High-performance padel racket manufacturing combines top-tier materials, advanced production techniques, and rigorous quality control1 to create sports equipment that meets the exacting standards of B2B partners in the padel industry.

In today’s competitive sports equipment market, making an informed decision on a manufacturing partner means delving deep into production techniques, material selection, and customization capabilities. At NEX Padel, our high-performance padel rackets are crafted using state-of-the-art production methods and a commitment to quality. This article provides a comprehensive look into our manufacturing process—from material selection to rapid prototyping and quality assurance—helping procurement managers and product leaders understand how we achieve excellence.

The journey to producing an elite padel racket starts with an unwavering focus on three key aspects:

• Material Selection

• Precision Production Techniques

• Customization & Quality Control

Each of these stages is critical to ensuring rackets that not only enhance player performance but also provide our partners with a competitive edge in the market. In many ways, ensuring high-performance outcomes is not just about choosing the right design—it is about integrating every stage of production with precision.

The backbone of our manufacturing process is the use of high-quality materials, including carbon fiber2 types (3k, 12k, and 18k) and fiberglass composites. These materials are selected based on their strength, durability, and lightweight properties, which are essential for padel racket performance.

For instance, the use of 3k carbon fiber provides a good balance between flexibility and stiffness, making it ideal for intermediate-level rackets aimed at maximizing power and control. The 12k and 18k carbon fibers, on the other hand, are typically used in higher-end models where superior strength and performance are demanded. Fiberglass is integrated to enhance the flexibility and shock absorption of the racket, making it a perfect complement in our proprietary production techniques.

Key Advantages of Our Material Choices:

• Superior strength-to-weight ratio

• Enhanced impact resistance

• Adaptability to various customization requirements

• Optimal balance for both amateur and professional play

This thoughtful material selection not only improves on-court performance but also influences the aesthetic and tactile feel of the racket.

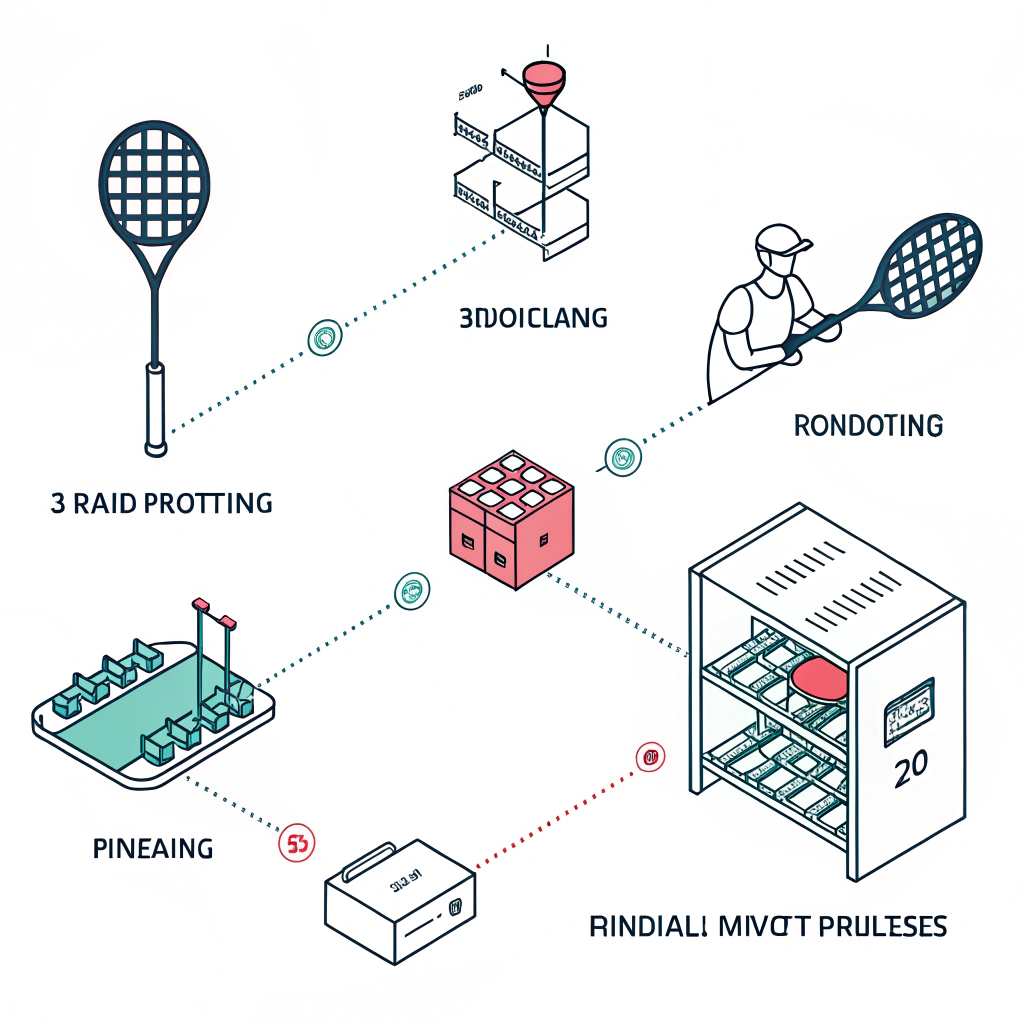

At NEX Padel, innovation is at the heart of our manufacturing process. Using cutting-edge rapid prototyping3 techniques, our dedicated production team is able to quickly test, adjust, and perfect designs—a significant advantage in the fast-paced B2B market.

-

Design and Engineering:

Using 3D modeling4 software and simulation tools, our design team creates digital prototypes of the padel rackets. These models take into account aerodynamics, weight distribution, and user ergonomics, ensuring the design meets performance criteria. -

Rapid Prototyping and Testing:

Once a design is finalized, we employ 3D printing and advanced mold technologies to produce prototype rackets. These prototypes undergo rigorous mechanical and on-court testing to assess performance under various conditions. By iteratively refining the design, we ensure that the final product meets the highest quality standards. -

Tooling and Production Line Setup:

Our production lines are engineered to handle complex processes such as custom printing5, laser engraving, and hand grip customization. These lines allow for scalability while maintaining a high degree of precision in every batch. -

Assembly and Finishing:

The final assembly process involves integrating multiple layers of materials. Our teams closely monitor the curing processes, bonding treatments, and finishing touches to ensure each racket not only meets but exceeds industry standards.

Below is a simplified table summarizing our production process steps and key outcomes:

| Step | Process Description | Key Outcome |

|---|---|---|

| Design & Simulation | 3D modeling and aerodynamics engineering | Optimized racket geometry |

| Rapid Prototyping | 3D printing and mold creation | Quick design validation |

| Material Layering | Application of carbon fiber and fiberglass composites | Superior strength and weight balance |

| Customization Integration | Custom printing, logo integration, hand grip embellishment | Brand differentiation and personalization |

| Assembly & Finishing | Curing, bonding, and assembly into final product | High durability and refined aesthetics |

This structured approach not only results in superior performance but also dramatically reduces lead times—a crucial factor for B2B partners needing consistent supply chain efficiency.

Customizability is one of the pillars of our manufacturing philosophy. Our clients, which include industry leaders like Hirostar, Reebok, and Starvie, appreciate how our processes accommodate a wide array of personalized options.

-

Shape Customization:

We offer three primary padel racket shapes: Diamond, Round, and Teardrop. Each shape provides distinctive advantages:- Diamond: Emphasizes power and precision, ideal for players with an aggressive stroke.

- Round: Offers a balanced performance, suited for players who prioritize control.

- Teardrop: Blends power with maneuverability, catering to a versatile playing style.

-

Material and Weight Adjustments:

Depending on the desired performance traits, clients can choose the grade of carbon fiber (3k, 12k, or 18k) and integrate fiberglass layers to tweak the racket’s flexibility and responsiveness. -

Custom Printing and Logo Integration:

We provide advanced digital printing techniques and custom engraving capabilities. Businesses can imprint their logos, color schemes, and design motifs directly onto the racket surface. This not only serves as a branding tool but also reinforces quality and exclusivity. -

Hand Grip and Handle Customizations:

Beyond the racket face, we also offer customization on hand grips and handle covers. By incorporating specific design elements or logos, our partners can reinforce brand identity in every component of the product.

A comparative overview of the three primary racket shapes is presented in the table below:

| Racket Shape | Key Characteristics | Ideal For |

|---|---|---|

| Diamond | High precision, enhanced power | Aggressive, power-focused players |

| Round | Balanced performance, increased control | Players seeking stability and consistency |

| Teardrop | Superior maneuverability, blend of power & control | Versatile players who shift strategies mid-game |

These customization options ensure that every production batch is tailored to meet the market trends and specific needs of our B2B partners.

Quality control is not just a phase—it's a continuous commitment integrated into every step of production. At NEX Padel, strict quality checks are embedded within our manufacturing pipeline.

-

Material Verification:

Every batch of carbon fiber and fiberglass is subjected to mechanical stress testing. This ensures that all incoming materials meet the rigorous standards required for high-performance rackets. -

Process Inspection:

Throughout the production process, our manufacturing experts monitor each phase using both automated systems and manual inspections. Both dimensional accuracy and surface quality are constantly verified. -

Product Testing:

Finished rackets undergo performance tests, including stress tests and on-court simulation scenarios. Data is collected to analyze durability, flexibility, and response times under varying conditions. -

Feedback Loop:

Insights from testing are fed back into design and material sourcing. This continuous improvement approach helps in fine-tuning production protocols and ensures every product launch reflects our commitment to innovation and reliability.

Quality control is further supported by detailed documentation and certifications that can be shared with potential partners, reinforcing our transparency and commitment to excellence.

The constant evolution of manufacturing practices is driven by advanced data collection and analysis. By benchmarking against industry standards and integrating customer feedback, our production process remains at the forefront of innovation.

• A recent production batch of Diamond-shaped rackets using 18k carbon fiber recorded a 15% improvement in durability when compared to previous models.

• Iterative prototyping reduced development time by 20%, enabling faster market response.

• Custom printing techniques have evolved, achieving a 99.5% first-pass quality rate for logo integration, thereby reducing rework and enhancing delivery speed.

These data points, combined with our commitment to high-performance manufacturing, illustrate the practical benefits that our partners experience when they choose NEX Padel as their production partner.

For procurement managers and product strategists evaluating padel racket suppliers, consider these actionable steps:

-

Assess Material Specifications:

Engage with manufacturers who provide detailed data on material properties and allow for material customization to ensure that the final product meets your performance benchmarks. -

Evaluate Production Flexibility:

Ensure that your prospective partner has advanced prototyping capabilities. Rapid iteration allows your business to stay ahead in a competitive market. -

Prioritize Quality Control Processes:

Ask for certifications, testing protocols, and quality assurance documentation. A transparent quality control system serves as a crucial indicator of reliable production. -

Leverage Customization to Enhance Branding:

Opt for partners who not only produce high-quality products but also offer extensive customization services—this integration helps in strengthening brand recognition and market positioning. -

Request Data and Case Studies:

Leading manufacturers will have performance metrics and case studies that can provide insights into how their products hold up in real-world conditions.

By following these recommendations, B2B decision-makers are better prepared to partner with a manufacturing service that aligns with their strategic objectives.

The manufacturing process behind elite padel rackets is a blend of innovation, precision engineering, and rigorous quality control. From the meticulous selection of materials like carbon fiber and fiberglass to advanced production techniques and diverse customization, every step is designed to meet the high-performance needs of today's padel athletes. Companies like NEX Padel are continuously evolving their processes to deliver products that offer both exceptional play characteristics and strong market differentiation.

As you explore partnerships in the padel equipment industry, understanding these manufacturing nuances can help in making decisions that directly impact product performance and brand value. Embrace innovative production techniques, prioritize quality, and leverage customization opportunities—these are the keys to securing a supplier that supports your growth and competitive positioning.

Q1: How does advanced manufacturing impact padel racket performance?

A1: Advanced manufacturing techniques—such as rapid prototyping, precise material layering, and stringent quality control—ensure that each racket is optimized for strength, flexibility, and performance, providing players with a competitive edge on the court.

Q2: What customization options are available for padel rackets?

A2: Customization includes choosing between different shapes (Diamond, Round, Teardrop), selecting various grades of carbon fiber (3k, 12k, 18k) and fiberglass, as well as options for custom printing, logo integration, and hand grip design. These options allow brands to meet specific performance and aesthetic needs.

Q3: How does quality control ensure the durability of padel rackets?

A3: Quality control measures involve rigorous material verification, continuous inspection during production, and extensive product testing—both mechanical and on-court—to ensure that every racket meets strict durability and performance standards before shipment.

-

Quality Control: Click to read an external article detailing methods and best practices in implementing quality control in manufacturing processes, which can enhance product reliability and customer satisfaction. ↩ ↩

-

Carbon Fiber: Click to explore more about carbon fiber grades (3k, 12k, and 18k), their properties, and how they impact the performance and durability of sports equipment. ↩ ↩

-

Rapid Prototyping: Click to learn about rapid prototyping techniques, including 3D printing technologies, that accelerate product development and testing, thereby reducing time-to-market. ↩ ↩

-

3D Modeling: Click to discover how 3D modeling software and simulation tools are used in product design and engineering, ensuring optimized performance and ergonomics. ↩ ↩

-

Custom Printing: Click to read about the latest innovations in custom printing for product personalization, which can help differentiate products in competitive markets. ↩ ↩