In the context of carbon fiber1 grades used in padel rackets, the quick answer is: 12K carbon fiber offers a softer, more vibration-absorbing feel compared to 3K carbon, which is more rigid and impact resistant; meanwhile, 18K and 24K provide further variations in stiffness, durability, and performance that can be matched to specific design and market requirements.

When sourcing high-performance padel rackets, it is essential to understand the key differences between various carbon fiber grades—namely 3K, 12K, 18K, and 24K. In this article, we will compare these grades to help B2B procurement managers and technical specialists make an informed decision that aligns with your brand’s quality standards and market positioning. Our analysis is grounded in technical performance data, advanced manufacturing insights from NEX Padel, and practical considerations for customization and production reliability.

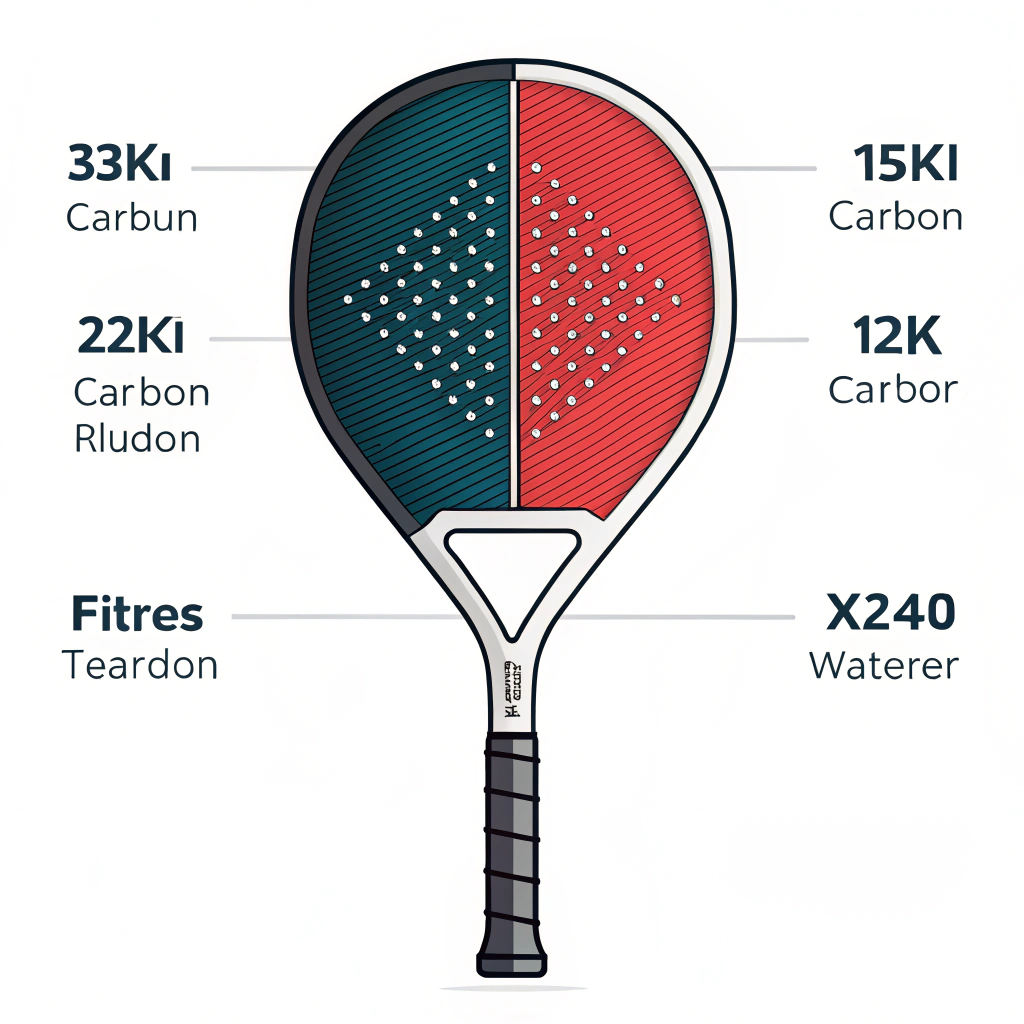

Carbon fiber is a crucial material in the production of modern padel rackets due to its high strength-to-weight ratio and excellent durability. The grade of carbon fiber—commonly indicated by a designation such as 3K, 12K, 18K, or 24K—refers to the number of carbon filaments bundled in a single tow or strand. More filaments generally result in a material with different mechanical properties:

- 3K Carbon Fiber2: Contains approximately 3,000 filaments per tow. It is known for its rigidity and high strength, making it ideal for players seeking power and precision.

- 12K Carbon Fiber3: With around 12,000 filaments per tow, this grade offers a balance between performance and flexibility. It absorbs vibrations better, leading to enhanced comfort and reduced arm fatigue.

- 18K & 24K Carbon Fiber: These higher filament counts typically provide even greater factors in stiffness variation and weight distribution. While less commonly used than 3K and 12K, they can cater to specialized performance demands, offering benefits such as improved impact resistance and aesthetic finishing options.

Each grade affects not just the mechanical performance of the racket, but also factors like cost, manufacturing complexity, and customization opportunities.

Below is a detailed comparison of the various carbon fiber grades used in padel rackets:

| Parameter | 3K Carbon Fiber | 12K Carbon Fiber | 18K/24K Carbon Fiber |

|---|---|---|---|

| Filament Count | ~3,000 per tow | ~12,000 per tow | 18,000 - 24,000 per tow |

| Rigidity and Strength | High rigidity; excellent impact absorption | Slightly softer with improved vibration dampening | Varies; generally, enhanced strength with specialized treatment |

| Feel and Flexibility | Offers a firm, precise feel | Provides a more flexible, comfortable feel for extended play | May offer tailored stiffness or flex characteristics depending on the composite design |

| Weight Distribution | Optimized for power-oriented play | Balances power with better control and reduced shock | Often used for premium or customized performance models |

| Cost Implications | Moderately priced due to standard use | Slightly higher cost due to more complex manufacturing | Costs can vary significantly depending on customization and finishing |

| Manufacturing Complexity | Lower complexity for rapid production | Requires careful calibration in layup and resin infusion | Demands advanced production techniques and higher quality control |

| Customization Options | Widely available across standard models | High potential for unique designs and branding integrations | Often reserved for high-end or niche market products |

The choice between carbon fiber grades directly affects the performance characteristics of padel rackets. Understanding these differences is vital for procurement managers looking to optimize product attributes for market-specific strategies:

-

Power and Control:

– 3K Carbon Fiber: Its inherent rigidity contributes to powerful strokes and precise ball placement. However, this performance can come at the cost of increased vibrations, which might lead to longer-term fatigue during extended matches.

– 12K Carbon Fiber: With a thread configuration that absorbs vibrations more effectively, 12K carbon fiber racket models offer excellent balance in power while reducing the physical strain on players. -

Durability and Impact Resistance:

– 3K vs 24K Carbon Fiber: The technical specifications of 3K carbon—featuring a strength range typically between 220-250 kg/mm²—make it resistant to pressure and impact shocks. Conversely, 24K carbon, although less rigid, can be engineered to enhance durability under specific conditions. This variation is useful for brands targeting a premium segment where durability and performance consistency are key. -

Customization and Market Differentiation:

– Customization Options: In today’s sports equipment market, the ability to customize not only the shape but also the material configuration opens up avenues for branding. NEX Padel offers advanced customization options, including tailor-made shapes, bespoke printing, and even logo customization on elements such as the hand grip and handle cover. This capability allows you to align the product closely with the brand identity, regardless of the carbon fiber grade selected. -

Manufacturing Considerations:

– With the high-paced demands of modern production, the selection of a carbon fiber grade also depends on how quickly prototypes can be made and orders delivered. NEX Padel’s advanced production techniques mean that whether you opt for 3K, 12K, or even higher grades, the production process remains reliable and timely.

– In addition, quality control is paramount. Each product undergoes rigorous tests to ensure the racket not only meets strength benchmarks but also aligns with the performance metrics expected by high-level players.

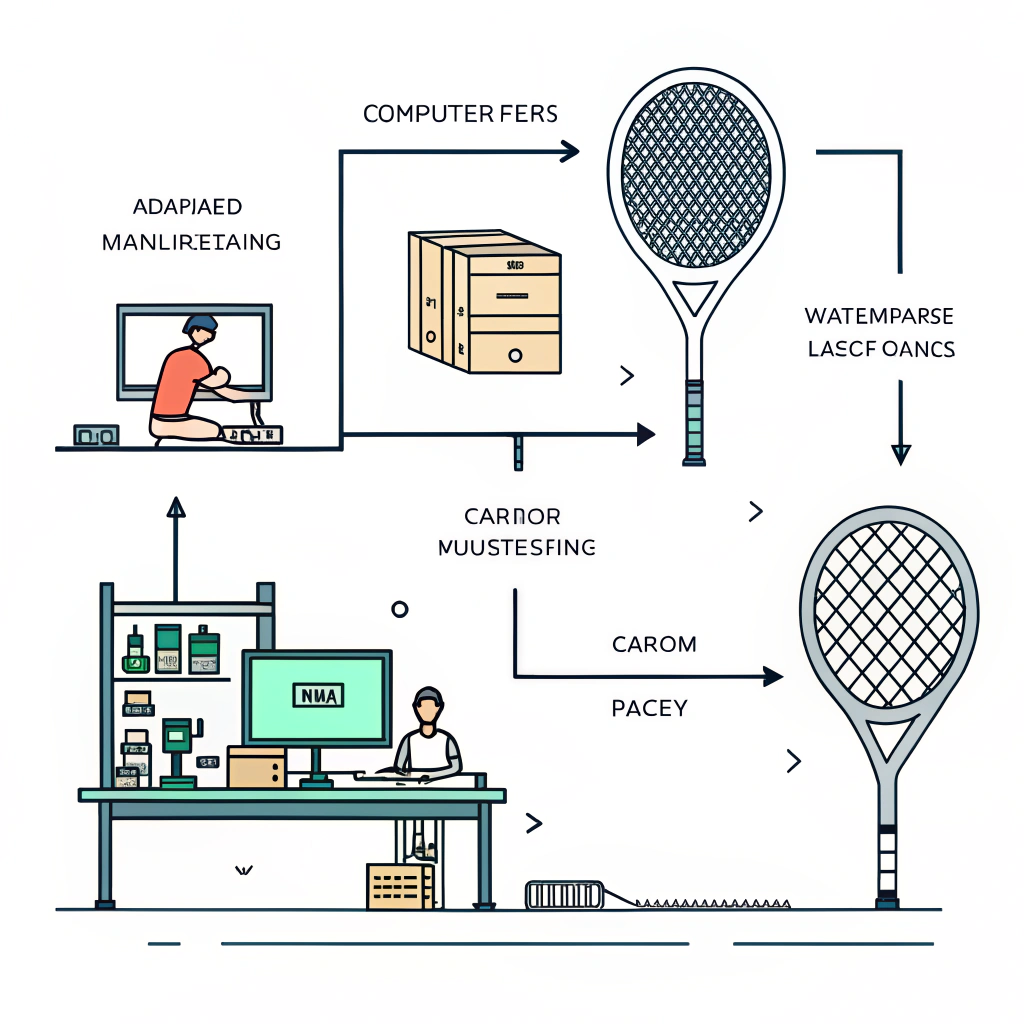

At NEX Padel, we leverage advanced production techniques to maintain a fine balance between performance and production efficiency. When working with different grades of carbon fiber, our manufacturing process involves several key stages:

-

Material Selection:

Every carbon fiber grade is selected based on its performance attributes and compatibility with our design philosophy. We source everything from 3K for models emphasizing power to 12K for those focused on vibration reduction. Certain premium models may incorporate 18K or 24K fibers to meet niche market demands. -

Layup Techniques4:

The layup process is critical in ensuring that the carbon fibers are aligned properly to maximize strength and flexibility. Our engineers use computer-aided design (CAD) and simulation software to map out the precise fiber directions and resin distribution, ensuring that the final product is consistent with the expected performance outcomes. -

Customization Capabilities5:

What sets us apart is our ability to provide fully customized solutions. From the racket shape to the hand grip logo, every aspect of the production is adjustable to accommodate unique client requirements. This adaptability is especially useful when integrating advanced materials like 12K, 18K, or 24K carbon fibers, which may demand specific handling during production. -

Quality Assurance:

Rigorous testing ensures every racket maintains structural integrity and performance consistency. Tests simulate various stress conditions (impact, bending, and fatigue tests) to ensure the chosen carbon fiber grade delivers on its promise of durability and performance reliability.

In summary, whether you are considering a more rigid design emphasizing power (3K) or opting for enhanced vibration absorption with a softer feel (12K), the production methodologies at NEX Padel are engineered to support your objectives. Our custom manufacturing process enables us to integrate advanced materials, ensuring that each racket not only meets industry standards but also exceeds player expectations.

When deciding on the appropriate carbon fiber grade, consider the following practical aspects:

-

Market Demand and Player Feedback:

Analyze feedback from target markets. If players in your target segment have reported arm fatigue or a need for smoother stroke execution, 12K or higher may be the preferred option. -

Cost vs. Performance Trade-offs:

A balance between performance characteristics and production costs is essential. While 3K may offer a cost-effective solution for power-driven play, the slight premium on 12K can be justified through reduced player fatigue and the potential for improved durability. -

Customization and Brand Positioning:

In a competitive market, the ability to customize product features is a significant differentiator. Whether it is the unique feel provided by 12K or the robust performance of 3K, ensure that the chosen carbon fiber grade not only resonates with player expectations but also aligns with your brand’s identity. -

Long-Term Production Strategy:

Consider your supply chain’s capacity and production timelines. NEX Padel’s efficient production cycle—from rapid prototyping to timely delivery—ensures that even highly customized orders involving advanced carbon fiber grades are fulfilled without delays. -

Innovation and Trends:

Stay abreast of the latest technological trends. As manufacturing techniques evolve, new composites and hybrid materials may offer even better performance. Early adoption or experimentation can offer a competitive edge.

This comparative analysis of carbon fiber grades underscores that there is no one-size-fits-all answer. Each grade—3K, 12K, and higher—offers distinct advantages that can be matched to your product strategy and target market:

-

3K Carbon Fiber:

Ideal for designs focused on rigidity and immediate power. It is best suited when impact resilience is the priority and cost efficiency is paramount. -

12K Carbon Fiber:

Provides a balanced combination of power and comfort by reducing vibrations. It is well-suited for brands that place a premium on extended play comfort and ergonomic benefits. -

18K/24K Carbon Fiber:

Although less common, these grades can be engineered for niche markets demanding specialized performance and premium quality. Their higher filament count offers tailored stiffness profiles and may serve high-end product lines.

For procurement managers, the key takeaway is to align your choice of carbon fiber grade with both performance objectives and production capabilities. Leverage the customization potential and advanced manufacturing techniques provided by trusted partners like NEX Padel to achieve an optimal balance. In today’s competitive landscape, investing in the right materials not only elevates product performance but also reinforces your brand’s reputation for quality and innovation.

In summary, review your target market’s preferences, balance cost and performance, and choose a carbon fiber grade that meets your quality requirements. Whether you are sourcing a robust 3K-based model or a more refined 12K variant, the decision should revolve around aligning with your long-term strategic goals.

• Is 3K carbon better than 12K padel?

12K carbon offers a softer and more comfortable feel with improved vibration absorption, which can reduce arm fatigue during prolonged play, while 3K is generally more rigid and provides precise impact resistance.

• What is the difference between 3K and 24K padel racquets?

3K carbon is typically stronger and more rigid, with a performance strength of around 220-250 kg/mm², whereas 24K carbon, while less rigid, can be engineered to emphasize durability and specialized performance, often catering to premium product lines.

• What is the difference between 3K and 12K carbon fiber paddle?

The primary difference is in the number of threads per tow—3K uses about 3,000 threads while 12K uses approximately 12,000 threads—which translates into 12K carbon offering greater flexibility and vibration dampening compared to the more rigid 3K fiber.

-

carbon fiber: Click to learn about its composition, properties, and why it is a preferred material in high-performance sporting goods manufacturing. ↩ ↩

-

3K Carbon Fiber: Click to understand the technical specifics of 3K carbon fiber, including its filament count and impact on racket performance. ↩ ↩

-

12K Carbon Fiber: Click to discover how 12K carbon fiber balances flexibility and strength, offering benefits such as improved vibration dampening. ↩ ↩

-

Layup Techniques: Click to explore the methods used to align carbon fibers during production, crucial for maximizing strength and consistency in sporting equipment. ↩ ↩

-

Customization Capabilities: Click to learn how tailored manufacturing processes enable unique product designs and branding opportunities in high-performance equipment. ↩ ↩