Custom-made padel paddles are produced by NEX Padel using advanced materials, precision engineering1, and extensive customization options that meet diverse brand requirements. In this article, we explore the common challenges faced by purchasing managers and product development leads, analyze why high-performance padel paddles are essential for sports equipment brands, and provide actionable solutions based on our proven manufacturing expertise.

In today’s competitive sports equipment market, brands need to stand out with products that not only deliver performance on the padel court but also reflect their unique identity. Custom padel paddles give brands the opportunity to create a signature product that resonates with their market. However, the process of selecting the right supplier can be challenging because it involves many factors:

• Ensuring consistent quality through advanced production techniques2

• Maintaining precise engineering for optimal gameplay

• Achieving fast turnaround times for rapid prototyping and timely delivery

• Accommodating a wide range of customization features, from shape specifications to custom printing and grip options

These challenges make it critical for purchasing managers to partner with a supplier who understands the intricacies of manufacturing high-performance padel paddles, while also being responsive to market demands and regulatory standards.

When considering a custom-made padel paddle supplier, brands face several common issues:

-

Material Selection and Production Variability:

Many manufacturers struggle to maintain quality between batches. In the case of padel paddles, consistency in structural integrity is vital. Advanced materials like glass fiber and various grades of carbon fiber (3k, 12k, 18k)3 need to be processed correctly to deliver the high durability and performance expected by athletes. -

Customization Complexity:

Padel paddles can be tailored in multiple dimensions – from the overall shape (Diamond, Round, or Teardrop) to the finer details such as custom printing, color schemes, and even logo placements on both paddle surface and accessories (hand grip and handle cover). Without a flexible production line, achieving this level of detail can be problematic. -

Time-to-Market Pressures:

For sports equipment brands, speed is of the essence. Prolonged lead times can lead to missed market windows, affecting brand competitiveness. Suppliers must therefore strike a balance between customization and accelerated production capabilities. -

Quality Assurance and Reliability:

For a high-performance product like a custom padel paddle, the criteria for performance and durability are non-negotiable. This requirement demands strict quality control measures throughout the manufacturing process, ensuring that every product delivered meets industry standards.

NEX Padel addresses these issues head-on, using advanced production techniques and a robust quality management system to ensure that every custom order meets the high standards required by our renowned B2B partners.

At NEX Padel, we have honed our craft to provide a full spectrum of customization options designed to suit the needs of diverse sports equipment brands. Our production methods integrate precision engineering with modern manufacturing techniques to offer a competitive edge. Key solutions include:

We work with a range of materials that allow for performance optimization based on player needs and brand specifications. These include:

- Glass fiber: Providing reliable flexibility and strength for entry-level to mid-tier performance.

- Carbon fiber (3k, 12k, 18k)3: Delivering varying degrees of stiffness and weight, these options are ideal for professional players and high-performance products.

The ability to choose between these materials ensures that each racket is perfectly balanced for strength, weight, and performance.

Our in-house design team can create padel paddles in any required shape. Commonly requested shapes include:

- Diamond: Known for power and a more angular, aggressive look.

- Round: Favored for its control and balanced play.

- Teardrop: Offering a mix of power and precision, it provides versatility suited to various playing styles.

Furthermore, we support completely bespoke shapes based on your brand’s design philosophy. To simplify the decision-making process, see the table below for an overview of our paddle shapes and their key performance characteristics:

| Paddle Shape | Key Benefits | Recommended For |

|---|---|---|

| Diamond | Enhanced power, aggressive hits | Advanced offensive players |

| Round | Improved control and maneuverability | All-level players |

| Teardrop | Balanced performance, versatile use | Intermediate to advanced players |

Beyond shape and material, every detail of your custom padel paddle can be personalized. Our services include:

- Custom Printing and Colors: Tailor the color scheme and print custom logos on the paddle surface to reinforce brand identity.

- Custom Hand Grip and Handle Cover: Personalize with logos or specific color accents to ensure even the accessory components reflect your brand.

- Full Customization Order: Whether you need a standardized series or a truly bespoke order, we are equipped to meet diverse demands.

This level of customization is essential not only to differentiate your product but also to engage your target customers with a unique branded experience.

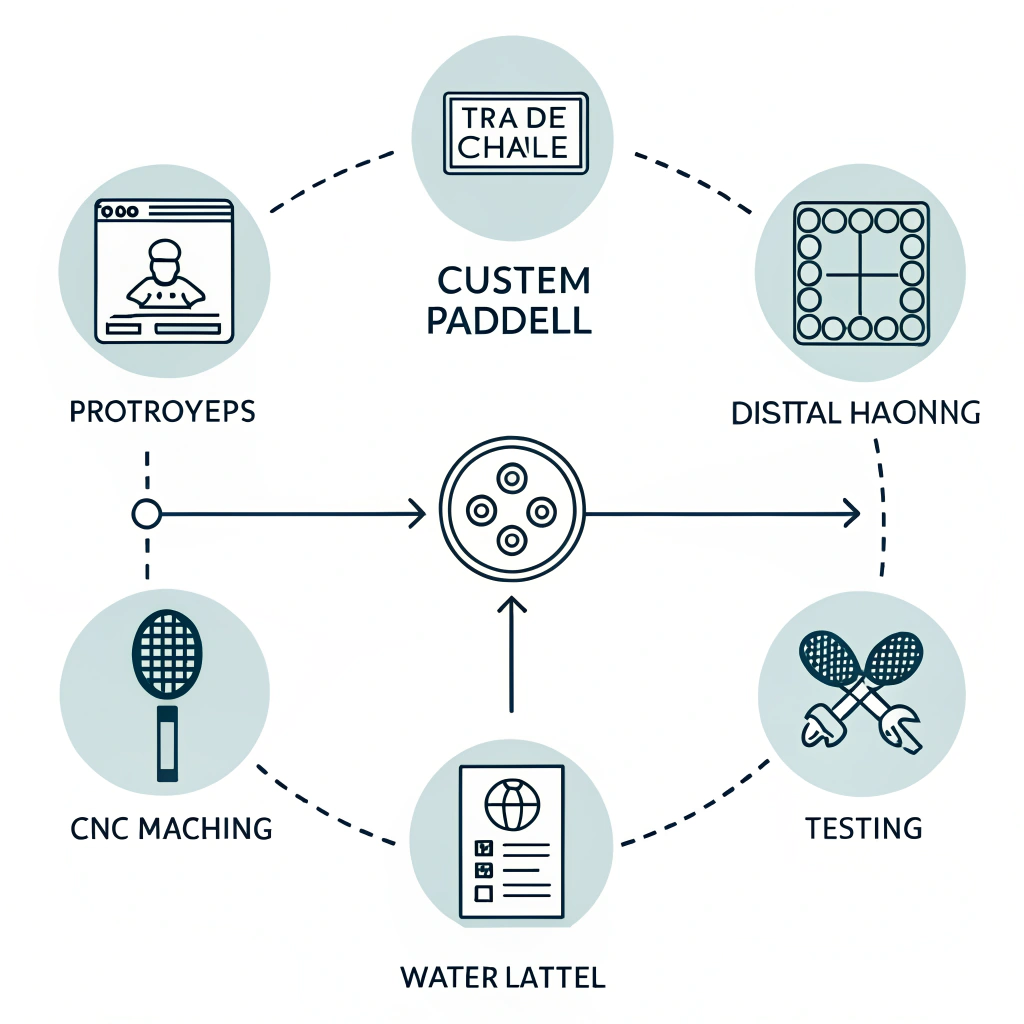

Choosing NEX Padel as your custom-made padel paddle supplier means simplifying the complex process of product design and production. Our strategy is based on clear, transparent steps that ensure rapid prototyping4, quality assurance, and timely delivery. Below is a step-by-step guide to our process:

-

Initial Consultation and Requirements Gathering:

We start by understanding your specific needs. Our team works closely with you to define product specifications including material selection, paddle design (Diamond, Round, Teardrop, or bespoke), and customization elements like printing and accessories. -

Design Prototype and Technical Specifications:

We develop digital models and technical drawings based on your inputs. Once the design is approved, we prepare detailed production blueprints that lay out all specifications with precision. -

Rapid Prototyping and Testing:

Leveraging our advanced manufacturing techniques, we produce prototypes using the chosen materials. Every prototype undergoes rigorous testing to ensure it meets performance standards and quality metrics. This stage is crucial for detecting and rectifying any design misalignments early on. -

Quality Assurance and Production:

After final approval of the prototypes, full-scale production begins. Our quality assurance5 team implements tracking and testing systems to ensure that every paddle adheres to our strict quality standards. -

Timely Delivery and After-Sales Support:

We understand the importance of speed in the sports equipment market. Therefore, we have optimized our logistics to guarantee swift deliveries. Furthermore, our after-sales support team stands ready to address any issues or customization tweaks post-delivery.

The following table summarizes our key process phases with estimated timelines and benefits:

| Process Phase | Estimated Timeline | Key Benefits |

|---|---|---|

| Consultation & Requirements Gathering | 1-2 Weeks | Tailored product design aligned with brand needs |

| Prototyping & Testing | 2-3 Weeks | Rapid iteration ensuring high quality and performance |

| Full Production | 3-4 Weeks | Consistency and precision in every custom-made paddle |

| Delivery & Support | 1-2 Weeks | Timely shipping and reliable after-sales service |

This structured approach guarantees that you can confidently plan your product launch, knowing that every stage of the production process is managed with expertise and precision.

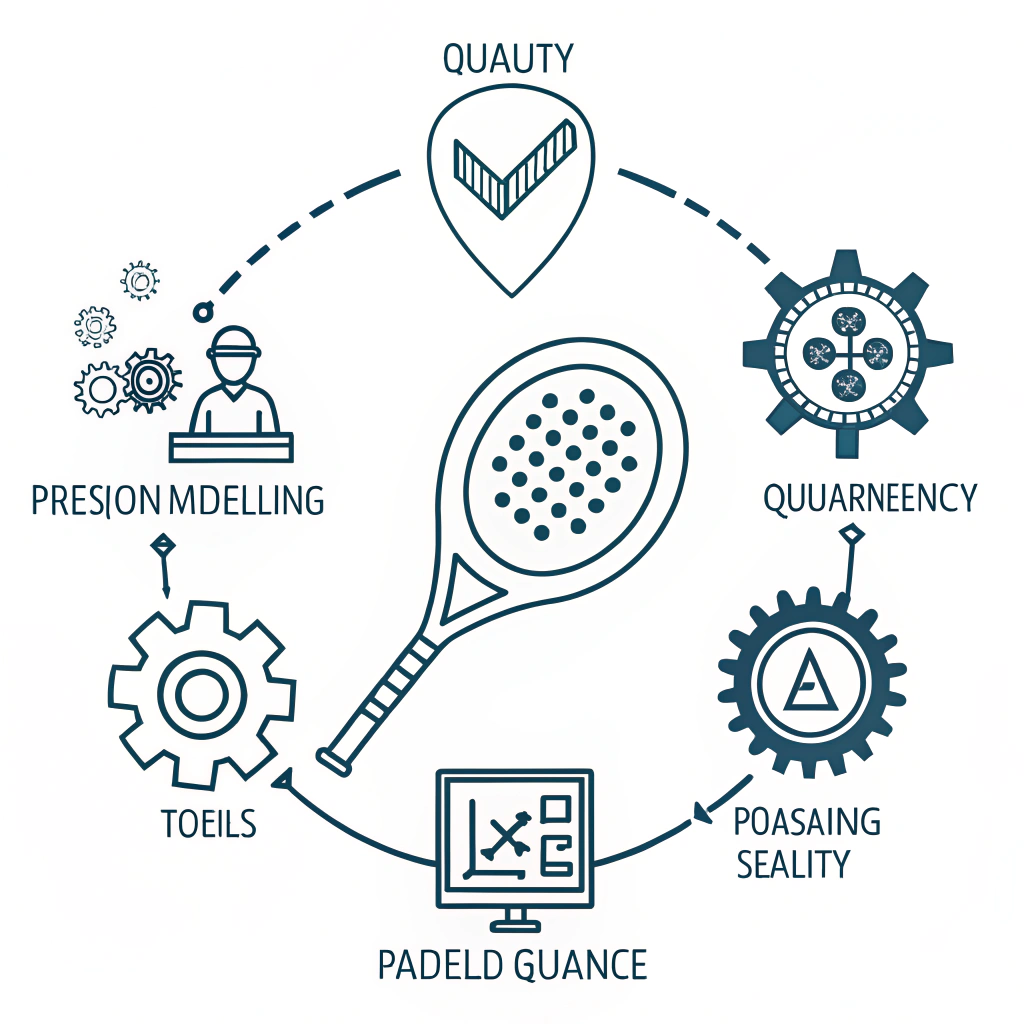

Quality assurance is at the heart of our operations at NEX Padel. Our production facilities in Jiaxing, Zhejiang, China are outfitted with state-of-the-art machinery and managed by a team with deep expertise in advanced carbon fiber and composite material technology. Key elements include:

-

Rigorous Testing Protocols:

Each batch of paddles is subjected to comprehensive strength and durability tests. Our testing ensures that every product is reliable on the court, with no compromise in performance even under high-pressure scenarios. -

Precision Engineering:

Our production process integrates digital modeling and advanced CNC machining, which significantly reduces variability. This precision engineering approach guarantees that every paddle meets high-performance benchmarks. -

Industry Certifications:

By adhering to international quality standards and industry certifications, we provide not only a product but also assurance that our paddles comply with rigorous safety and performance regulations. This is critical when forming long-term partnerships with global sports brands who seek consistent quality. -

Continuous Process Improvement:

Innovation guides our work—our R&D department continually explores enhancements in production techniques, ensuring that NEX Padel remains at the forefront of the custom sports equipment manufacturing industry.

Consider a leading sports brand that needed a unique padel paddle to distinguish itself in a saturated market. By partnering with NEX Padel, they achieved:

• A fully customized paddle design that aligned with their brand identity

• Utilization of high-grade carbon fiber for durability and optimal weight distribution

• Tailored enhancements, including custom printing and personalized grip design

• A rapid turnaround from prototyping to full production, enabling a timely market launch

As a result, the brand not only improved its product performance but also reinforced its market position with a distinct, quality-assured offering. This case study demonstrates the value of partnering with a specialized supplier who can deliver on both technical and branding fronts.

The market for padel paddles is evolving rapidly, and your brand’s success hinges on both performance and unique brand expression. At NEX Padel, our commitment to precision engineering, advanced material usage, and comprehensive customization solutions ensures that your custom-made padel paddles will meet and exceed market expectations.

To recap, by choosing NEX Padel as your supplier you gain:

• Access to advanced production technologies and materials

• A flexible, step-by-step process that minimizes risks and speeds up market delivery

• Outstanding quality assurance backed by rigorous testing protocols

• Comprehensive customization that allows full brand expression

We invite you to take the next step in elevating your brand’s product portfolio. Contact us to discuss your custom padel paddle needs and explore how our solutions can help secure your competitive edge in the dynamic sports equipment market.

Q1: What are the benefits of custom-made padel paddles for sports equipment brands?

A1: Custom-made padel paddles allow brands to differentiate themselves with precise engineering, tailored designs, and high-quality materials. This customization reinforces brand identity and improves on-court performance with a product built specifically to meet unique market needs.

Q2: How do advanced materials like carbon fiber enhance padel paddle performance?

A2: Advanced materials such as various grades of carbon fiber improve paddle strength, durability, and weight balance. These materials ensure that paddles provide superior performance and longevity, catering to both amateur and professional players.

Q3: What customization services does NEX Padel offer for padel paddle production?

A3: NEX Padel provides comprehensive customization options including the selection from Diamond, Round, and Teardrop paddle shapes, custom printing and color schemes, and personalized accessories like hand grips and handle covers. This flexibility allows brands to create a product that truly reflects their identity.

-

precision engineering: Click to learn how precise measurement and advanced manufacturing processes enhance product performance and reduce variability in production. ↩

-

advanced production techniques: Click to explore modern manufacturing methods that streamline production, ensure consistency, and minimize defects in custom products. ↩

-

carbon fiber (3k, 12k, 18k): Click to understand the different grades of carbon fiber, their material properties, and how each impacts durability and performance. ↩ ↩2

-

rapid prototyping: Click to discover how iterative design and testing methods accelerate product development, reduce time-to-market, and improve overall quality. ↩

-

quality assurance: Click to read about strategies and standards used to maintain product integrity, meet regulatory requirements, and ensure customer satisfaction. ↩