At NEX Padel we deliver high-performance padel tennis rackets that empower distributors and brand managers to meet market demands. Our advanced production techniques, full customization options, and rigorous quality control ensure you receive rackets that consistently perform, reflecting the unique preferences of your target market.

In today’s competitive global sports equipment market, procurement managers and B2B buyers need a trusted manufacturing partner who can offer:

• Consistent quality

• Technical excellence in design and production

• Flexibility in customization

• Timely delivery and reliable supply

Many companies face challenges when aligning production capabilities with market demands. From sourcing materials like glass fiber1 and multiple grades of carbon fiber2 (3K, 12K, 18K) to meeting diverse shape requirements such as Diamond, Round, and Teardrop, the complexity of customization increases. Moreover, the reliability of sample production and rapid delivery schedules is critical for building your brand’s reputation.

Several factors contribute to the difficulties in selecting a padel tennis racket manufacturer:

-

Material Diversity: The use of materials such as glass fiber and various carbon fiber types requires specialized knowledge and equipment. Quality control is essential to meet performance expectations.

-

Customization Demand: With the growing emphasis on brand differentiation, there is a high demand for custom shapes, printing, hand grip designs, and color variations that suit individual brand identities.

-

Manufacturing Precision: Advanced production techniques, including precise carbon layering and tailored molding for Diamond, Round, and Teardrop shapes, are necessary to ensure each racket meets performance standards.

-

Supply Chain Efficiency: Speed in sampling and timely delivery are paramount. Delays or inconsistencies in manufacturing can disrupt your product launch timelines and market competitiveness.

At NEX Padel, we address these challenges by implementing a robust manufacturing process, backed by our state-of-the-art facilities in Jiaxing, Zhejiang. Here’s how we optimize our production process to meet B2B demands:

• Material Mastery: We use a range of materials—from glass fiber to high-grade carbon fiber (3K, 12K, 18K)—to craft rackets that combine durability with lightweight performance. This diversity in material selection allows for enhanced product performance tailored to different play styles and player needs.

• Customization at Its Core: Our production lines are engineered for full customization. Whether you need specific shapes (Diamond, Round, or Teardrop), custom printing, or personalized hand grip designs, our systems are designed to incorporate these requests seamlessly.

• Rapid Sampling and Timely Delivery: Quick prototyping coupled with strict quality control measures allows us to deliver samples rapidly, helping you validate product design and quality. This efficiency is critical in keeping your supply chain agile.

• Quality Assurance: Our commitment to quality extends beyond visual and design customization. We conduct rigorous performance tests on each batch, ensuring that every racket meets high performance standards for both professional and amateur players.

Below is a comparative table outlining key factors in padel tennis racket manufacturing, demonstrating where NEX Padel excels:

| Feature | NEX Padel Advantage | Competitor A | Competitor B |

|---|---|---|---|

| Material Options | Glass fiber, 3K, 12K, 18K carbon fiber | Limited to 3K carbon fiber | 3K and 12K carbon fiber only |

| Customization Flexibility | Fully customizable shapes (Diamond, Round, Teardrop) with printing and logo options | Standard shapes only | Limited customization in printing only |

| Production Techniques | Advanced layering, precise molding, high-quality finishing | Conventional methods | Less emphasis on precision |

| Quality Control and Testing | Comprehensive testing protocol, ensuring durability and playability | Basic quality check | Inconsistent quality checks |

| Sampling & Delivery Time | Fast sampling and timely delivery guaranteed by streamlined operations | Moderate sampling speed | Longer delivery lead times |

| Partnership with Global Brands | Trusted by brands like Hirostar, Reebok, and Starvie | Fewer global partnerships | Limited brand endorsements |

This table highlights our technical expertise and comprehensive service, ensuring our partners receive a product that is competitive in a fast-changing market.

Choosing the right material is fundamental to producing high-performance padel rackets. At NEX Padel, we adopt a meticulous selection process for:

• Glass Fiber1: Known for its resilience and shock-absorption capabilities, ideal for players requiring additional control and stability.

• Carbon Fiber2 (3K, 12K, 18K): Provides enhanced stiffness and durability with a lightweight profile. Higher grade options such as 18K ensure the finest balance between power and precision.

Each material is carefully tested for factors such as tensile strength and flexibility to ensure compatibility with specific racket designs.

We understand that customization is key in defining brand identity. Our manufacturing facility enables:

• Shape Customization: Whether you need a Diamond, Round, or Teardrop shape, each design is engineered for optimal performance.

• Graphic and Logo Integration: Our advanced printing technology permits high-definition and durable printing that withstands the rigors of the sport.

• Personalized Hand Grip: Custom designs, including logo placement, ensure the grip meets ergonomic and aesthetic requirements.

This integrated approach allows you to differentiate your products in a saturated market, offering tailor-made solutions that resonate with both professional athletes and amateur enthusiasts.

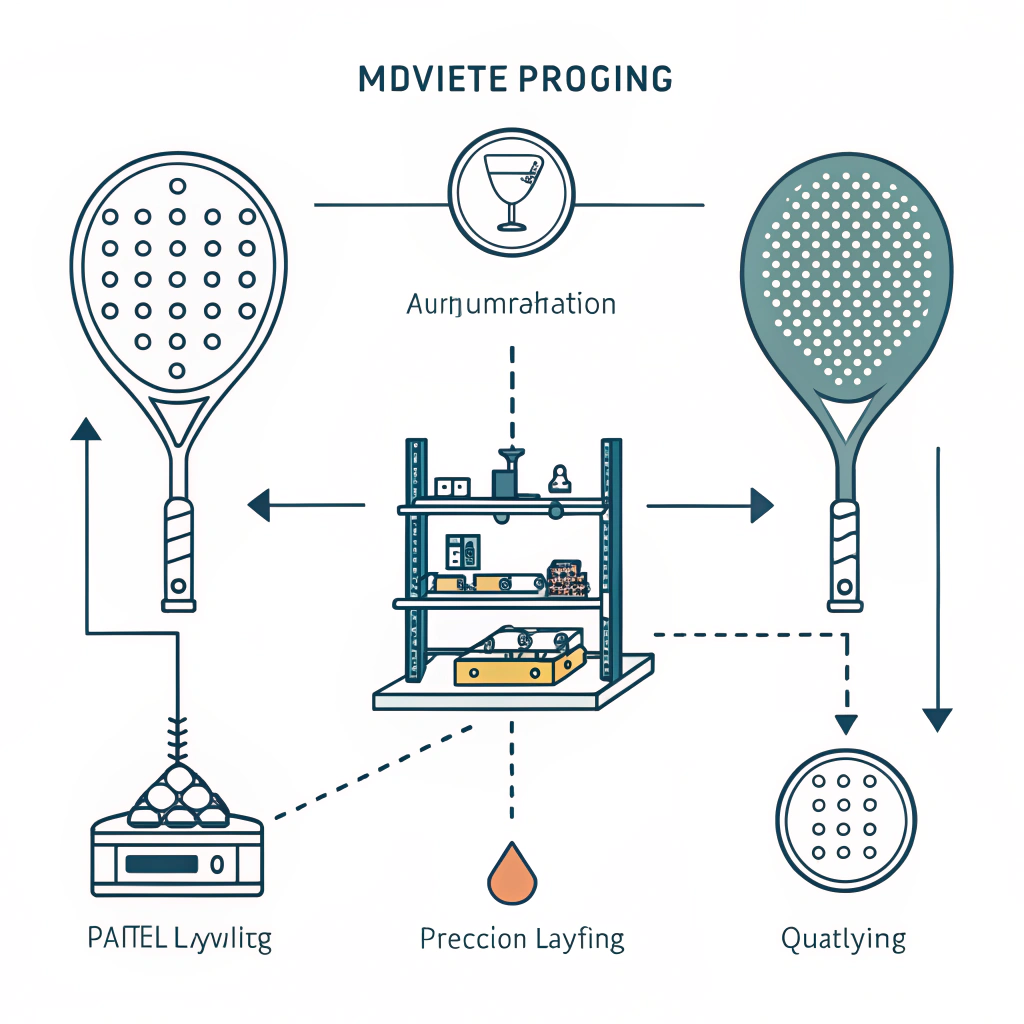

The production process at NEX Padel is built on a foundation of innovation and precision. Our advanced manufacturing techniques include:

- Automated Layering3: Advanced machinery ensures precise layering of carbon fibers and glass fibers, reducing human error and delivering consistent racket performance.

- Precision Molding4: Computer-controlled molds guarantee uniform shapes—crucial for balancing weight distribution and achieving optimal flight trajectories.

- Comprehensive Testing: Each batch of rackets undergoes a series of tests simulating various play conditions, ensuring that durability and performance metrics meet the highest standards.

This holistic approach not only minimizes production defects but also provides your brand with high-quality products that have been rigorously validated.

Timely production and reliable delivery are at the heart of efficient supply chain management. Our operations model is designed with the following key aspects:

• Rapid Prototyping5: Quick sampling techniques allow for rapid feedback and necessary design adjustments before mass production. This reduces lead times and enhances customer satisfaction.

• Streamlined Supply Chain: Our strategic location in Jiaxing, Zhejiang enables us to implement efficient logistics, ensuring products reach you on schedule.

• Batch Quality Assurance: Final products are subjected to an additional round of quality inspections to ensure uniformity in every shipment.

Our commitment to operational excellence ensures that from initial sampling to final delivery, you experience a smooth and transparent procurement process.

Consider a recent partnership where a well-known sports equipment distributor needed a rapid turnaround for a new product line. The requirements included advanced customization, high durability, and an expedited timeline.

• Challenge: The client needed custom-designed rackets with specific color and graphic requirements, alongside a guarantee of high performance.

• Action: NEX Padel engaged with the client from the design phase, providing detailed material insights and sample prototypes. Our custom production process allowed for changes based on early testing feedback.

• Result: The final product not only met the client’s specifications but exceeded performance expectations. The distributor was able to launch their product line ahead of schedule, leading to enhanced market presence and positive customer feedback.

This case underlines how our approach to material selection, customization, and operational efficiency drives customer success.

Partnering with a reputable padel tennis racket manufacturer is essential for B2B buyers looking to secure a competitive edge. NEX Padel’s combination of advanced production techniques, extensive customization, and robust quality assurance makes us the partner of choice for global brands and distributors.

In summary, consider these key action points when evaluating padel equipment suppliers:

- Ensure your supplier offers diverse material options and proven performance validation.

- Evaluate the flexibility for product customization, including shape, graphics, and ergonomic features.

- Prioritize operational efficiency, from rapid sampling to on-time delivery.

By aligning your procurement strategy with a dependable manufacturer like NEX Padel, you can confidently meet your market demands with products that reflect quality, innovation, and commitment to excellence.

People Also Ask

• Who manufactures padel rackets?

NEX Padel is a leading manufacturer based in Jiaxing, Zhejiang, specializing in high-performance padel tennis rackets. Our state-of-the-art techniques and diverse material options, including glass fiber and varying grades of carbon fiber, ensure that each racket meets rigorous quality standards.

• What rackets do professional padel players use?

Professional padel players rely on high-performance rackets that offer both precision and customization. Our rackets are designed to meet professional demands, similar to those used by top players around the world, by providing options in Diamond, Round, and Teardrop shapes along with customizable printing and hand grip features.

-

Glass fiber: Click to learn about the properties and manufacturing benefits of glass fiber in sports equipment, including its shock-absorption and durability advantages. ↩ ↩ ↩2

-

Carbon fiber: Click to explore the different grades of carbon fiber, their performance benefits, and how they are used to enhance racket strength and precision. ↩ ↩ ↩2

-

Automated Layering: Click to understand how automated layering technology ensures consistency and quality in the manufacturing process by minimizing human error. ↩ ↩

-

Precision Molding: Click to discover the role of computer-controlled precision molding in achieving uniform racket shapes and optimal performance characteristics. ↩ ↩

-

Rapid Prototyping: Click to learn about rapid prototyping techniques that reduce lead times and enable quick feedback for design improvements in manufacturing. ↩ ↩