The Complete Padel Racket Buying Guide: A Quick Answer

This guide explains how to choose, compare, and source high-performance padel rackets to meet your business needs. We cover the key factors—including materials, design options, customizable features, and manufacturing efficiency—so that procurement manager1s can make informed decisions when selecting between various suppliers and models from leading companies like NEX Padel.

Selecting the right padel racket starts by evaluating your specific business requirements. As a procurement manager1 (already marked) in practice, you must consider performance, material quality, design feasibility, and lead time reliability. Leading manufacturers offer rackets in various designs: Diamond, Round, and Teardrop—all with unique performance characteristics. This guide provides clarity around these factors, ensuring you find the ideal partner for your sports equipment needs.

Procurement teams often face several challenges when sourcing padel rackets:

- Ensuring the materials used (such as carbon fiber types like 3k, 12k, and 18k) match the targeted playing profile. In the Materials & Manufacturing Techniques section, the text mentions fiberglass and carbon fiber2, which is a key material in racket production.

- Differentiating between racket designs that emphasize power versus control.

- Managing production lead times while maintaining high-quality production standards.

These challenges are compounded by an array of suppliers, each with differing customization and manufacturing capabilities. This guide aims to simplify your decision process through a structured, solution-driven overview.

Materials play a critical role in determining a racket's performance. The majority of high-performance padel rackets come with a combination of fiberglass and carbon fiber2. Manufacturers like NEX Padel offer different grades:

- 3k Carbon Fiber: Balances performance and cost-effectiveness, suitable for mid-range products.

- 12k Carbon Fiber: Offers enhanced stiffness and durability, often found in premium models.

- 18k Carbon Fiber: The choice for elite models requiring maximum performance under high stress conditions.

The advanced production techniques employed ensure that every racket meets strict industrial standards for precision and long-term durability. Such techniques also allow for Rapid Prototyping3 and efficient lead time management4, which are critical for businesses requiring agile supply chains.

Padel rackets come in three primary shapes, each catering to distinct playing behaviors:

Diamond Shape:

- Favored for players looking to maximize power.

- Its head-heavy design often produces aggressive shots.

- Best suited for advanced players who rely on swift, powerful movements.

Round Racket:

- Prioritizes control, making it ideal for players who rely on precision and consistency.

- A balanced option that minimizes mishits during intense exchanges.

- Suitable for all-round play, especially during long tournaments.

Teardrop Design:

- Bridges the gap between round and diamond shapes by offering a mix of control and power.

- Provides versatility to adapt to varying game styles.

Below is a table comparing these designs:

| Design Type | Emphasis | Ideal For | Pros | Cons |

|---|---|---|---|---|

| Diamond | Power | Aggressive players | High power output; dynamic shots | Can be less forgiving on control |

| Round | Control | Precision players | Superior control; balanced play | May lack aggressive power |

| Teardrop | Balance | All-round performance | Versatile; adaptable | May not excel in one specific area |

Customization5 and Branding:

Modern padel racket manufacturers, especially market leaders like NEX Padel, offer extensive customization options. This includes not only custom shapes but also personalized printing and color options on the racket surface and accessories such as hand grips and protective covers. For distributors, such customization is a valuable asset for brand differentiation and attracting consumer loyalty.

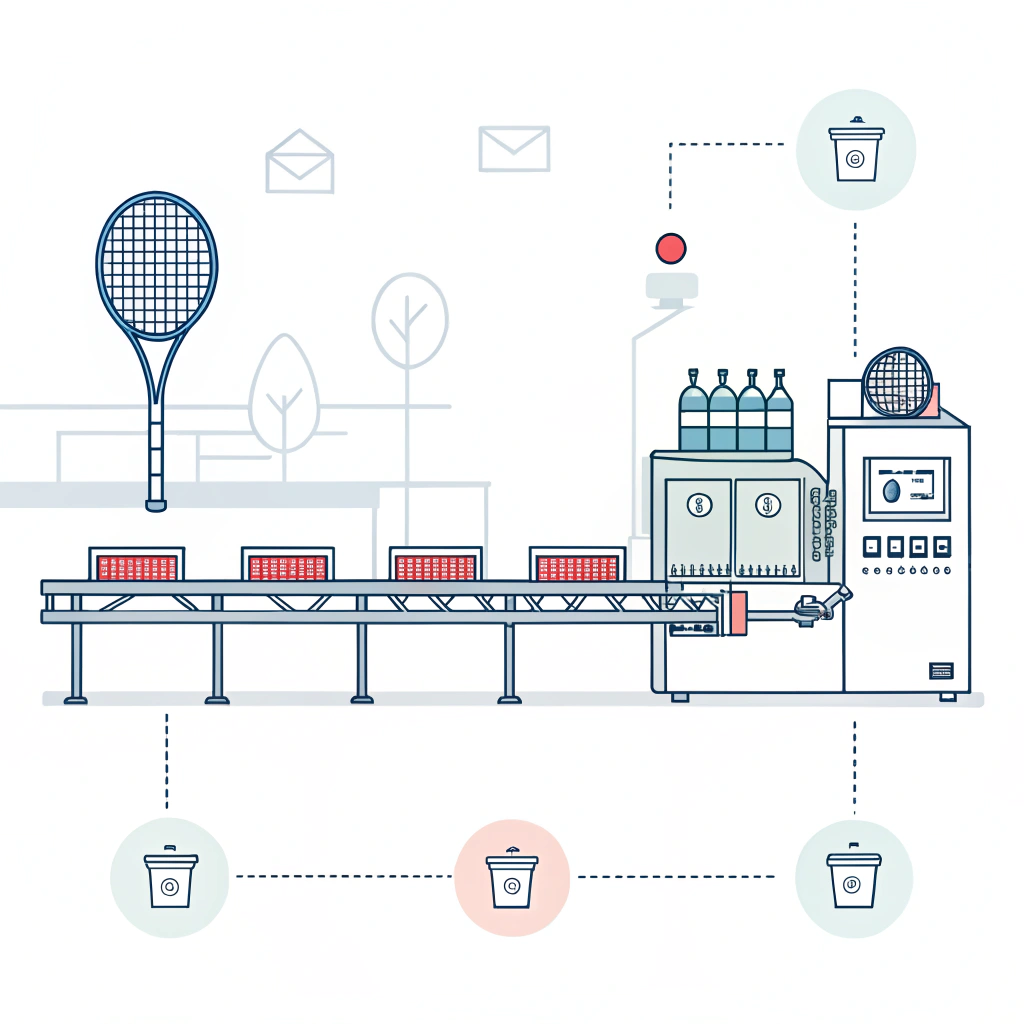

Manufacturing padel rackets that satisfy both performance and durability standards is a multi-step process:

-

Material Sourcing and Quality Control:

Every part of the racket—from the core materials to the finishing touches—is subject to rigorous quality checks. Suppliers often utilize state-of-the-art production techniques to ensure that materials like carbon fiber are consistently manufactured to deliver top performance. -

Design and Prototyping:

Rapid Prototyping3 and testing phases are critical for achieving a design that meets both player expectations and industrial standards. NEX Padel's capability to quickly produce samples and adjust their production line according to the customer’s specifications sets them apart in the B2B market. -

Customized Production:

The ability to offer fully customized rackets with various design geometries and branding options is a significant competitive advantage. This includes custom logo printing on the hand grip and racket cover, which further enhances market differentiation and brand identity. -

Lead Time Management:

Timely delivery is a vital consideration for procurement managers. With sophisticated production scheduling and inventory management, leading manufacturers provide reliable lead time management4 even when handling bulk orders. This efficiency is crucial to minimize stock shortages and promote a smooth distribution cycle.

Procurement decisions in the sports equipment industry are influenced heavily by supplier reliability. Here are some key aspects to consider:

-

Production Capacity & Scalability:

Ensure that the supplier can scale production to meet your business demands. NEX Padel’s experience with well-known brands like Hirostar, Reebok, and Starvie demonstrates their ability to handle both small and large volume orders seamlessly. -

Cost Efficiency vs. Quality Trade-offs:

Decide whether your business acutely prioritizes premium materials and high-performance features, or if a more cost-effective option meets your immediate needs with the potential for future upgrades. It’s essential to balance these aspects without sacrificing long-term durability and player satisfaction. -

After-Sales Support and Warranty Policies:

Quality assurance does not end at production. Robust after-sales support and comprehensive warranty policies play an essential role in procurement decisions, reducing risks associated with faulty products.

A notable case study involves a sports distribution firm that faced challenges in sourcing high-performance padel rackets that met both quality and customization criteria. Below are the milestones of their successful experience:

-

Initial Assessment:

The company evaluated several suppliers based on material quality, production lead time, and customization abilities. They found that only a few manufacturers had the expertise in using advanced carbon fiber2 technology combined with rapid prototyping3 capabilities. -

Collaboration with NEX Padel:

The firm collaborated with NEX Padel to test samples which were customized in both design and color. The ability to adjust the racket’s design from Diamond to Teardrop forms allowed the client to target multiple player profiles, enhancing their market reach. -

Outcome and Benefits:

The partnership led to a 20% reduction in lead times and improved product quality. The customized branding options created a unique selling proposition, leading to a higher market penetration that ultimately increased sales volumes.

Below is a simplified summary of the process:

| Phase | Action Taken | Outcome |

|---|---|---|

| Assessment | Evaluated suppliers based on key performance areas | Identified supplier with robust capabilities |

| Sample Testing | Customized design trials and material evaluation | Successful adaptation to market needs |

| Large-Scale Partnership | Instituted full-scale production with custom designs | Decreased lead times; increased market competitiveness |

To sum up, when considering the procurement of high-performance padel rackets, the key is to focus on:

- Material Quality: Ensure that the rackets utilize appropriate grades of carbon fiber (3k, 12k, 18k) tailored to your target market’s performance needs.

- Design Options: Evaluate the advantages of Diamond, Round, and Teardrop shapes to best cater to varying player profiles.

- Customization Capabilities: Leverage Customization5 opportunities such as custom shapes, printed logos, and color variations to build a strong brand identity.

- Production Efficiency: Prioritize suppliers with proven production efficiency, quality control, and prompt lead time management4. This minimizes inventory risks and aligns your supply chain with market demands.

For procurement managers, aligning these factors with your business goals will streamline the decision-making process and guarantee high-quality, durable products that can significantly enhance your market offering. Take the next step by engaging suppliers with industry-leading production techniques and robust customization capabilities, ensuring your product line stands out in a competitive B2B market.

How to know what padel racket to buy?

A padel racket should be selected based on player style and game requirements. Typically, a control racket offers precision for strategic play, a power racket provides strong, aggressive shots, and a balanced racket delivers a mix of control and power. Evaluate your target market’s needs to determine which style best meets your customer demands.

What is the best padel racket to get?

There isn’t a one-size-fits-all answer as the best padel racket depends on specific performance requirements. Top models from leading brands, including those with advanced carbon fiber construction and customization options, are popular. Rackets that blend durability with performance metrics, like those produced by NEX Padel, are highly recommended for quality and consistency.

How much should I spend on a padel racket?

The investment in padel rackets varies depending on player needs and quality expectations. As a guideline, advanced players and distributors seeking high-performance features often invest in models starting at around £170, with premium options reaching above £400. Ultimately, the decision should balance budget constraints with desired performance outcomes.

-

procurement manager: Click to discover the role of procurement management in sourcing high-quality products and streamlining operations. ↩ ↩ ↩2

-

carbon fiber: Click to read about this high-strength, lightweight material used in manufacturing for enhanced performance and durability. ↩ ↩ ↩2 ↩3

-

Rapid Prototyping: Click to learn how rapid prototyping speeds up design iterations and improves product development efficiency. ↩ ↩ ↩2 ↩3

-

lead time management: Click to explore strategies for reducing production delays and optimizing supply chain performance. ↩ ↩ ↩2 ↩3

-

Customization: Click to understand the benefits of product customization in establishing a competitive market advantage. ↩ ↩ ↩2