NEX Padel delivers high-performance padel rackets that excel in durability, custom design, and advanced material technology1. Their products, available in Diamond, Round, and Teardrop shapes, incorporate a range of materials—from fiberglass to high-grade carbon fiber2 options (3k, 12k, 18k)—ensuring they meet the rigorous demands of sports equipment distributors seeking innovation and performance.

In today’s competitive sporting goods market, procurement managers face the challenge of selecting a reliable supplier that not only offers top-tier products but also delivers on customization and production precision. At NEX Padel, we understand that every detail—from the racket’s design shape to its raw material composition—plays a critical role in performance and durability. Our comprehensive approach is designed to support B2B sourcing specialists seeking clear, technical specifications and industry benchmarks while comparing suppliers side by side.

One of the key decision criteria is the design of the padel racket. The three main shapes available—Diamond, Round, and Teardrop—each serve specific performance needs.

• The Diamond shape generally offers superior power and a forward center of gravity for aggressive play.

• The Round shape emphasizes balance and control, ideal for versatile players who want ease of handling and maneuverability.

• The Teardrop shape strikes a balance between power and control by offering a slight power bias without drastically affecting maneuverability.

Below is a comparative summary table providing a quick reference for these design options:

| Shape | Primary Benefit | Target Player Type | Design Focus |

|---|---|---|---|

| Diamond | Maximum power | Advanced, aggressive players | Off-center weight for powerful shots |

| Round | Enhanced control | Beginners and defensive players | Central balance for effortless handling |

| Teardrop | Balanced performance | Intermediate players | Combination of power and control |

This table is a quick decision guide for procurement managers who are comparing suppliers based on design options.

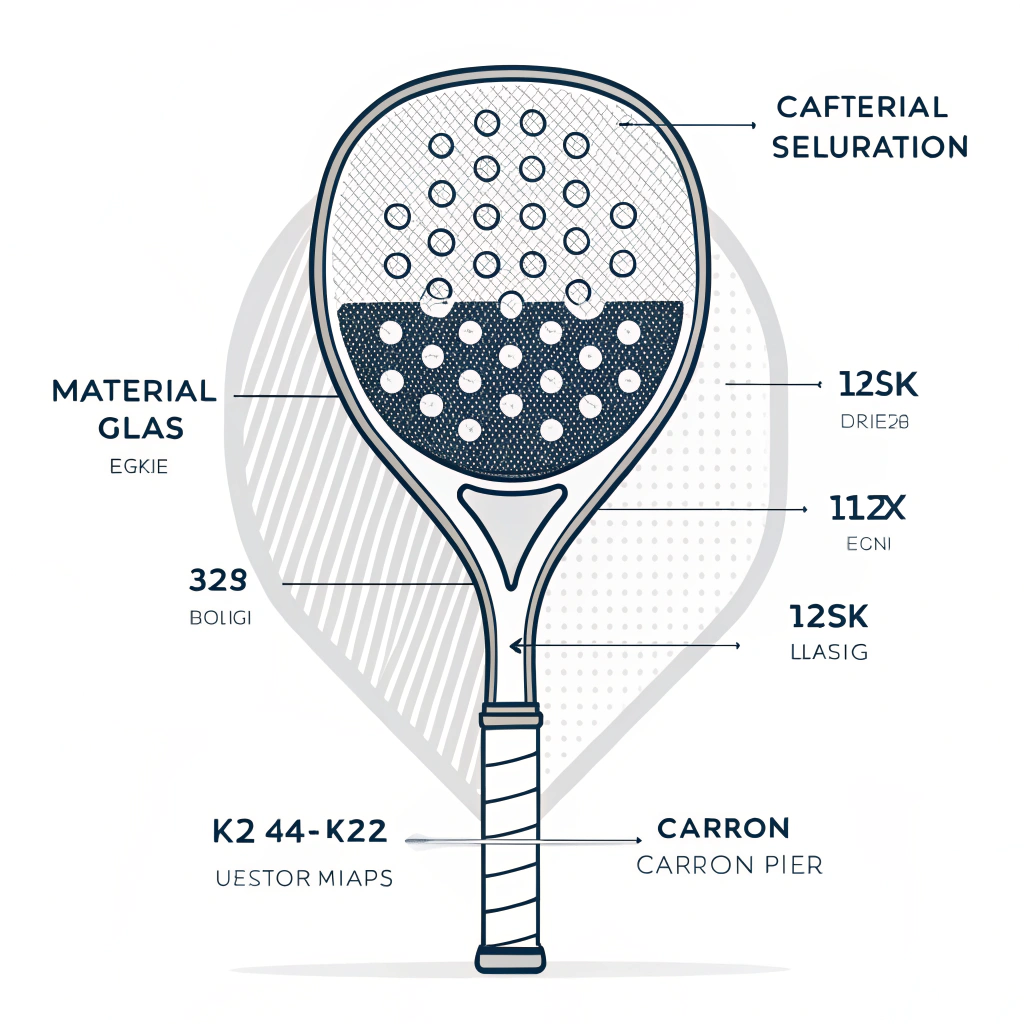

Material selection is another critical factor for padel rackets. NEX Padel’s manufacturing process offers a range of high-performance materials including traditional fiberglass and several grades of carbon fiber—3k, 12k, and 18k. Each material has its unique properties:

• Fiberglass is known for its flexibility and cost-effectiveness while still offering balanced performance.

• 3k carbon provides enhanced stiffness and durability, making it suitable for a wider range of play styles.

• 12k carbon strikes a balance by offering improved rigidity and energy transfer.

• 18k carbon represents the pinnacle of performance, delivering superior compression and weight reduction necessary for top-tier competition.

A detailed understanding of these materials allows procurement managers to assess whether a supplier not only can produce a high-performance product but also adapt their offerings to the target market’s needs.

Customization is equally essential in today’s market. At NEX Padel, our capabilities extend beyond the basic design features. We offer full customization3 including:

• Custom printing on the racket frame, enabling brands to embed their logos and designs directly onto the product.

• Hand grip customization where the hand grip and its cover can be personalized with your logo, ensuring the equipment reflects brand identity and uniqueness.

• Full shape customization allows us to tailor the racket form (including non-standard shapes) based on customer demands, supporting brands that want to stand out in the competitive sports equipment market.

By leveraging customized production techniques, we not only address aesthetic preferences but also enhance the technical performance of the racket. This level of detail is of great value during the solution comparison phase for procurement teams who require precise specifications and robust quality assurance data.

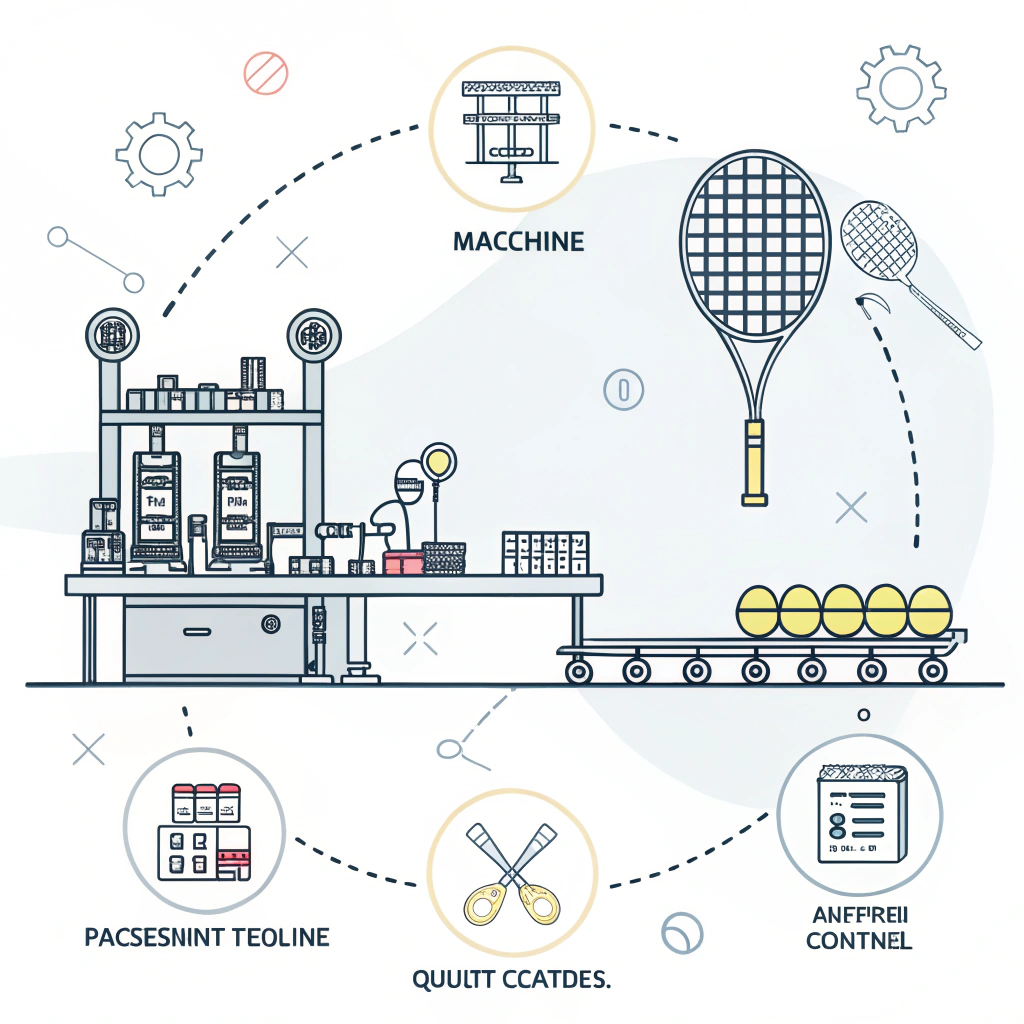

From a production perspective, NEX Padel employs advanced manufacturing processes that ensure rapid prototyping4 and quick turnaround times. Our efficient and agile supply chain is a critical advantage for our B2B partners. Key aspects include:

• Advanced production techniques that integrate precision machining with high-quality material bonding.

• Strict quality control protocols at every manufacturing stage—starting from raw material inspection to final product testing.

• The ability to scale quickly for large orders while retaining high standards across all products.

Below is a simplified table showcasing some of our key production metrics:

| Metric | NEX Padel Standard | Industry Benchmark |

|---|---|---|

| Lead Time | Rapid sampling and quick turnaround (< 3 weeks) | 4-6 weeks average |

| Material Quality Control | Multi-stage inspection (raw to finished product) | Single-stage inspection |

| Customization Capability | Full custom printing & design customization | Limited customization options |

These production insights are essential for procurement managers whose priority is to ensure consistency, quality, and timely delivery of high-performance sports equipment.

Beyond product and production details, the broader industry landscape also influences sourcing decisions. Prominent brands like Hirostar, Reebok, and Starvie have experienced the benefits of our precise engineering and customized production capabilities. This industry recognition serves as an external benchmark, illustrating that our solutions align with the performance and durability expectations of leading sports equipment brands.

Many industry players now focus on material innovation and design versatility. At NEX Padel, our investments in material research and development have led to innovative advancements in the use of carbon fibers. These advancements result in improved racket stiffness, better energy transfer, and overall enhanced performance on the court.

In a competitive market, procurement managers are encouraged to weigh the importance of:

• Material innovation and consistency

• Customized production capabilities and flexibility

• Speed of delivery and responsiveness to market demands

• Proven track record with renowned industry brands

By comparing these aspects against alternative suppliers, purchasing specialists can make more informed decisions that drive both quality and performance for their retail or distribution portfolios.

To assist in evaluating the best supplier for your padel rackets, here’s a multi-dimensional comparison for decision-making:

- Performance and Design:

• Consider how each shape (Diamond, Round, Teardrop) aligns with your customers’ playing styles.

• Evaluate the balance between power and control as well as weight distribution across designs. - Material Quality:

• Assess the advantages offered by fiberglass versus the various grades of carbon.

• Ensure that the composite materials meet long-term durability standards. - Customization and Branding:

• Look for suppliers offering full printing customization, including logo placement on both the FRAME and HAND GRIP.

• Verify that design modifications do not compromise the product’s technical performance. - Production Efficiency and Reliability:

• Ensure suppliers have robust quality control processes in place and can deliver within tight schedules.

• Favor those with proven partnerships with industry brands, signaling reliability in high-volume orders.

A quick decision table for these criteria can help you systematically analyze your supplier options:

| Evaluation Criteria | Key Considerations | NEX Padel Advantage |

|---|---|---|

| Design Options | Variety (Diamond, Round, Teardrop) | Full range with customized shapes available |

| Material Innovation | Fiberglass vs. Carbon grades (3k, 12k, 18k) | Multiple high-grade options with proven performance |

| Customization Capability | Full printing, logo integration on racket/grip | Extensive customization including hand grip logos and bespoke printing |

| Production Efficiency | Lead times, quality control, scalability | Rapid sampling and consistent quality control |

By systematically comparing these aspects, procurement managers can successfully make a decision that aligns with both technical performance and market trends.

Our approach at NEX Padel is not only about matching specifications; it’s about understanding your business requirements and delivering solutions that drive success. The materials we use are carefully tested and verified against industry standards, ensuring that every racket that leaves our production line is built for competitive edge and robust durability.

Looking closely at the customization process, our engineering teams use state-of-the-art machinery and computer-aided design5 tools to achieve precision in every detail. This includes rigorous testing to balance weight distribution and stiffness—a critical factor in providing both powerful and controlled strokes on the court. This level of technical detail and commitment to quality is what differentiates NEX Padel in a crowded market.

For companies looking to partner with a supplier that can provide rapid sample production, rapid turnaround in high-volume orders, and a track record of serving major brands, NEX Padel stands out as a strategic partner. Our commitment to advanced production methodologies not only minimizes risk but also supports ongoing innovation through continuous feedback loops with our B2B customers.

Additionally, our technical support team is available to help answer any product-specific or logistical questions you might have. When evaluators seek detailed technical forecasts or ask for performance validations, our transparent data, backed by rigorous quality assurance protocols, makes decision-making straightforward. It is this clarity and commitment to excellence that builds trust and solidifies long-term partnerships.

In conclusion, when sourcing high-performance padel rackets, procurement managers should consider the full spectrum of performance elements—from design and material innovations to customization capabilities and production efficiencies. NEX Padel offers a comprehensive solution that not only meets but exceeds these standards. Our engineering excellence, combined with extensive customization options and a robust supply chain, positions us as a top choice in the B2B marketplace.

We encourage you to compare these detailed technical specifications and supplier capabilities against your current and prospective vendors. By doing so, you ensure that your final decision is backed by data, deeply aligned with market needs, and set to deliver high performance on every level.

People Also Ask

Q1: What are the key design differences among Diamond, Round, and Teardrop padel rackets?

A1: Diamond-shaped rackets typically offer more power with a higher center of gravity, Round ones emphasize balance and control, and Teardrop designs provide a compromise between power and maneuverability.

Q2: How do material choices like fiberglass, 3k carbon, 12k carbon, and 18k carbon impact performance?

A2: Fiberglass offers flexibility and cost-effectiveness, while 3k, 12k, and 18k carbon fibers increase stiffness, durability, and overall energy transfer. The higher the carbon grade, the lighter and more responsive the racket becomes, enhancing performance and durability.

Q3: What customization options are available for padel rackets in B2B procurement?

A3: Suppliers like NEX Padel offer comprehensive customization including bespoke printing, custom hand grip logos, and even full shape adjustments. These options allow brands to incorporate their unique designs without compromising technical performance.

-

advanced material technology: Read the article to understand how innovative materials improve product durability and performance in demanding sporting environments. ↩ ↩

-

carbon fiber: Read the article to learn about the different grades of carbon fiber, their properties, and how they enhance the racket’s overall performance. ↩ ↩

-

full customization: Read the article to see how bespoke customization options can enhance brand identity and tailor product features to specific market needs. ↩ ↩

-

rapid prototyping: Read the article to discover how rapid prototyping accelerates product development and reduces time-to-market in high-demand industries. ↩ ↩

-

computer-aided design: Read the article to explore how computer-aided design tools enable precise engineering and optimized product performance. ↩ ↩