Selecting the right padel racket is crucial for businesses seeking to enhance their product offerings and meet the high-performance expectations of professional players. In this article, we explore the technical differences between Diamond, Round, and Teardrop racket designs, discuss advanced production techniques like carbon fiber reinforcement1, and explain how custom manufacturing2 from NEX Padel meets diverse market needs with precision and durability.

For B2B decision-makers, evaluating padel rackets involves a careful comparison of design features, material choices, and manufacturing capabilities. At NEX Padel, our expertise in producing high-performance sports equipment with advanced production techniques ensures that every design is optimized for performance and durability.

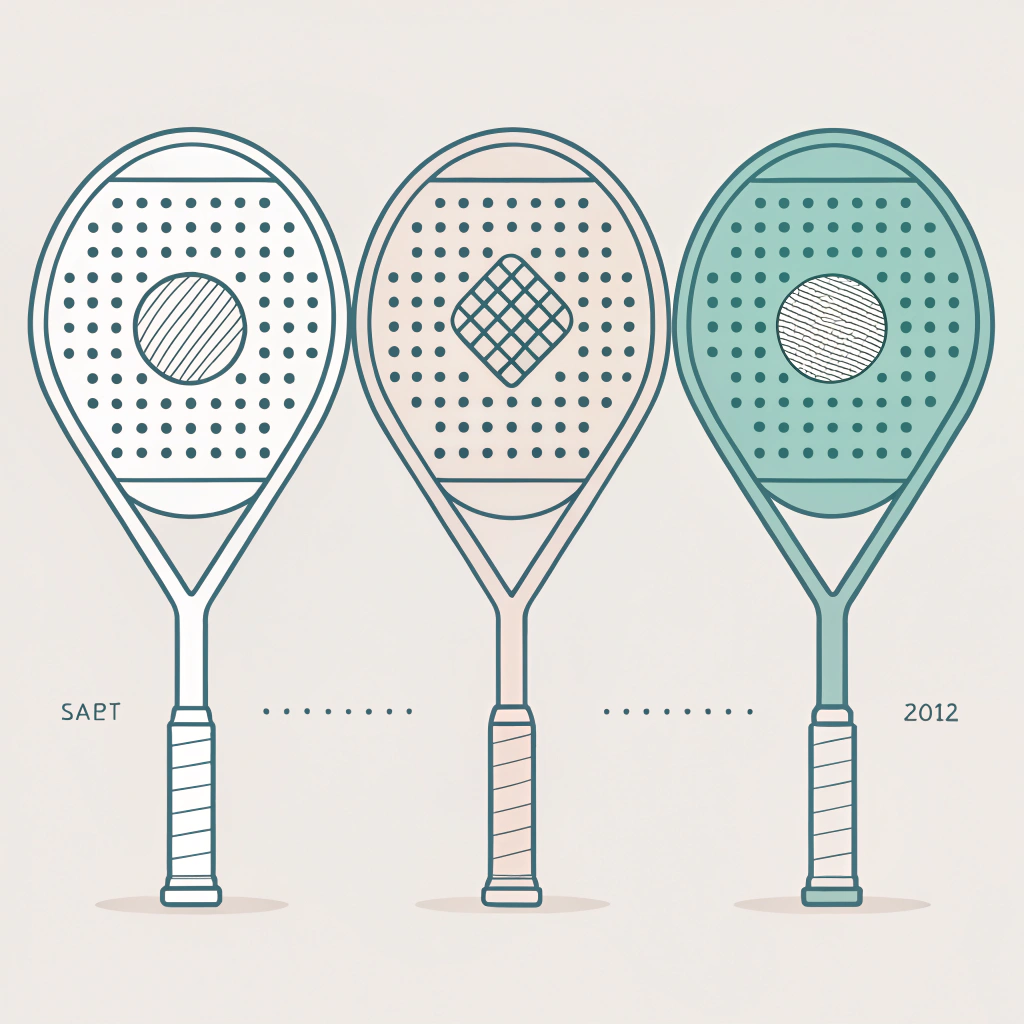

The three primary designs—Diamond, Round, and Teardrop—offer distinct performance characteristics:

- Diamond Rackets: These rackets provide increased control and power. They are designed for players seeking precision and are popular in high-intensity matches where shot placement is critical.

- Round Rackets: Favored for their greater maneuverability and larger sweet spots, round rackets offer balanced performance. They are an excellent choice for players who require both comfort and versatility.

- Teardrop Rackets: These rackets blend control and power in a balanced manner. Their shape helps in delivering smooth transitions between defense and offense, making them suitable for a wide range of playstyles.

Understanding the technical characteristics behind each shape is key when positioning your sports equipment offerings in today’s competitive market.

One of the major selling points of NEX Padel's products is the use of premium materials. Our rackets are manufactured using glass fiber and carbon fiber variants such as 3k, 12k, and 18k carbon fiber. Here’s why these materials matter:

- Durability: Carbon fiber construction offers greater strength-to-weight ratio and longevity compared to traditional materials. This ensures that even with high-frequency play, the racket maintains its performance.

- Precision: Using advanced production techniques, our custom manufacturing process creates consistent products with minimal variance. This precision benefits both OEM partners3 and end customers looking for reliability.

- Customization: The ability to customize features such as color, printing, hand grip, and handle cover with bespoke logos means that you can offer a unique product to various market segments.

Our commitment to quality is supported by rigorous testing protocols and collaborative efforts with well-known brands such as Hirostar, Reebok, and Starvie. This collaboration ensures that the rackets not only meet international standards but also adapt to the evolving demands of professional play.

To provide a clear decision-making framework, consider the following table which highlights the important aspects of each design:

| Feature | Diamond Racket | Round Racket | Teardrop Racket |

|---|---|---|---|

| Shape & Balance | Elongated head, higher center of mass for power shots | Circular shape with a balanced center for control and comfort | Tapered shape combining control with power efficiency |

| Playing Style Suitability | Best for aggressive, control-focused play | Ideal for beginners and intermediate players seeking optimal sweet spot | Suitable for versatile play, offering both power and maneuverability |

| Material Compatibility | Optimized for high-tension carbon fiber reinforcement | Compatible with both glass fiber and carbon fiber for balanced performance | Customizable material options to fine-tune gameplay dynamics |

| Customization Options | Supports design modifications including weight distribution adjustments | Allows extensive custom printing and logo placements on hand grip & cover | Offers both standard and fully-custom shapes to match specific playing styles |

| Production Precision | High precision required due to shape complexity | Standard production precision with robust performance | Moderate production complexity with balanced performance characteristics |

This table should serve as a helpful guide when positioning your product lineup, ensuring that each product’s unique strengths are clearly presented to potential customers.

NEX Padel employs state-of-the-art production processes that contribute significantly to the quality and performance of our padel rackets. Here’s an overview of our manufacturing excellence:

-

State-of-the-Art Molding and Curing Processes4:

Our manufacturing facilities use high-temperature curing and precision molding techniques. These processes ensure that each racket, whether made of glass fiber or advanced carbon fiber variants, meets stringent quality standards and delivers exceptional performance. -

Automated Precision and Quality Control:

Benefiting from automated production lines, we achieve consistency in design and material application. Precision scan systems continuously monitor dimensions and weight balance, essential for maintaining high performance over batch production. -

Customization Capability:

We support full custom production where B2B clients can specify details such as the racket's shape (including custom variants of Diamond, Round, or Teardrop), printing, color options, and even handle customization. This flexibility allows distributors and sports organizations to create a uniquely branded product that aligns with their strategic market positioning. -

Reliable Supply Chain Management5:

Quick prototyping and fast delivery schedules are central to our operations. With an efficient supply chain network, NEX Padel ensures minimal downtime from sample approval to bulk order shipment.

By leveraging these advanced manufacturing methods, businesses can confidently offer gear that not only looks premium but also performs under the demands of high-level play.

When choosing padel equipment, procurement specialists and club managers must take into account a variety of performance factors and post-sale support. Here are some important considerations:

-

Durability Under Intensive Use:

In environments where players use their rackets frequently, understanding the impact of material wear is key. While a deeply reinforced racket made from 18k carbon fiber may offer extended durability, managing weight and balance is paramount to maintain maneuverability. -

Customization for Brand Identity:

Padel clubs and sports organizations often require gear that reflects their brand identity. Our customization options allow for tailoring not just the racket's technical specifications but also its aesthetic aspects, which is essential for marketing and brand differentiation. -

Performance Impact on Play:

The balance, sweet spot size, and handle design directly affect both player performance and comfort. Providing clear technical comparisons supports the decision-making process for clubs and distributors. With our OEM capabilities, you can choose production details that align with the desired performance characteristics, whether it is maximizing power or enhancing control. -

Long-Term Cost Efficiency:

While the initial investment in premium rackets like those built with advanced carbon fiber might seem higher, their reliability and longevity can lead to lower replacement frequency, ultimately offering greater long-term cost efficiency. -

After-Sales Support and Warranty:

An often-overlooked element, after-sales support, is crucial in B2B procurement. NEX Padel stands behind our products with a commitment to quality, offering warranty options and technical support to ensure customer satisfaction over the product lifecycle.

By addressing these factors, B2B decision-makers can ensure that the padel equipment they procure not only meets technical performance criteria but also supports a sustainable, customer-focused business strategy.

In summary, the selection of the right padel racket involves understanding the differences between design types, material properties, and production techniques. The Diamond, Round, and Teardrop designs each offer distinct benefits catering to various playstyles and market niches. By leveraging advanced carbon fiber reinforcement and state-of-the-art manufacturing methods, NEX Padel provides products that stand out in terms of quality and performance.

Here are a few actionable recommendations for decision-makers:

- Assess Your Target Market: Evaluate the playing styles and preferences in your primary market. This insight will guide you in choosing a design that best meets your customers’ needs.

- Leverage Customization Options: Use the full range of customization—from shape and material upgrades to branding elements—to offer unique products that align with your brand’s identity.

- Consider Long-Term Cost Efficiency: Look beyond the initial cost. High-quality production and materials can lead to significant savings over time thanks to reduced replacement and maintenance needs.

- Engage with Experienced Manufacturers: Partner with a manufacturer who not only understands advanced production techniques but also offers full OEM capabilities to support your business growth.

By taking these steps, sports equipment distributors, padel club managers, and procurement specialists can confidently invest in padel rackets that are engineered for top performance and tailored to meet their specific market demands.

Q: What is the lifespan of a padel racket?

A: For players who use their racket daily, you can expect it to last between 4-6 months before noticeable wear in the core. For regular play two to three times a week, a well-constructed padel racket should last about a year with proper maintenance.

Q: Do expensive padel rackets make a difference?

A: While higher-priced padel rackets often employ advanced materials and precise engineering, they are not always the best choice for beginners or intermediate players. More expensive rackets typically feature a smaller sweet spot and a harder feel, which can require a higher skill level to leverage effectively.

Q: How to tell a good padel racket?

A: Key factors include the racket’s shape and balance, the weight in relation to power and maneuverability, handle size and length for comfort and control, and the material used, which impacts overall performance and durability. These aspects collectively determine the quality and suitability for different playstyles.

-

carbon fiber reinforcement: Read more to understand how integrating carbon fiber reinforcement can significantly enhance the strength-to-weight ratio and durability of sports equipment. ↩

-

custom manufacturing: Discover insights into custom manufacturing processes that allow for tailored production runs and bespoke product features, ensuring alignment with specific market demands. ↩

-

OEM partners: Learn how partnerships with OEMs streamline product development and ensure consistent quality through established manufacturing standards. ↩

-

Molding and Curing Processes: Explore detailed information on state-of-the-art molding and curing processes that guarantee precision and reliability in high-performance product manufacturing. ↩

-

Supply Chain Management: Find out how robust supply chain management practices can optimize prototyping, production lead times, and overall operational efficiency. ↩