In brief, partnering with NEX Padel gives B2B procurement specialists a comprehensive solution for custom padel rackets by leveraging advanced production techniques, premium materials, and flexible OEM/ODM1 services. This article compares key customization options, production timelines, and technical specifications to support informed decision-making in the sports equipment industry.

As the padel market expands, brand managers and equipment distributors increasingly look for suppliers who not only deliver exceptional performance but also offer extensive customization options. NEX Padel stands out due to its commitment to quality, precision, and rapid prototyping. The ability to design a padel racket that aligns with your brand’s identity is not simply about aesthetics—it also involves material innovation, structural integrity, and performance consistency.

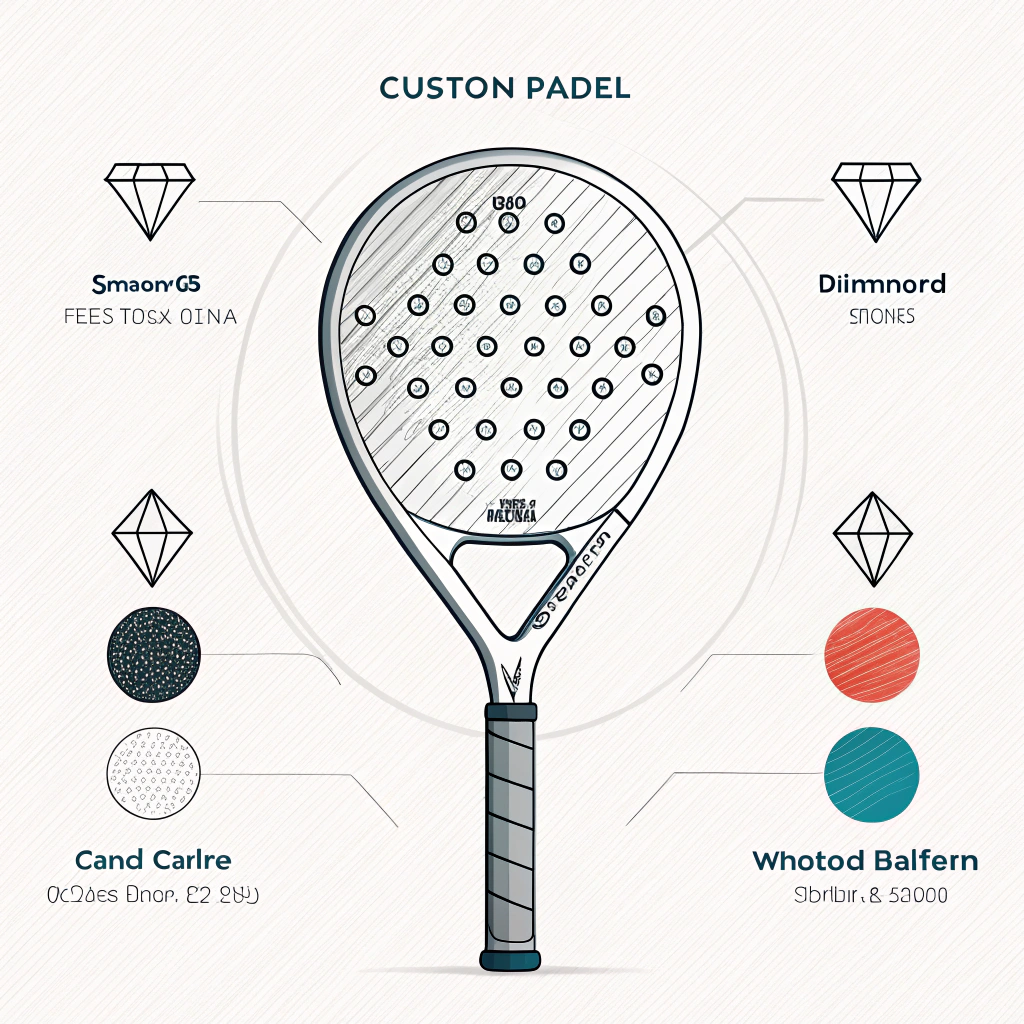

From the selection of materials, such as different carbon fiber variants2 (including 3k, 12k, and 18k), to the ability to create tailored shapes like Diamond, Round, and Teardrop, manufacturers are now providing more than ever before. Advanced production techniques ensure that the racket is lightweight yet durable, offering superior control and power on the court.

Selecting the right material is crucial when designing a high-performance padel racket. With advanced materials such as carbon fiber available in multiple grades, manufacturers can tailor rackets to different playing styles and levels. Here are some key points to consider:

- 3k Carbon Fiber: Offers a balanced mix of strength and flexibility, suitable for a wide range of players.

- 12k Carbon Fiber: Provides enhanced stiffness for players who favor aggressive play and require a more dynamic response.

- 18k Carbon Fiber: Ideal for elite players seeking rigid structures and maximum power with precise ball control.

Each variant provides a different combination of performance benefits. This allows you to align your product offering with specific market segments and player preferences.

NEX Padel employs advanced production techniques that ensure every racket meets stringent quality standards. High-speed CNC machines3, precision molding, and composite layering techniques contribute to the overall durability and performance consistency of the racket. Detailed quality control processes ensure that every component, from the frame to the handle, adheres to manufacturing excellence.

Customization is taken to the next level by offering global brands a myriad of options:

- Custom Printing & Logo Application: Ensure that every racket reflects your brand’s identity. From intricate patterning to bold logo placement, the full customization service enhances both aesthetics and brand recall.

- Hand Grip and Handle Cap Options: Besides the racket frame, you can also customize accessories such as hand grips and handle covers. This attention to detail reinforces a complete brand experience.

- Shape Customization: Choose from standard shapes like Diamond, Round, or Teardrop, or work with experts to develop a fully custom design that stands out in the market.

These options mean that every facet of the racket can be aligned with specific brand values and performance requirements.

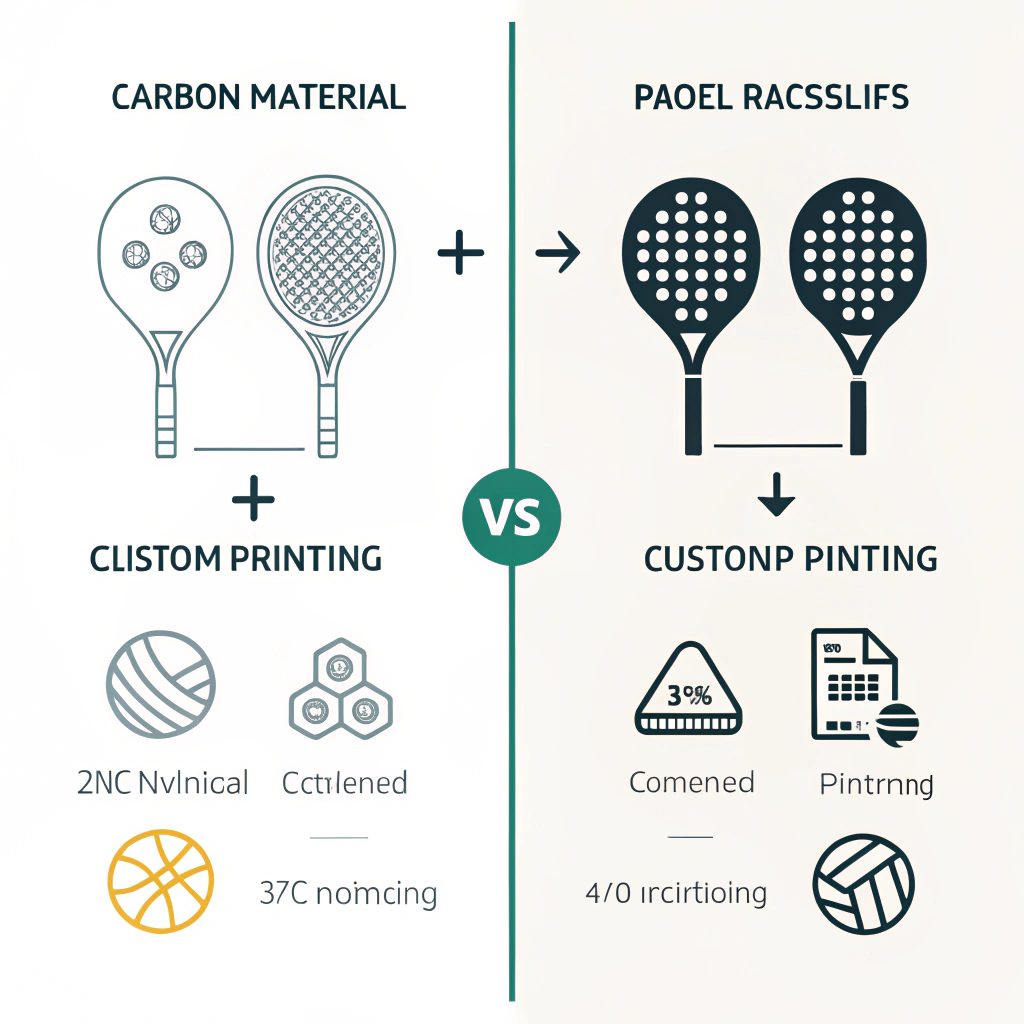

For decision-makers, quick comparisons often drive purchasing decisions. Below is a table summarizing the key differences between customization options available at NEX Padel and typical market alternatives.

| Customization Aspect | NEX Padel Offerings | Market Standard |

|---|---|---|

| Material Range | 3k, 12k, and 18k Carbon Fiber variants | Limited to one or two variants |

| Racket Shapes | Diamond, Round, Teardrop, Fully custom shapes | Predefined standard shapes |

| Custom Printing & Logos | High-resolution custom printing with multiple color options | Basic logo printing |

| Production Techniques | Advanced CNC machining, composite layering, rapid prototyping | Conventional production methods |

| Quality Control | Rigorous QC with full traceability | Varies by supplier |

| Accessory Customization | Custom hand grips and handle covers available | Limited accessory options |

| Turnaround Time | Fast sampling and on-time delivery | Often longer lead times |

| OEM/ODM Flexibility | Tailored production runs and flexible order sizes | Less flexible, high minimum orders |

This table demonstrates that NEX Padel offers a superior blend of quality, flexibility, and technology—key factors that differentiate a reliable manufacturing partner in the competitive sports equipment industry.

When designing a padel racket, technical precision underpins both performance and durability. NEX Padel leverages state-of-the-art equipment to produce rackets that can be fine-tuned to specific play styles. The integration of advanced CNC machinery ensures consistent precision across large production runs, irrespective of complexity.

The use of advanced composite materials4 not only reinforces the racket’s structural integrity but also allows for lightweight design alterations that impact maneuverability and power significantly. The manufacturing process involves layers of carbon fiber strategically placed to distribute stress and absorb impact, ensuring that every racket performs reliably, even under competitive conditions.

Manufacturers today are focusing on rapid prototyping5 to reduce lead times, a crucial factor for B2B procurement in a fast-evolving market. By embracing digital design simulations and 3D printing for initial prototypes, NEX Padel can rapidly iterate and perfect designs before full-scale production. This results in reduced development stages and faster time-to-market, giving brand managers confidence in scaling custom production.

Quality assurance is critical in ensuring that every padel racket meets both performance standards and the expected aesthetic. Stringent control measures are applied throughout the manufacturing process—from material selection to final product testing. Modern technology enables the tracking of each component’s origin, allowing for a full audit trail.

Moreover, fast prototyping allows for adjustments based on live feedback, which is essential for meeting dynamic market requirements. This also enables trial customization runs before full production, ensuring that any design imperfections are caught early. The combination of quality assurance practices and advanced production techniques guarantees a product that not only looks distinct but also plays impeccably on the court.

Consider the example of a leading sports brand that sought to expand its product line with a series of custom padel rackets. The company's requirements included:

- Unique branding with custom logos and distinctive racket shapes

- High-performance materials with clear demarcation among carbon fiber variants

- Customizable hand grips and accessory modifications

NEX Padel collaborated closely with the brand, beginning with detailed design sketches and rapid 3D prototyping. The project evolved through multiple iterations, ensuring that every design detail was tailored to meet both aesthetic and performance benchmarks. Using advanced production techniques, the partnership was able to reduce the typical lead time significantly while maintaining rigorous quality control. The result was a bespoke line of rackets that not only captured market attention but also delivered exceptional playable performance.

Several well-known brands such as Hirostar, Reebok, and Starvie have benefited from such close OEM/ODM collaborations. They value the flexibility in production volumes and the ability to swiftly adapt to market trends—an aspect that is critical in the fast-paced sports equipment industry.

For sports equipment distributors and brand managers looking to elevate their product offerings with customized padel rackets, here are some practical steps to consider:

-

Define Your Brand Identity:

Ensure that your customization requirements (color, logo, design) reflect your brand’s unique identity. A detailed creative brief can help streamline communication with your manufacturing partner. -

Evaluate Material Options:

Choose the carbon fiber variant that best suits your target demographic. For instance, opting for 18k carbon fiber might be ideal for a premium line aimed at elite players, whereas 3k or 12k variants can serve broader consumer base needs. -

Assess Production Capabilities:

Look for suppliers offering advanced production techniques and rapid prototyping. This minimizes design errors and reduces market entry time. Ensure that their quality control processes match your standards. -

Flexibility in Order Quantities:

Partner with manufacturers offering flexible OEM/ODM options. This allows for test runs and gradual market scaling rather than committing to a high minimum order count. -

Consider End-to-End Solutions:

Evaluate suppliers who provide customization not just for the racket frame, but also for accessories such as hand grips and handle covers. Full customization enhances the overall customer experience and brand value. -

Leverage Data and Case Studies:

Examine industry case studies or testimonials from other successful OEM/ODM partnerships. These insights can validate the supplier’s expertise and reliability. -

Budget and Timeline Considerations:

Clearly outline your budget and desired turnaround time. Advanced communication on these fronts from the start can prevent delays and ensure that quality is not compromised for speed.

Selecting the right manufacturing partner for customized padel rackets involves a careful balance between design flexibility, material quality, production speed, and ultimately, the overall brand vision. NEX Padel provides an integrated solution that addresses all these aspects—from advanced material selection to rigorous quality control practices and rapid prototyping.

For B2B procurement specialists and brand managers, the key takeaway is to seek partners who not only understand the technical aspects of padel racket production but also support your brand’s ethos. With the expansive customization options available, you can confidently enhance your product portfolio, catering to diverse market demands while ensuring consistency and excellence on every racket.

By aligning your strategic objectives with a partner that champions both innovation and reliability, you pave the way for products that resonate with consumers and stand out in a competitive market. Start by evaluating your current production needs, and then explore the full suite of customization options that can redefine your brand’s presence in the sports equipment industry.

How to design a padel racket?

Designing a padel racket starts with defining your market goals—whether aiming for a compact design or an expansive, eye-catching look. First, decide the type of racket by choosing the appropriate shape, such as Diamond, Round, or Teardrop, based on the playing style. Next, focus on material selection; using advanced composites like various carbon fiber variants is crucial for performance enhancement. Finally, incorporate custom printing or logo placements to align the design with your brand identity.

How to customize your racquet?

Customization involves several approaches. You can modify the racket’s weight distribution by adding tungsten putty or lead weight in the butt cap, use cotton for securing extra weight, or opt for epoxy as a substitute for lead tape. Such adjustments not only impact the racket’s maneuverability but also allow for a tailored feel that complements your specific playing style and market demands.

What is the best brand for padel racket?

While several brands offer high-quality padel rackets, the best brand often depends on specific performance requirements and design preferences. For instance, brands like Bullpadel or Babolat are known for power-oriented models, whereas NEX Padel excels by combining advanced production techniques with extensive customization options to deliver both performance and unique brand aesthetics.

-

OEM/ODM: Click to learn how Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) partnerships can offer tailored production solutions, enhancing flexibility and reducing time-to-market. ^↩ ↩

-

carbon fiber variants: Click to understand the differences between various carbon fiber grades (3k, 12k, 18k) and how each affects racket performance and durability. ^↩ ↩

-

CNC machines: Click to explore how Computer Numerical Control (CNC) machines contribute to precision manufacturing, ensuring consistent quality in high-volume production. ^↩ ↩

-

advanced composite materials: Click to learn about advanced composite materials, their properties, and why they are vital for achieving lightweight yet durable sports equipment. ^↩ ↩

-

rapid prototyping: Click to discover the benefits of rapid prototyping in reducing development cycles and enabling quick adjustments based on feedback. ^↩ ↩