Inertial properties1 are critical to optimizing padel racket performance by influencing swing speed, balance, and overall control, making them a key consideration for both design engineers and procurement managers.

In padel rackets, inertial properties—primarily the moment of inertia2 and the mass distribution—play a crucial role in determining how the racket responds during play. These properties govern how the racket accelerates, how it handles sudden direction changes, and even how stable it is during impact. For manufacturers and procurement professionals, understanding the impact of these factors is essential to meet performance specifications and design requirements.

In physics, inertia is a measure of an object's resistance to change in its motion. In padel rackets, this is primarily quantified as the moment of inertia, representing how the mass is distributed relative to the pivot point. A higher moment of inertia generally means the racket is more resistant to twisting and offers greater stability during impact, yet it might also reduce maneuverability. Conversely, a lower moment of inertia can enhance swing speed and rapid adjustments, but may compromise control and shock absorption.

Understanding inertial properties leads to a clearer grasp of why different racket designs like Diamond, Round, or Teardrop feel distinct on the court. Each design strategically manipulates mass distribution to cater to different playing styles, from those requiring rapid wrist action to players who prioritize anchoring stability for power strokes.

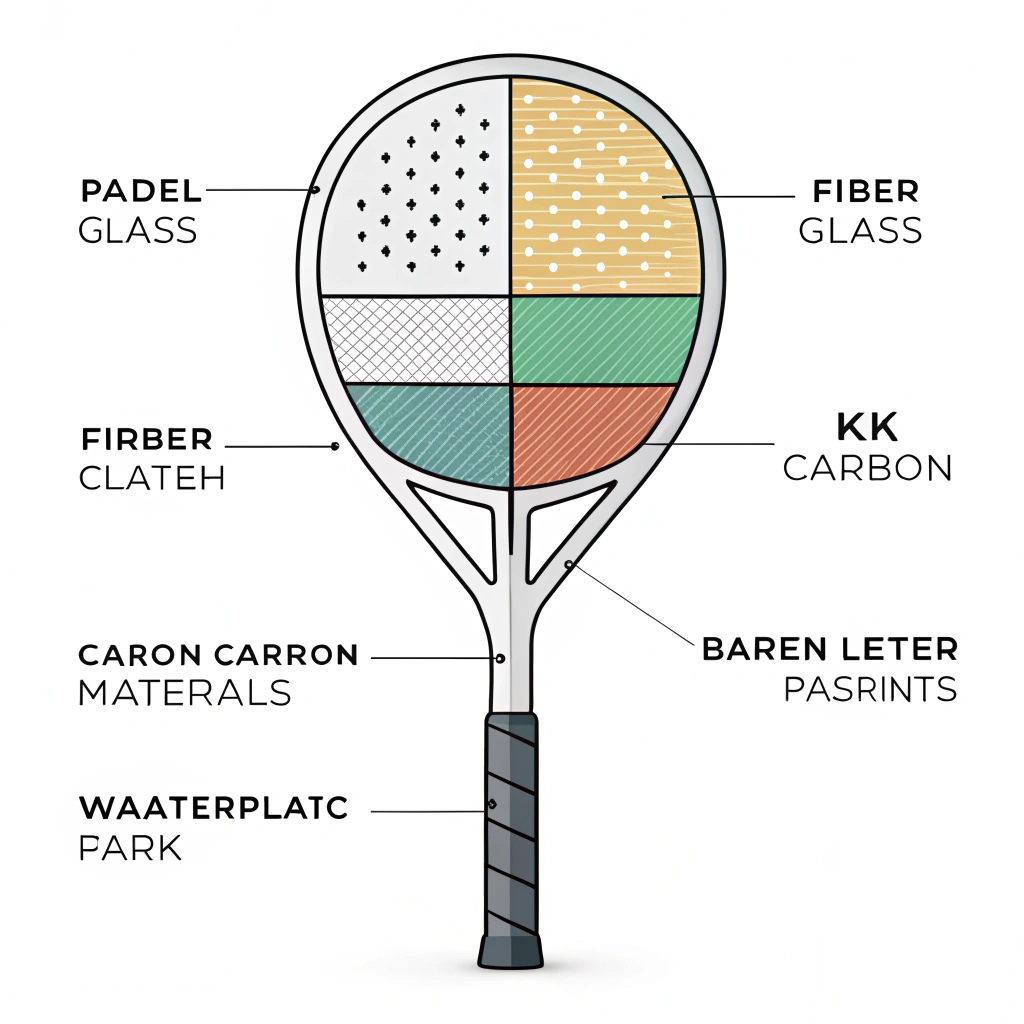

The materials used in padel rackets have a profound influence on their inertial characteristics. At NEX Padel, we use a range of materials from fiberglass to various grades of carbon fiber3 such as 3k, 12k, and 18k. Each material offers unique benefits:

- Fiberglass: Provides a more forgiving feel, often used in entry-level models. However, it can lack the stiffness required for optimal power transmission.

- 3k Carbon Fiber: Balances lightness and durability, making it a popular choice for intermediate models.

- 12k and 18k Carbon Fiber: Offer increased stiffness and impact resistance. These are typically featured in high-performance rackets aimed at professional players.

These materials are carefully selected based on their ability to affect the mass distribution and stiffness of the racket. The production process, involving advanced molding and curing techniques, ensures consistency and durability. This precision engineering helps optimize the inertial properties by minimizing unwanted vibrations and ensuring that energy transfer from the player to the ball is efficient.

| Material Type | Weight Impact | Stiffness Level | Fatigue Resistance | Typical Usage |

|---|---|---|---|---|

| Fiberglass | Heavier | Lower | Moderate | Entry-level rackets |

| 3k Carbon Fiber | Lightweight | Moderate | High | Intermediate performance |

| 12k Carbon Fiber | Lightweight | High | Very High | Professional rackets |

| 18k Carbon Fiber | Ultra-lightweight | Very High | Extremely High | Top-tier performance |

Choosing the right material directly impacts the inertial properties. For instance, the superior fatigue resistance and stiffness of 18k carbon fiber contribute to a more stable yet responsive design. This makes it ideal for players who demand rapid energy transfer and minimal vibration on impact.

The design of a padel racket is not only about aesthetics; it’s deeply intertwined with the functional aspects dictated by inertial properties. Modern racket designs incorporate intricate details that allow manufacturers to customize the balance point, which can be adjusted by modifying the placement of reinforcements or using different composite layering techniques.

Different shapes affect the mass distribution:

- Diamond-shaped rackets typically concentrate more mass at the top. This increases the moment of inertia, offering enhanced power but possibly reduced maneuverability.

- Round-shaped rackets provide more evenly distributed mass, resulting in improved control and forgiveness on off-center hits.

- Teardrop-shaped rackets combine both power and control features by achieving a middle ground in mass distribution.

The overall balance of the racket is a result of clever engineering combined with precise production techniques. Manufacturers can modify the inertial properties by adjusting:

- Weight distribution along the racket’s head and handle.

- Density and layering of carbon fiber, which can be customized further with different weave patterns.

- Integration of dampening materials to reduce vibration and improve comfort.

| Racket Shape | Target Player Type | Key Inertial Focus | Recommended Material Choices |

|---|---|---|---|

| Diamond | Aggressive players needing power | High moment of inertia | 12k/18k Carbon Fiber with reinforcement |

| Round | Versatile players valuing control | Even mass distribution | 3k/12k Carbon Fiber blend |

| Teardrop | All-round players | Balanced power and control | Custom mix, potential for full customization |

This table serves as a guide to help B2B buyers understand how design choices directly relate to performance. Decision-makers can align their procurement strategies with the specific needs of their target customer base, ensuring that product offerings meet performance and market demands.

At NEX Padel, we pride ourselves on using advanced production techniques4 to achieve precision and durability in our rackets. These methods include:

- Rapid Prototyping: We can quickly produce multiple prototypes using state-of-the-art 3D modeling and CNC machining5. This allows for iterative testing of inertial properties and balance optimizations.

- Custom Molding and Layering: Each racket is produced with fine-tuned composite layers that can be customized for specific inertial attributes. Our processes ensure that the carbon fiber layers—whether 3k, 12k, or 18k—are optimally aligned for consistent performance.

- Quality Monitoring: Rigorous testing protocols are in place to measure fatigue resistance, impact absorption, and even moment of inertia. These tests simulate real playing conditions and confirm that each racket meets strict quality and performance standards.

These production techniques not only improve product performance but also reduce the turnaround time for customized orders. With innovations such as custom-printed designs and personalized grip options, we cater to brands looking to offer unique, high-performance solutions to their clientele.

To further illustrate how our methodologies maintain quality, consider this quality assurance checklist:

- Dimensional accuracy of mass distribution

- Fatigue tests under repetitive impact loads

- Consistency in composite layering and curing

- Customization accuracy for balance point adjustments

- Compliance with international standards for padel rackets

Any deviation in these parameters can significantly alter the inertial response of the racket, which in turn affects player performance. For this reason, every batch is subject to detailed testing and validation.

For every technical decision-maker and procurement manager, it is essential to align your product selection with the specific inertial performance you aim to achieve. Here are some actionable insights:

- Evaluate Material Quality: Understand the differences between fiberglass and various carbon fiber grades. Use our material comparison table as a reference to select a material that meets your specific performance objectives, whether it’s enhanced stiffness or improved fatigue resistance.

- Prioritize Design Customization: Consider the advantages of different racket shapes. For example, if your clientele are power players, opt for a Diamond shape with high moment of inertia. Conversely, for versatility and control, a Round shape might be a better offering.

- Implement Advanced Testing Protocols: Ensure that your procurement includes products that have undergone rigorous testing. Inertial measurement and balance assessment can be critical differentiators in the competitive padel market.

- Focus on Production Efficiency: Look for manufacturers like NEX Padel who integrate rapid prototyping and advanced quality assurance in their production line. This not only helps in reducing lead times but also guarantees that each product meets a high-performance standard.

| Consideration | Impact on Performance | Recommendation |

|---|---|---|

| Material Selection | Affects stiffness and energy transfer | Use high-grade carbon fibers for premium performance |

| Racket Design and Shape | Determines balance and agility | Tailor design to player profile (Diamond for power, Round for control) |

| Quality Assurance Protocol | Ensures consistency and reliability | Adopt products with comprehensive inertial testing |

| Production Techniques | Influences customization turnaround | Partner with a manufacturer employing advanced production methods |

These steps, when incorporated into your procurement strategy, can significantly enhance the performance profile of the padel rackets you offer. By focusing on the inertial properties, you also ensure that every racket aligns with modern demands for precision, control, and durability.

Understanding and controlling the inertial properties of padel rackets is critical for delivering a high-performance product that meets the evolving demands of professional players. From material selection to design optimization using advanced production methods, every detail plays a part in shaping the final product’s capabilities.

As a B2B professional, taking these technical aspects into account enables you to:

- Achieve a balance between power and control.

- Enhance player performance by optimizing mass distribution.

- Ensure your product meets industry standards and consumer expectations.

Our experience at NEX Padel demonstrates that innovation in material engineering and production techniques is the key to creating superior padel rackets. Armed with detailed knowledge and actionable insights, we invite you to explore our range of high-performance rackets and discover how precision engineering meets sports dynamics in every product.

For further discussions on integrating these techniques into your design or procurement process, feel free to reach out to our team for a consultation.

What should I look for in a padel racket?

Look for critical aspects such as grip size, weight, balance, racket handle design, throat integrity, head shape, and core construction. Ensuring these components align with your playing style and performance expectations is crucial.

What is the difference between cheap and expensive padel rackets?

Expensive padel rackets typically use high-quality materials like advanced carbon fiber, resulting in a stronger, lighter, and more responsive racket. In contrast, cheaper rackets may rely on less durable materials such as fiberglass, leading to differences in performance and longevity.

What are the padel racket regulations?

Padel racket regulations generally specify that the racket consists of two main parts: the head and the grip. The dimensions for grip length and thickness, as well as the overall dimensions of the head, are regulated to ensure fair play and standardization in the sport.

-

Inertial Properties: Click to learn how the resistance to change in motion affects racket performance, influencing swing speed, balance, and control. ↩

-

Moment of Inertia: Click to understand how the distribution of mass relative to the pivot affects stability and maneuverability during play. ↩

-

Carbon Fiber: Click to explore the benefits of using various grades of carbon fiber in padel rackets for improved stiffness, durability, and energy transfer. ↩

-

Advanced Production Techniques: Click to learn about modern manufacturing processes that ensure precision, durability, and optimized performance in sporting goods. ↩

-

CNC Machining: Click to read about how computer-controlled machining enhances production accuracy and prototyping speed in the manufacturing industry. ↩