For padel racket selection, you must look closely at design, materials, and advanced customization1 options to ensure your product lineup meets market demands while achieving high performance. Choosing the ideal padel racket requires a balance among shape, carbon fiber2 specifications, production quality, and OEM support3—all essential factors in making a sound purchasing decision.

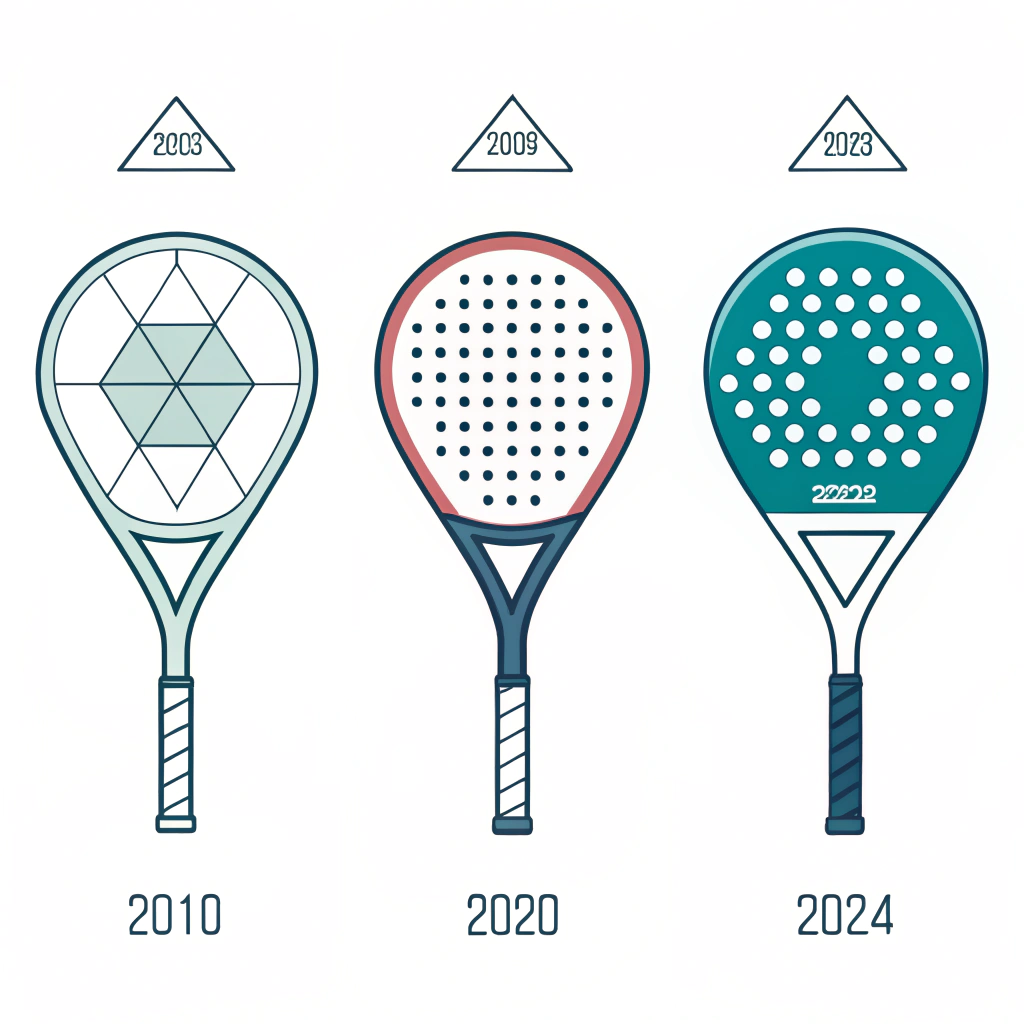

When evaluating padel rackets, the design features are a key differentiator influencing both on-court performance and customer satisfaction. Our high-performance rackets at NEX Padel are engineered to accommodate diverse play styles while maintaining the precision and durability our B2B customers expect. In a competitive landscape, three primary designs are often under consideration: Diamond, Round, and Teardrop. Each shape brings unique performance characteristics:

- Diamond Shape: Typically engineered for players seeking power. The design channels energy efficiently, offering enhanced ball speed and a more aggressive hitting style. However, this can result in smaller sweet spots, demanding precise impact zones.

- Round Shape: Known for ease of use and consistently accessible control. This design provides a larger sweet spot, which is ideal for beginners and intermediate players who value maneuverability and balance during play.

- Teardrop Shape: Strikes a balance between power and control. It is a versatile option given its balanced weight distribution, making it suitable for a varied range of playstyles.

Choosing a shape should be based on your target market’s needs, whether that is high-precision play or an approachable, forgiving design for average players.

When it comes to high-performance padel rackets, the choice of raw materials is critical. Our rackets are crafted using different types of carbon fiber2 – from 3k to 12k and even 18k variants – each catering to specific performance characteristics:

- 3k Carbon Fiber: Provides enhanced flexibility and is often used in rackets geared toward beginners or those who need a more forgiving feel.

- 12k Carbon Fiber: Offers a balance between rigidity and flexibility. This type is common in mid-range rackets where both power and control are required.

- 18k Carbon Fiber: Prioritized for maximum stiffness and minimum vibration, suitable for advanced players who seek extra power and precision while staying within the trade-offs of a smaller sweet spot.

In addition to carbon fiber, our production techniques include advanced quality assurance4 protocols to ensure consistency and reliability across each batch. With state-of-the-art machinery and strict quality standards based in Jiaxing, Zhejiang, China, NEX Padel guarantees that every padel racket is produced to meet global OEM standards and delivery timelines.

Combining expertise in material science with proven manufacturing practices provides our customers with products that excel in terms of both performance and durability.

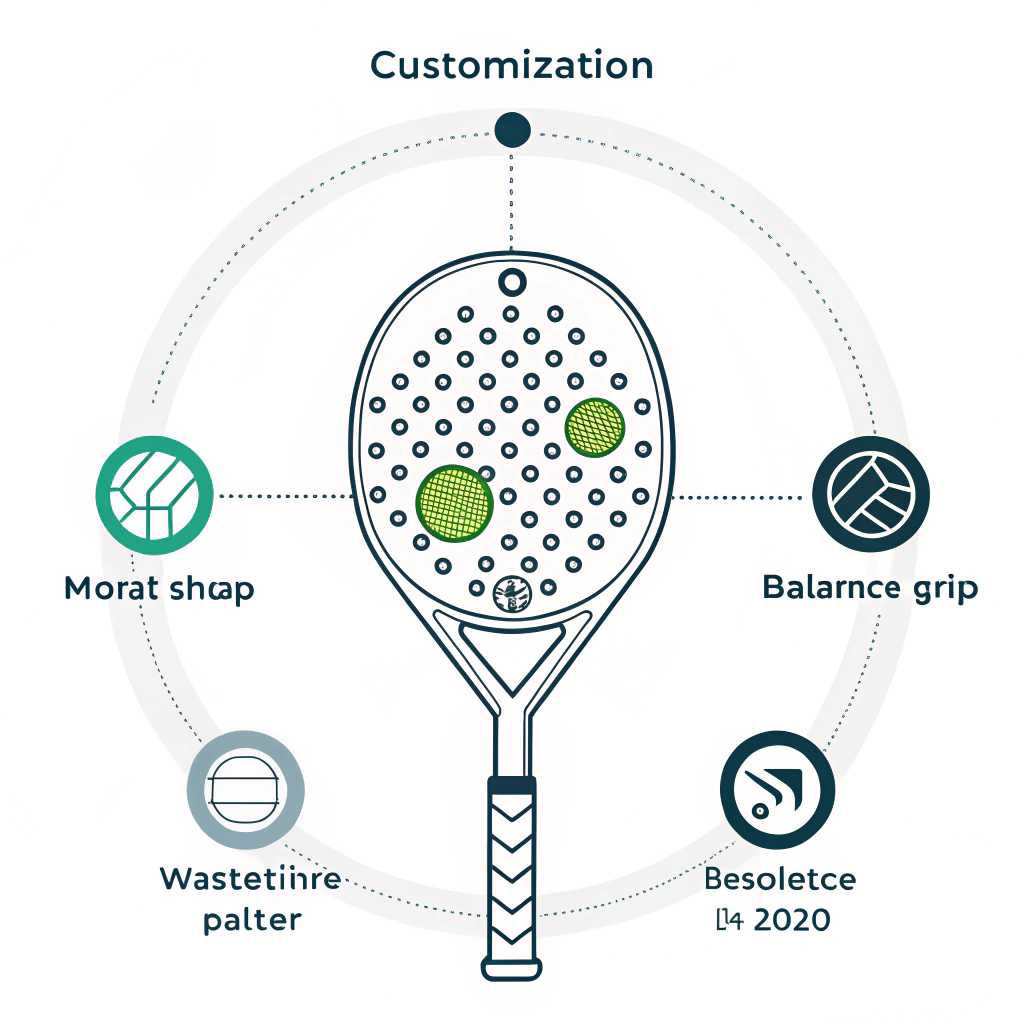

For sports equipment distributors and retail chains, product differentiation through customization is increasingly important. NEX Padel not only supplies high-performance padel rackets but also supports extensive customization services:

- Shape Customization: Beyond our standard Diamond, Round, and Teardrop options, full customization allows brands to modify the racket’s silhouette to create a distinct identity in the market.

- Branding and Aesthetics: Custom imprinting on the body, hand grip (hand gel), and handle caps offers a seamless integration with your brand’s aesthetics. Whether it’s color adjustments or logo placement, our advanced printing techniques deliver professional quality.

- Technical Adaptations: In addition to aesthetic considerations, we understand that specific technical tweaks, such as slight modifications in balance or weight distribution, can lead to significant performance benefits. Our production team works closely with retailers to adapt designs that honor both style and function.

These customization options play a pivotal role in B2B decisions, as distributors can offer unique products that stand out in a crowded market, providing an edge over generic alternatives.

To simplify the decision-making process, the following table summarizes the main differences between the three primary padel racket designs offered by NEX Padel:

| Feature | Diamond Shape | Round Shape | Teardrop Shape |

|---|---|---|---|

| Performance | Power-focused; optimized for aggressive play | Control-oriented; ideal for beginners | Balanced performance; combination of power & control |

| Sweet Spot Size | Smaller; requires precision | Larger; easier to hit consistently | Moderate; offers compromise between precision and forgiveness |

| User Profile | Advanced players seeking power | Intermediate/beginner players needing simplicity | Versatile players looking for balanced play |

| Carbon Fiber Usage | Often paired with 18k for stiffness | Typically utilizes 3k to 12k fibers for flexibility | Can be combined with various carbon fiber grades for balance |

| Customization Potential | High for advanced techniques | High for general modifications | High for both performance tweaks and branding |

This table helps clarify the distinctions most relevant to the decision stage – ensuring that product comparisons center on factors that affect performance outcomes, durability, and market differentiation.

For procurement managers, supply chain reliability is as essential as product quality. At NEX Padel, we prioritize performance consistency coupled with efficient production and delivery systems. Here are a few aspects we excel at:

- High-Performance Manufacturing Techniques: Our production process leverages advanced machinery, ensuring that each padel racket, whether using 3k, 12k, or 18k carbon fiber, meets strict quality standards.

- Speed to Market: Quick prototyping5 and efficient production lines allow us to offer short lead times, which is crucial in fast-paced markets.

- Quality Assurance: Every batch of rackets undergoes rigorous testing and inspection. Our quality assurance processes are designed to catch deviations early, ensuring that only products meeting the highest standards reach our clients.

- OEM Partnerships: By partnering with established brands such as Hirostar, Reebok, and Starvie, we reinforce our capabilities and refine our production techniques, providing a template for success across our product offerings.

These operational strengths are key factors when considering bulk purchasing—ensuring that supply is not only reliable in quality but also timely in delivery, which aligns with strict market schedules.

When you weigh your options for padel rackets, consider the following key factors:

- Design and Playability

- Evaluate whether your target customer base leans more towards power or control. For instance, Diamond-shaped rackets deliver high power with a focused sweet spot, whereas Round shapes are more forgiving and accessible to a wider range of players.

- Material and Durability

- Understand the impact of different carbon fiber2 grades on the racket's performance. Higher carbon fiber counts generally translate to increased stiffness and power but might compromise on ease of handling for less experienced players.

- Customization Capability

- Consider the level of branding required. Customized options can significantly boost your product’s market appeal if executed with precise technical and aesthetic modifications.

- Production Efficiency and Supply Reliability

- Ensure that the manufacturing partner can meet your timelines without sacrificing quality. At NEX Padel, our streamlined production processes and rigorous quality checks ensure that your orders are delivered on time, every time.

- Market Differentiation

- In competitive markets, every detail matters. From the shape and materials to OEM customizations like printings and logo placements, your product should stand out in terms of both technical superiority and aesthetic appeal.

These considerations are the cornerstone of making a well-informed procurement decision. An investment in the right product line is not only a commitment to quality but also a strategic move that can help your brand capture market share.

Choosing the right padel racket for your business involves careful evaluation of design shapes, material choices, production technologies, and customization capabilities. Our detailed comparison and clear understanding of OEM and production efficiency at NEX Padel provide you with a viable solution to meet the diverse needs of today’s padel enthusiasts.

To put it succinctly, advanced material selection such as various grades of carbon fiber2, along with the choice between Diamond, Round, and Teardrop designs, plays a crucial role in the final performance outcome. Coupled with our ability to customize every aspect of the racket—from handle grips to full shape modifications—we equip distributors and retailers with products that not only meet but exceed customer expectations.

If you are in the process of evaluating suppliers or upgrading your product lineup, consider the technical rigour and customization potential behind every product. Our rapid prototyping and short lead times ensure that your supply chain remains robust while maintaining a competitive edge. Take the next logical step and engage with us for a detailed technical consultation or sample order review. With a blend of cutting-edge production technology and deep industry insights, NEX Padel is ready to support your strategic decisions.

We invite you to discuss how our high-performance, customizable padel rackets can align with your business goals. As the market continues to evolve, a partnership with a manufacturer committed to quality and innovation can redefine what your brand offers.

Q: How do I choose the right padel racket for me?

A: Consider the racket’s shape, weight, balance, handle size, and materials. Evaluate if you need a power-focused design (Diamond), a more control-oriented option (Round), or a balanced alternative (Teardrop) to match your playing style and customer needs.

Q: How do I find the right racquet for me?

A: Focus on three key elements: head size, weight, and string pattern. A larger head size typically provides more power, a lighter racket can enhance power while a heavier one may increase control, and the configuration of the string bed influences the balance between power and control.

Q: Do expensive padel rackets make a difference?

A: More expensive padel rackets are generally designed for advanced performance, though they may feature smaller sweet spots and increased stiffness. They are not necessarily better for beginner or intermediate players, as those may benefit more from designs offering easier maneuverability.

-

Customization: Click to learn how tailored modifications can help your business create unique products that better align with market needs and brand identity. Back to customization ↩

-

Carbon fiber: Click to explore the technical properties of carbon fiber, including different grades and their impact on performance and durability. Back to carbon fiber ↩ ↩2 ↩3 ↩4

-

OEM support: Click to understand the benefits of OEM support, including manufacturer collaborations that ensure consistency and reliability in supply chain management. Back to OEM support ↩

-

Quality assurance: Click to read more about quality assurance protocols and how they help maintain high production standards essential for B2B success. Back to quality assurance ↩

-

Quick prototyping: Click to discover the advantages of quick prototyping in reducing lead times and enhancing product development efficiency. Back to quick prototyping ↩