Wholesale paddle suppliers play a crucial role in empowering sports distributors to differentiate their offerings with high-performance, customized products. In essence, they must deliver superior quality, rapid production cycles, and extensive personalization options to meet market demands.

Distributors and purchasing managers face a challenging choice when sourcing wholesale paddle equipment. The market is highly competitive and filled with suppliers who vary widely in their production quality, customization capabilities, and speed of delivery. The challenge is to select a partner who not only meets industry standards but also offers advanced production techniques and the flexibility needed to support your business growth.

Many B2B buyers today are increasingly focused on obtaining products that stand out in the retail environment. They are not only looking for a cost-effective solution but also want to ensure that the products are made from high-quality materials such as glass fiber, 3k, 12k, and 18k carbon fiber1. These materials ensure durability and performance on the court, which in turn builds brand reputation for the distributor. In addition to material quality, the ability to fully customize the product—from paddle shapes to custom printed logos on hand grips—serves as a powerful differentiator.

-

Quality Assurance2 and Material Selection

High-performance paddles must be crafted from premium materials. Suppliers often use basic materials, but a leading partner will offer a range of options, including glass fiber and various grades of carbon fiber. The choice of material directly affects weight, balance, and longevity, which are critical performance attributes in a competitive sporting environment. -

Customization Capabilities3

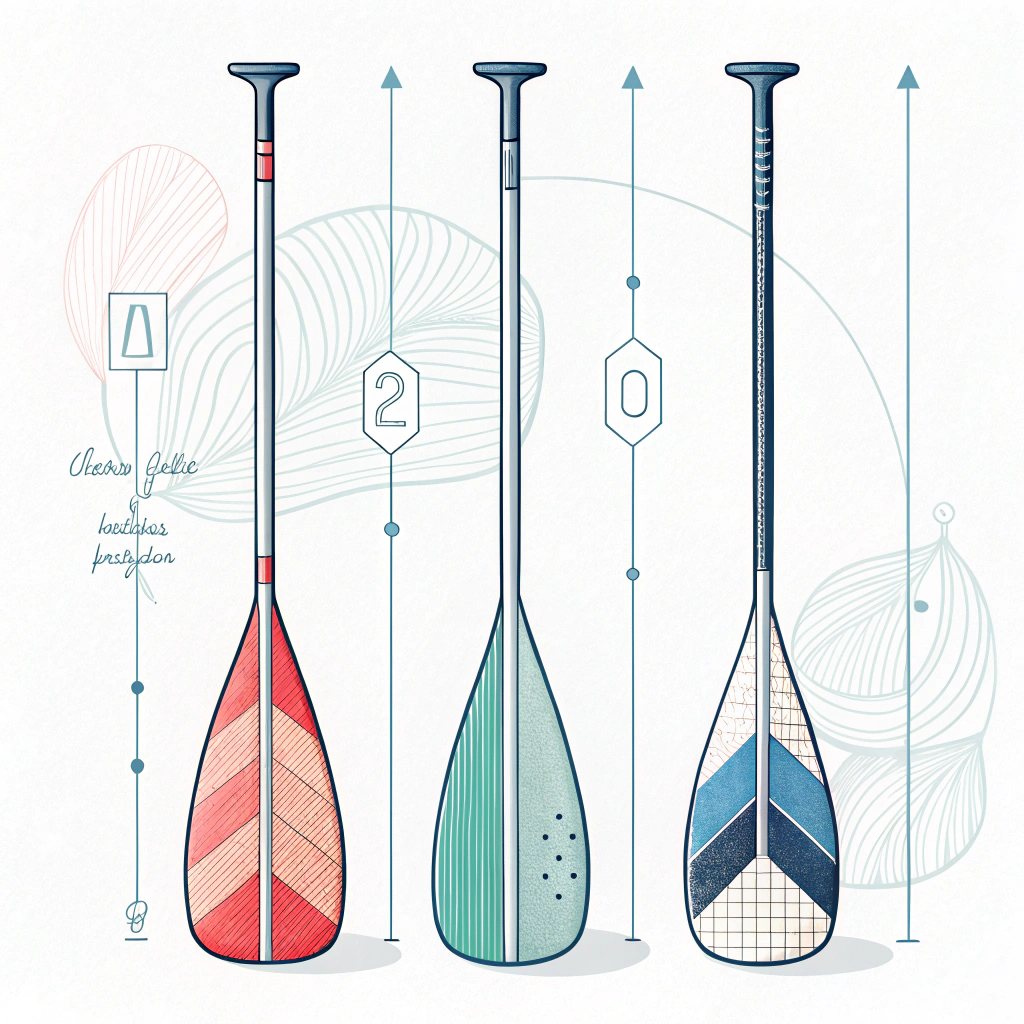

For distributors aiming to offer unique, branded products, customization is more than a nice-to-have—it’s a necessity. This includes not only paddle design (with shapes such as Diamond, Round, and Teardrop) but also custom colors, printing, and even personalized components like hand grips and handle covers. Customization enhances product appeal and supports brand differentiation. -

Production and Turnaround Time

In today’s fast-paced market, efficient production cycles and on-time deliveries are essential. Suppliers with advanced production techniques4 can not only maintain high quality but also reduce lead times. Fast turnaround is particularly important for distributors aiming to launch products in line with market trends or seasonal demands. -

Supply Chain Reliability5

Consistent supply and dependable service are the backbone of any B2B partnership. Distributors must ensure that suppliers have robust logistics, quality controls, and scalable operations that can sustain both small orders and large, ongoing supply contracts.

These core factors provide a framework for evaluating potential suppliers in a transparent and objective manner.

Below is a comprehensive comparison table that outlines key features and how leading suppliers like NEX Padel stand out when compared to common industry standards.

| Feature | Industry Standard | NEX Padel Advantage |

|---|---|---|

| Material Quality | Typically offers glass fiber or basic carbon options | Wide selection from high-quality glass fiber to advanced 3k, 12k, and 18k carbon fiber ensuring superior performance |

| Customization Options | Limited options; standard shapes and colors | Full customization including paddle shape (Diamond, Round, Teardrop, or custom), custom printing, and branded hand grips |

| Production Turnaround | Longer lead times, less efficient techniques | Advanced production techniques for fast sampling and timely delivery |

| Quality Assurance | Basic quality checks and certifications | Rigorous quality monitoring with detailed production protocols and industry certifications |

| Supply Chain Reliability | Uncertain logistics with potential delays | Proven track record working with globally recognized brands such as Hirostar, Reebok, and Starvie |

| After-sales Service | Rudimentary support | Comprehensive support including flexible order modifications and continuous product updates |

This detailed comparison helps B2B buyers identify what truly matters: a supplier who can guarantee not only excellent product quality but also adaptability to meet specific business needs.

Having a high-performance wholesale paddle supplier is not just about the products—it’s about strategic alignment with your business objectives. Here are some common scenarios and insights into how partnering with a leading supplier can add value to your business:

-

Brand Differentiation Through Customization

In an increasingly saturated market, having exclusive, customized equipment can be a key selling point. For instance, a distributor may choose to offer paddles that align perfectly with their brand’s aesthetic and quality expectations. This is made possible when the supplier supports fully customized paddle shapes, colors, and printed elements. -

Responding to Market Trends with Quick Turnaround

Seasonal shifts and trending designs demand agility. A supplier who can rapidly produce and deliver products ensures that distributors can capitalize on emerging trends without missing market windows. Fast sampling and delivery mean that you can consistently refresh your product lines based on consumer demands. -

Ensured Quality for High-Performance Athletes

Whether your customers are recreational players or professional competitors, high-quality equipment is critical. Paddles manufactured with premium materials coupled with precision production techniques deliver performance benefits such as better control, lightness, and durability. This reliability enhances customer satisfaction and drives repeat business. -

Flexibility to Scale Orders

As your business grows, having a supplier capable of handling both small and large orders is essential. A reliable partner can adapt to your changing volume requirements and coordinate their logistics to ensure that scaling up or down does not affect quality or delivery timelines.

These strategic insights underscore that the relationship with a wholesale supplier is not a one-time transaction—it’s a long-term partnership that supports sustainable business growth.

Based on the critical factors discussed above, here are actionable recommendations for distributors and purchasing managers evaluating wholesale paddle suppliers:

-

Conduct a Detailed Capability Audit

Before finalizing a supplier, request detailed documentation on their material specifications, production techniques, quality assurance measures, and customization options. A comparative analysis using a table similar to the one above can be very beneficial. -

Prioritize Suppliers with Proven Market Credentials

Working with suppliers who have fulfilled orders for major brands ensures a level of trust and reliability. For example, NEX Padel’s history with well-known international brands is a strong indicator of their stringent quality controls and timely delivery practices. -

Engage in Regular Communication

Establish clear channels of communication to discuss order requirements, customization details, and any potential adjustments. Regular updates and proactive customer service can prevent issues and keep the supply chain running smoothly. -

Test Sample Orders

Before making large-scale commitments, place sample orders to verify that the production and customization meet your quality expectations. Quick turnaround and quality consistency during the sampling phase are often a good predictor of future performance. -

Leverage Industry Data and Trends

Stay informed about market trends and evolving consumer preferences. Use reliable data and case studies to guide your selection process. Suppliers that can adapt swiftly to these trends, like those employing advanced production techniques, can provide you with a competitive edge. -

Assess Long-term Partnership Potential

Beyond just meeting immediate product needs, consider how the supplier can support your future business growth. Assess their capability to innovate, manage increased volumes, and potentially expand their product lines to keep pace with market dynamics.

These recommendations form a robust strategy for ensuring that your selection process leads to a partnership that is beneficial both in the short and long term.

In summary, choosing the right wholesale paddle supplier is pivotal for business success in the competitive sporting goods market. Distributors need to focus on key differentiators such as superior material quality, extensive customization capabilities, rapid production turnaround, robust quality assurance, and reliable supply chain management. By conducting a thorough comparative analysis and leveraging strategic insights, B2B buyers can make informed decisions that drive market differentiation and boost customer satisfaction.

The selection process involves not only evaluating product specifications but also assessing long-term partnership potential. A supplier like NEX Padel, with its established reputation, advanced production techniques, and comprehensive customization offerings, stands out as a strong partner for those looking to deliver high-performance, exclusive products.

Ultimately, taking the time to meticulously compare suppliers and understand the full scope of what they offer will save time, reduce risks, and lead to a more profitable partnership. Distributors should consider both current market needs and future trends to ensure that their product lines remain competitive and appealing in a rapidly evolving industry.

People Also Ask

Q: What should B2B buyers look for in a wholesale sports equipment supplier?

A: B2B buyers should focus on quality assurance, material selection, customization options, fast production turnaround, and reliable supply chain management to ensure products meet high-performance standards.

Q: How do customization options affect product selection for distributors?

A: Customization not only helps maintain brand identity but also gives distributors the ability to offer unique products tailored to customer preferences, enhancing market differentiation and customer loyalty.

Q: What are the benefits of partnering with a supplier that uses advanced production techniques?

A: Suppliers with advanced production techniques ensure high-quality output, reduced lead times, and consistent product performance, enabling distributors to respond quickly to market trends and customer demands.

-

carbon fiber: Click to learn how carbon fiber is used to enhance durability and performance in high-end sports equipment, ensuring competitive advantages in today's market. ^Return ↩

-

Quality Assurance: Click to understand the critical role quality assurance plays in maintaining material standards and production consistency, which is vital for long-term business success. ^Return ↩

-

Customization Capabilities: Click to explore how robust customization options can help differentiate products in a crowded market and build a unique brand identity. ^Return ↩

-

advanced production techniques: Click to discover the benefits of utilizing cutting-edge production methods that reduce lead times while maintaining superior quality. ^Return ↩

-

Supply Chain Reliability: Click to read about building a dependable supply chain that supports scalability and ensures timely delivery in the competitive B2B landscape. ^Return ↩