Quick Answer: EVA foam variations1 significantly affect elements like energy absorption2, vibration damping3, and overall durability in padel rackets. Understanding these technical differences helps manufacturers tailor designs to balance power and precision, providing players with performance-enhancing options while giving procurement managers clear data for cost-effective, innovative solutions.

In today’s competitive padel market, EVA foam variations1 play a crucial role in defining racket performance. Whether you are looking to optimize power for aggressive gameplay or achieving precision with improved vibration control, selecting the right EVA foam composition is paramount. With our advanced production techniques and a diverse range of materials—from fiberglass composites to carbon fiber integrations—our approach at NEX Padel helps solve common challenges faced by product procurement managers in the sports equipment industry.

Padel racket manufacturers are constantly challenged to create a product that balances power, control, and durability. One of the main components under scrutiny is the EVA foam integrated into the racket’s core. The EVA foam1 provides not only shock absorption but also influences the energy transfer during ball strikes. However, the variations in foam types, density, and formulation lead to diverse performance characteristics. This raises several critical questions for B2B procurement professionals:

- How do different EVA foam compositions influence racket performance?

- What trade-offs exist between power generation and vibration control?

- How can manufacturers maintain high durability while allowing for customization?

These questions are central to ensuring the selected materials yield the desired performance attributes in the final padel racket.

The performance of a padel racket is deeply intertwined with the physical and chemical properties of its EVA foam core. Here are key factors that influence performance:

-

Density and Elasticity:

Higher density EVA foams tend to provide better stability and durability while lower density types offer superior flexibility and energy absorption. For instance, denser compositions favor control, but might sacrifice some responsiveness in delivering power. -

Energy Absorption and Vibration Damping:

The ability of EVA foam to absorb shock is pivotal in reducing vibrations during high-impact strokes. Variations in molecular structure and cross-linking within the foam can either enhance or limit this damping capability. An optimal formulation ensures players receive a balanced feel without discomfort. -

Thermal and Mechanical Stability:

Different EVA formulations respond variably under fluctuating temperatures and mechanical stresses. This influences how the racket behaves during prolonged use. A foam with good tensile strength4 (typically 0.3 to 0.5 MPa) and elongation capabilities (200-600%) ensures resilience even under repetitive stress. -

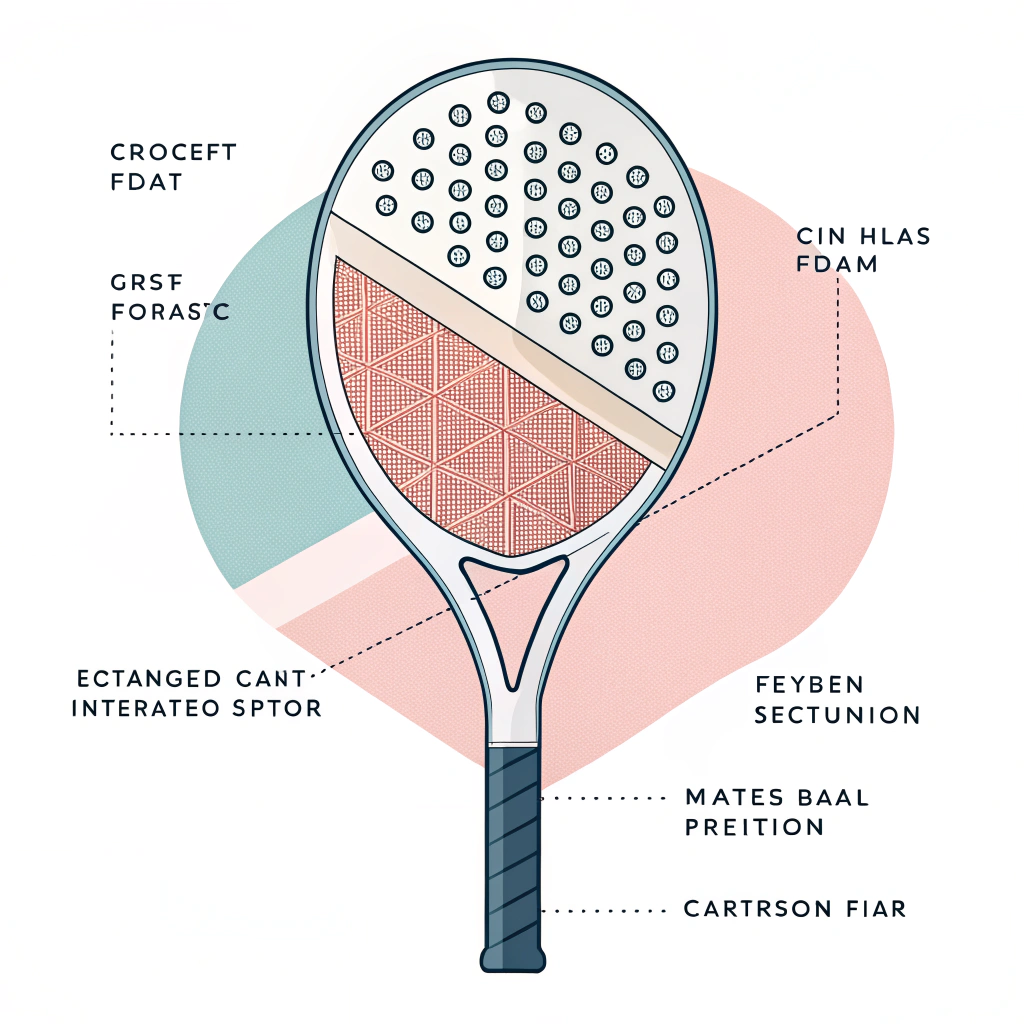

Customization and Material Integration:

Integrating traditional EVA with advanced materials such as carbon fiber further complicates the matrix. Precision in manufacturing is needed to balance these elements, influencing factors like the racket’s weight distribution and overall power delivery.

To address these challenges, manufacturers can adopt a systematic approach when selecting EVA foam variations. Below is a detailed comparison table that outlines the key properties and potential applications of various EVA foam types used in padel rackets:

| EVA Foam Type | Density | Energy Absorption | Vibration Damping | Durability | Ideal For |

|---|---|---|---|---|---|

| Low-Density EVA | 20-30 kg/m³ | High | Moderate | Moderate | Power-focused designs, lightweight rackets |

| Medium-Density EVA | 30-40 kg/m³ | Balanced | High | High | All-round performance, superior control |

| High-Density EVA | 40-50 kg/m³ | Moderate | High | Very High | Precision and control, heavier duels |

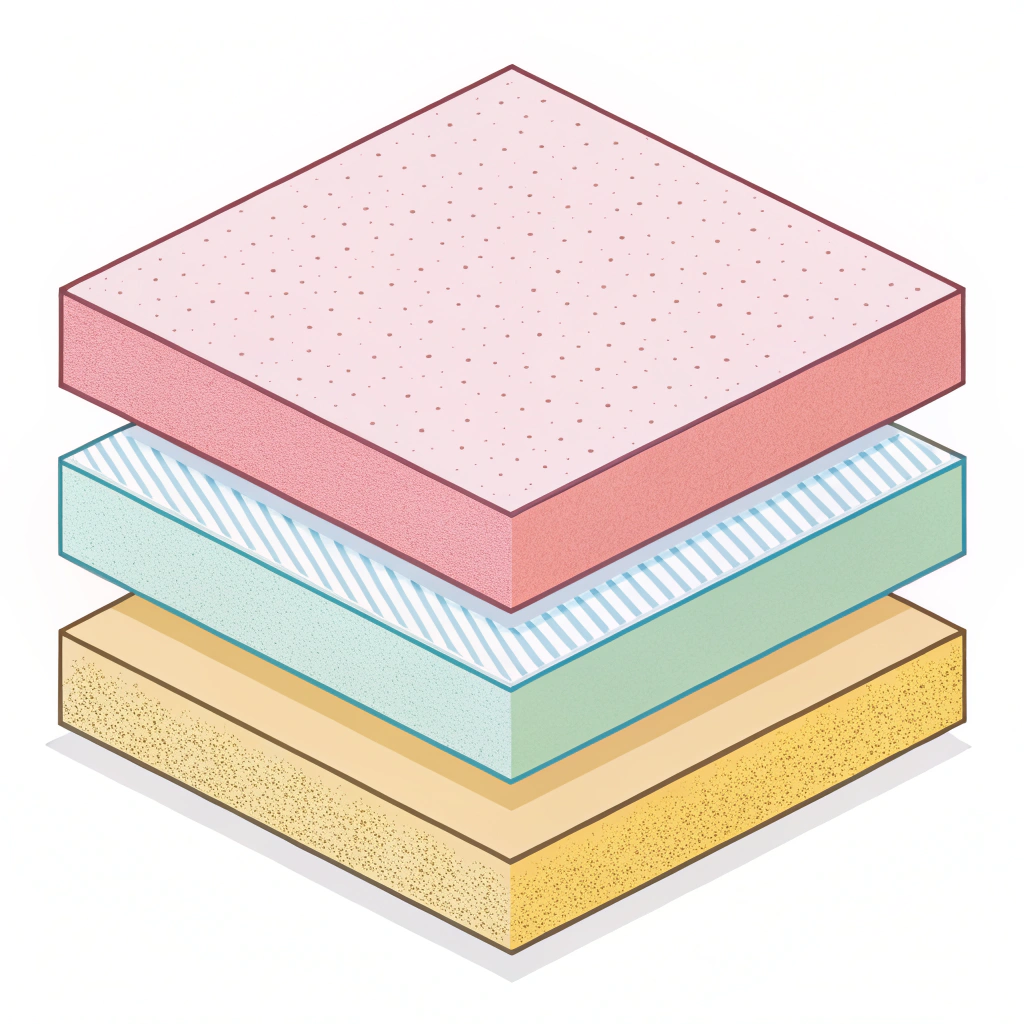

Customization Tip:

Manufacturers can customize these foam variations by adjusting layering techniques or by combining multiple types to achieve a hybrid effect. For example, a sandwich-layer configuration where a low-density foam core is encased by a medium-density layer can maximize both shot power and vibration control, while maintaining durability.

The energy absorption2 of EVA foam is of paramount importance. When a ball impacts the racket face, the foam should absorb a significant portion of the energy while efficiently transferring the remainder to the ball for an explosive shot. This balance directly affects a player’s ability to generate power without suffering from adverse vibrations that can lead to discomfort or even injury.

- Technical Insight:

Advanced EVA formulations utilize molecular adjustments that enhance energy transfer efficiency. In our production, we specifically measure energy absorption rates, optimizing our foam’s density to ensure a reliable coefficient of restitution (COR)5. This metric indicates how much energy returns to the ball during impact—a critical factor in power generation.

Vibration control is not just about comfort but also about stability and accuracy during play. Vibration damping3 serves as a buffer that minimizes the transfer of high-frequency vibrations to the player’s arm.

- Manufacturing Consideration:

Variations in EVA’s molecular structure can significantly alter its inherent damping properties. By fine-tuning compounding agents and curing times, manufacturers can produce foam that not only cushions impacts but also stabilizes the racket during fast-paced rallies. This careful balance is especially important in products aimed at competitive or professional players.

Rackets are subjected to continuous stress, and any judder within the material could compromise performance over time. EVA foam with enhanced tensile strength (ranging from 0.3 to 0.5 MPa) and a high elongation percentage offers the ideal remedy. Maintaining these properties throughout the lifecycle of the racket is a challenge that requires stringent quality controls and repeated testing cycles.

- Quality Assurance:

At NEX Padel, our testing protocols simulate real-world usage to ensure that our EVA foam materials do not degrade under sustained operational stress. This reliability has positioned us as a trusted partner for market-leading brands like Hirostar, Reebok, and Starvie.

When integrating various EVA foam types into a padel racket, manufacturers can follow several practical steps to ensure a consistent, high-quality product outcome.

-

Material Selection:

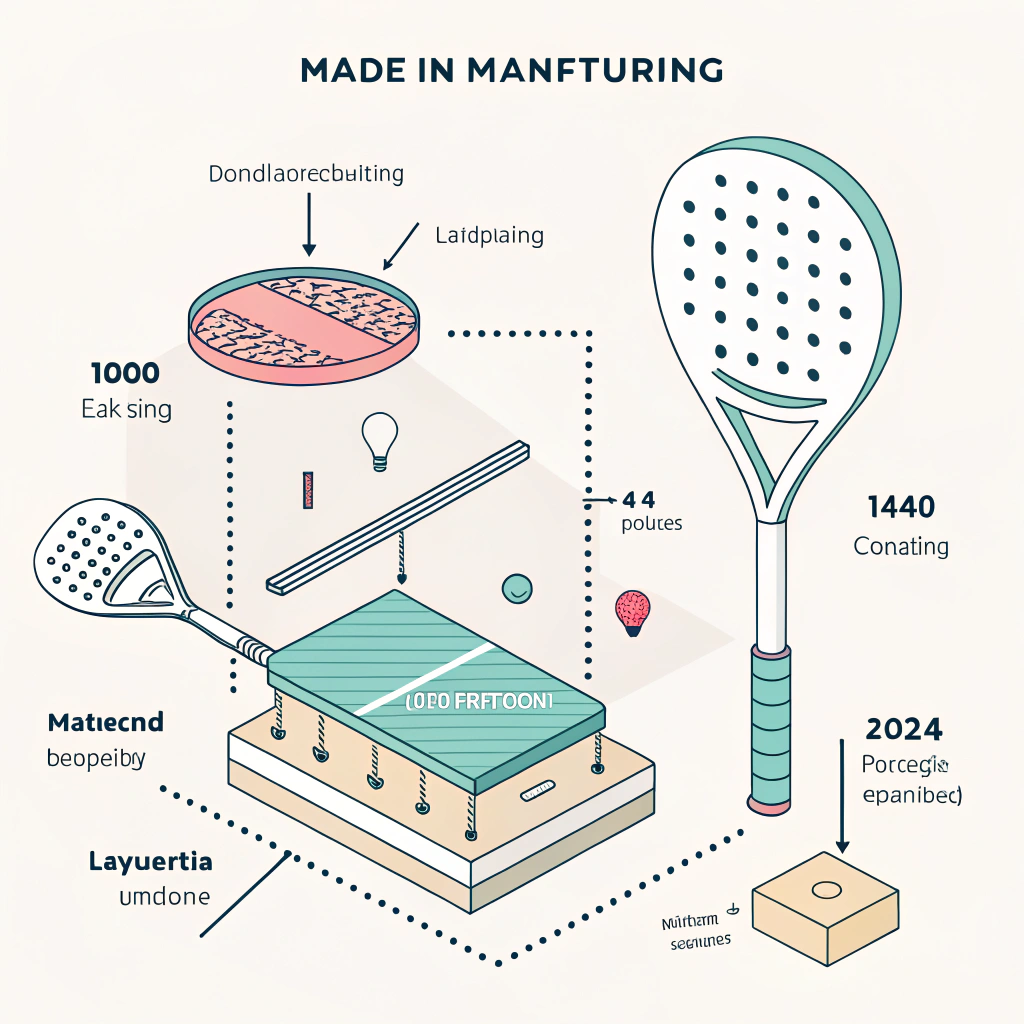

Evaluate the specific performance goals of your target market. For instance, if the focus is on aggressive power delivery, lean towards a lower density EVA formulation that offers high energy absorption. -

Prototyping and Testing:

Rapid prototyping combined with real-time computerized simulations helps in anticipating how the racket behaves under dynamic play. Data from these tests inform adjustments before final production. -

Layering and Customization:

Leverage multi-layer techniques to combine complementary properties of different EVA foam types. A common strategy is creating a gradient where energy absorption and damping characteristics are refined across layers. A typical configuration might include a core layer to maximize power and outer layers that boost stability and control. -

Integration with Other Materials:

Consider how EVA foam interacts with other key components, such as the carbon fiber reinforcements found in high-end rackets. These integrated materials provide additional rigidity and can compensate if any foam layer begins to show wear under rigorous use. -

Quality Control and Compliance:

Regular inspection protocols and performance testing are essential. Adhering to international standards for sports equipment ensures that every batch meets consistent quality metrics—thereby reducing variance and increasing overall product reliability.

In an industry where innovation drives market success, the strategic application of EVA foam variations is a differentiator. Here are key benefits driving industry adoption:

-

Performance Customization:

Brands can tailor rackets to match different playing styles. This personalization increases appeal in diverse market segments, from recreational to elite-level play. -

Cost Efficiency and Production Scalability:

By utilizing advanced production techniques and material optimization, manufacturers achieve both cost savings and scalability in design. This is critical for global brands looking to remain competitive while scaling operations. -

Innovation as a Brand Value Proposition:

In a market saturated with standard products, offering scientifically backed material innovations like optimized EVA foam can solidify a brand’s reputation for quality and performance. This competitive edge becomes a significant selling point during procurement decisions.

For product procurement managers and manufacturers alike, the insights into EVA foam variations provide a clear pathway to enhance product performance and market differentiation:

-

Invest in Advanced Material Research:

Collaborate with technical experts to continuously refine material formulations. Regularly updating your EVA foam technology ensures products remain modern and competitive. -

Utilize Data-Driven Customization:

Leverage detailed performance analyses from testing cycles to fine-tune each racket model. Using data to drive customization decisions will result in products that closely align with market demands. -

Enhance Integration Processes:

Streamline manufacturing processes to allow for easy integration of EVA foam variations with other high-performance materials like carbon fiber. This synergy between components amplifies the overall performance of the racket. -

Commit to Quality Controls:

Implement strict quality assurance protocols to ensure each product meets the expected durability and performance standards. Continuous feedback loops between production data and product design will help maintain innovation at the forefront. -

Engage with Supply Chain Partners:

Establish robust supply chain communications to ensure that the specialized EVA foam variations and accompanying materials are delivered on time and with high quality. This reliability is key to maintaining market competitiveness.

In summary, EVA foam variations are a pivotal aspect of padel racket design, affecting everything from power output and vibration control to overall durability. By understanding and applying material science insights, manufacturers can create rackets that meet specific performance demands while also ensuring cost-effectiveness and production reliability. For procurement managers, these technical insights serve as essential guidelines to support informed decision-making, ultimately leading to competitive and innovative products in the padel market.

Embracing these strategies not only fosters product differentiation but also positions brands like yours to excel in dynamic and highly competitive markets. Now is the time to leverage technical excellence to drive innovation and secure a competitive edge in the sports equipment industry.

Q: What is the best padel racket for power?

A: The best padel rackets for power incorporate specialized materials, including optimally formulated EVA foam, to deliver explosive energy transfer and shock absorption. Products like the Adipower 3.1 and others noted for high energy response have been designed to maximize power, making them ideal for players seeking a strong, aggressive play style.

Q: What is a power foam padel?

A: Power foam in padel rackets is engineered to be highly responsive, delivering aggressive energy transfer while also managing vibration effectively. This technology is ideal for players who favor powerful shots, as it enhances the explosive energy necessary for forceful plays.

Q: What is the strength of EVA foam?

A: EVA foam typically exhibits a tensile strength between 0.3 to 0.5 MPa and can elongate substantially before failure, with elongation values ranging from 200% to 600%. This combination of strength and flexibility contributes to its durability and effective vibration damping in padel rackets.

-

EVA foam variations: Click to explore a detailed overview of different EVA foam formulations and how variations in composition influence performance, durability, and cost-effectiveness in high-performance sports equipment. ↩ ↩ ↩2 ↩3

-

energy absorption: Click to learn about the mechanisms of energy absorption in materials and how this property contributes to reducing impact forces during play. ↩ ↩ ↩2

-

vibration damping: Click to discover the science behind vibration damping, its impact on equipment stability, and techniques for optimizing vibration control in sporting goods. ↩ ↩ ↩2

-

tensile strength: Click to understand tensile strength, its critical role in material durability, and how it ensures consistent performance in high-stress environments. ↩ ↩

-

coefficient of restitution (COR): Click to delve into the concept of the coefficient of restitution, exploring how it quantifies energy return during impacts and influences overall power in ball sports. ↩ ↩