A custom padel racket manufacturer must combine advanced materials, precise production techniques, and flexible customization options to truly support your business objectives. This article explains the challenges in custom padel racket manufacturing, analyzes the causes behind common issues, and provides clear, actionable solutions for sports equipment companies seeking a reliable OEM partner1.

When sports equipment companies look for custom padel rackets, they want more than just a product—they need a partner who understands quality, precision, and the specific requirements of evolving padel performance trends. Key challenges often include aligning technical specifications with cost objectives, ensuring consistent quality across production batches, and offering a variety of Customization Options2 to meet market demands. In this context, NEX Padel leverages advanced carbon fiber technologies3, such as 3k, 12k, and 18k variations, to produce high-performance rackets that serve renowned brands like Hirostar, Reebok, and Starvie.

The core issues in the custom padel racket manufacturing process largely stem from the following factors:

-

Material Selection and Quality Control

Choosing the right materials—from fiberglass to various grades of carbon fiber—can be complex, as each offers different performance benefits. Without rigorous quality control protocols, even premium materials can result in inconsistent product performance. -

Advanced Production Techniques4

High-performance padel rackets demand highly optimized production processes. Dissimilar cutting, layering, and curing techniques can affect the overall strength, precision, and durability of the final product. -

Customization and Flexibility

Offering versatile customization options—such as different racket shapes (Diamond, Round, Teardrop) and personalized hand grips—is essential for meeting market demands. However, balancing customization with manufacturing efficiency often presents a unique challenge. -

Timely Production and Delivery

In this fast-paced sports market, supply chain reliability is critical. Prolonged production lead times or manufacturing delays can jeopardize vendor relationships and end-customer satisfaction.

To tackle these challenges, our approach emphasizes streamlined production, robust quality assurance, and extensive customization options. Below is a clear list of solutions you can expect when partnering with a leading custom padel racket manufacturer like NEX Padel:

| Challenge | Our Proven Solution |

|---|---|

| Material Quality Control | Strict selection and testing protocols for Fiberglass, 3k, 12k, and 18k carbon fibers |

| Advanced Production Techniques | Utilization of precision machinery and proven production methodologies to ensure durability and performance |

| Customization Options | Offering multiple racket shapes (Diamond, Round, Teardrop) and full-customization (printing, colors, logo placement) |

| Timely Production and Delivery | Rapid prototyping and reliable production timelines backed by extensive factory insights and global logistics |

| Comprehensive Quality Assurance | Systematic quality assurance processes and performance testing at every stage of production |

Adopting this comprehensive solution is not only about addressing the immediate manufacturing concerns but also about reinforcing your long-term competitive edge in the padel market.

A deeper dive into our production techniques reveals how each step adds value to your final product:

-

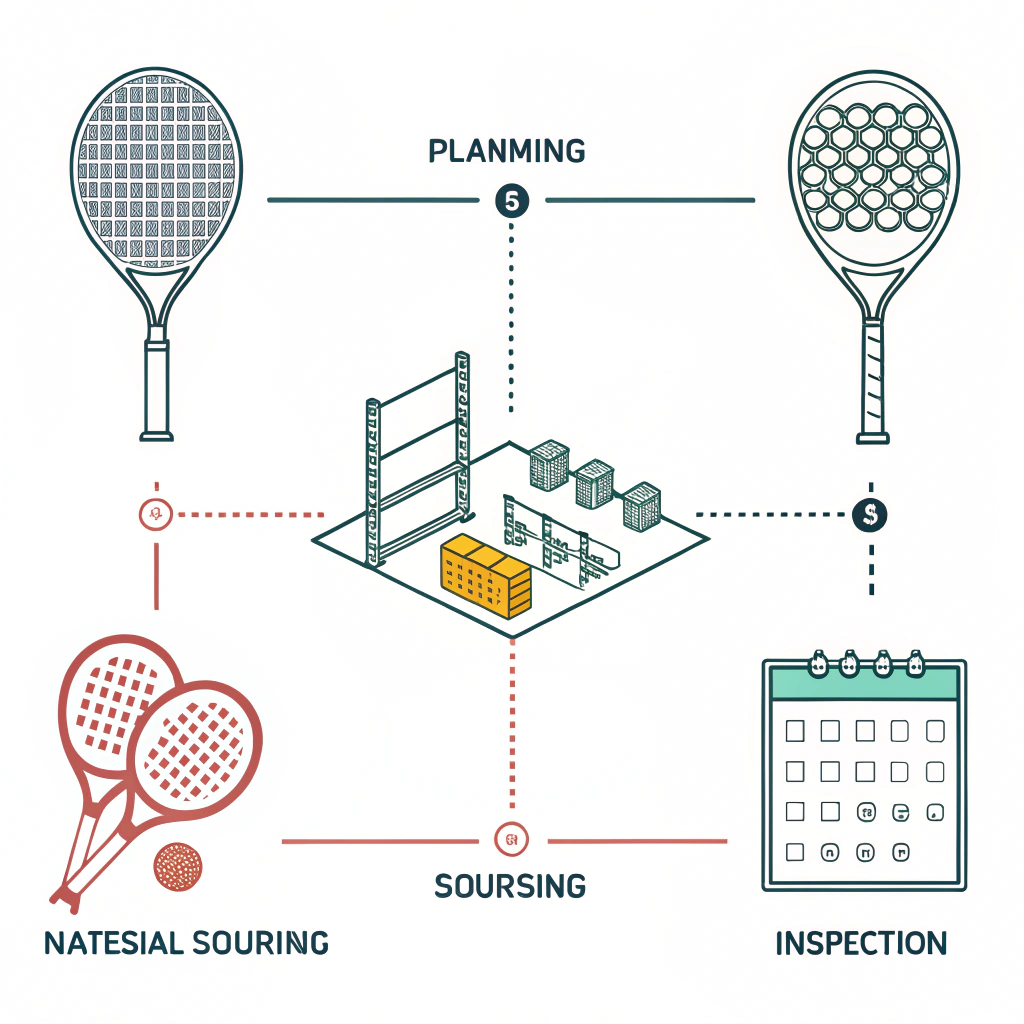

Pre-production planning:

At the beginning of every project, our engineering team collaborates closely with clients to understand specific technical needs. Detailed blueprints and CAD designs guide the manufacturing process, ensuring precision from the start. -

Material sourcing and testing:

We source only high-grade materials. Rigorous testing ensures that each batch, whether it's woven fiberglass or cutting-edge carbon fiber, meets pre-defined quality standards. Quality Assurance5 is embedded into every stage to avoid any deviations that might affect performance. -

Customized production processes:

With our extensive experience as an OEM padel production partner, we have honed our production techniques to support full customizations. Whether you need the classic Diamond, Round, or Teardrop racket shape—or a completely new version—our agile production system can accommodate these nuanced shifts with ease. -

Final assembly and inspection:

Post-production, a comprehensive inspection cycle helps identify any potential defects and ensures that every padel racket leaving our factory meets the strictest industry standards. This step is essential for maintaining the performance and durability that our international clients rely on.

When selecting a manufacturing partner for custom padel rackets, consider the following key points:

● Material Expertise: Understand the importance of different carbon fiber grades and how they impact the racket's stiffness, flexibility, and overall performance. Our expertise in using 3k, 12k, and 18k carbon fiber allows us to tailor each product to your precise needs.

● Customization Capabilities: In today’s competitive market, rackets are no longer one-size-fits-all. The ability to customize not only racket shape but also aesthetics—such as colors, printed logos, and even individual components like hand grips or handle covers—is paramount. We pride ourselves on being flexible to your unique requirements.

● Production and Delivery Efficiency: Balancing fast turnaround times with stringent quality controls is key. Our streamlined production process minimizes lead times while ensuring that every batch is meticulously crafted and inspected.

● Reliability and Industry Experience: Working with globally recognized brands demonstrates our capability to handle large-scale production without compromising on quality. Trust in our factory insights and innovative production techniques gives you the confidence to invest in products that resonate with your end markets.

An example case study illustrates our commitment to quality and reliability. One of our long-term partners in Europe required an extensive customization of padel rackets to satisfy a niche segment of leisure players. With an emphasis on maintaining balance between performance and cost, we utilized our custom tooling to develop a unique teardrop design featuring a special graphic print and enhanced grip ergonomics. The result was a highly successful product line that met both performance benchmarks and aesthetic appeal, leading to increased market share for our partner.

In addition to our successful case studies, here are some important technical considerations that further emphasize our comprehensive approach:

● Production Flexibility:

Our manufacturing processes allow for full customization—from altering racket geometry to integrating special features requested by our clients. This adaptability is essential to meet diverse regional and competitive market requirements.

● Quality Assurance Methods:

Each production stage implements detailed checklists and data logging. We utilize sensors and advanced imaging systems that capture minute details. This high level of precision aims to minimize manufacturing variances and maintain product consistency across large volumes.

● Cost-Effective Manufacturing:

While technological advancements may suggest high production costs, our streamlined processes and batch optimization ensure that we offer competitive pricing without compromising the quality of each padel racket. This dual emphasis on cost-effectiveness and superior performance is a major reason why many top brands continue to choose us as their OEM manufacturing partner.

● End-to-End Service:

Not only do we manufacture custom padel rackets, but we also offer complementary products such as padel balls. Our padel balls are produced in two variants, 45% wool and 57% wool, utilizing pressurized tube packaging to ensure consistent performance. This integrated service approach underlines our commitment to quality and comprehensive client support.

To sum up, the world of custom padel racket manufacturing requires a partner who understands both the technical intricacies and the business demands of the marketplace. We at NEX Padel are committed to delivering high-performance products that are tailored to your needs, backed by extensive technical know-how and a proven track record with leading global sports brands. Whether your focus is on advanced carbon fiber applications, precise customization, or reliable production timelines, our expertise ensures that your investment translates into superior performance and market advantage.

Our recommendation is to conduct a detailed assessment of potential partners by comparing material quality, customization flexibility, production techniques, and overall reliability. Supply chain integrity and cost-efficiency should also be key considerations. Taking these practical steps will ultimately help you select the right custom padel racket manufacturer who aligns with your quality and cost objectives.

By choosing an experienced, tech-driven manufacturer, you also open the door to innovative design improvements and enhanced athletic performance—critical factors in a competitive sports market. The right partnership will not only fulfill your current technical requirements but can also provide strategic advice on future product developments, helping you stay ahead of industry trends.

Ultimately, the decision point is grounded in understanding how well your manufacturing partner can deliver both on promises and on performance. With our robust production capabilities, high-quality materials, and proven track record, NEX Padel stands ready to address all your custom padel racket needs with precision, reliability, and innovation.

People Also Ask

Q: How can a manufacturer ensure consistent quality in custom padel rackets?

A: Consistent quality is ensured through rigorous material testing, precision production techniques, and comprehensive quality control measures at every production stage.

Q: What materials are most effective for high-performance padel rackets?

A: High-performance padel rackets are often made using advanced carbon fibers (such as 3k, 12k, and 18k), combined with quality fiberglass, ensuring a balance between strength, flexibility, and durability.

Q: Why is customization important for padel racket manufacturing?

A: Customization enables manufacturers to meet varied market demands by offering unique shapes, colors, logos, and ergonomic features, thereby enhancing both performance and brand value.

-

OEM partner: Reading about OEM partnerships will help you understand the strategic benefits, supply chain integration, and operational synergies offered by collaborating with an experienced original equipment manufacturer. Back to OEM partner ↩

-

Customization Options: Discover how offering a range of customization options can meet diverse market demands and drive product differentiation in competitive industries. Back to Customization Options ↩

-

Carbon Fiber Technologies: Reading about carbon fiber technologies provides insights into material grades, performance benefits, and manufacturing considerations when using 3k, 12k, and 18k fibers in high-performance sporting goods. Back to Carbon Fiber Technologies ↩

-

Advanced Production Techniques: Learn about advanced production techniques that optimize cutting, layering, and curing processes to ensure durability and precision in manufacturing. Back to Advanced Production Techniques ↩

-

Quality Assurance: This article explains best practices in quality assurance, outlining how rigorous testing and systematic quality control contribute to consistent product performance. Back to Quality Assurance ↩