a score of 40-40 in padel, the receiving team has the option to choose which side they want to receive the serve. The point won immediately after a 40-40 score determines the winner of the game. This rule is designed to add strategic depth during critical scoring points.

Q2: Why is padel so expensive?

A: Padel equipment costs can be influenced by multiple factors, including supply and demand dynamics and installation costs. High demand for padel, combined with the specialized construction required for items such as glass walls on courts, drives up the prices compared to traditional sports equipment.

Q3: What brand is best for padel?

A: The best padel brand often depends on specific player needs and preferences. Market leaders include brands such as Babolat, NOX, HEAD, Bullpadel, and Adidas, each offering unique technologies and designs. When considering a brand, factors like innovation, material quality, and customization capabilities play a key role—qualities that are central to NEX Padel’s manufacturing approach.

-

procurement challenges: Read this article to understand the complexities of supplier selection and strategies to overcome issues in ensuring consistent quality and customization in B2B procurement. ↩

-

carbon fiber (3k, 12k, and 18k): Click to learn more about the different grades of carbon fiber, their properties, and how they impact the performance and durability of high-performance sporting equipment. ↩ ↩2

-

Rapid Prototyping: Discover how rapid prototyping accelerates product development cycles, allowing for quicker market launches and iterative testing of innovative designs. ↩

-

Supply Chain Efficiency: Gain insights into optimizing supply chain operations to reduce lead times and ensure consistent, on-time delivery in competitive markets. ↩

-

Quality Assurance: Explore comprehensive quality assurance methodologies that ensure products meet rigorous performance standards and exceed customer expectations. ↩