In 2025, high-performance padel rackets that combine advanced carbon fiber technology1 and precision engineering2 are the key to success for B2B sourcing. The best choices, such as Diamond, Round, and Teardrop shapes, offer unique benefits in terms of balance, control, and customization3, which are vital for meeting market demands and enhancing product lineups.

The sport of padel continues to experience rapid growth, leading to a surge in market demand for cutting-edge equipment. For procurement managers and product strategists, sourcing high-performance padel rackets involves a detailed comparison of technical aspects, material quality, and customization options. At NEX Padel, our commitment to innovative production techniques and premium materials makes us a trusted partner in this competitive landscape.

Our advanced padel rackets are engineered using materials such as glass fiber and various grades of carbon fiber (3k, 12k, and 18k). These materials cater to different levels of play and performance preferences, ensuring that every racket meets strict durability and precision standards. Whether you're looking to expand your product offerings or seeking a custom-designed solution, understanding the distinctions between racket types is essential.

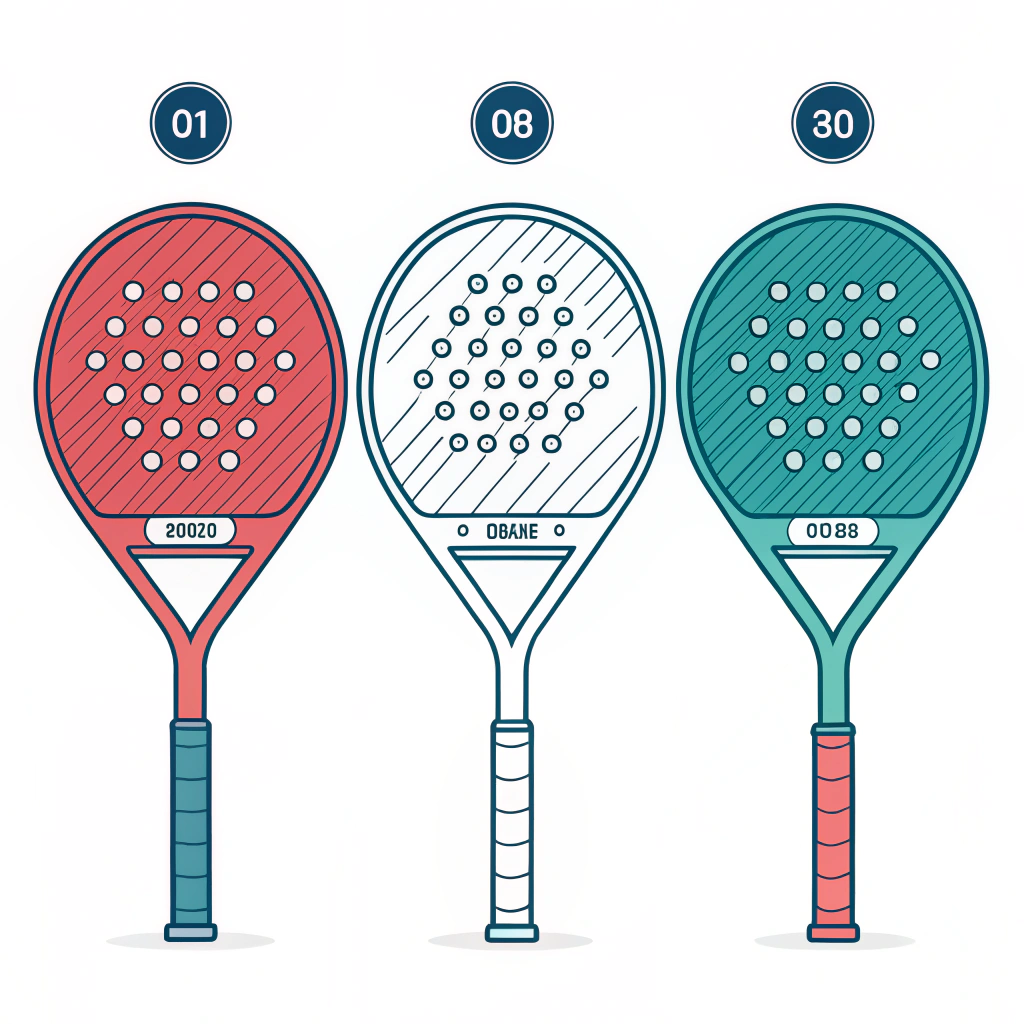

When considering the best padel racket for your business, it is crucial to compare the three primary shapes—Diamond, Round, and Teardrop. Each shape has distinct characteristics that affect performance, balance, and user suitability:

- Diamond Padel Rackets: Typically offer a balance skewed towards power. The shape is designed to amplify the impact force, making it popular among aggressive players who favor strong offensive play.

- Round Padel Rackets: Emphasize control and maneuverability. Their curved design provides a larger sweet spot, leading to easier handling and enhanced precision, which is ideal for players focusing on technique.

- Teardrop Padel Rackets: Serve as a versatile option, blending the high power of Diamond models with the control of Round models. Their design offers an optimal compromise between offense and defense.

This differentiation is fundamental when aligning purchasing decisions with product characteristics, target player profiles, and overall market trends.

Below is a table summarizing key technical specifications and performance benefits of Diamond, Round, and Teardrop padel rackets:

| Feature | Diamond Padel Rackets | Round Padel Rackets | Teardrop Padel Rackets |

|---|---|---|---|

| Balance | Head-heavy for increased power | Evenly balanced for optimal control | Semi-balanced to blend power and control |

| Sweet Spot Size | Smaller sweet spot favors precision for experienced players | Larger sweet spot for forgiving play | Moderate sweet spot suitable for all-round performance |

| Material Emphasis | Often uses advanced carbon fiber (12k/18k) | May utilize a mix of glass fiber and carbon fiber | Typically incorporates a balanced combination of fibers |

| Player Type | Aggressive, power-focused players | Control-focused, tactical players | Versatile players who value both power and control |

| Customization | Custom shapes, logo placement on hand grip | Custom print and color design | Flexible customization with specific weight distribution adjustments |

| Cost Consideration | Premium pricing due to material and design complexity | Mid-range, accessible for broader markets | Competitive pricing with versatile features |

Modern padel rackets rely heavily on material technology to achieve high performance. At NEX Padel, our manufacturing process leverages different grades of carbon fiber—3k, 12k, and 18k—to deliver varied performance outcomes:

- 3k Carbon Fiber: Widely used for entry-level to mid-tier rackets, offering a good balance between performance and cost. Its structure provides adequate stiffness and resistance to stress.

- 12k Carbon Fiber: Provides a superior level of stiffness and durability, making it ideal for higher-end rackets that demand precision. This grade enhances power transmission while maintaining a lightweight profile.

- 18k Carbon Fiber: The pinnacle of high-performance equipment, used in premium models for its exceptional rigidity and strength. It ensures less vibration upon impact and offers a remarkable blend of power and control.

These variations allow our clients to choose products that precisely match their strategic objectives, whether targeting price-sensitive markets or premium performance segments.

Every aspect of padel racket performance—from power delivery to vibration dampening—is influenced by engineering precision. The integration of technology and material science in our products translates into measurable performance metrics that matter to B2B buyers:

- Weight Distribution: Optimized in each model to reduce player fatigue and enhance swing efficiency.

- Vibration Dampening4: Advanced carbon fiber configurations significantly reduce vibrations, leading to improved control and player comfort.

- Impact Resistance: Our rigorous testing protocols ensure that every paddle meets strict durability standards, even under intense play conditions.

- Balance and Maneuverability: Detailed analysis of balance profiles helps players select a racket that complements their style, whether for offensive power or defensive stability.

Innovating within these dimensions not only improves player performance but also builds trust among retailers and distributors seeking reliable, scientifically tested products for their customers.

The padel industry is evolving quickly, driven by increasing global interest and technological advancements in equipment manufacturing. Strategic sourcing decisions must take into account both current market trends and future consumer expectations. Some of the key trends include:

- Rising Demand for Customization: As the market becomes more competitive, B2B buyers are looking for products that can be tailored to specific customer needs. Customization options such as bespoke shapes, logo placements on hand grips, and personalized color schemes add significant value.

- Enhanced Production Techniques: Advances in production techniques enable faster sampling, quality checks, and on-time delivery. Our commitment to agile production processes5 ensures that procurement managers receive products that meet both market and regulatory standards.

- Focus on Material Innovation: With an increasingly tech-focused consumer base, the integration of materials like high-grade carbon fiber is becoming a standard. Understandably, technology-driven specifications such as weight reduction, stiffness, and durability drive purchase decisions.

For decision-makers aiming to future-proof their product line-ups, aligning with manufacturers who continuously innovate is crucial. NEX Padel's partnership with renowned brands such as Hirostar, Reebok, and Starvie highlights our credibility in meeting these market needs.

A significant competitive edge for padel equipment providers comes from the ability to offer custom solutions. NEX Padel supports extensive customization across multiple product dimensions:

- Custom Shapes: Beyond conventional Diamond, Round, and Teardrop profiles, we offer tailor-made designs to meet niche market demands.

- Personalized Prints and Colors: Through advanced printing techniques, each racket can be personalized with unique color schemes and logos, elevating brand identity.

- Accessory Customization: In addition to the rackets, custom logo options are available on hand grips and handle covers, ensuring a cohesive product offering.

- Technical Adjustments: Minor modifications in weight distribution and balance can be customized based on specific player preferences and market trends.

This level of adaptability is instrumental for distributors looking to differentiate their product offerings in a saturated market. By providing these options, manufacturers help clients build stronger brand recognition and customer loyalty.

When evaluating padel rackets for 2025, B2B buyers must consider a balance of technical precision and strategic market positioning. Here are some actionable recommendations:

- Evaluate Technical Specifications Against Market Trends: Compare the performance metrics of different padel racket models to ensure they meet current consumer expectations. Focus on weight, balance, and vibration dampening as key differentiators.

- Prioritize Customization Options: Ensure that the equipment can be personalized to match your brand identity and consumer preferences. Custom solutions are a significant value-add in competitive markets.

- Invest in Long-Term Partnerships: Partner with manufacturers like NEX Padel who have a proven track record of innovation, quality control, and efficient delivery. Such collaborations can lead to faster product iterations, reduced lead times, and enhanced product reliability.

- Balance Cost and Performance: While premium models offer superior technical features, mid-range options might be more suitable for broader market distribution. Consider a diversified product portfolio to meet varied consumer segments.

By integrating these strategic measures, procurement managers can make informed decisions that not only optimize product performance but also bolster market competitiveness.

In summary, selecting the right padel racket in 2025 requires a comprehensive understanding of product shapes, material innovations, technical performance metrics, and customization capabilities. The comparisons between Diamond, Round, and Teardrop models highlight that each design serves a unique sports performance niche. For B2B buyers, aligning these technical insights with broader market trends enables a more strategic sourcing decision.

At NEX Padel, our dedication to high-quality production techniques, rapid prototyping, and on-time delivery stands as a competitive advantage in the padel industry. Whether you are looking to source premium carbon fiber rackets or explore custom configurations, our expertise is designed to support your product strategy and market positioning.

We encourage procurement managers and product strategists to dive deeper into the technical data, engage with expert partners, and continuously monitor industry trends to ensure that your product lineup remains ahead of the curve.

Q: What key factors should be considered when sourcing high-performance padel rackets?

A: Key factors include material quality (e.g., advanced carbon fiber grades), technical specifications such as weight distribution and vibration dampening, customization options, and market trends. These parameters ensure that the product meets performance and consumer demand.

Q: How do Diamond, Round, and Teardrop rackets differ in terms of performance?

A: Diamond rackets typically offer a power-oriented design with a head-heavy balance, Round rackets focus on control with a larger sweet spot, and Teardrop rackets balance power and control, making them versatile for various playing styles.

Q: Why is customization important in the padel racket market?

A: Customization allows brands to differentiate their products through personalized design features, including unique shapes, colors, and logo placements. This flexibility meets diverse consumer preferences and enhances brand identity in a competitive market.

-

advanced carbon fiber technology: Click to learn how advanced carbon fiber technology enhances racket durability and performance by offering superior strength-to-weight ratios, making it essential for high-performance sports equipment. ↩ ↩

-

precision engineering: Click to explore the role of precision engineering in ensuring that every component of the racket is optimized for peak performance and efficiency, crucial for meeting stringent quality standards. ↩ ↩

-

customization: Click to understand how customization provides tailored solutions that meet specific market demands, allowing brands to offer unique product features and personalizations that drive consumer loyalty. ↩ ↩

-

vibration dampening: Click to find out how vibration dampening technologies improve player comfort and control by reducing unwanted vibrations during play, thereby enhancing overall performance and product longevity. ↩ ↩

-

agile production processes: Click to learn more about agile production processes that enable manufacturers to rapidly adapt to market changes, reduce lead times, and ensure consistent product quality for competitive sourcing. ↩ ↩