Essential Padel Gear for 2025 elevates your game by offering high-performance, innovative, and customizable1 equipment designed with advanced production techniques2 and quality assurance3 to meet the evolving demands of padel clubs and distributors.

As the padel industry moves rapidly into 2025, the focus on bold innovation, quality materials, and tailor-made solutions has never been greater. In today’s competitive market, padel gear innovation has become critical for businesses looking to elevate their game. In this article, we explore key innovations in padel equipment, from the latest manufacturing techniques to advanced materials, all backed by robust quality standards. This guide is designed for procurement managers and specialty sports distributors seeking reliable, high-performance products that set their brands apart.

Recent market insights reveal a steadily increasing demand for gear that not only performs but also embodies the blend of aesthetics and engineering. Padel clubs and distributors today seek equipment that not only appeals to professional players but is also built to last under the demands of intense gameplay. Some crucial trends include:

- Advanced Production Processes: Manufacturers are increasingly using cutting-edge techniques that ensure precision and durability. Technologies such as automated layering in carbon fiber production, refined molding techniques for Diamond, Round, and Teardrop designs, and quality control systems provide consistent outputs.

- Material Innovations: The choice between carbon fiber and fiberglass is no longer a mere decision of cost versus performance. Instead, brands are expected to understand the nuances of each material. Carbon fiber variants like 3k, 12k, and 18k weaves4 offer diverse performance characteristics to meet the specific needs of players at various levels.

- Customization Capabilities: With the rise of personalized sports equipment, customization isn’t just an option—it’s a necessity. From custom logo prints to tailored shapes and color schemes, suppliers must offer flexible options that can differentiate a brand in the marketplace.

- Enhanced Ball Specifications: Apart from rackets, padel balls are also evolving. Today’s balls benefit from innovations like pressurized tube packaging5 that maintains optimal pressure and offers greater consistency in bounce and durability.

These trends are driven by both technological advances and growing consumer expectations, making it imperative for suppliers to adapt quickly and deliver state-of-the-art products.

A dominating debate in high-performance padel equipment is the choice of material. Here’s a closer look at why many clubs are shifting towards sophisticated composite materials:

Carbon Fiber:

- Performance Edge: Carbon fiber rackets, especially those using 3k, 12k, and 18k weaves, are known for their excellent stiffness-to-weight ratios. They provide superior control, power, and resilience, vital for high-level competitive play.

- Durability: The inherent strength of carbon fiber ensures that rackets withstand high-speed impacts and repetitive stress without compromising performance.

- Customization: Carbon fiber components allow for diverse customizations, including personalized designs, textures, and finishes. This flexibility makes them ideal for exclusive club brands striving to offer something unique.

Fiberglass:

- Flexibility: While fiberglass offers a slightly different feel and increased flexibility, it remains popular among beginners and intermediate players due to its forgiving nature.

- Cost-Effectiveness: Generally, fiberglass rackets can be produced at a lower cost, making them an attractive option for clubs on a budget or those offering entry-level products.

- Maintenance: Fiberglass materials are also easier to maintain, offering long-lasting reliability with the right care routine.

| Material Type | Performance Characteristics | Durability | Customization Potential | Price Impact |

|---|---|---|---|---|

| Carbon Fiber | High stiffness, enhanced control, and power | Superior; optimized with 3k, 12k, 18k weaves | High; custom shapes, logos, colors | Higher cost due to advanced production techniques |

| Fiberglass | More flexible, ideal for beginners | Durable with proper care | Moderate; less complex customization options | Lower cost; suitable for entry-level products |

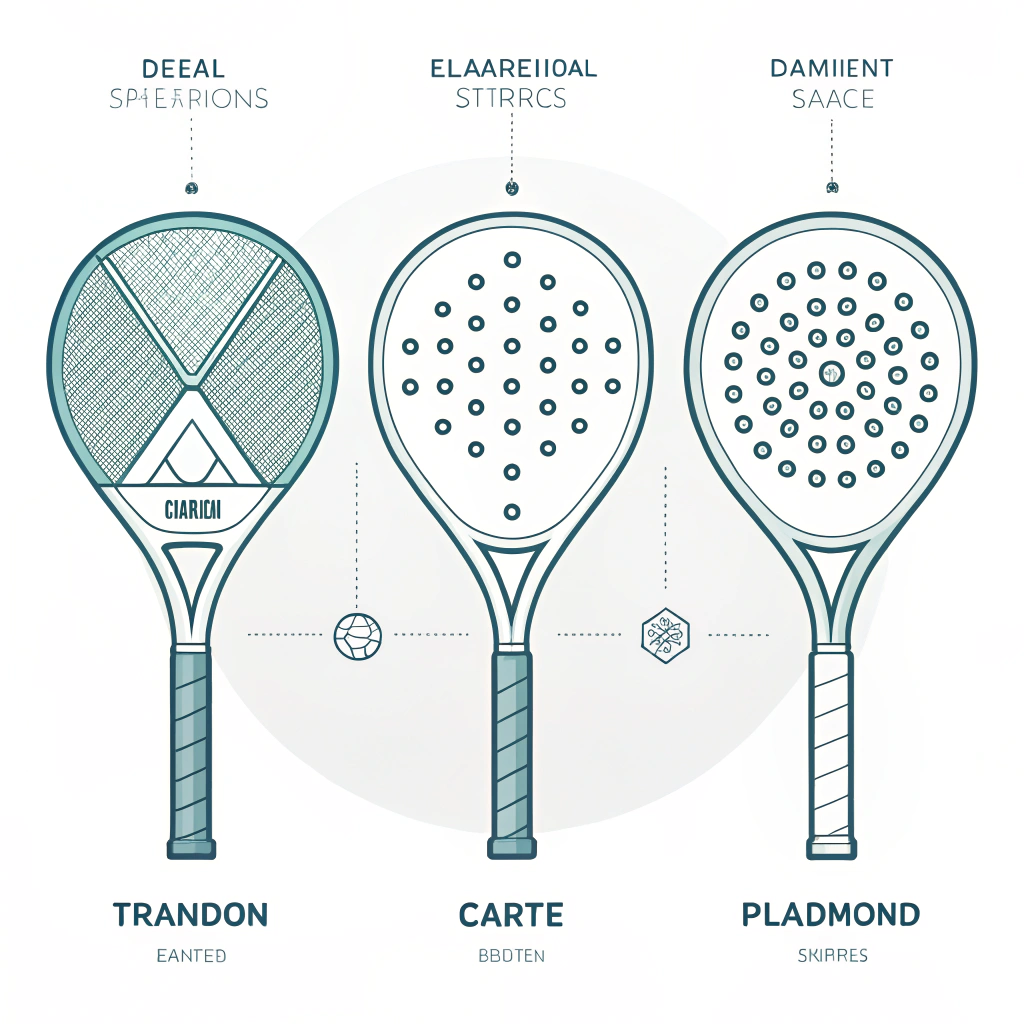

Another essential consideration for 2025 padel gear is the design of the rackets, which significantly impacts player performance and game dynamics. Manufacturers now offer three primary designs, each catering to unique play styles:

-

Diamond Rackets: Engineered for players seeking maximum power and aggressive play, Diamond rackets typically feature a more angular shape which facilitates a stronger impact upon the ball. The concentrated sweet spot and heavier balance contribute to a forceful shot, but they may require advanced skills for optimal use.

-

Round Rackets: This design is balanced and versatile, offering a larger sweet spot for improved control. Round rackets are particularly popular with players who value consistency and accuracy. The even distribution of weight makes them user-friendly, especially for mid-level to advanced players.

-

Teardrop Rackets: Combining aspects of both power and control, Teardrop rackets provide a moderate balance between the aggressive play style of the Diamond design and the user-friendly nature of the Round type. This design is ideal for players looking to transition between different strategies during a match.

Our capability to offer full customization means that these base models can be modified to better suit the performance needs or brand identity of your club. Options include custom prints, color matching, and even adjustments to weight distribution based on player feedback.

In today's competitive gear market, the reliability of the supply chain is as crucial as the performance of the product itself. At NEX Padel, we distinguish ourselves through advanced manufacturing techniques that ensure a high level of quality assurance and fast turnaround times. Key aspects include:

- Precision Engineering: Every padel racket undergoes a rigorous production process that starts with high-quality raw materials, precise layering, bonding, and curing processes. This ensures that each racket meets stringent performance standards.

- Customization Workflow: Using modern production systems, we facilitate quick design modifications such as shape alterations, color changes, and custom logo imprints on hand grips and racket surfaces. This process is streamlined to ensure minimal lead time without sacrificing quality.

- Quality Checkpoints: Multiple inspection stages throughout the production process help to catch potential defects early. Advanced testing methods, from impact tests to stress analysis, are employed to guarantee product integrity.

- Ball Packaging Innovation: Our padel balls benefit from pressurized tube packaging that ensures the ball maintains the correct pressure for optimal performance. The two types available—45% wool and 57% wool—are both subject to stringent quality controls before leaving the factory, ensuring consistency and trust in every game.

Below is a table summarizing our manufacturing techniques and corresponding benefits:

| Process Stage | Technique Description | Quality Benefit | Turnaround Impact |

|---|---|---|---|

| Raw Material Selection | Use of high-grade carbon fiber and fiberglass | Improved performance and longevity | Reliable baseline for quality |

| Precision Layering & Bonding | Automated systems for even distribution | Enhanced consistency and control | Efficient workflow for fast output |

| Customization Integration | Flexible design software and quick-change systems | Personalization options | Rapid modification without delays |

| Quality Inspection & Testing | Multi-stage testing (impact, durability) | Reduced defect rates | Assurance of high-performance gear |

| Packaging & Delivery | Pressurized tube packaging for balls | Maintains proper ball pressure | Secure, prompt delivery |

In today’s B2B market, procurement managers are not only looking to purchase equipment—they aim to secure a strategic advantage by selecting a supplier who can offer products that enhance their brand identity. Customized padel gear becomes a key differentiator in a crowded market. Consider the following points when evaluating custom options:

- Brand Loyalty Enhancement: Customized designs—from logos on hand grips to personalized racket color schemes—reinforce brand recognition and build customer loyalty.

- Performance Optimization: Customized weight distribution and grip design can be tailored to the specific needs of your players, ensuring that every piece of equipment contributes to optimal performance.

- Competitive Differentiation: In an environment where many clubs have access to similar products, unique gear can serve as a powerful marketing tool, attracting new memberships and elevating the overall reputation of the club.

- Cost Efficiency: While the upfront investment might be higher, the long-term benefits of customized, high-quality equipment—in terms of player satisfaction and reduced replacements—can outweigh these costs.

Based on the latest trends and manufacturing insights, here are some recommendations for procurement managers looking to upgrade their padel gear:

- Begin by evaluating your club’s needs and the needs of your players. Consider whether the emphasis should be on power, control, or a combination of both when choosing between Diamond, Round, or Teardrop racket designs.

- Assess your budget relative to the desired quality level. While carbon fiber solutions offer superior performance, fiberglass options remain a solid choice for more cost-sensitive scenarios.

- Prioritize suppliers who provide customization. Tailoring gear not only differentiates your offerings but, when supported by a fast turnaround and robust quality checks, increases overall reliability.

- Demand detailed manufacturing transparency. Suppliers should be able to demonstrate advanced production techniques, quality checkpoints, and rigorous testing.

- Consider the full spectrum of padel gear. Beyond rackets, ensure that balls and accessories like hand grips and racket covers are also engineered to deliver consistency and durability under high-performance conditions.

These actionable recommendations can help you make an informed decision in selecting a supplier that aligns with your operational goals for the 2025 season.

PAA 1: What makes high-performance padel gear different for 2025?

Answer: High-performance padel gear for 2025 integrates advanced manufacturing techniques, innovative materials, and highly customizable designs. These factors combine to offer superior durability, optimized weight distribution, and enhanced control, ensuring that both professional and amateur players receive equipment tailored to their performance needs.

PAA 2: How can customization in padel gear improve brand identity?

Answer: Customization allows padel clubs and distributors to incorporate personalized logos, colors, and design elements into their equipment. This level of personalization not only reinforces brand recognition but also demonstrates a commitment to quality and performance, setting one’s offerings apart in a competitive market.

PAA 3: Why is quality assurance in padel equipment manufacturing important?

Answer: Quality assurance ensures that every piece of padel gear meets strict performance standards through rigorous testing and precision manufacturing processes. This not only guarantees consistency in product performance but also reduces long-term maintenance costs and enhances player satisfaction, making it essential for both brand reputation and operational efficiency.

-

Customizable: Learn about the benefits of tailoring products to meet specific client or market needs, enhancing brand differentiation and customer satisfaction through personalization. ↩

-

Advanced production techniques: Reading this article will provide insights on how state-of-the-art manufacturing processes are utilized to improve product precision, durability, and overall performance in competitive sports equipment. ↩

-

Quality assurance: Discover how rigorous testing and control measures ensure that sports equipment consistently meets high-performance standards, reducing defects and boosting long-term reliability. ↩

-

3k, 12k, and 18k weaves: Understand the technical differences between various carbon fiber weave types, and how these variations impact the performance, stiffness, and weight of high-end sports equipment. ↩

-

Pressurized tube packaging: Explore the innovative packaging methods that help maintain optimal ball pressure and performance, ensuring consistency and durability during play. ↩