Low MOQ1 padel racket manufacturing with advanced material options2 offers procurement managers the ideal solution for quality, customization, and rapid delivery. In this article, we compare the critical aspects of low MOQ production, advanced materials, and design options to help you make an informed decision.

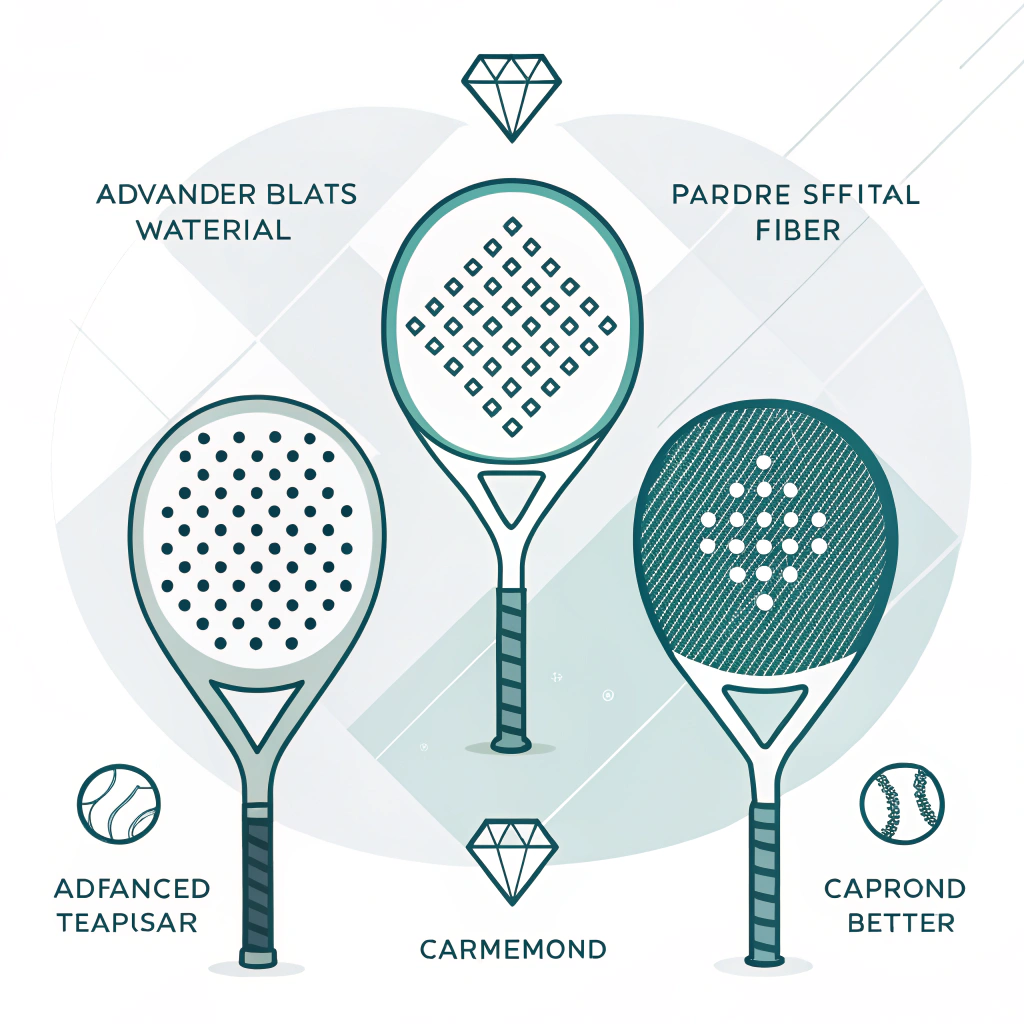

For many B2B buyers, the ability to order in low minimum order quantities (MOQ) without compromising on quality is essential. Low MOQ manufacturing enables brands to test new markets, manage budgets more effectively, and quickly adapt to changing consumer demands. At NEX Padel, we specialize in producing high-performance padel rackets tailored to your design and quantity requirements, offering advanced material options such as glass fiber, **3k, 12k, and 18k carbon fiber3.

Low MOQ solutions benefit procurement managers by reducing financial risk while allowing access to cutting-edge manufacturing technology and flexible customization. With options ranging from the popular diamond shape to round and teardrop designs, you can select a model that meets specific performance and handling characteristics demanded by your customers.

One of the key advantages of working with a manufacturer like NEX Padel is our capacity to provide fully customizable designs. Custom printing, color options, and even personalized hand grip and handle cover logo designs mean that your brand identity can shine through every detail of the final product.

- Glass Fiber: An excellent option for enhanced durability and a balanced feel.

- Carbon Fiber (3k, 12k, 18k): Offers enhanced strength and design versatility with varying degrees of stiffness and weight. These materials ensure that every racket delivers precise control and power.

Manufacturers using these advanced materials can cater to various performance levels from beginner to professional players, ensuring each racket is optimized for both comfort and strength.

The significance of advanced materials translates directly into the performance, durability, and customer satisfaction of your sports equipment. This allows your brand to stand out in a competitive market, reassuring procurement managers and product developers that every detail from material selection to rapid prototyping is meticulously handled.

When selecting a padel racket, design plays a crucial role in performance. We offer three main design types for your consideration:

- Characteristics: Generally provides increased power due to a more forward balance.

- Ideal for: Advanced players who demand aggressive play.

- Customization: Can be tailored with specific weight distributions and carbon fiber configurations for enhanced performance.

- Characteristics: Focuses on control and maneuverability with a lower balance—ideal for players seeking comfort and consistency.

- Ideal for: Beginners and intermediate players.

- Customization: Options to adjust grip size, handle design, and printing.

- Characteristics: Offers a balance between control and power, providing a versatile solution for players transitioning between playing styles.

- Ideal for: Mixed-level players who value flexibility.

- Customization: Can be fully tailored in terms of weight distribution and cosmetic design.

Below is a table summarizing the key differences among these racket designs:

| Feature | Diamond Shape | Round Design | Teardrop Design |

|---|---|---|---|

| Playing Style | Power-oriented, aggressive | Control-oriented, comfort | Balanced between power and control |

| Balance | High, forward-focused | Low, balanced towards the grip | Medium balance |

| Customization | Advanced material adjustments, design variations | Extensive custom printing, handle customization | Flexible customization options |

| Ideal User | Advanced players | Beginners & intermediates | Mixed-level players |

Understanding the subtle differences between these designs helps you decide which type best fits your target market’s needs.

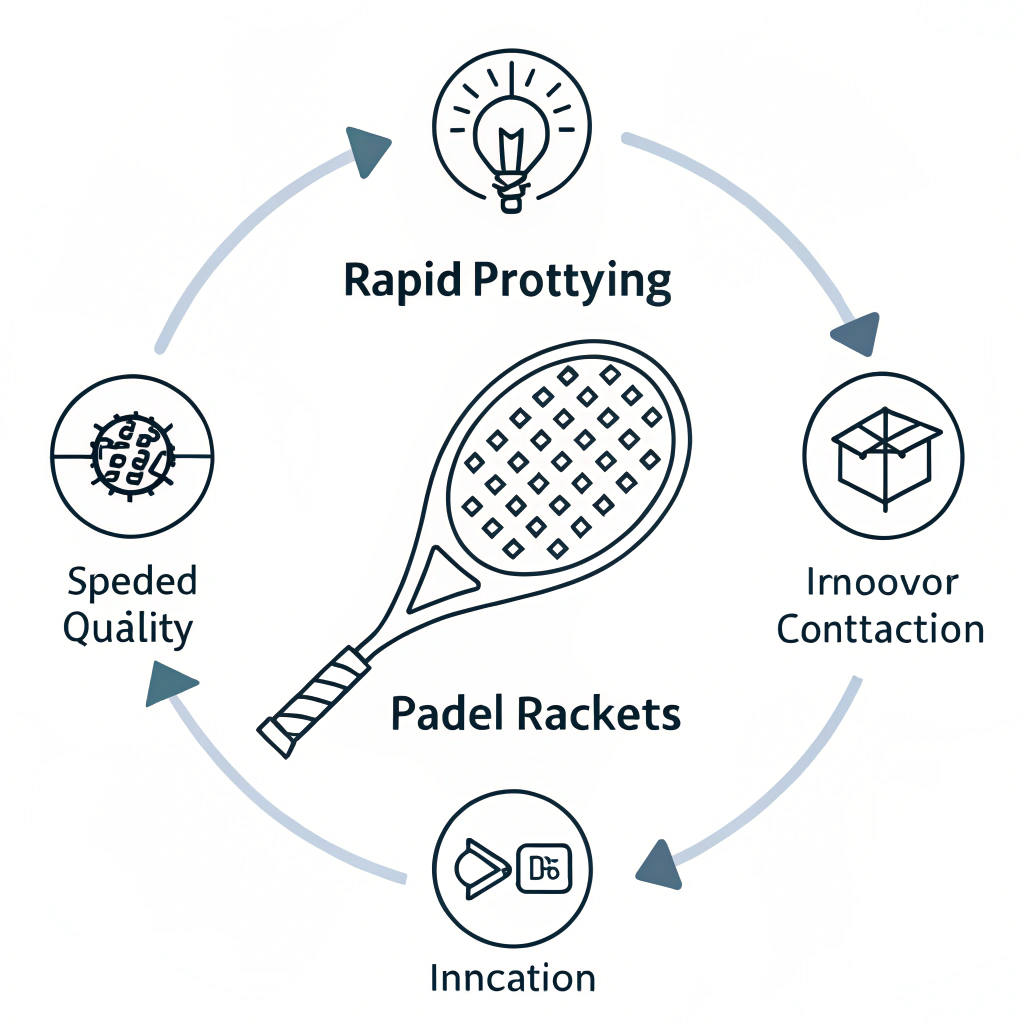

Low MOQ & Rapid Prototyping4: Key Considerations for Procurement

In today’s fast-paced market, the ability to move quickly with new designs is critical. Low MOQ combined with rapid prototyping4 allows you to:

- Test Market Trends: Launch new designs without committing to large volumes.

- Reduce Inventory Risk: Order quantities that suit market demand and manage cash flow better.

- Accelerate Time-to-Market: Fast turnaround times enable you to quickly respond to customer feedback and market trends.

Manufacturing with low MOQ does not mean compromising on precision engineering or product quality. At NEX Padel, we utilize advanced production techniques to ensure every padel racket meets strict performance standards. Our process includes a detailed quality control methodology that covers each step from material selection to final inspection, ensuring excellent consistency across all orders.

Consider the following table that highlights why low MOQ manufacturing is a game changer for modern sports brands:

| Benefit | Explanation |

|---|---|

| Financial Flexibility | Lower initial investment allows testing new markets without heavy financial risk. |

| Customization Opportunities | Full control over design, colors, and logos to match brand identity. |

| Rapid Market Entry | Fast prototyping and production cycles help you stay ahead in a competitive market. |

| Reduced Inventory Costs | Only produce what is needed, reducing warehouse and storage expenses. |

| Quality Assurance | Advanced manufacturing techniques ensure durability and performance. |

When evaluating manufacturers for low MOQ padel rackets, consider these best practices:

-

Assess Material Quality: Ensure that the manufacturer uses high-quality materials like advanced carbon fiber and glass fiber. These materials significantly affect the racket’s performance, durability, and overall playability.

-

Customization Capabilities: Look for suppliers who offer comprehensive customization options beyond just the racket face. Custom hand grips, handle covers, and even printing techniques can enhance your brand’s uniqueness in the market.

-

Production Efficiency: A manufacturer with rapid prototyping capabilities and timely delivery ensures that your product development cycle is not hindered by manufacturing delays. Quick sample turnaround times also allow faster decision-making on design improvements.

-

Industry Certifications: Check for certifications and credentials that affirm the manufacturer’s commitment to quality. This can include ISO certifications5, industry-specific quality seals, or testimonials from well-known brands.

-

After-Sales Support: Post-production support such as quality control, replacement policies, and technical assistance are critical elements that contribute to a smooth procurement experience.

By applying these best practices, you can ensure that your next padel racket order not only meets market demands but also enhances your brand positioning in a competitive landscape.

At NEX Padel, we understand the unique challenges faced by procurement managers and product developers in the sports equipment industry. Our commitment to low MOQ production coupled with extensive customization options sets us apart in the market. We work with advanced materials to produce rackets that meet the specific performance and aesthetic needs of your brand, ensuring that every product is a testament to precision engineering.

Key strengths include:

- Flexible Production Options: Adaptable to order quantities that suit your market testing needs.

- High-Performance Materials: Utilizing premium carbon fiber and glass fiber for unmatched durability and performance.

- Comprehensive Customization: From racket shape variations (diamond, round, teardrop) to customizable hand grips and logo printing.

- Reliable Turnaround: Our fast prototyping and on-time delivery processes enable you to work with tight deadlines and market demands.

When you choose NEX Padel, you are choosing a partner who values quality, precision, and customer-centric production. We support industry-leading brands such as Hirostar, Reebok, and Starvie by providing products that align with evolving consumer expectations and market trends.

In summary, low MOQ padel racket manufacturing with advanced materials and full customization capabilities offers a competitive edge to sports equipment brands. Whether you are looking to explore innovative designs or respond swiftly to market trends, choosing the right manufacturing partner is paramount. When assessing potential suppliers, consider their material options, customization flexibility, production speed, and quality control processes.

Our recommendation: Engage with providers like NEX Padel who offer comprehensive manufacturing solutions designed to eliminate risk, enhance product quality, and accelerate your time-to-market. Evaluate your current product requirements against our capabilities, and consider initiating a small order to test our rapid prototyping and quality assurance firsthand.

Empower your procurement strategy by choosing a partner that understands your market needs and delivers excellence every time. For more detailed product specifications or to discuss your customization requirements, reach out to our expert team at NEX Padel.

What does a low balance padel racket mean?

A low balance padel racket concentrates its weight closer to the grip, ensuring that the balance is oriented toward the player’s hand. This design enhances maneuverability and control, making it particularly beneficial for round-shaped rackets or models with distributed weight near the handle.

What is the best budget padel racket?

Budget padel rackets vary in their features and performance based on pricing. While several models exist on the market, the best option depends on the player's skill level and playing style. Manufacturers such as NEX Padel focus on quality materials and customization, ensuring that even more affordable options meet robust performance standards.

What is the difference between cheap and expensive padel rackets?

The main difference lies in materials, design, and performance characteristics. More expensive rackets may feature refined materials and enhanced precision, but they are not necessarily better for beginners. Cheaper rackets often offer larger sweet spots and easier maneuverability, which can be more suitable for novice or intermediate players.

-

Low MOQ: Read the article to understand how low minimum order quantities reduce financial risk and enable market testing with flexible production planning. ↩ ↩

-

Advanced material options: Read the article to learn about the benefits of advanced material options in enhancing product performance and durability. ↩ ↩

-

Carbon fiber: Read the article to explore the properties and advantages of carbon fiber, a lightweight yet strong material crucial for high-performance sports equipment. ↩ ↩

-

Rapid prototyping: Read the article to discover how rapid prototyping accelerates product development and shortens time-to-market for innovative designs. ↩ ↩ ↩2

-

ISO certifications: Read the article to understand the importance of industry certifications like ISO in ensuring manufacturing quality and reliability. ↩ ↩