In 2025, padel rackets are set to experience a technological leap driven by advanced production techniques1, innovative materials, and a surge in customization2. In this article, we explore the trends that are shaping the future of padel equipment, particularly for procurement and product development professionals who seek robust, high-performance solutions.

With increasing demand for precision, durability, and performance enhancement, padel rackets in 2025 will incorporate advanced production techniques such as carbon fiber3 reinforcements in various grades—from 3k to 12k to 18k. These improvements not only lead to superior playability but also offer customization options in shape and detailing. The market is also witnessing a rise in tailor-made solutions such as Diamond, Round, and Teardrop designs that cater to individual playing styles and brand identities.

The padel industry is rapidly evolving, and the integration of carbon fiber in padel racket construction is one of the most influential trends. Manufacturers have long relied on glass fiber for its durability, but today’s market is moving towards carbon fiber composites in various iterations, including 3k, 12k, and 18k weaves. Each grade offers unique benefits:

- 3k Carbon Fiber: Offers a balance of flexibility and weight reduction ideal for players seeking enhanced maneuverability.

- 12k and 18k Carbon Fiber: These provide higher rigidity and improved energy transfer, which can boost power without adding excessive weight.

This material revolution is driven by customer demand for equipment that not only looks sleek but also provides a significant performance edge.

The evolution of design is another key trend for 2025 padel rackets. Traditional shapes are being reimagined with design features that improve balance and control on the court. The primary shapes under evaluation include:

- Diamond: Typically offers increased power thanks to its design that emphasizes the sweet spot.

- Round: Known for its balance, offering both power and control in equal measure.

- Teardrop: Combines the benefits of both, providing a versatile option for players looking for a compromise between power and maneuverability.

Manufacturers like NEX Padel have refined these shapes based on rigorous testing and continuous feedback from players and sports experts. This focus on shape innovation helps brands differentiate themselves in an increasingly competitive market.

Customization has become a major selling point for padel rackets today. Retailers and end-users demand products that are not just off-the-shelf but personalized, with options for:

- Full custom shapes and design adjustments

- Custom printings, including logo placements and color specifications

- Tailored accessories such as hand grip, logo-filled hand strap covers, and even unique packaging for the balls

By leveraging full customization, companies can offer a product that resonates with an individual’s style while simultaneously reinforcing brand identity. This trend is particularly important for B2B clients who want their distributors to carry products that stand out in a saturated market.

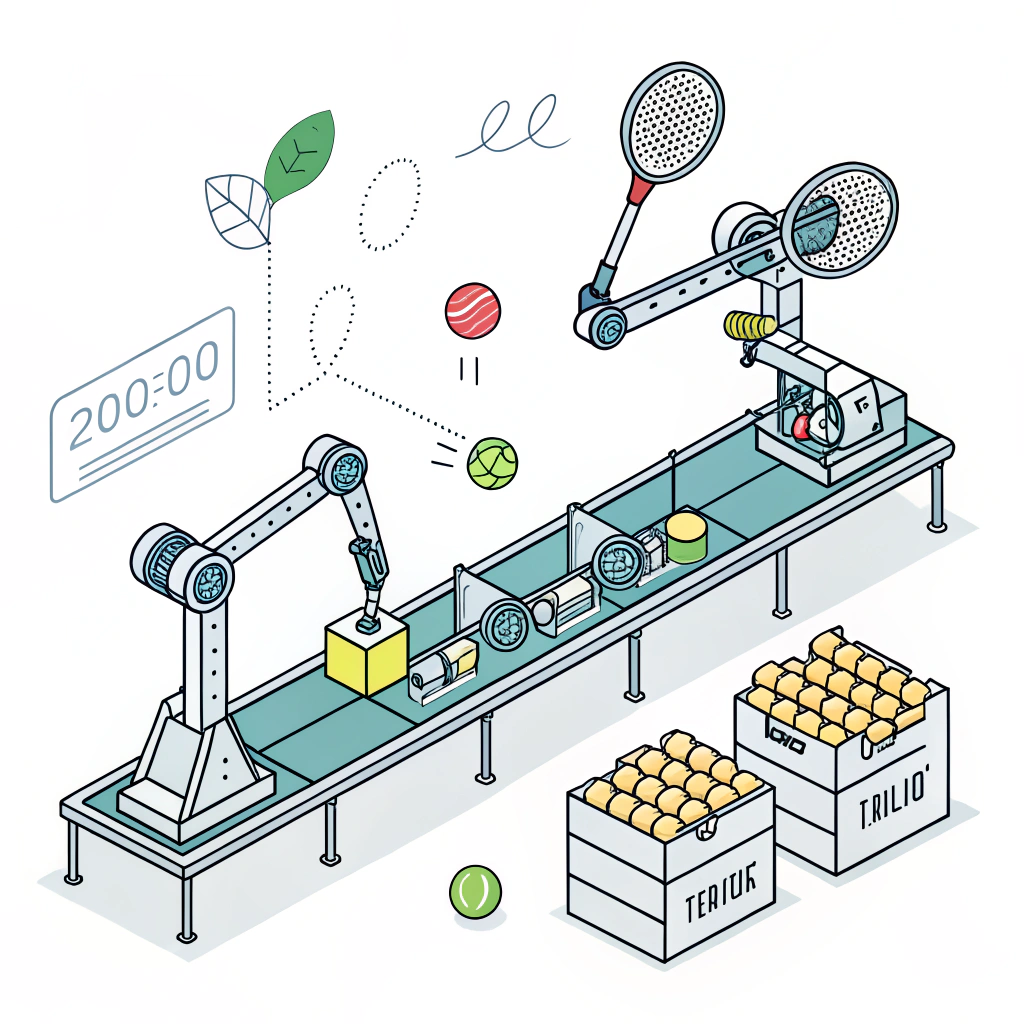

Advanced production methodologies are transforming the way padel rackets are manufactured. Automation in cutting, molding, and assembly phases has enhanced product consistency and reduced turnaround times. Key improvements include:

- Precision Cutting Techniques: Utilizing laser-guided cutting tools to optimize material usage and eliminate waste.

-

- robotic assembly4: Ensuring every padel racket adheres to exacting measurements and material inclusion.

- Quality Control Systems: Real-time quality monitoring during production helps detect anomalies early, ensuring that only rackets meeting strict performance standards reach the market.

This systematic approach has allowed manufacturers like NEX Padel to build a reputation for reliability and high performance—a crucial factor for industry procurement managers who must balance cost with quality.

Sustainable Manufacturing5 and Energy Efficiency

Sustainability is no longer optional. The manufacturing sector is increasingly adopting energy-efficient practices and sustainable material sourcing. Companies are investing in eco-friendly production processes that reduce the carbon footprint without compromising on product quality or performance. For procurement managers, this means aligning with suppliers who prioritize both technological excellence and environmental responsibility.

Consider a scenario where a sports equipment distributor needs to replenish stock ahead of a competitive season. With traditional production cycles, delays can be costly. In contrast, NEX Padel’s streamlined process—bolstered by real-time system monitoring and rapid prototyping—enables a significantly shorter turnaround time. A detailed case study showed that by reducing production cycles by up to 30%, the distributor could meet demand peaks more efficiently. This case illustrates how integrating advanced production techniques can provide an edge in a fast-paced market.

Below is a table summarizing the key characteristics of different materials and design shapes for 2025 padel rackets:

| Material/Shape | Key Benefits | Ideal Application | Customization Options |

|---|---|---|---|

| Glass Fiber | High durability, cost-effective | Entry-level to intermediate rackets | Limited |

| 3k Carbon Fiber | Excellent flexibility and lightness | Players needing high maneuverability | Custom prints & shapes |

| 12k/18k Carbon Fiber | High rigidity, enhanced power transfer | Advanced players and professional use | Full customization available |

| Diamond Shape | Maximizes sweet spot for power | Aggressive playing style | Custom handle, grip, and printing |

| Round Shape | Balanced power and control | Versatile, for varied playing styles | Custom color and detailing |

| Teardrop Shape | Compromise between power and control | Intermediate to professional level | Logo and design customization |

This table offers a concise comparison that can help decision-makers quickly assess the merits of each option, guiding procurement decisions based on performance needs and budget considerations.

As we approach 2025, several market dynamics are influencing purchasing decisions and product development strategies:

- Increasing Demand for Performance Enhancements: With growing competitive scenes in padel sports, athletes and enthusiasts are looking for rackets that offer improved responsiveness and durability.

- Global Supply Chain Evolution: The need for timely delivery and consistent quality across international markets has driven manufacturers to optimize production processes. Procurement managers are prioritizing suppliers that demonstrate robust logistics and rapid prototyping capabilities.

- Technological Integration: Innovations in sensor technology and IoT are starting to be integrated into rackets, enabling performance tracking and personalized analytics. Although still in early adoption stages, these add-on features may soon become mainstream, influencing supplier selection.

For companies like NEX Padel, the focus on continuous innovation in design and production reassures B2B clients of their capability in delivering high-performance products. Such strategic partnerships are crucial when consumers demand rackets that combine tradition with cutting-edge technology. For procurement managers, this means selecting suppliers who not only meet the current market requirements but are also equipped to adapt to future trends.

Procurement and product development teams need to evaluate suppliers on several fronts:

- Technical Capability: Does the supplier utilize the latest manufacturing techniques such as robotic assembly and precision cutting?

- Customization Flexibility: Can the supplier offer tailored solutions that align with specific brand requirements?

- Production Speed: How quickly can the supplier respond to urgent orders without compromising quality?

- Sustainability Practices: Are they investing in eco-friendly and sustainable practices in their manufacturing processes?

Addressing these critical factors will allow decision-makers to align their procurement strategies with long-term growth and customer satisfaction.

- Evaluate Material Options Thoroughly: Understand the nuances between glass fiber and various grades of carbon fiber. Ensure that the material chosen aligns with the expected performance outcomes for your target market.

- Prioritize Supplier Innovation: Seek out suppliers embracing advanced production techniques and customization capabilities. In doing so, you ensure that your product line remains competitive and responsive to the rapidly evolving market needs.

- Consider Customization as a Differentiator: With the increasing importance of brand identity, ensure that your chosen supplier offers extensive customization options. This includes not only racket shapes such as Diamond, Round, and Teardrop but also personalized elements like grip design and printing.

- Assess Supply Chain Efficiency: The ability to quickly adapt to market demands and manage logistics is critical. Work with suppliers who demonstrate robust and efficient production cycles.

- Adopt a Sustainability Mindset: Align your procurement strategy with suppliers who commit to sustainable practices. This is not only a matter of corporate responsibility but also a competitive advantage as consumer awareness of environmental issues continues to grow.

By following these recommendations, procurement managers can stay ahead in selecting a supplier that delivers high-quality, performance-enhanced padel rackets in 2025 and beyond.

In summary, the padel rackets of 2025 will be defined by their use of advanced production techniques, innovative material applications, and high degrees of customization. For B2B buyers in sports equipment distribution and product development, aligning with suppliers who are at the forefront of these trends is essential. The race towards more efficient production cycles, coupled with the drive for superior design and sustainability, will set industry leaders apart.

Companies like NEX Padel, with their comprehensive expertise spanning from material innovation to rapid prototyping, provide a strong competitive edge. As the market evolves, procurement decisions based on clear performance metrics and supplier capability assessments will be crucial in ensuring long-term success. Embrace these trends, focus on quality and customization, and be prepared for a dynamic future where innovation and tradition blend seamlessly to create high-performance sports equipment.

People Also Ask

Q1: What are the main trends shaping padel rackets in 2025?

A1: The main trends include the adoption of advanced production techniques using various grades of carbon fiber, innovative design shapes such as Diamond, Round, and Teardrop, and extensive customization options for branding and performance.

Q2: How do advanced production techniques improve the performance of padel rackets?

A2: Advanced production techniques, including precision cutting, robotic assembly, and real-time quality control, ensure greater consistency, enhanced material performance, and accelerated production cycles, all of which contribute to improved racket performance on the court.

Q3: What customization options are available for padel rackets in 2025?

A3: Customization options include personalized racket shapes, custom prints and logo placements, tailored hand grips, and design modifications, allowing brands and players to achieve both performance benefits and distinctive aesthetics.

-

advanced production techniques: Reading the article will provide insights into how modern manufacturing methods drive innovation and improve operational efficiency. ↩

-

customization: Reading the article will help understand how personalized design options can differentiate products and align with brand identity. ↩

-

carbon fiber: Reading the article will explain the benefits and applications of carbon fiber in enhancing product performance and durability. ↩

-

robotic assembly: Reading the article will shed light on how automation and robotics improve manufacturing precision and scalability. ↩

-

Sustainable Manufacturing: Reading the article will discuss energy-efficient and environmentally responsible production practices that contribute to long-term sustainability. ↩