Quick answer: 18K carbon fiber1 in padel rackets means a material composed of 18,000 very fine threads per stripe, offering increased rigidity and precision compared to lower strand counts. This design is ideal for players with refined techniques seeking power and accuracy, while still ensuring durability and the level of customization required by professional clubs and distributors.

In today’s high-performance padel market, procurement managers2 and sports equipment distributors are faced with the challenge of selecting the most suitable padel rackets that offer both excellent playability and superior durability. As the industry evolves, materials like 18K carbon fiber have emerged as game changers when compared with traditional options such as 3K and 12K carbon. This article presents a detailed comparative analysis to help decision makers evaluate the benefits of 18K carbon fiber versus alternatives.

The Comparison Dilemma: 18K vs. 12K Carbon Fiber3 vs. 3K Carbon Fiber4

Procurement professionals need to closely assess how different carbon fiber specifications impact racket performance. The choice between 3K, 12K, and 18K carbon fiber is pivotal, especially for clubs and distributors seeking enhanced performance, precision engineering, and better longevity in their equipment.

One of the key differentiations lies in the composition and behavior of the carbon fiber. Here’s a quick breakdown:

- 3K Carbon Fiber: Uses 3,000 threads per stripe. It offers more elasticity, which results in a softer touch and better forgiveness upon impact. Its flexibility makes it ideal for players who require comfort and extended playability.

- 12K Carbon Fiber: Comprising 12,000 threads per stripe. This material strikes a balance between flexibility and rigidity. It offers improved control relative to 3K while still providing a comfortable impact feel suitable for a broader range of players.

- 18K Carbon Fiber: With 18,000 threads per stripe, 18K is the most rigid option. This higher count results in a racket that delivers precise impacts and more power. However, it also means a stiffer surface, which may be less forgiving if the player’s technique isn’t well developed.

Below is a comparison table that outlines the main differences:

| Specification | 3K Carbon Fiber | 12K Carbon Fiber | 18K Carbon Fiber |

|---|---|---|---|

| Threads per Stripe | 3,000 | 12,000 | 18,000 |

| Flexibility | Highest (More elastic) | Moderate | Lowest (Most rigid) |

| Impact Feel | Softer impact | Balanced impact | Firm impact with precision |

| Power Generation | Less power-focused | Moderate power | High power, precision-based |

| Ideal For | Comfort and extended play | Versatile play styles | Advanced players seeking power and accuracy |

| Customization | Widely adaptable | Customizable with balanced traits | Customizable with precision profiles |

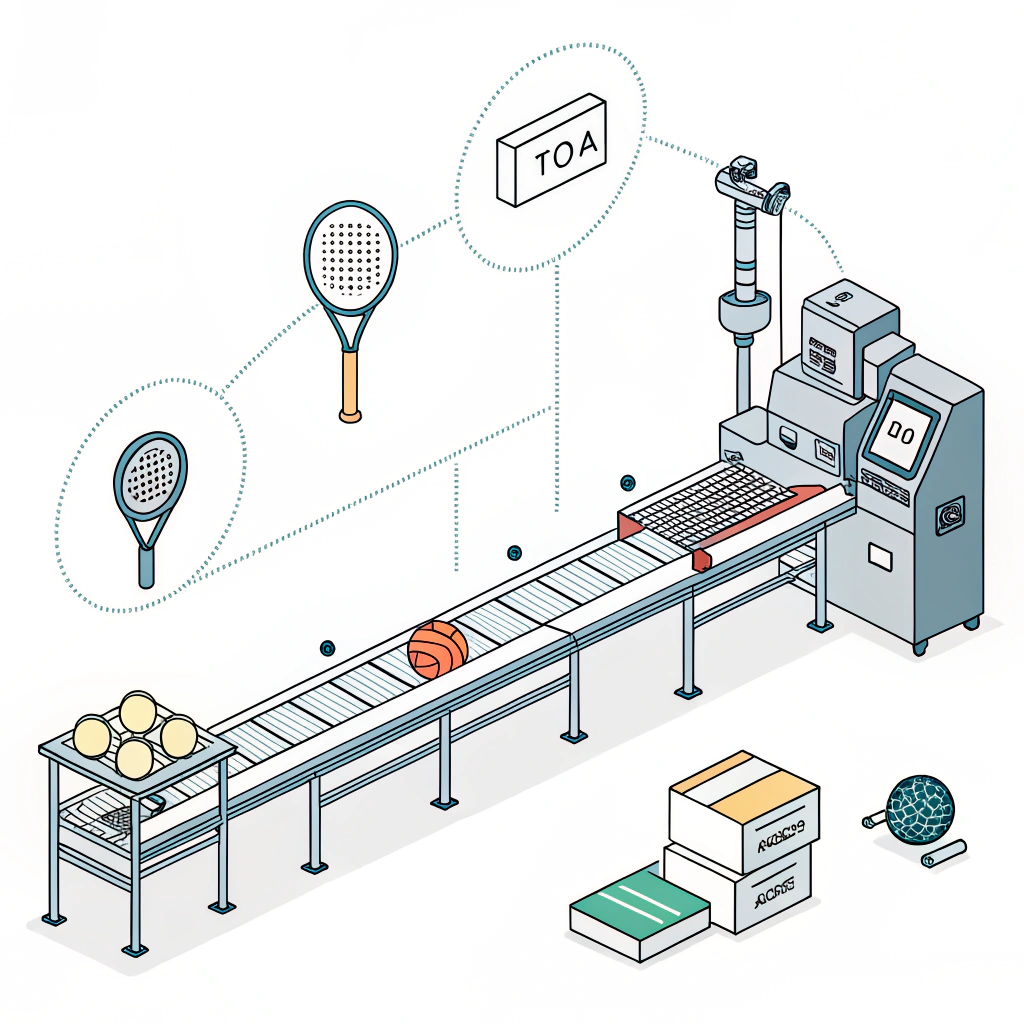

At NEX Padel, our advanced production techniques ensure that every padel racket meets the exacting standards required by professionals. The manufacturing process for 18K carbon fiber rackets incorporates precision engineering and rigorous quality control that sets it apart from other materials.

-

High-Precision Molding:

Using state-of-the-art fabrication facilities, our production process for 18K carbon fiber rackets achieves unmatched precision. This high-value material requires careful layering and curing processes to maintain structural integrity. -

Tailored Customization:

Our range includes Diamond, Round, and Teardrop shaped rackets. Beyond shape, we offer customization for printing, color, hand grip (hand glue), and handle covers with custom logos. Distributors benefit from the ability to adapt the design to meet brand requirements seamlessly. -

Material Superiority and Reliability:

The quality and consistency of 18K carbon fiber ensure that every racket maintains its performance metrics even under extensive use. This material superiority translates into greater durability and long-term satisfaction among end users.

Below is a simplified process flow table for our production techniques:

| Production Stage | Key Process Details | Benefits |

|---|---|---|

| Material Selection | Source high-quality carbon fiber (18K, 12K, 3K) | Material consistency and strength |

| Molding and Curing | High-precision mold shaping and cure cycles | Enhanced precision and durability |

| Customization | Custom print, color, hand grip, and handle cover options | Tailored products for brand identity |

| Quality Control | Rigorous performance and durability tests | Assurance of long-term performance |

For B2B procurement managers, understanding the technical performance of padel rackets is crucial. Here are several performance aspects to consider:

The rigidity offered by 18K carbon fiber directly affects the power and accuracy of the racket. A more rigid surface means that players—with a refined technique—can harness greater power and deliver more precise shots. However, this rigidity translates to a stiffer feedback, requiring advanced skill to fully utilize the racket's potential.

For players who favor a more forgiving touch, such as beginners or those with slower swing speeds, a 3K or 12K carbon fiber construction might be preferable. These materials deliver a softer impact feel that can reduce the risk of mishits and provide enhanced comfort during prolonged play periods.

Another key metric is the balance and overall weight distribution of the racket. The density of 18K carbon fiber can influence the racket’s weight, but our engineering solutions ensure that the final product maintains an ideal balance between maneuverability and stability. This optimization is crucial for professional players and club owners who require high-performance equipment that also supports long match durations and training sessions.

Integrating extensive R&D and performance testing, NEX Padel leverages industry benchmarks to ensure that every racket design, whether 18K, 12K, or 3K, meets competitive standards. Comparative studies in laboratory settings have shown that 18K rackets signify a higher power output and refined directional control—a distinct competitive advantage for advanced players and teams.

For procurement managers, consistent quality, on-time delivery, and the ability to customize orders are as critical as the technical specifications of the rackets. With NEX Padel, these factors play a fundamental role in our business relationships:

-

Quality Assurance:

Every batch undergoes comprehensive quality checks to ensure material consistency, assembly precision, and long-term durability. This rigorous protocol guarantees that distributors receive products that perform reliably in high-intensity match scenarios. -

Customization & Flexibility:

Our extensive customization options mean that distributors and club owners can commission orders that reflect brand identity while meeting technical performance criteria. This adaptability is crucial in markets where competitive differentiation can lead to market success. -

Timely Production & Delivery:

Leveraging advanced manufacturing processes, NEX Padel ensures that sample approvals, production runs, and bulk deliveries occur within strict timelines. Our commitment to both quality and efficiency makes us a dependable partner for leading sports brands like Hirostar, Reebok, and Starvie. -

Industry Expertise:

Backed by years of experience as an original equipment manufacturer (OEM5) for various renowned brands, our team is well-versed in aligning production capabilities with market needs. From pre-production design consultations to after-sales support, our goal is to empower our partners with reliable, high-performing padel equipment.

In summary, 18K carbon fiber padel rackets offer a unique combination of rigidity, power, and precision that makes them particularly appealing to advanced players and professional clubs. When compared with 3K and 12K variants, the 18K option stands out for its superior performance characteristics. However, this comes with a caveat: the need for players to have refined techniques to fully leverage the benefits.

For procurement managers and sports equipment distributors, the decision should be guided not only by technical metrics—such as thread count, rigidity, and impact feel—but also by factors like customization options, production timelines, and supplier reliability. NEX Padel’s state-of-the-art manufacturing processes, combined with our flexibility in customization, ensure that our 18K carbon fiber rackets meet the high-performance demands of today's competitive padel environment.

Action steps for B2B buyers:

- Request detailed performance reports and sample rackets to compare feel and performance.

- Evaluate customization options by discussing design specifications with our technical team.

- Assess supplier reliability by reviewing past case studies and client testimonials.

- Place a pilot order to test the rackets in a real-world competitive environment, ensuring they align with your club or brand’s standards.

By making an informed decision based on a thorough comparison, you can secure equipment that not only elevates game performance but also reinforces your brand’s commitment to quality and innovation.

People Also Ask

Q: What does 18K padel racket mean?

A: An 18K padel racket is made with 18,000 carbon fiber strands per stripe, resulting in a more rigid and precise hitting surface that offers high power and accuracy, ideal for advanced players.

Q: Is 18K carbon harder than 12K?

A: Yes, 18K carbon is harder than 12K carbon. Higher K values indicate increased rigidity; therefore, 18K offers a firmer hitting surface while providing greater control for skilled players.

Q: What is the difference between 3K and 12K carbon fiber padel?

A: The primary difference is the number of carbon fiber strands used; 3K has 3,000 strands while 12K uses 12,000 strands. This results in 12K carbon providing greater flexibility compared to 3K, which offers a softer touch on impact.

-

18K carbon fiber: Click to learn about the advanced properties of 18K carbon fiber, including its composition, rigidity, and how its high strand count enhances racket performance. ↩

-

procurement managers: Click to learn more about the role of procurement managers in sourcing high-performance equipment and ensuring supplier reliability. ↩

-

12K Carbon Fiber: Click to understand the balance 12K carbon fiber offers between flexibility and rigidity, making it a versatile option for various play styles. ↩

-

3K Carbon Fiber: Click to explore the features of 3K carbon fiber, its elastic properties, and why it may be preferred for extended play and comfort. ↩

-

OEM: Click to read about Original Equipment Manufacturers, their role in quality assurance, and how OEM partnerships drive industry innovation. ↩