Custom Teardrop Padel Rackets offer an excellent blend of power and control through advanced manufacturing and material technologies, making them an ideal choice for customization and high-performance play.

In today’s fast-paced padel market, procurement and product developers are under increasing pressure to source equipment that not only satisfies playing performance but also adheres to strict quality, durability, and customization requirements. NEX Padel stands at the forefront of this challenge by providing high-performance custom padel rackets. Our Teardrop rackets, along with our Diamond and Round offerings, are built with advanced materials—including various grades of carbon fiber1 (3k, 12k, 18k)—and flexible production techniques that ensure precision, fast turnaround times, and adherence to OEM2 requirements.

In this article, we will break down the technical aspects of our custom Teardrop padel rackets, discuss the advantages of advanced materials and production processes, and provide actionable insights for procurement managers who need to make an informed decision.

Modern padel market stakeholders face a multi-faceted challenge. On one end, consumers demand rackets that have a finely tuned balance between offensive power and defensive control. On the other, distributors and clubs expect product consistency, robust materials, and rapid supply chain fulfillment. The problem is the traditional one-size-fits-all approach from some manufacturers, which may not meet advanced performance specifications or customization needs.

Here are the primary challenges procurement managers face:

- Identifying materials that ensure durability and optimal performance on the court.

- Balancing customization options such as shape, printing, and ergonomic design with cost and production efficiency.

- Achieving a competitive advantage by offering products that are tailored to different player levels and playing styles.

- Ensuring that OEM products adhere to strict quality and performance standards without compromising on design and aesthetics.

At NEX Padel, we have invested heavily in advanced material technologies to address these challenges. Our racket production employs cutting-edge carbon fiber materials in different grades—3k, 12k, and 18k—each offering distinct advantages.

- 3k Carbon Fiber: Provides a balanced mix of strength and flexibility. It is ideal for players who require a forgiving but dynamic response.

- 12k Carbon Fiber: Offers enhanced rigidity, which results in a more controlled reaction, perfect for players focused on precision.

- 18k Carbon Fiber: Delivers unmatched durability and precision, suited for high-level competitive play where every millisecond counts.

These materials are integrated into our production process using state-of-the-art techniques that ensure not only consistent quality but also scalability for mass production or limited edition runs.

Our Teardrop shape is a prime example of successful customization. This shape strikes an innovative balance—positioning the sweet spot slightly higher on the racket. This harnesses greater power potential while still preserving the essential control so critical during defensive plays. The customizable options extend beyond mere shape:

- Print and Color Customization: We offer a full spectrum of custom printing technologies so that each racket can embody distinct team colors, logos, or branding messages.

- Ergonomic Customization: Options for personalized hand grips, including logos on hand grips and handle covers, make the equipment truly unique.

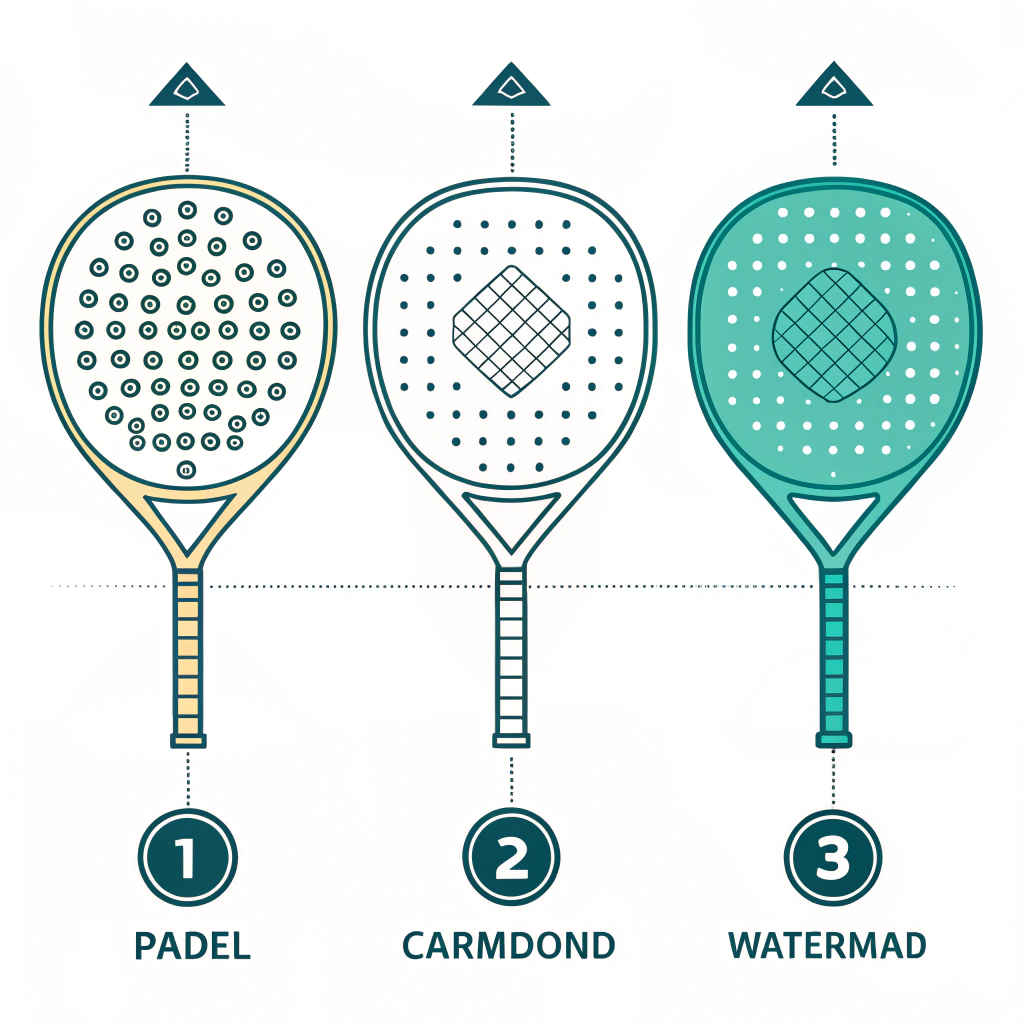

- Shape Variations: Beyond Teardrop, our portfolio includes Diamond and Round shapes, all of which can be tailored further to meet specific market requirements.

This breadth of customization helps our partners differentiate their offerings in an increasingly competitive market by aligning equipment with specific player needs or brand identity.

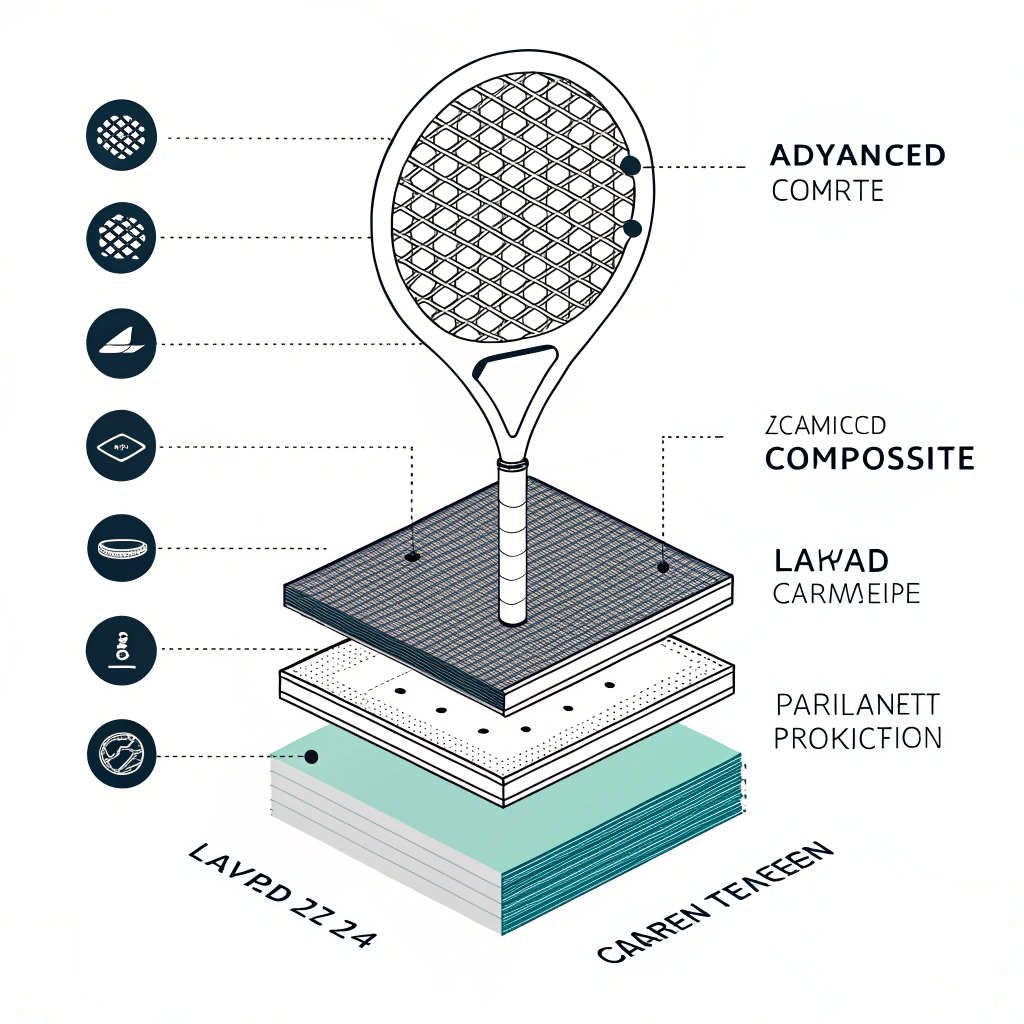

Our production process at NEX Padel is engineered for speed and precision. The key elements of our process include:

-

Rapid Prototyping3 and Customization

Through advanced CAD/CAM technologies4, we can design and fine-tune the Teardrop shape to exact specifications. This digital modeling approach accelerates the prototyping phase and allows quick iterations based on client feedback. -

Advanced Composite Layup Techniques5

Utilizing multiple layers of advanced carbon fibers and resin systems, we create composite structures that are both lightweight and resistant to impact. The lamination process is pivotal in achieving the perfect balance between stiffness and elasticity, which is especially important in the Teardrop design where feel and feedback during play are critical. -

Quality Control and Durability Assurance

Every step of production is monitored for compliance with international quality standards. Our rigorous testing phases include impact resistance, flexural strength analysis, and advanced fatigue testing. This meticulous approach ensures that the rackets not only meet but exceed performance criteria for competitive play.

| Material Grade | Flexibility | Rigidity | Durability | Ideal Player Profile |

|---|---|---|---|---|

| 3k | High | Moderate | High | Beginners to intermediate players |

| 12k | Moderate | High | Very High | Precision-focused, competitive players |

| 18k | Low | Very High | Maximum | Elite, professional-level players |

The table above summarizes the material options that influence the performance and feel of the racket. Choosing the right material depends on the player’s needs and the intended market positioning of the product. With our robust production process, NEX Padel is uniquely positioned to match material capabilities with player demand—efficiently and reliably.

As the pursuit of differentiation grows, customization becomes a key asset value enhancer. Besides the flexible material options, our customization extends to various functional and aesthetic elements:

-

Custom Shapes: While our Teardrop rackets provide an excellent balance, customers have the option to select Diamond or Round shapes when specific performance characteristics are desired.

-

OEM Production: We support full OEM capabilities, meaning that our partners can present their own branding, designs, and proprietary specifications. This level of customization fosters a deeper connection between the end-user and the brand.

-

Color and Print: Custom color schemes, including unique print details on the face and handle details, are available to suit seasonal trends, club colors, or sponsorship requirements.

-

Accessory Customization: Not only are the rackets fully customizable, but accessories like hand grips and handle covers can also be personalized with logos or additional design elements. This feature is particularly valuable for padel clubs and sports distributors looking to maintain a cohesive brand image across all player equipment.

Our seamless integration of customization options with advanced production methods ensures that the final product is not only high performance but also truly unique. This holistic approach to customization empowers businesses to offer gear that can be directly mapped to market demands, boosting customer confidence and loyalty.

Before making procurement decisions, it is essential to consider certain factors that have a direct impact on the overall product performance and lifecycle:

-

Material Selection

The grade of carbon fiber used directly influences both the power and durability of the racket. Buyers should align their material choice with the target player demographics. -

Customization Scope vs. Production Lead Time

Increased customization may lead to longer lead times. It is important to balance the need for personalized designs with efficient production workflows. -

Cost Effectiveness

While performance is paramount, the cost implications of advanced materials and extensive customization must be factored in. Our pricing models are competitive and scalable, ensuring that even high-end customization projects can be completed within budget. -

Testing and Quality Assurance

Ensure the manufacturer adheres to robust quality assurance protocols. NEX Padel’s track record in meeting international standards and rapid sample approvals is a strong indicator of reliable performance. -

After-Sales Support and OEM Services

A manufacturer offering comprehensive after-sales support and OEM services can significantly enhance the product lifecycle. Our commitment extends beyond manufacturing—we partner with clients in continuous product improvement and market adaptation.

Consider the experience of a renowned padel club that sought to improve its on-court performance and brand visibility. Their key challenges were:

- Delivering a product with consistent high performance.

- Reinforcing the club’s brand through unique product design.

- Managing production timelines in alignment with tournament schedules.

NEX Padel partnered with this club to deliver a series of custom Teardrop padel rackets. The approach included:

- Material Matching: After analyzing performance needs, we recommended a 12k carbon fiber configuration that balanced rigidity and flexibility perfectly.

- Design Customization: Incorporating the club’s branding through detailed print and personalized handle grips.

- Rapid Prototyping & Testing: By using our advanced digital modeling tools, we fast-tracked the approval process, ensuring the rackets were tournament-ready well ahead of schedule.

The results were striking: On-court performance improved markedly, and the club experienced an increase in membership engagement, partly thanks to the distinctive, custom-designed rackets. This case underscores why customized equipment from a reliable manufacturer is a key differentiator in a competitive market.

In conclusion, sourcing Custom Padel Rackets—especially the innovative Teardrop design—from a supplier with advanced production capabilities like NEX Padel can significantly enhance your product offering. Our integration of next-level carbon fiber technology, flexibility in customization, rigorous quality control, and swift prototyping meets all the demands of modern padel players and clubs.

To summarize:

- Teardrop rackets blend power and control, making them a versatile option for different skill levels.

- Advanced materials, including 3k, 12k, and 18k carbon fibers, are selected to match player skill and performance requirements.

- Extensive customization ensures that each racket can be branded and tailored specifically, enhancing market differentiation.

- Rigorous production standards and rapid prototyping reduce lead times and ensure consistent quality.

For procurement managers seeking a balance between performance, durability, and customization, partnering with NEX Padel represents a strategic decision that meets market demands and positions your products ahead of the competition. We invite you to explore further, request samples, and discuss customization options with our team to drive your product’s success.

Q1: Is teardrop padel racket good?

A: Yes, teardrop rackets offer a balanced combination of power and control. With a slightly higher sweet spot, these rackets can generate increased power without compromising control, making them adaptable to different play situations.

Q2: Do expensive padel rackets make a difference?

A: While higher-priced rackets often incorporate advanced materials and smaller sweet spots for enhanced precision, they may not be ideal for beginners or intermediate players. The performance benefits are more pronounced in competitive settings rather than in entry-level play.

Q3: Is drop shot a good padel brand?

A: Drop Shot is recognized for using premium materials and innovative technologies within their padel tour rackets, setting a high standard for quality and performance in the market.

-

carbon fiber: Reading this article provides insights into the properties and benefits of carbon fiber materials used in high-performance sports equipment, including aspects like durability, weight reduction, and strength optimization. ↩ ↩

-

OEM: Explore the value of Original Equipment Manufacturer (OEM) partnerships, which can offer advantages in quality control, branding possibilities, and production efficiency in sports equipment manufacturing. ↩ ↩

-

Rapid Prototyping: Discover how rapid prototyping accelerates product development by enabling quick testing and refinement of designs, reducing time-to-market for new products. ↩ ↩

-

CAD/CAM technologies: Learn how Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) streamline the design process, enabling precise digital modeling and rapid iterations for product development. ↩ ↩

-

Composite Layup Techniques: Understand the advanced methods used in layering composite materials to achieve an optimal balance of strength, flexibility, and weight in high-performance products. ↩ ↩