NEX Padel stands out as the advanced manufacturing partner for high-performance pickleball paddles by combining state‑of‑the‑art production techniques1, versatile customization2 and strict quality control—making us a strong candidate for long-term business partnerships.

In today’s competitive sports equipment market, B2B procurement managers and distributors are increasingly focused on manufacturers who not only meet quality standards but also deliver innovative production techniques. Manufacturers are evaluated on technical prowess, production efficiency, and customization flexibility. NEX Padel leverages advanced materials—ranging from fiberglass to premium carbon fiber variants (3k, 12k, 18k)3—to produce paddles that excel in durability and performance.

The search for the right manufacturing partner involves answering key questions such as:

• How robust are the production processes?

• What customization capabilities does the manufacturer offer?

• Is the supply chain efficient and reliable?

By addressing these questions, businesses can make informed decisions that enhance their market competitiveness.

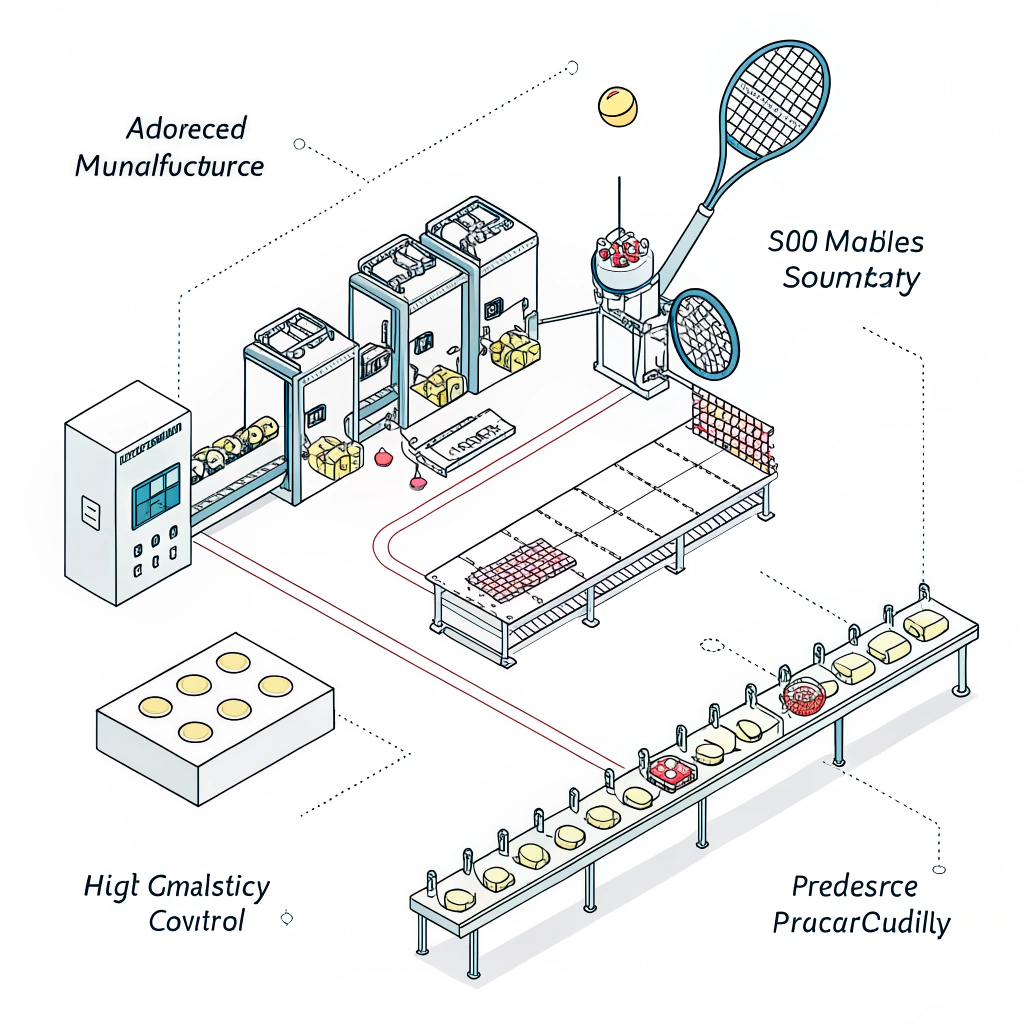

Manufacturing excellence for pickleball paddles hinges on the integration of innovative production techniques. At NEX Padel, our production process is defined by:

- Material Quality: Using high-grade carbon fiber (3k, 12k, and 18k) ensures exceptional strength without compromising weight.

- Precision Crafting: Advanced machinery and skilled technicians create a consistently balanced paddle, ensuring performance under high stress.

- Customization Flexibility: Our processes support full customization in shape, printing, color, and even specialized parts like hand grips and handle covers.

These production elements minimize defects and improve overall product durability, a critical factor for procurement managers looking to reduce warranty claims and customer dissatisfaction.

Cost-effectiveness doesn't only come from the unit price but from a reliable delivery schedule and minimized downtimes. Our quick prototyping and on-time delivery guarantee that distributors can plan well ahead for market demands. The streamlined communication between our design and production teams ensures that orders are processed without delays.

Modern sports equipment distributors need the ability to offer differentiated products. Customization is not merely an aesthetic upgrade; it directly impacts brand positioning and market competitiveness. Our manufacturing setup includes:

- Custom printing options for logos and designs.

- Alternative configurations such as diamond, round, and teardrop shapes.

- Variants in cushioning and grip for ergonomic advantages.

Customization options allow our partners to tailor products to specific market segments, meeting both professional and amateur players' requirements.

A clear comparison between manufacturers can help highlight the strengths that distinguish NEX Padel:

| Criteria | NEX Padel | Typical Competitor |

|---|---|---|

| Material Variants | Fiberglass, 3k, 12k, 18k Carbon Fiber | Limited options, often only fiberglass or 3k carbon |

| Customization Options | Full customization (shape, print, color, grip) | Minimal to moderate customization |

| Production Speed | Rapid prototyping and timely delivery | Longer lead times |

| Quality Control | Rigorous multi-stage quality assurance | Standard industry quality checks |

| OEM Partnerships4 | Supported partnerships with brands like Reebok, Hirostar, Starvie | Less extensive OEM background |

| Supply Chain Efficiency | Integrated supply chain5, on-time order fulfillment | Often fragmented, with potential delays |

This table summarizes why partners focusing on quality, innovation, and flexibility should lean towards NEX Padel. The ability to cater to diverse specifications while ensuring precision can significantly mitigate risks associated with manufacturing inconsistencies.

High-performance pickleball paddles benefit from the use of premium materials. NEX Padel’s inclusion of various carbon fiber types allows customization in performance characteristics:

- 3k Carbon Fiber: Offers a balance between weight and stiffness, ideal for players seeking moderate control.

- 12k & 18k Carbon Fiber: These options provide increased durability and a more robust structure, fitting for competitive play and higher impact scenarios.

These materials undergo thorough testing to verify their performance under stress, ensuring that paddles maintain their integrity even after extensive use. This reduces the likelihood of product returns or warranty claims.

While traditional manufacturing methods may suffice for basic levels of play, precise control over each paddle's balance and feel is a competitive advantage. Our state-of-the-art machinery and dedicated quality control teams offer:

- Consistent weight distribution through advanced molding techniques.

- Enhanced edge reinforcement using composite layering technology.

- Optimized grip ergonomics which improve user performance and comfort.

Such precision leads to a product that is not only reliable but also allows end users to maximize their performance on the court. This is key for distributors who need to ensure end-user satisfaction and brand reputation.

Customization is central to our value proposition. A personalized paddle that aligns with a brand’s identity can significantly increase product loyalty among sports enthusiasts. Additionally, variability in design allows distributors to target different market segments. Whether it’s an amateur league or professional competition, the ability to customize ensures that every player can find a product that suits their style and performance needs.

| Custom Feature | Options Available | Impact on End-User Experience |

|---|---|---|

| Paddle Shape | Diamond, Round, Teardrop, Fully Customizable | Affects balance and weight distribution |

| Printing & Color | Multiple colors and print designs; logo options | Enhances brand recognition, aesthetic appeal |

| Grip & Handle | Custom logos, tailored ergonomic design | Improves handling and overall comfort |

This granular approach to customization ensures that distributors have a competitive advantage by offering products that truly resonate with consumer needs.

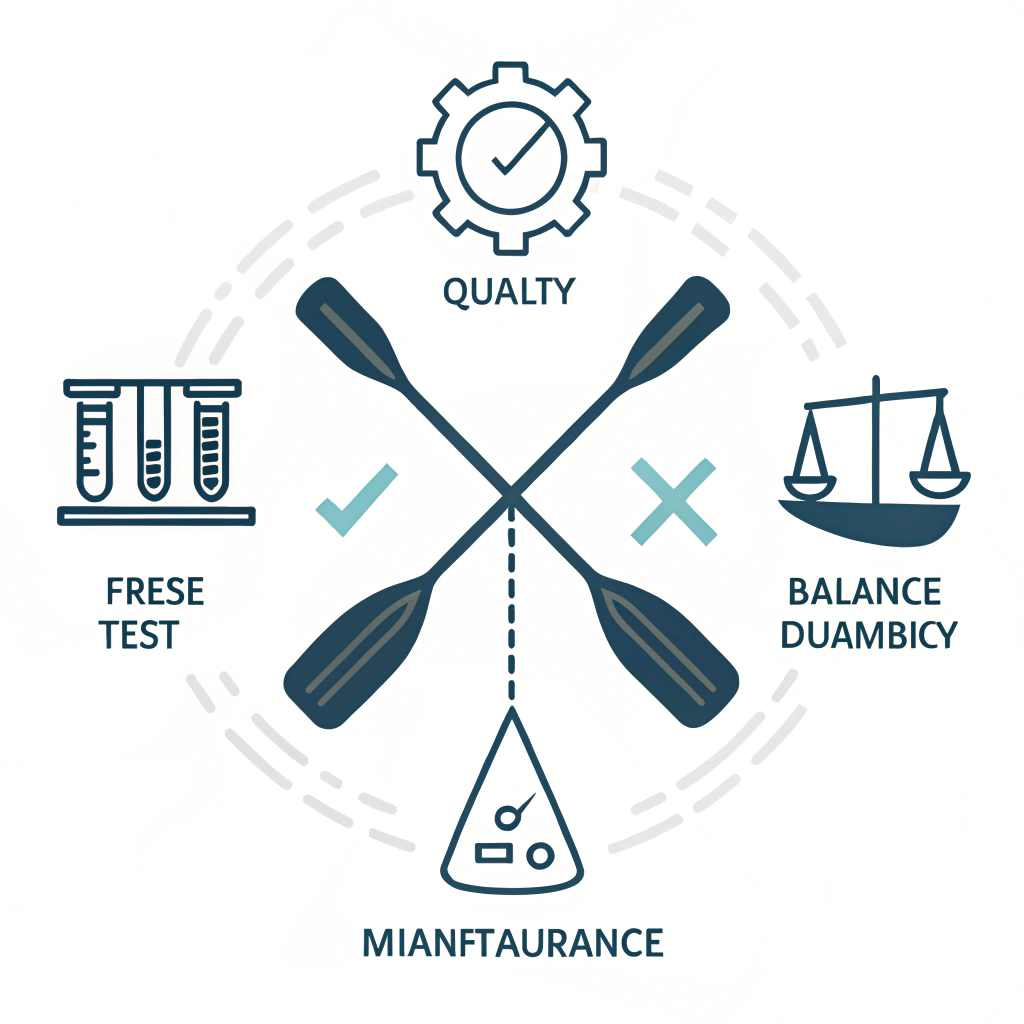

Quality assurance is not just about meeting industry standards; it is the backbone of customer trust and long-term partnerships. NEX Padel employs rigorous multi-stage testing protocols that include:

- Material integrity tests to assess the strength and performance of carbon fiber variants.

- Precision balance checks to ensure the paddle’s optimal performance.

- Durability analysis through repetitive stress tests.

These measures help eliminate inconsistencies and guarantee that every product shipped meets the highest quality standards.

An effective supply chain is crucial for maintaining production schedules and ensuring timely delivery. NEX Padel’s supply chain is managed through an integrated system that synchronizes orders with production and distribution. This not only helps in reducing lead times but also ensures that inventory levels are optimized, avoiding overproduction or stock shortages. Reliable lead times and on-time deliveries strengthen the trust between manufacturers and distributors, making for a smooth, continuous business relationship.

Over the years, NEX Padel has built a robust portfolio by working with renowned brands such as Hirostar, Reebok, and Starvie. These partnerships are a testament to our capability to meet diverse production needs and maintain high-quality standards. For instance:

- Hirostar Partnership: Demonstrated how custom grip design and optimized paddle balance contribute to enhanced player performance in competitive scenarios.

- Reebok Collaboration: Focused on cutting-edge carbon fiber technology to produce paddles that perform reliably under high-stress conditions.

- Starvie Association: Highlighted the importance of fast prototyping and agile production in responding to market trends and consumer demands.

The successes of these OEM collaborations underscore the significance of choosing a manufacturing partner that not only understands the technical aspects of production but also possesses the agility required to adapt to market shifts.

For procurement managers and sports equipment distributors, the decision to partner with a manufacturer extends beyond simple cost comparisons. Strategic benefits include:

- Enhanced Product Performance: Advanced materials and precision production result in paddles that deliver superior performance.

- Reduced Operational Risks: Robust quality control and timely deliveries mitigate the risks of delays and product failures.

- Market Differentiation: Extensive customization capabilities allow businesses to offer unique products tailored to specific market needs.

- Long-Term Partnership Potential: Consistent quality and efficient production foster reliable long-term business relationships.

- Conduct a Comprehensive Evaluation: Ensure that the manufacturer’s production capabilities, quality control processes, and customization options are aligned with your business needs.

- Request Technical Demonstrations: Verify the technical credentials by requesting samples and demonstrations of the manufacturing process.

- Prioritize Long-Term Partnerships: Consider the manufacturer’s track record and ability to adapt to evolving market trends for a sustainable relationship.

- Insist on Transparency: Work with manufacturers that offer transparency in their production processes and supply chain management, ensuring minimal operational risks.

- Leverage OEM Success Stories: Use case studies and past successful partnerships as benchmarks when evaluating potential suppliers.

By incorporating these recommendations, procurement managers can mitigate risks and secure the success of their product offerings in a competitive market.

In summary, selecting the right manufacturer for pickleball paddles is a decision that should be based on a thorough evaluation of production techniques, quality control, customization, and supply chain efficiency. NEX Padel exemplifies advanced manufacturing with precision engineering, rapid prototyping, and extensive customization capabilities—ensuring products that meet the high-performance demands of today’s sports market.

For B2B procurement managers and distributors, partnering with a manufacturer like NEX Padel means gaining a competitive edge through reliable product performance and strategic innovation. Our commitment to excellence, combined with real-world OEM success stories, makes NEX Padel the ideal choice for businesses seeking a robust, innovative manufacturing partner.

Make an informed decision today by examining the technical details, reviewing successful case studies, and verifying our extensive customization options—ultimately paving the way for successful, long-term business partnerships.

• Which manufacturing techniques ensure durability in pickleball paddles?

Advanced composite layering of materials such as premium carbon fiber and precise molding techniques contribute to improved durability in pickleball paddles. Rigorous quality control processes and repeated stress tests further ensure long-lasting performance.

• How does customization impact paddle performance?

Customization not only provides aesthetic appeal but also influences weight distribution, balance, and grip ergonomics. Tailoring the paddle design to specific user needs can enhance performance while reinforcing brand identity.

• What quality assurance processes should be prioritized in paddle manufacturing?

Key processes include multi-stage quality checks covering material integrity, balance verification, and durability testing. Transparent supply chain management combined with on-time production further contributes to reliable, high-quality paddle manufacturing.

-

state‑of‑the‑art production techniques: Click to explore detailed insights on modern manufacturing processes and how they enhance product performance through innovative methods. ↩

-

versatile customization: Click to learn more about strategies for offering product variations that meet diverse consumer and brand requirements. ↩

-

premium carbon fiber variants (3k, 12k, 18k): Click to understand the differences between carbon fiber types and their impact on performance and durability. ↩

-

OEM Partnerships: Click to read about the benefits and complexities of Original Equipment Manufacturer collaborations in the sports equipment industry. ↩

-

Integrated supply chain: Click to discover how end-to-end supply chain integration can boost efficiency and reliability in manufacturing. ↩