Quick Answer: For high-performance padel rackets, the optimal choice hinges on material precision, design innovations1, and customization potential2 to match specific play styles and procurement demands. NEX Padel’s advanced production techniques using carbon fibre (3k, 12k, 18k)3 ensure that every detail meets strict quality and durability standards.

In an increasingly competitive padel market, procurement professionals must weigh manifold technical and design aspects before making a purchasing decision. As B2B experts, sports equipment procurement managers, and padel club owners, your emphasis is on quality, customization, and reliability. With NEX Padel’s state-of-the-art manufacturing methods, our high-performance padel rackets are engineered to deliver precision, durability, and adaptability, ensuring your investments meet both current demands and future trends.

When evaluating padel rackets, the twin pillars of material technology4 and design structure play a pivotal role. NEX Padel offers rackets built from a range of advanced materials—from fiberglass for entry-level needs to 3k, 12k, and 18k carbon fibre for premium performance. Each material configuration contributes distinct benefits:

- Fiberglass: Offers flexibility and cost efficiency, ideal for players who are acclimatizing to the game.

- 3k Carbon Fibre: Provides a balanced mix of strength and lightness, suitable for mid-level competitions.

- 12k and 18k Carbon Fibre: Deliver superior rigidity and power transfer; these materials are preferred for top-tier performance and professional-level play.

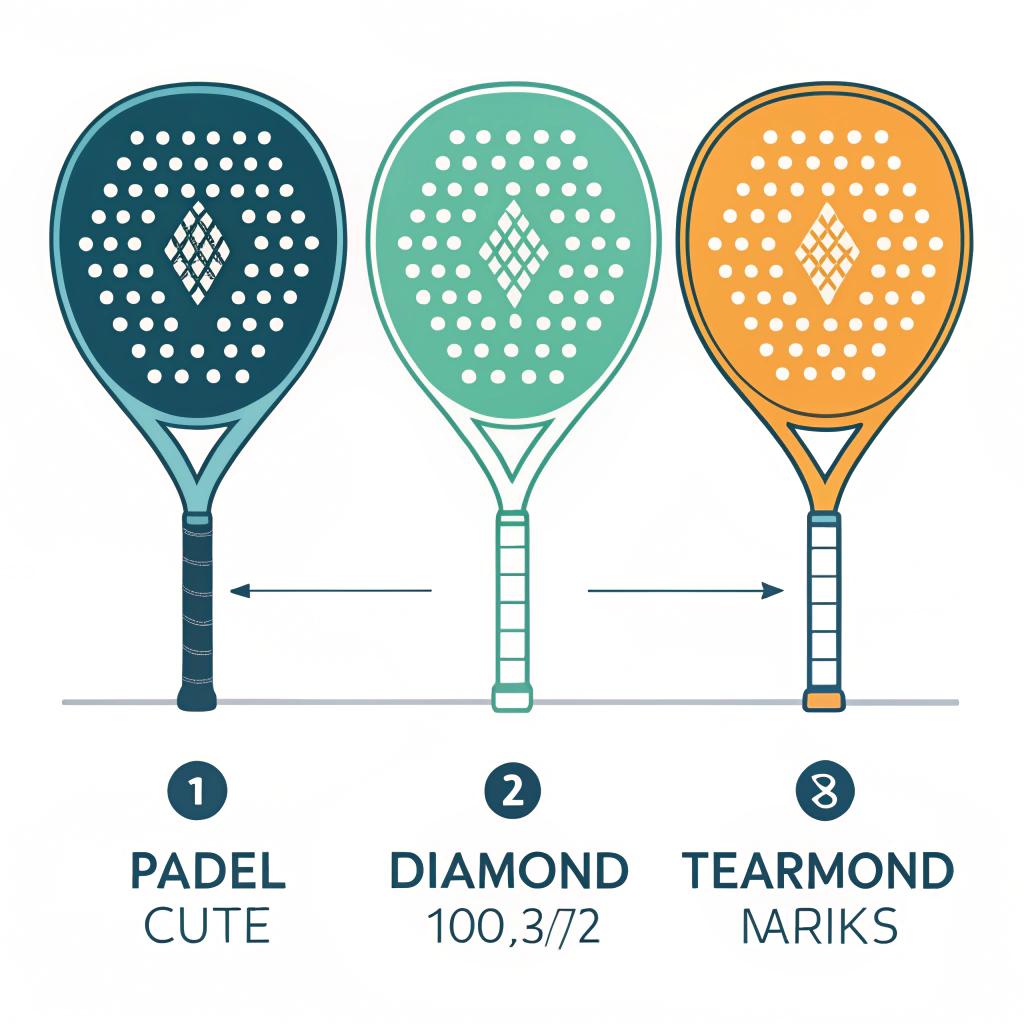

Coupled with various design geometries such as Diamond, Round, and Teardrop, you can fine-tune racket features to meet specific player profiles and league requirements.

To make an informed purchase, consider these crucial parameters:

-

Performance Demands:

- Evaluate the intensity of use. High-performance rackets with superior material properties offer an edge in competitive play.

- Consider the type of player and typical match dynamics. Customization options allow matching specific play styles.

-

Customization and Branding:

- Beyond basic specifications, bespoke designs with customized logos, prepaid handgrips, and tailored color schemes help reinforce your brand identity.

- Full customization extends to racket shapes, ensuring that design nuances like the Diamond, Round, or Teardrop appeal to both professional athletes and premium clientele.

-

Production Efficiency and Turnaround:

- Speed in prototyping and production is crucial for seasonal sports events. NEX Padel’s advanced manufacturing process ensures quick sampling and timely delivery, meeting tight procurement deadlines.

-

Cost vs. Quality Analysis:

- While higher-grade materials such as 12k and 18k carbon fibre rackets often command a premium, their performance enhancements, longevity, and precise production make them a valuable investment.

- Cost-effective models using advanced fiberglass or 3k carbon fibre offer a balanced solution for markets with budget constraints.

Below is a comparative table detailing the key differences across our product lines, helping you decide which model aligns with your procurement priorities.

| Specification | Diamond Design | Round Design | Teardrop Design |

|---|---|---|---|

| Material Options | Fiberglass, 3k, 12k, 18k CF | Fiberglass, 3k, 12k CF | 3k, 12k, 18k Carbon Fibre |

| Player Profile | Aggressive play style, power shots | All-round usage, high maneuverability | Control-oriented, precision strikes |

| Customization | Full customization available (logo, color, hand grip) | Moderate customization options | High-level customization, shape & design tweaks |

| Production Speed | rapid sampling and prototyping5 | Standard turnaround | Tailored production process |

| Performance Focus | Enhanced rigidity and power | Balance between power and control | Superior control with enhanced touch |

| Price Bracket | Premium | Mid-range | Premium to high-end |

CF: Carbon Fibre

This table should help you align your purchasing strategy with the operational requirements and player demographics of your organization. Consider not only the performance and cost factors but also brand positioning and after-sales service when making your decision.

At the heart of any high-performance padel racket lies its material composition. NEX Padel leverages advanced carbon fibre technologies—3k, 12k, and 18k—to optimize performance. These materials are renowned for their resilience, light-weight properties, and ability to translate energy efficiently.

-

3k Carbon Fibre Rackets:

- Well-suited for players who require a blend of durability and flexibility.

- Consistent performance across diverse playing conditions.

-

12k Carbon Fibre Rackets:

- Strikes an excellent balance between rigidity and lightness.

- Offers increased power without sacrificing control—ideal for competitive scenarios.

-

18k Carbon Fibre Rackets:

- The pinnacle of racket engineering, designed for top-level professionals.

- Maximizes power transfer and minimizes vibration for enhanced accuracy during high-impact plays.

The science behind these materials also permits close monitoring during the production phase, ensuring every batch of rackets aligns with our stringent quality standards. Further, these technologies enable meaningful customization, allowing each product to be tailored to the specific needs of clubs, retailers, and professional athletes.

Customization is not just a marketing tool—it significantly influences player performance and brand affinity. At NEX Padel, we provide extensive customization options, including:

- Racket Shapes: Choose between Diamond, Round, and Teardrop to match different playing styles.

- Printing and Color Customization: Enable brands to express their identity through vibrant color schemes and logo placements.

- Accessory Personalization: Hand grips and handle covers can be printed with tailored logos, adding a personal touch to every racket.

Beyond aesthetic appeal, customization allows for engineering tweaks that can enhance performance on the court. For instance, slight adjustments in racket shape affect aerodynamics and vibration control, which are critical for players at various skill levels.

Organizations procuring these rackets can benefit from unique customization that doubles as both a performance enhancer and a branding asset, further reinforcing long-term partnerships and customer loyalty.

When assessing high-performance equipment, empirical data and case studies are invaluable. Here are three key factors that have historically influenced buyer decisions:

-

Consistency in Production Quality:

- NEX Padel has a proven track record of rapid prototyping without compromising on consistency. Industry benchmarks show that quick turnaround times are directly correlated with lower defect rates in high-volume production.

-

Enhanced Player Performance:

- Independent studies and user feedback have consistently highlighted that premium materials result in better power transfer, improved accuracy, and reduced fatigue during prolonged play.

-

Cost Efficiency Over Time:

- While premium rackets might seem expensive at first glance, the long-term benefits include durability and sustained performance. These factors culminate in reduced replacement costs and overall enhancements in the game experience.

A deeper analysis reveals that in international markets, clients who opt for high-end customization witness a trend of increased brand engagement and loyalty from players, translating to repeat business and sustained market presence.

Given the competitive landscape, procurement professionals should adhere to the following guidelines when selecting optimal padel rackets for their clients or clubs:

-

Evaluate Long-Term Performance:

Consider the correlation between material quality and the potential for repeat usage. Investing in superior materials like 12k or 18k carbon fibre could offer long-term cost benefits by reducing replacement frequency. -

Align Customization with Customer Profiles:

For clubs or retailers targeting premium segments, customization in design and accessory elements is crucial. Ensure that the chosen product range offers both performance and distinctive branding opportunities. -

Balance Production Efficiency with Quality Requirements:

Ensure your supplier can maintain rapid prototyping cycles without compromising quality. This agility is vital, especially when facing seasonal demands and unexpected market shifts. -

Leverage Data and Case Studies:

Use empirical evidence to support your purchasing decisions. Case studies from existing partnerships can provide a clear picture of the performance improvements witnessed after integrating our high-performance rackets.

In summary, the decision-making process for choosing high-performance padel rackets must integrate material science, design innovation, and a strong customization framework. With NEX Padel’s expertise, you obtain not only superior engineering but also the agility of a manufacturing partner that understands rapid market changes and client-specific requirements.

What brand is best for padel?

While several brands offer high-quality padel rackets, the best brand largely depends on your specific performance needs and procurement strategy. Leading brands focus on advanced materials, such as carbon fibre variants, and offer tailored customization options. At NEX Padel, we use state-of-the-art production techniques to ensure every racket meets rigorous standards for power, durability, and precision.

Do expensive padel rackets make a difference?

Yes, expensive padel rackets are typically designed with advanced materials and precision engineering that improve performance, comfort, and durability, particularly for regular and competitive play. For professionals, investing in a high-quality racket brings noticeable improvements in control and power. However, for beginners or casual players, these enhancements may not justify the premium cost.

What racket does Chingotto use?

Federico Chingotto has been known to choose rackets that provide precision and control, such as the Bullpadel Neuron Premier. These rackets incorporate innovative structures and design systems that are tailored for high-level performance and responsive play on the court.

-

design innovations: Reading the linked article will help you understand the significance of innovating design geometries—such as Diamond, Round, and Teardrop—in enhancing racket aerodynamics and performance. ↩

-

customization potential: Explore how bespoke design and customization options can be leveraged to tailor products to specific play styles and brand identities, adding both performance and marketing value. ↩

-

carbon fibre (3k, 12k, 18k): This article explains the differences between 3k, 12k, and 18k carbon fibre, detailing their unique properties, benefits, and suitability for different performance levels. ↩

-

material technology: Gain insights into the advanced material technologies used in padel racket manufacturing and how they contribute to performance, durability, and efficiency in sports equipment. ↩

-

rapid sampling and prototyping: Learn about the processes and benefits of rapid sampling and prototyping in manufacturing, which are crucial for ensuring fast turnaround times and maintaining high production quality. ↩