In brief, tennis and padel balls are engineered with distinct specifications tailored to their respective games. Tennis balls typically offer higher rebound performance and durability, while padel balls are designed for controlled play in enclosed courts with specialized gas-filled and material compositions. This article delves into a detailed comparison of manufacturing processes, material specifications, and performance features, equipping procurement managers and product development specialists with the technical insights needed for informed B2B sourcing decisions.

Procurement professionals in the sports industry require products that meet rigorous quality standards and guarantee consistent performance. Knowledge of the production nuances and technical specifications of sports balls—specifically tennis balls and padel balls—is crucial for aligning with consumer expectations and industry certifications.

At NEX Padel, we not only manufacture state-of-the-art padel rackets but also supply high-quality padel balls. Our products are produced using advanced production techniques in Jiaxing, Zhejiang, China, ensuring every item conforms to industry-leading quality control and manufacturing standards. Our expertise solidifies our reputation among prominent sports brands worldwide.

When selecting sports balls, the end-user experience and product longevity depend on several variables, including internal pressurization, material composition, and durability under play conditions. Below, we detail the primary differences between tennis and padel balls.

-

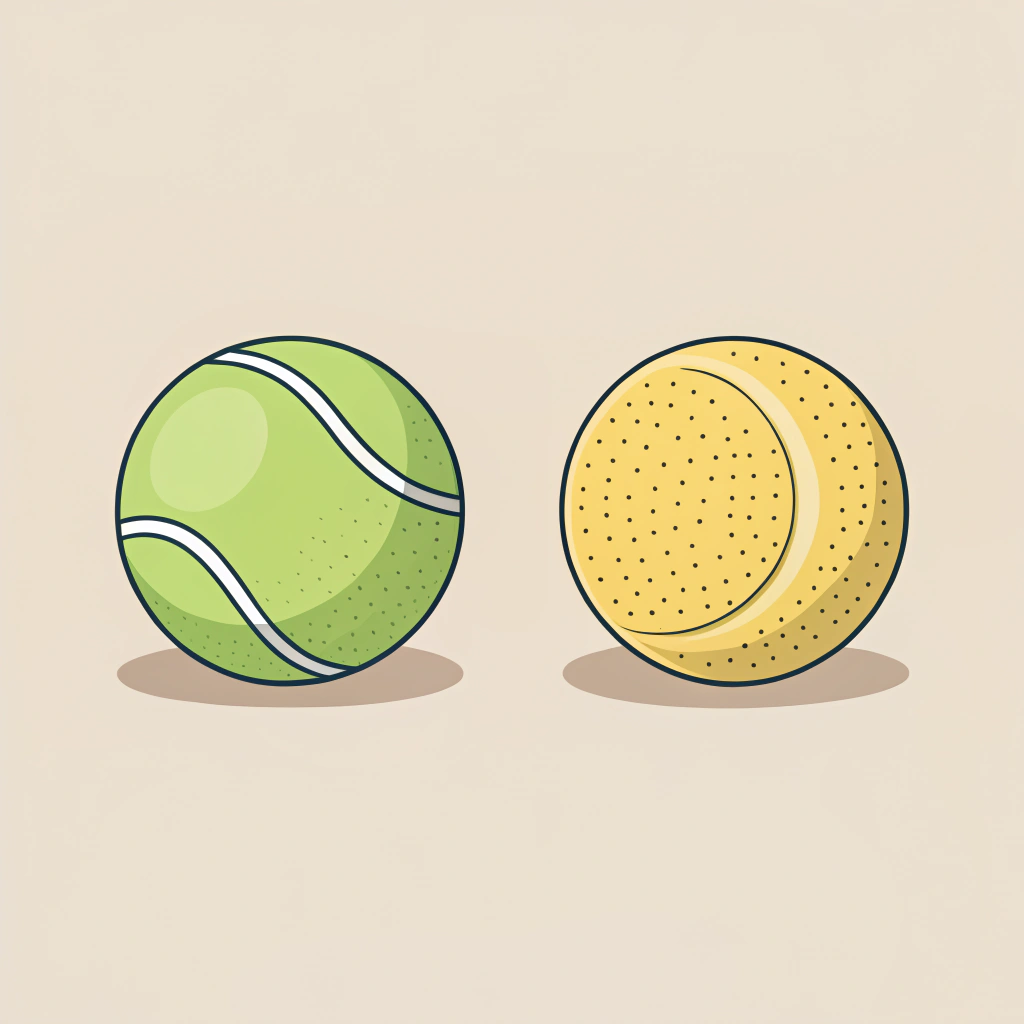

Tennis Balls:

- Often available as pressureless or gas-filled balls.

- Gas-filled tennis balls1 are crafted for a softer touch and enhanced comfort but can lose pressure faster over time.

- The outer felt is engineered to provide consistent bounce and high speed, optimized for larger, open-court play scenarios.

-

Padel Balls:

- Exclusively gas-filled to ensure a controlled, slower bounce suitable for enclosed padel courts.

- Designed to possess slightly lower initial pressure, making rallies easier to manage and prolonging ball life during play.

- Uses durable material formulations that work well with both 45% wool2 and 57% wool3 blends, offering varied performance characteristics to cater to different playing environments.

NEX Padel leverages cutting-edge manufacturing practices to ensure that every product undergoes rigorous performance testing and quality control. Our balls, whether for padel or adapted from tennis standards, are encased in pressurized tube packaging4—a critical consideration to maintain pressure and balance for optimal performance during extended use.

To further assist procurement managers and stakeholders in their decision-making, the following table summarizes the technical differences and key features of tennis and padel balls:

| Feature | Tennis Balls | Padel Balls |

|---|---|---|

| Internal Pressure | Gas-filled (softer) or pressureless variants | Exclusively gas-filled for controlled bounce |

| Bounce and Rebound Characteristics | Higher bounce and speed; designed for open courts | Softer initial bounce; ideal for enclosed, glass-walled courts |

| Material Composition | Standard felt and rubber with high durability | Specialized felt optimized for 45% and 57% wool compositions |

| Customization Options | Limited customization in terms of color and branding | Extensive customization including logo printing on hand grip and ball surface |

| Production Quality Control | Varied with supplier, may need additional testing | Stringent quality control measures ensuring consistent pressure and performance |

| Expected Lifespan | Durable under high-impact play; however, pressure loss can occur over time | Designed for longer shelf life under controlled play conditions due to specific gas properties and material resilience |

This table provides a clear snapshot for B2B buyers, highlighting how each product caters to its respective sport’s demands.

For companies engaged in sourcing sports equipment, supplier reliability is paramount. At NEX Padel, our advanced production techniques ensure that our padel balls meet the following criteria:

-

Precision Manufacturing:

Advanced production lines guarantee uniform ball dimensions and consistent pressure across batches. This reliability is essential when balls are used in competitive sports, promoting fair play and predictable performance. -

Quality Control Protocols5

Our quality control involves multiple testing stages. From raw material inspection to final pressure testing, every step adheres to international industry certifications. This process minimizes variations, ensuring each ball delivers consistent performance. -

Customization Versatility:

We offer comprehensive customization options. Our padel balls and tennis ball counterparts (where applicable) can be tailored in terms of color, imprint, and packaging. For instance, brand-specific logos can be imprinted on the hand grip or ball surface, making the product not only high-performing but also a strong marketing asset. -

Material Selection:

Understanding the blend ratios such as 45% wool2 and 57% wool3 is critical. These specifications influence the ball's elasticity and durability. Our technical team selects the ideal material composition to strike the perfect balance between performance and longevity. -

Packaging and Logistics:

With innovations in pressurized tube packaging4, we ensure each ball retains its optimal pressure during transit and storage. This packaging solution further enhances the product's shelf life, making it a cost-effective option for large-scale distributors.

To ascertain the performance of our sports balls, we conduct comprehensive testing under various conditions. These tests evaluate aspects such as:

-

Pressure Retention:

Measuring how long gas-filled balls maintain their optimal pressure. -

Bounce Consistency:

Assessing the rebound characteristics on different surfaces, ensuring they meet the regulation standards set by sports governing bodies. -

Wear and Durability:

Simulating extended play conditions to identify potential wear issues. This helps determine the expected lifespan under normal usage.

These tests are not only crucial for quality assurance but are also informative for buyers who aim to understand the technical merits of the products they plan to stock.

Procurement managers must consider how the product performs in everyday contexts:

-

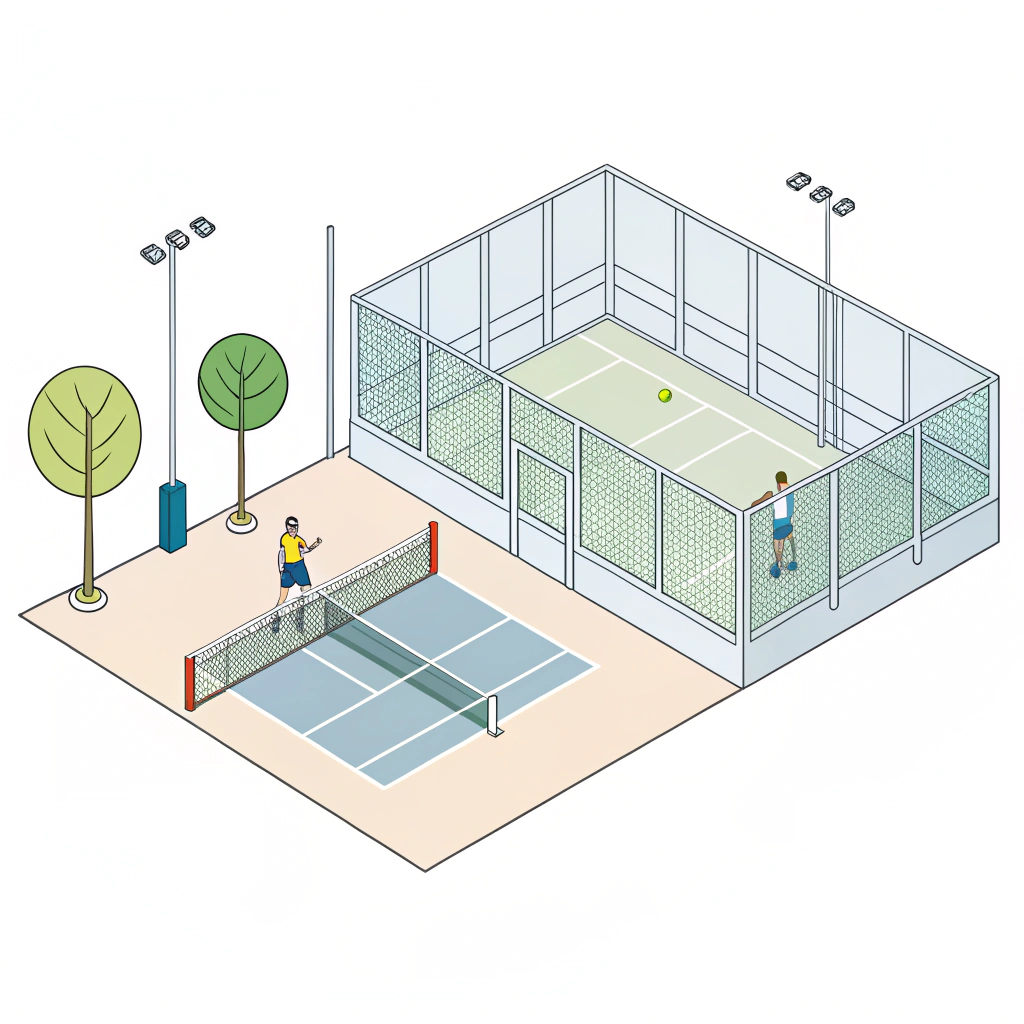

Tennis Industry:

Tennis balls are used in a variety of environments, from professional tournaments to local clubs. The high bounce and speed are appreciated in large, well-maintained courts but may require regular replacement as pressure diminishes. -

Padel Environment:

Padel, being a fast-growing sport, demands balls that are specifically tailored for its unique court design. The controlled bounce and enhanced durability allow for longer rallies and reduced ball degradation, making them an ideal choice for clubs and sports facilities focusing on padel. -

Dual-Purpose Usage:

While some may consider using tennis balls in padel, it is important to note that the characteristics of tennis balls—such as higher bounce and harder impact—can adversely affect gameplay in padel courts. Additionally, tennis balls are more likely to cause damage to the unique materials (like glass walls) common in padel arenas.

When evaluating a potential supplier, B2B buyers should consider the following aspects to ensure long-term product satisfaction and cost-effectiveness:

-

Supplier Reliability and Certification:

A supplier with a strong track record in quality and delivery times, like NEX Padel, will offer robust production capabilities and comprehensive after-sales support. Industry certifications and rigorous quality controls are indicators of a reliable partner. -

Customization Capabilities:

In markets where branding and differentiation are key competitive advantages, the ability to customize products is invaluable. Evaluate whether your supplier can offer bespoke options—from custom color schemes to imprinted logos on balls and accessories. -

Technical Specifications and Compatibility:

Ensure that the technical specifications of the product align with the intended use. For instance, in padel, the ball’s pressure and material composition are critical for maintaining consistent play quality. In contrast, tennis balls need to meet standards for speed, bounce, and durability. -

Cost-Performance Ratio:

A thorough cost-benefit analysis should include not only the initial procurement cost but also long-term performance factors. Products that maintain quality over extended use help offset initial investments through lower replacement rates and higher customer satisfaction. -

Support for Supply Chain Management:

Evaluate the supplier’s commitment to transparent production practices, timely delivery, and effective quality management. A strong supply chain partner will provide insights and data on performance testing and manufacturing processes that help mitigate procurement risks.

For companies navigating the sports equipment market, understanding the nuances between tennis and padel balls is essential. Here are key recommendations:

-

If your target market values high-speed, aggressive play typically found in tennis, then prioritizing products that offer a robust rebound and consistent pressure retention (even if they require more frequent replacement) is critical.

-

Conversely, if your focus is on the rapidly growing padel market, opting for balls specifically engineered for controlled bounce and extended durability is advisable. NEX Padel’s rigorously tested balls are designed with such parameters in mind, making them an excellent choice for establishments emphasizing quality and consistency.

-

Consider running pilot tests with limited product batches to gather on-field performance data before committing to large-scale orders. This approach allows your organization to align its procurement strategy with verified quality metrics and real-user feedback.

Ultimately, the procurement process should balance technical specifications with supplier reliability and customization options. By understanding these technical differences and production methodologies, you can make an informed decision that elevates your product offerings and satisfies end-consumer expectations.

Q: Can I use tennis balls for padel?

A: While tennis balls can be used for padel, they are not ideal. Tennis balls tend to bounce faster and harder, which can disrupt the controlled play of padel. Moreover, using tennis balls may lead to quicker wear of your padel equipment and can potentially damage court features, such as glass walls, due to their harder impact.

Q: Is there a difference between a padel ball and tennis ball?

A: Yes, there is a significant difference. Tennis balls can be either pressureless or gas-filled, with gas-filled variants being softer initially but losing pressure more quickly. In contrast, padel balls are always gas-filled to ensure a softer start and to accommodate the controlled pace required in padel, though they gradually become softer over time.

Q: Is padel ball easier than tennis?

A: Padel is generally considered easier for beginners compared to tennis. Most individuals can learn the basics of padel in under an hour, whereas achieving proficiency in tennis typically takes several lessons over a longer period, building confidence more slowly.

-

Gas-filled tennis balls: Click to learn about the engineering behind gas-filled tennis balls, their pressure dynamics, and how they contribute to performance and comfort in high-speed play. ↩

-

45% wool: Click to understand the significance of a 45% wool blend in sports ball manufacturing, its impact on elasticity, durability, and overall performance. ↩ ↩2

-

57% wool: Click to discover how a 57% wool blend influences the material properties of sports balls and the resulting performance under different play conditions. ↩ ↩2

-

Pressurized tube packaging: Click to explore how pressurized tube packaging maintains optimal ball pressure during transit and prolonged storage, ensuring consistent product performance. ↩ ↩2

-

Quality Control Protocols: Click to review the rigorous quality control protocols applied during production, including testing methods and standards that ensure each ball meets industry certifications. ↩