When choosing a private label padel OEM1 partner, key factors include product quality, customization capabilities, production lead time, and competitive pricing. NEX Padel meets these needs by offering advanced manufacturing techniques2, full customization options3, and efficient delivery for high-performance padel equipment.

In today’s competitive sports retail and distribution market, selecting a reliable OEM partner is critical for brands aiming to differentiate their private label padel products. Many procurement managers and brand owners face the dilemma of choosing a manufacturer that not only delivers high-quality products but also supports extensive customization, efficient production schedules, and robust quality control measures4.

NEX Padel is positioned as a leading manufacturer in this space. With decades of cumulative expertise and a focus on precision engineering, our production facilities in Jiaxing, Zhejiang, China leverage the latest technological advancements to produce high-performance padel rackets and specialized padel balls. Furthermore, our flexible approach enables us to meet the diverse needs of retailers and brand owners enthusiastically seeking to expand their product lines.

One of the major challenges and opportunities in private label padel production is the ability to offer diverse customization options. Brands want to create products that not only meet the performance standards demanded by players but also stand out in terms of design and branding. NEX Padel addresses this need through multiple avenues:

-

Material Variety – We work with materials ranging from high-quality fiberglass to carbon fibers such as 3k, 12k, and 18k. This variety allows us to tailor the manufacturing process to the specific performance and pricing needs of our clients.

-

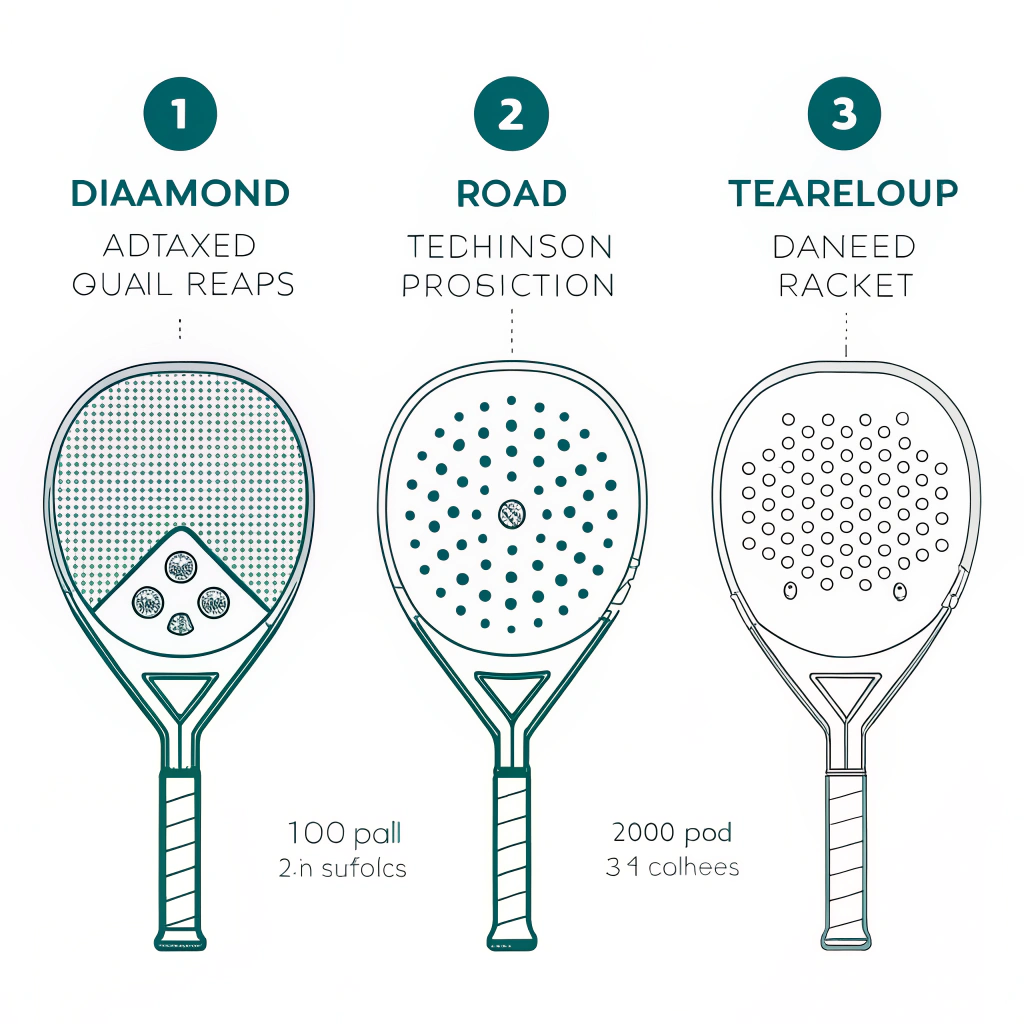

Shape Customization – Our production line is capable of producing three distinct padel racket types—Diamond, Round, and Teardrop. Additionally, full-shape customization is available to support unique design concepts that align with a brand’s identity.

-

Branding Options – Beyond the base product, we offer customized printing and color options, as well as tailor-made hand grips and handle covers featuring custom logos. This comprehensive approach to branding ensures that our OEM partners can achieve a truly differentiated product.

NEX Padel utilizes advanced production techniques that include cutting-edge carbon fiber processing and strict quality control measures. These factors guarantee that every product that leaves our facility not only meets but often surpasses industry standards.

The shape of a padel racket significantly influences its performance on the court. Understanding the differences between the types of rackets available can help procurement managers make informed decisions that best meet the playing styles and market positioning of their brands.

- Diamond Shape: This design focuses on providing maximum power and precision, typically favored by advanced players who demand high performance even in challenging match conditions.

- Round Shape: The round shape offers a balanced approach, providing a blend of power, control, and comfort. This versatile design can appeal to a wide range of players.

- Teardrop Shape: Bridging the gap between the diamond and round designs, teardrop rackets combine top-tier power with enhanced maneuverability. They are often preferred by players looking to exploit both offensive and defensive tactics effectively.

By offering various shapes, we ensure that our partners can cater to different market segments. The ability to select and customize based on shape—and further personalize with material or branding options—provides a competitive edge in a crowded market.

For any OEM in the sports equipment industry, maintaining a high level of quality while ensuring timely delivery are non-negotiable essentials. At NEX Padel, our commitment to quality is evident in our rigorous production process. The stringent quality control measures are applied at every stage of manufacturing, from material selection to final inspections. This diligence minimizes the risk of defects and reinforces the trust that our clients place in us.

- Advanced Production Techniques: Utilization of automated systems and state-of-the-art machinery to ensure precision and consistency.

- Rigorous Testing: Each batch of products undergoes thorough physical and performance tests, ensuring that the products meet specified industry standards.

- Continuous Improvement: Feedback loops from our OEM partners and market performance data help us continuously refine our production processes.

Moreover, our strategic location in Jiaxing enables us to offer rapid production cycles5 and flexible scheduling. For businesses that prioritize fast turnaround times, this capability is a clear advantage over many competitors in the B2B sports supplier domain.

When evaluating potential manufacturing partners for private label padel equipment, procurement managers need a clear view of how each partner performs in critical areas. The table below offers a side-by-side comparison of key factors between NEX Padel and typical competitors in the market.

| Factor | NEX Padel | Competitor A | Competitor B |

|---|---|---|---|

| Customization Options | Full shape customization (Diamond, Round, Teardrop, and bespoke shapes) with branding, custom paints, and accessories. | Limited to standard models with minimal customization. | Moderate customization with preset models. |

| Material Quality | High-grade fiberglass to multi-k carbon fibers (3k, 12k, 18k) ensuring durability and precision. | Uses standard materials that may lack high performance characteristics. | Similar high-level materials but less variety. |

| Production Lead Time | Streamlined processes allow for rapid turnarounds and flexible production schedules. | Longer lead times due to less efficient production systems. | Competitive but subject to supply chain delays. |

| Quality Control | Advanced quality control with stringent testing and continuous improvement process. | Basic QC ensuring only minimal standards are met. | Standard QC, occasional inconsistencies. |

| Pricing Structure | Competitive pricing with transparent cost models and volume-based discounts. | Higher costs, often with less pricing flexibility. | Variable pricing but potentially less cost-effective for large orders. |

This table underscores why NEX Padel is an attractive choice for those looking to invest in a long-term, reliable manufacturing partner. The combination of innovative technology, expansive customization capabilities, and efficient production lead times differentiates us from many competitors.

Beyond production capabilities, the strategic use of custom padel products as a marketing differentiator cannot be understated. Brands that successfully incorporate tailored padel equipment into their product lines can position themselves as leaders in innovation and quality. Here are several strategies that underline the market value of custom padel products:

-

Elevating Brand Identity: Customization enables brands to showcase their identity through unique color schemes, logos, and product designs. This differentiation adds value in the eyes of both players and fans.

-

Product Line Diversification: A wide range of customizable options allows brand owners to cater to niche market segments. For example, offering variations in racket shape and materials can satisfy both professional athletes and casual players.

-

Enhanced Customer Engagement: Custom products tend to create buzz and increase customer engagement. When players see equipment that aligns with their preferences and style, it enhances overall brand loyalty and recognition.

NEX Padel’s full customization capability means we work closely with our OEM partners to help them innovate. The collaborative process ensures that every product aligns with the brand’s vision while meeting the high demands of performance and durability expected in padel sports.

A number of well-known brands have already forged successful partnerships with NEX Padel. For instance, global names such as Hirostar, Reebok, and Starvie have leveraged our expertise in contract manufacturing to create custom products that resonate with their target customers.

One leading sports retailer was facing stiff competition and sought a way to stand apart from market rivals. By partnering with NEX Padel, they were able to:

- Introduce a new line of custom padel rackets featuring proprietary design elements.

- Benefit from fast production cycles and maintain a steady market supply.

- Gain access to exclusive customization features, including bespoke grip designs and innovative material combinations.

This case exemplifies how a strong OEM partnership can significantly boost a brand’s competitiveness and market share, making NEX Padel a trusted ally in the journey toward excellence in sports equipment manufacturing.

In summary, when deciding on a partner for private label padel equipment, it is essential to consider the full spectrum of factors that affect both product quality and market success. NEX Padel stands out with its advanced production technologies, extensive customization capabilities, rapid production cycles, and rigorous quality control measures.

Procurement managers and brand owners should:

- Evaluate material quality and customization options.

- Compare lead times and production efficiency.

- Consider the flexibility of production processes and the ability to maintain quality consistency.

- Look at success case studies as benchmarks for potential outcomes.

By aligning with a proactive and innovative manufacturer like NEX Padel, businesses can not only secure a reliable supply chain but also leverage their products as unique selling propositions in a competitive market. The comprehensive support from our advanced manufacturing processes ensures that every custom padel product meets the high standards required by elite athletes and discerning customers alike.

Taking the next step means engaging in a detailed consultation to discuss your specific needs. Let us work together to design a padel product portfolio that elevates your brand and meets market demands with precision and excellence.

Q: What customization options do private label padel products offer?

A: Private label padel products offer extensive customization options including full shape design (Diamond, Round, Teardrop, or bespoke designs), custom color schemes, logo placement, personalized hand grips, and specialized printing, ensuring that each product aligns with your brand identity.

Q: How does NEX Padel ensure product quality?

A: NEX Padel employs advanced production techniques, high-quality materials (from fiberglass to various grades of carbon fiber), and rigorous quality control measures throughout the manufacturing process, ensuring every product meets strict performance and durability standards.

Q: What production lead time can one expect when partnering with NEX Padel?

A: With streamlined manufacturing processes and flexible scheduling, NEX Padel provides fast turnaround times and efficient production lead times, ensuring a reliable and timely supply for your private label padel products.

-

OEM: Read more to understand the role and benefits of collaborating with an Original Equipment Manufacturer (OEM) in streamlining production processes and ensuring product quality. ↩ ↩

-

advanced manufacturing techniques: Learn about the innovative methods that drive efficiency and precision in production, helping to boost competitiveness in the market. ↩ ↩

-

full customization options: Discover the advantages of offering tailor-made solutions in product design and functionality to meet diverse brand requirements. ↩ ↩

-

quality control measures: Explore the systematic processes that ensure every product meets rigorous industry standards for durability and performance. ↩ ↩

-

rapid production cycles: Find out how shortening production times can enhance supply chain efficiency and responsiveness, providing a competitive edge. ↩ ↩