Quick Answer: Choosing between FOAM rubber1 and EVA rubber2 for padel equipment depends on specific performance needs—EVA offers a lightweight, cost-effective solution ideal for manufacturing efficiency and energy absorption, while FOAM rubber provides superior vibration damping3 and durability, making it more suitable for high-impact applications.

In today’s competitive sports equipment market, manufacturers and distributors must carefully evaluate material options to ensure quality, performance, and cost-effectiveness. For padel equipment, the decision often narrows down to selecting the ideal cushioning material. In this article, we explore the technical properties, performance metrics, and cost implications of FOAM rubber and EVA rubber, providing procurement managers and technical designers with the insights necessary to make an informed recommendation.

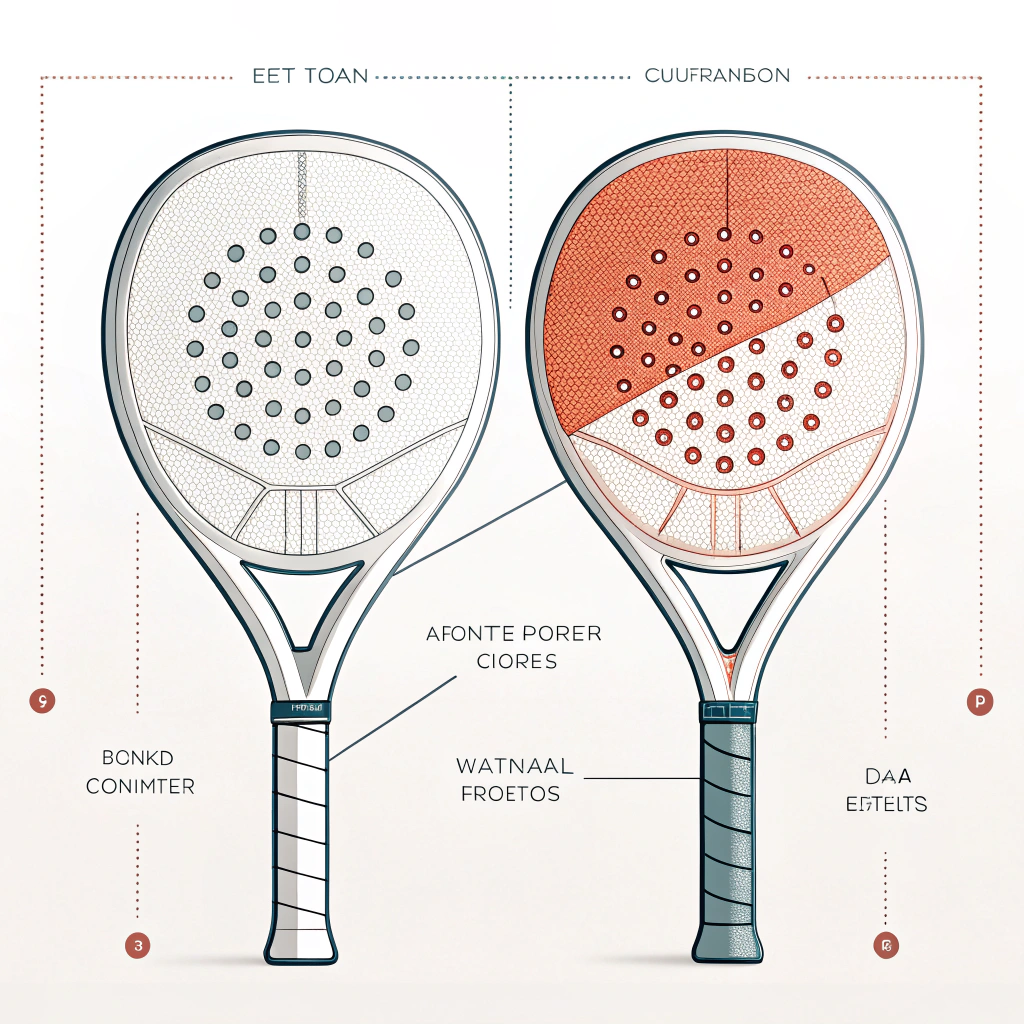

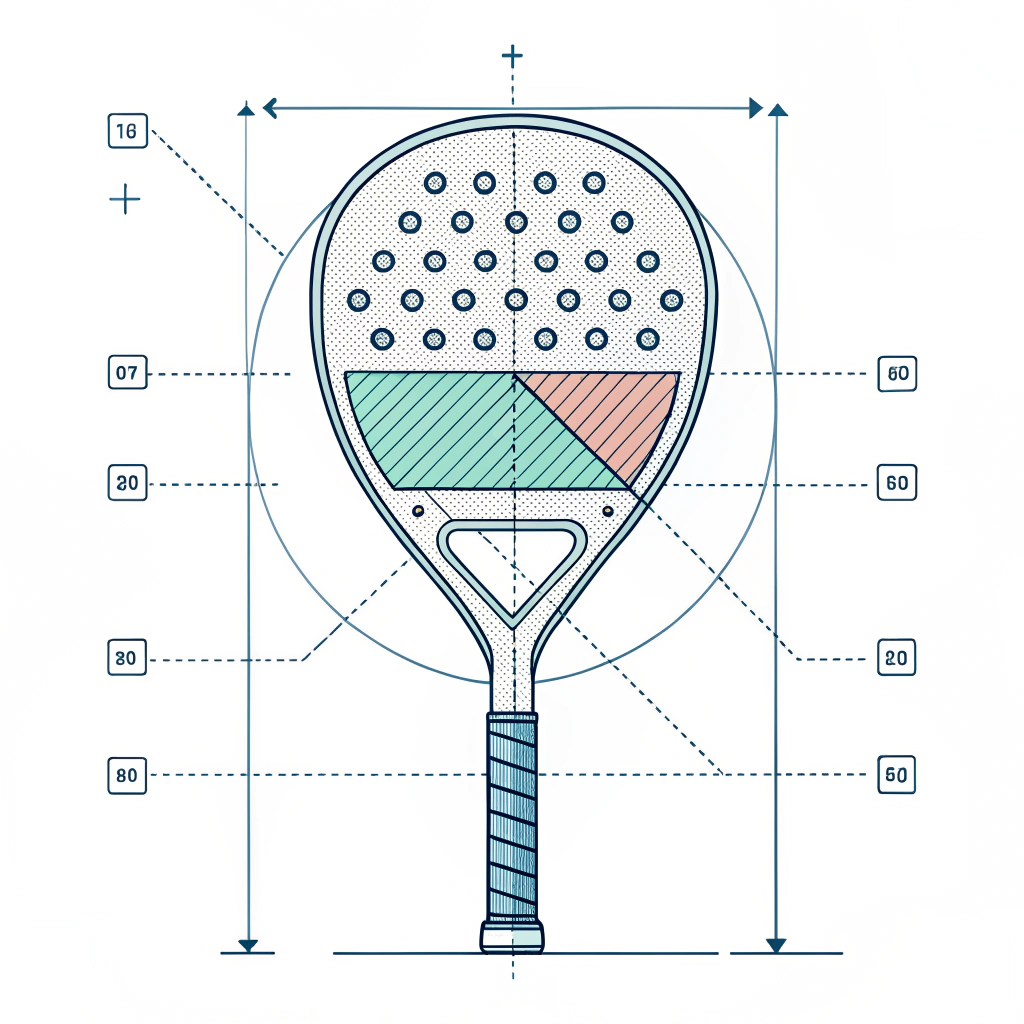

Padel’s fast-paced and high-impact nature demands equipment that offers both comfort and durability. As a crucial player in the supply chain, you must balance production efficiency with product quality. The materials used, particularly in rackets and accessories, greatly influence vibration absorption, shock dispersion, and overall feel. For instance, the core structure of padel rackets often incorporates foam materials designed to enhance control and responsiveness while minimizing impact forces.

When specifications such as weight, rigidity, and resilience are scrutinized, the selection between FOAM rubber and EVA rubber becomes a pivotal decision. This article delves into the properties and performance of these materials to guide your selection process.

When evaluating materials for padel equipment, several key aspects should be considered:

- EVA Rubber: Ethylene-vinyl acetate (commonly referred to as EVA) is known for its higher density compared to some other foams. This characteristic provides a reliable structure while keeping the overall weight relatively low. Its lightness enhances manufacturing efficiency and makes the end product easier to handle.

- FOAM Rubber: FOAM rubber typically has a slightly lower density, contributing to smooth energy absorption and better shock dispersion. However, its weight may vary depending on the specific formulation used.

- FOAM Rubber: Offering excellent vibration absorption and superior resilience under repeated mechanical stress, FOAM rubber stands out in situations where durability is paramount. Its ability to endure continuous impact without significant degradation makes it ideal for high-traffic and heavy-use scenarios.

- EVA Rubber: While EVA is cost-effective and performs well in terms of impact absorption, its resistance to sharp objects or heavy loads may be less robust. EVA’s formulation typically makes it more prone to denting or cutting under extreme conditions.

- EVA Rubber: The lower production cost and wide availability of EVA rubber make it particularly attractive for manufacturers who are cost-sensitive. Its economic advantage plays a significant role when balancing budget constraints with performance realities.

- FOAM Rubber: Though FOAM rubber may come at a higher price point, its enhanced durability and effectively consistent performance can translate into lower lifetime costs by reducing replacement frequency.

- FOAM Rubber: The inherent structure of FOAM rubber excels at dissipating energy from impacts, thereby reducing vibrations. This quality is critical for padel rackets, where maintaining a stable strike on the ball translates to improved control.

- EVA Rubber: EVA foam, while capable of absorbing impacts, tends to have a slightly rigid structure. This rigidity can be beneficial in some contexts, offering quick recovery after compression, yet it might not be as effective as FOAM rubber in reducing prolonged vibrations.

- EVA Rubber: Its adaptability during molding and ease of customization make EVA an attractive option for manufacturers. EVA can be tailored to achieve specific foam densities and hardness levels, satisfying diverse design requirements.

- FOAM Rubber: FOAM rubber is flexible in design too, but its usage might be more specialized where high resilience and sustained performance are prerequisites.

Below is a comparative table summarizing the two materials based on the discussed performance metrics:

| Performance Metric | FOAM Rubber | EVA Rubber |

|---|---|---|

| Density | Lower to moderate; variable by formulation | Typically higher density |

| Weight | Generally slightly heavier | Lightweight and easier to handle |

| Durability | Excellent vibration absorption and longevity | Good, but less robust against sharp impacts |

| Cost-Effectiveness | Higher initial cost, lower long-term expenses | More cost-effective upfront |

| Impact Absorption | Superior energy dissipation | Quick rebound, moderate energy absorption |

| Manufacturing Flexibility | Customization possible; best for specialized applications | Highly adaptable with various molding techniques |

| Suitable Applications | High-impact, heavy-use scenarios | Standard applications with moderate demands |

The choice between FOAM rubber and EVA rubber often depends on the specific application within padel equipment production:

For padel rackets, the core material dramatically affects the player’s feel and control. Manufacturers often prefer:

- FOAM Rubber: When the goal is to maximize vibration dampening and provide a premium feel during high-impact strikes.

- EVA Rubber: As an ideal solution when targeting cost-sensitive models, enabling faster production and lighter racket designs while maintaining satisfactory performance.

The importance of customized grip and handle designs can also influence material selection:

- FOAM Rubber: Its durability ensures that custom embossing or printed logos remain intact, even under heavy use.

- EVA Rubber: The customization ease makes it ideal for varied shapes and sizes, especially when rapid prototyping and design iterations are necessary. rapid prototyping4

For accessories such as pads and cushioning mats used in training or court maintenance:

- EVA Rubber: Often becomes the material of choice due to its lower cost and sufficient resilience, particularly in medium-traffic areas.

- FOAM Rubber: Might be reserved for areas that demand higher durability and consistent performance under heavy usage scenarios.

When making the material selection, procurement managers should consider both the production environment and the end-use requirements. Key aspects include:

- EVA Rubber: Its ease of molding and rapid production cycle can significantly cut down manufacturing lead times. This is crucial when orders demand quick turnaround or when supply chain uncertainties emerge.

- FOAM Rubber: Although it might require slightly more meticulous handling during production, its performance consistency ensures that the finished product meets high-quality standards.

Both materials demand rigorous quality control. Standard tests for durability, tensile strength, and thermal stability need to be established to ensure that each batch meets industry standards. Regular monitoring and precise control of production techniques are essential, especially since padel equipment must withstand the rigors of high-speed play.

A detailed cost analysis should include:

- Initial raw material costs

- Production cycle time

- Maintenance of production machinery

- Expected product life cycle

For many companies, the slight premium on FOAM rubber can be justified by lower maintenance costs and higher customer satisfaction based on performance. In contrast, EVA rubber appeals when the production volume takes precedence and cost control is paramount.

At NEX Padel, we have extensive experience in handling a wide range of materials, from EVA and FOAM rubber to advanced carbon fiber composites5 used in our Diamond, Round, and Teardrop padel racket ranges. Our production techniques emphasize rapid prototyping4 and customization, meeting the varying demands of major brands such as Hirostar, Reebok, and Starvie.

For example, when designing a new padel racket, our technical team considers:

- The trade-offs between weight and control.

- The customer’s feedback on racket “feel” during play.

- Long-term durability metrics tested under simulated high-play conditions.

We have observed that while EVA rubber consistently supports tighter control and faster manufacturing cycles, FOAM rubber offers a performance edge that appeals to professional players who demand reduced vibrations during prolonged use.

Additionally, our continuous collaboration with research institutes on material science helps ensure that we keep improving the technical parameters of our products. This means that even subtle adjustments in the formulation can have a marked impact on cost-effectiveness and customer satisfaction.

For mid-level procurement managers and technical designers making a decision on material selection, consider the following action points:

- Evaluate the specific application requirements: Determine whether vibration control, durability, or cost-efficiency is prioritized.

- Review your production capabilities: Assess if your current manufacturing line is optimized for handling either material without significant modifications.

- Leverage case studies: Look at performance data from similar products in the market. For instance, NEX Padel’s experience shows that customizing grips with FOAM rubber can significantly enhance product performance in high-frequency usage scenarios.

- Consider long-term sustainability and maintenance: Factor in the lifecycle costs—materials that last longer may offer savings despite a higher upfront cost.

- Stay updated with industry trends: Regularly consult updated technical specifications and market analyses to ensure your choices remain competitive, particularly as new formulations and production techniques emerge.

Selecting the right material for padel equipment is a multi-faceted decision that hinges on striking the appropriate balance between performance, durability, and cost-effectiveness. EVA rubber offers a lightweight, economically attractive option ideal for fast-paced manufacturing environments. In contrast, FOAM rubber stands out as the material of choice for applications demanding superior shock absorption and vibration damping.

By understanding the intrinsic properties and performance trade-offs of these materials, procurement managers can confidently recommend solutions that not only meet industry standards but also deliver enhanced product performance to end users. We encourage you to analyze your specific requirements and collaborate with trusted manufacturers like NEX Padel, who leverage advanced production techniques and robust quality control protocols to offer tailored solutions.

For further technical discussions or to initiate a pilot production campaign, please contact our materials engineering team.

Q1: Is EVA foam better than rubber foam?

A1: EVA foam is lighter and more cost-effective, offering good impact absorption but may be prone to denting or cutting from sharp objects. In contrast, rubber foam is denser and more durable, making it better suited for high-traffic, heavy-load applications.

Q2: What is EVA in padel?

A2: EVA, or ethylene-vinyl acetate, is a polymer used to create the foam core in padel rackets. It provides a lightweight structure with effective energy absorption, balancing performance with cost in manufacturing.

Q3: What is the difference between EVA foam and PE foam?

A3: EVA foam generally has a higher density and offers enhanced vibration absorption, though it is heavier. PE foam is more versatile, providing good durability and adaptability, making it suitable for a range of industrial and packaging applications.

-

FOAM rubber: Click here to explore how foam rubber is engineered for high-impact sports equipment, emphasizing its shock-absorbing and durability properties. ↩

-

EVA rubber: Click here for an in-depth look at EVA rubber, including its composition, benefits in lightweight design, and cost-effectiveness in production. ↩

-

vibration damping: Click here to learn more about vibration damping mechanisms in sports equipment and how they improve user performance and product longevity. ↩

-

rapid prototyping: Click here to understand rapid prototyping techniques that accelerate product development and customization in manufacturing environments. ↩ ↩2

-

advanced carbon fiber composites: Click here to read about advanced carbon fiber composites, their role in enhancing performance, and how they are integrated into premium sports equipment solutions. ↩