Selecting the right padel equipment manufacturer can dramatically impact your brand’s success. In today’s competitive market, understanding the technical capabilities, quality standards, customization options1, and delivery performance of your partner is critical. This article explains how to evaluate these factors and why partnering with an experienced manufacturer like NEX Padel can give you an edge.

Padel is rapidly growing as a sport worldwide, leading to increased demand for high-performance padel rackets and accessories. As a decision maker at a sports equipment firm or distributor, you face a multitude of challenges when selecting a manufacturing partner. You must weigh technical competency, product quality, rapid prototyping, and delivery reliability—all while ensuring the products meet your brand’s customization needs.

Many companies struggle with sourcing because they often lack detailed technical insights into production techniques. With diverse materials like glass fiber2 and advanced carbon fibers (3k, 12k, 18k), along with the trend for bespoke designs, the process can be complex. Moreover, the decision is not only about the end product but also about aligning with a partner who can support your branding and provide fast, reliable service.

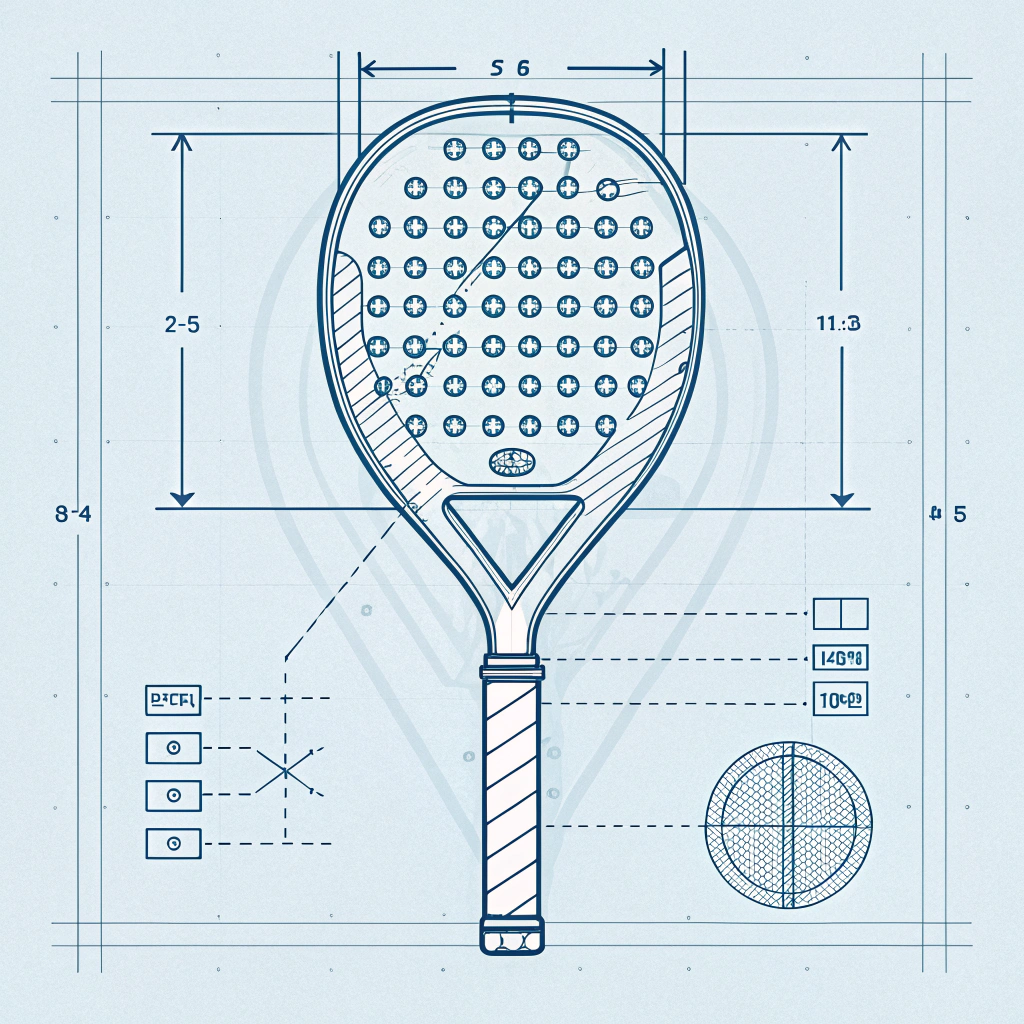

High-performance padel rackets require a combination of advanced materials, precision engineering, and innovative design. At NEX Padel, our decades-long experience in high-quality manufacturing lets us deliver exceptional products that satisfy the rigorous demands of professional play. Below are some key technical aspects typically evaluated:

-

Materials and Composition:

Our rackets use materials ranging from glass fiber2 to premium carbon fibers (3k, 12k, 18k). This diversity allows you to target multiple market segments—from entry-level products to high-end performance gear. -

Production Techniques:

Advanced production processes such as automated layering, precise molding, and stringent quality control yield rackets with superior durability and performance consistency. -

Customization Options:

We offer three principal racket shapes: Diamond, Round, and Teardrop. Beyond basic shapes, options like custom imprinting on the racket surface, hand grip logo customization, and even personalized handle covers set our products apart. -

quality assurance3: Consistency and durability are verified through rigorous testing at every stage of production—ensuring that each racket meets international quality standards.

Below is an overview comparison table that outlines how NEX Padel’s capabilities align with industry requirements and buyer expectations:

| Criteria | NEX Padel Strengths | Industry Average |

|---|---|---|

| Material Quality | Advanced Glass & Multiple Carbon Fiber Options | Standard composite materials |

| Production Techniques | High-precision automated processes; strict QC protocols | Manual or semi-automated processes |

| Customization | Multiple racket formats & branding options (hand grip, logo) | Limited to standard designs |

| Fast Prototyping | Rapid sample creation and adjustments available | Longer turnaround times |

| Delivery Reliability | Prioritized supply chain & timely shipments | Variable lead times |

Customization is a cornerstone of successful product differentiation in a competitive market. With padel rackets, the ability to tailor shapes, prints, and finishes to your brand identity is imperative. Our factory supports:

-

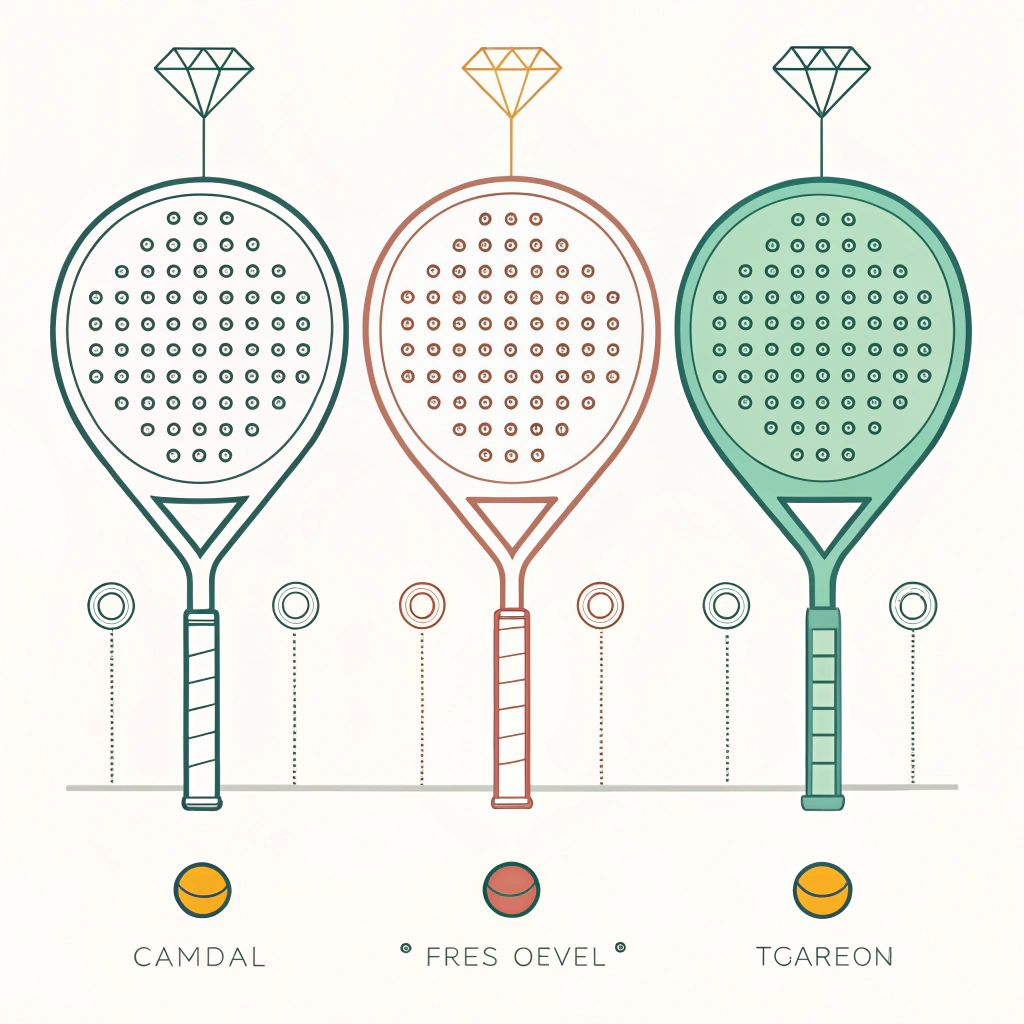

Shape Options:

Choose from Diamond, Round, and Teardrop racket designs. Each shape offers distinct performance characteristics—allowing you to hone in on your target market’s performance preferences. -

Branding Opportunities:

Custom printing technology enables the clear display of company logos, official colors, and taglines. Additionally, customization extends to the hand grip and handle covers, making it easier for your brand to stand out on the court. -

Material and Weight Customization:

By adjusting the type of fiber and layer configuration, we provide rackets that have customizable weight distribution and balance, catering to various styles of play from recreational to competitive levels. -

Accessory Integration:

In addition to rackets, we also supply padel balls and other accessories. Our ball offerings come with precise quality controls and packaging methods (for instance, using Pressurized tube technology) to ensure optimal performance on the court.

Using our design-to-delivery approach, you can be confident that your orders reflect both technical excellence and customized branding suited to your markets.

In today’s market, time-to-market is a crucial competitive advantage. When working with a high-performance manufacturer like NEX Padel, you benefit from a streamlined prototyping process that minimizes delays. Key factors include:

-

rapid prototyping4: Quick sample production cycles mean that you receive prototypes rapidly. This accelerates the testing phase and allows you to iterate designs faster, ensuring that your final product is market-ready without prolonged waiting periods.

-

Efficient Production Workflow:

Our use of advanced automated processes minimizes errors while ensuring consistent quality across large production batches. This reliability is essential in maintaining inventory levels and meeting large-scale orders. -

Supply Chain Coordination:

With a robust supply chain5 network, we guarantee timely delivery—mitigating the risks associated with production delays. This consistency supports your brand’s promise to customers and enhances overall market confidence. -

Proven Track Record:

Our established partnerships with renowned brands like Hirostar, Reebok, and Starvie attest to our ability to manage high-stakes, high-volume projects without compromising quality.

These integrated facets of fast prototyping and prompt delivery make NEX Padel a manufacturer that understands the urgent needs of B2B buyers, ensuring your business remains agile in a competitive environment.

The decision to choose a manufacturing partner involves comparing various factors side by side. Here is a detailed look at how NEX Padel stands in comparison to standard market options:

-

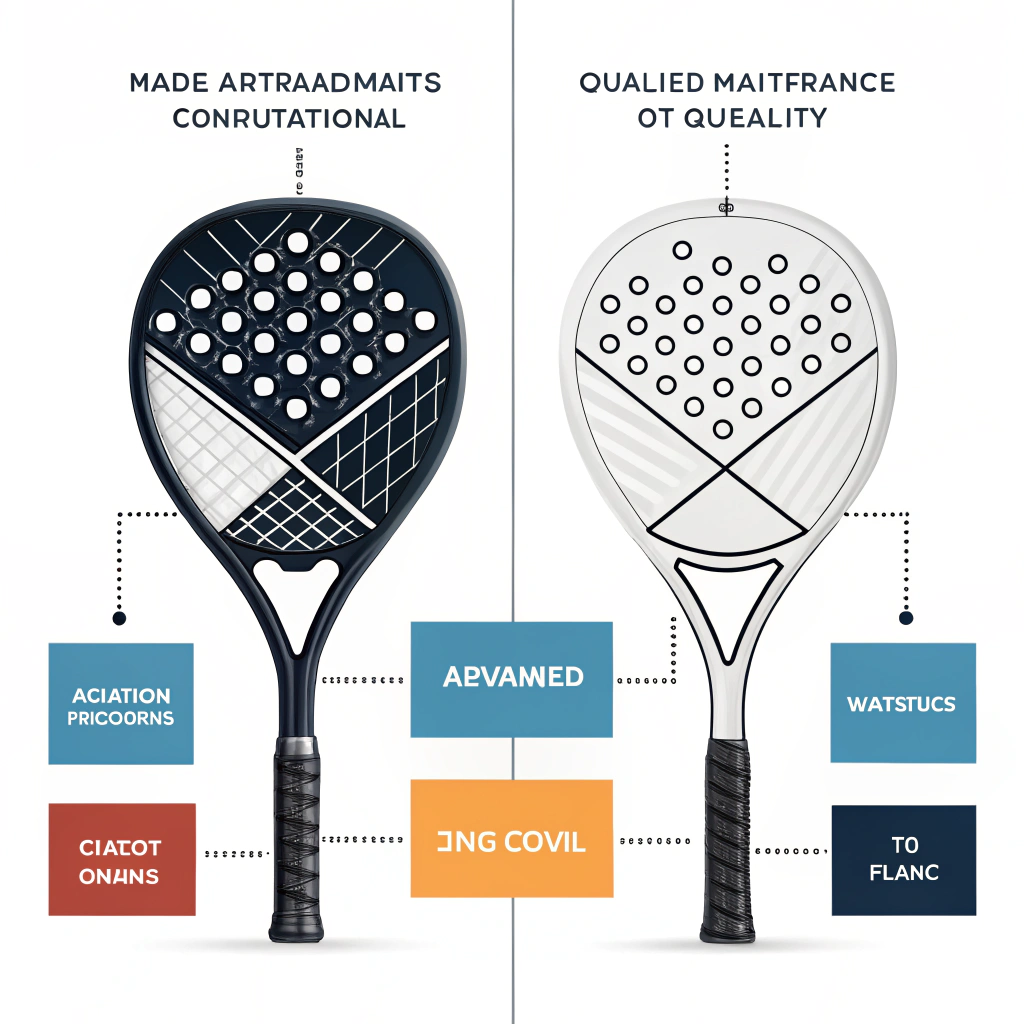

Technical Expertise and Advanced Materials:

- Many manufacturers offer generic composite rackets with standard materials. In contrast, NEX Padel provides a variety of material options, from glass fiber2 to high-end carbon fiber variants like 3k, 12k, and 18k.

- Our Technical Edge: Using diverse materials allows us to engineer rackets that are specifically tuned for performance and durability.

-

Customization Capabilities:

- Off-the-shelf products may limit your brand’s potential due to their lack of personality.

- Our Customization Options: Whether you need a uniquely shaped racket or bespoke branding on every component, our extensive customization options empower your brand’s identity.

-

Turnaround Speed and Reliability:

- In some cases, delays in prototyping and mass production can impact your product launch timelines.

- Our Commitment: Fast prototyping and reliable production schedules ensure that your orders are completed with precision and on time, securing your competitive position in the market.

-

Quality Control:

- While general manufacturers might rely on basic quality checks, our multi-step inspection process minimizes defects and ensures that every product meets rigorous standards.

- Using advanced production techniques and stringent quality assurance protocols, we consistently deliver high-performance products.

The following table summarizes these differences and reinforces why NEX Padel is an ideal partner:

| Key Factor | Standard Manufacturer | NEX Padel’s Offering |

|---|---|---|

| Material Varieties | Limited material options | Glass Fiber, Carbon Fiber (3k, 12k, 18k) |

| Product Customization | Minimal design options | Full customization: shape, print, hand grip, etc. |

| Production Speed | Longer prototyping cycles | Rapid prototyping enabled by advanced tech |

| Quality Assurance | Basic quality checks | Comprehensive, multi-step quality control |

| Delivery Reliability | Inconsistent timelines | Prioritized supply chain with timely delivery |

The performance of padel equipment is best illustrated by real-world examples and data. Several leading sports brands have switched to partnering with specialized manufacturers like NEX Padel to meet growing consumer demand for superior equipment. For instance:

-

Case Study 1: Premium Brand Customization

A well-known sports equipment brand sought unique design characteristics to differentiate its product in the crowded padel market. Leveraging our customization capabilities—ranging from unique racket shapes to personalized hand grips—they successfully established a market presence that saw a significant uptick in consumer engagement and sales. -

Case Study 2: Rapid Market Entry

In another instance, a distributor faced tight deadlines to launch a new line of padel gear. Our rapid prototyping, combined with our rigorous quality control and reliable delivery schedules, ensured that the products reached market on time, thus seizing the competitive window in an emerging industry.

Market data also supports the growth potential of padel products globally. With supply chains increasingly leaning towards efficiency and customization, companies that align themselves with partners who understand these nuances are poised to thrive. Research has shown that brands prioritizing custom product offerings and quick turnaround times tend to outperform those using generic equipment—making the selection of a specialized manufacturer not just a choice, but a strategic imperative.

For brand managers, sourcing specialists, and business development executives evaluating new partners in the padel market, consider the following action steps:

-

Analyze your product needs concerning material quality and design specifications. Ensure that your potential partner can offer diverse material options and precise engineering to meet these needs.

-

Evaluate customization capabilities. Verify that the manufacturer can deliver tailored solutions—from racket shapes (Diamond, Round, Teardrop) to branded customization on hand grips and other accessories.

-

Prioritize speed and reliability. In fast-paced markets, the ability to prototype rapidly and deliver consistently is crucial. Ask potential partners about their prototyping timelines, QC processes, and supply chain strategies.

-

Assess track records. Look for case studies or customer testimonials that demonstrate a manufacturer’s ability to meet deadlines and maintain product quality under high-volume conditions.

-

Engage directly. A personal discussion or factory visit can provide insights that numbers on paper cannot. Establish clear communication channels to ensure your brand’s vision is fully understood and implemented.

Following these recommendations will help you make an informed decision and build a long-term, successful partnership.

Choosing the right padel equipment manufacturer is a strategic decision—one that can redefine your brand’s market position. By focusing on key aspects such as technical expertise, advanced materials, customization flexibility, rapid prototyping, and reliable delivery, you can unlock greater market success. NEX Padel stands out in these areas, evidenced by our refined production methods, extensive customization options, and proven track record with industry leaders.

For your brand, partnering with a dedicated, innovative manufacturer not only ensures product excellence but also empowers you to meet the evolving expectations of padel players worldwide. Embrace the competitive edge and let your brand soar by choosing a partner who understands both the art and science of high-performance padel equipment.

-

What are the benefits of using custom padel rackets for a brand?

Custom padel rackets enable brands to create unique product identities through personalized design options, improved performance characteristics, and enhanced customer engagement while ensuring quality and durability. -

How does advanced material selection impact padel racket performance?

Advanced material choices such as glass fiber and varied carbon fibers (3k, 12k, 18k) improve racket strength, weight distribution, and durability, offering players tailored performance that meets different play styles and performance levels. -

Why is rapid prototyping critical in padel equipment manufacturing?

Rapid prototyping reduces time-to-market by allowing quick evaluation and iteration of designs, ensuring that final products meet quality standards and consumer expectations, which is crucial for competitive market positioning.

-

customization options: Click to discover how tailored product features can enhance brand identity and meet specific market demands. ↩ ↩

-

glass fiber: Click to read more about the properties, applications, and benefits of using glass fiber in high-performance sporting goods. ↩ ↩ ↩2 ↩3

-

quality assurance: Click to explore methods and protocols for ensuring high-quality production standards in manufacturing. ↩ ↩

-

rapid prototyping: Click to learn about the process and advantages of rapid prototyping in reducing time-to-market for new product designs. ↩ ↩

-

supply chain: Click to understand how an efficient supply chain can streamline production, optimize delivery, and mitigate business risks. ↩ ↩