The optimal padel racket sweet spot is achieved through a careful balance of structural design, material selection, and precise production techniques that ensure consistent performance. In this article, we explore common challenges in producing a high-performance padel racket, analyze how different materials such as 3k, 12k, and 18k carbon fiber1 influence performance, and present practical solutions that integrate ballistics analysis2 and technical specifications. Our goal is to help B2B decision-makers choose production methods that optimize the racket’s sweet spot for enhanced gameplay performance.

Every padel racket manufacturer strives to create a racket where the sweet spot—the optimal impact point for ball contact—is maximized. This specific area translates to improved ball speed, better control, and overall enhanced performance for the end user. However, achieving an optimal sweet spot is no simple feat.

Key challenges include:

• Consistency in manufacturing

• Precise control of material properties

• Balancing structural design and production efficiency

A detailed understanding of these factors is critical for technical managers, product developers, and procurement specialists when evaluating manufacturing processes. The interplay between the racket's shape, material integrity, and overall weight distribution fundamentally affects the sweet spot’s location and size, which in turn influences player performance.

The choice of materials plays a pivotal role in determining a racket’s sweet spot. At NEX Padel, our products are crafted from a range of 3k, 12k, and 18k carbon fiber1—namely 3k, 12k, and 18k. Each of these variants brings its unique performance characteristics:

- 3k Carbon Fiber: Typically offers a balance between flexibility and strength. This variant can be used for creating rackets with a larger sweet spot as it allows some degree of deformation, absorbing shock upon impact.

- 12k Carbon Fiber: Provides a middle ground with improved stiffness and durability, ideal for mid to advanced frames that require both performance and resistance.

- 18k Carbon Fiber: Known for its superior stiffness and high-performance potential, 18k fibers produce a racket with a very focused sweet spot, suitable for players looking for precision and control.

Understanding the intrinsic properties of these materials helps manufacturers to fine-tune the racket’s design and production process. Integrating ballistics analysis2 during production ensures that the sweet spot is not only well-defined but also consistent across batches, meeting the high expectations of performance-oriented users.

The process of optimizing the sweet spot begins with a robust design and engineering approach. The following key aspects are essential in the production process:

By conducting a thorough structural analysis, manufacturers can simulate the stress distribution across the racket frame. This simulation is crucial in identifying the impact point where the highest concentration of energy transfer occurs—the sweet spot. Advanced techniques like finite element analysis (FEA)3 are widely employed to predict the mechanical behavior of rackets made with different carbon fiber variants.

The manufacturing process must consistently reproduce the designed specifications. At NEX Padel, we use advanced production techniques such as automated layering and curing processes that ensure the materials are bonded effectively. This not only maximizes durability but also stabilizes the sweet spot across every unit produced.

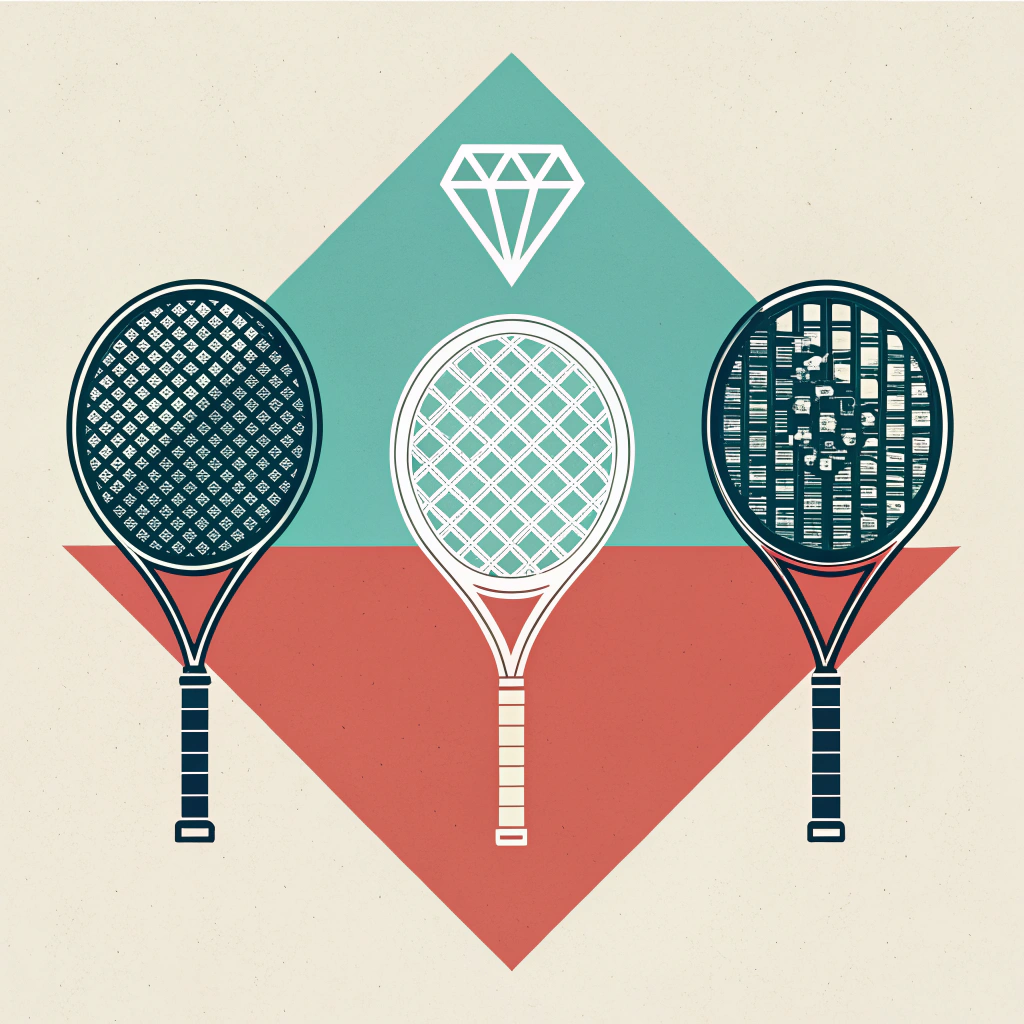

Customization is a significant factor that influences the racket balance and sweet spot. Our three primary shapes—Diamond, Round, and Teardrop—each offer different performance characteristics:

- Diamond Shape: Typically provides enhanced power and precision, suitable for advanced players.

- Round Shape: Offers a larger sweet spot, making it easier for beginners and intermediate players to achieve consistent hits.

- Teardrop Shape: Balances between power and control, appealing to a broader range of performance needs.

The ability to customize not only the racket shape but also details such as custom printing, colors, hand grip, and handle cover design allows brands to tailor their products to specific market demands while ensuring that the technical attributes remain uncompromised.

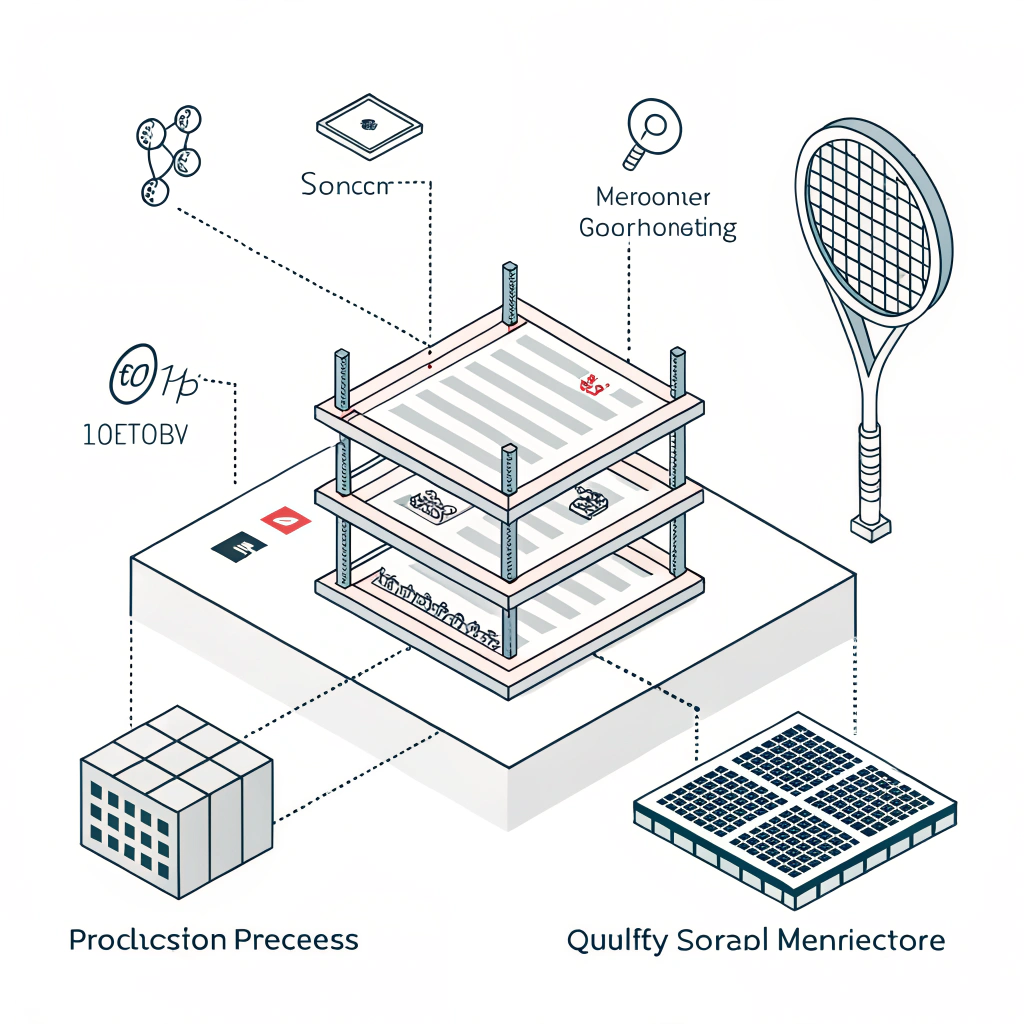

The following steps outline the process of producing a padel racket with an optimized sweet spot, from design to final production:

-

Concept and Design:

- Begin with an in-depth analysis of the desired performance characteristics.

- Use design software to map out the structural integrity of the racket.

- Define key areas such as the sweet spot based on the chosen materials and shape.

-

Material Selection and Testing:

- Choose the appropriate carbon fiber variant (3k, 12k, or 18k) based on performance requirements.

- Conduct laboratory tests to determine the mechanical properties of the selected material.

- Use ballistics analysis to assess impact behavior and energy transfer.

-

Prototype Development:

- Create prototypes using advanced production techniques.

- Test prototypes under various conditions to measure the effective sweet spot and balance.

- Gather performance data and adjust design parameters accordingly.

-

Production Scale-Up:

- Transition from prototype to mass production while ensuring consistency.

- Implement quality control measures at each stage of production.

- Use automation and precision engineering to maintain material integrity and design fidelity.

-

Customization and Finishing Touches:

- Offer full customization including unique shapes, print designs, and color schemes.

- Ensure that all custom elements do not adversely affect the critical performance metrics.

- Final inspection and quality assurance to confirm the sweet spot parameters meet specifications.

-

Feedback and Continuous Improvement:

- Collect performance feedback from professional players and industry experts.

- Refine the design and production process based on real-world usage data.

- Implement continuous improvement protocols to enhance future product iterations.

A simplified table summarizing the steps and key considerations is provided below:

| Stage | Key Activities | Output |

|---|---|---|

| Concept and Design | Structural analysis, FEA simulations | Optimized design blueprint |

| Material Selection | Testing of carbon fiber variants; ballistics analysis | Material specification and performance data |

| Prototype Development | Initial builds; dynamic impact tests | Validated prototype with defined sweet spot |

| Production Scale-Up | Quality control, automation integration | Consistent mass production |

| Customization | Custom shapes, prints, and colors | Tailored product meeting niche market demands |

| Quality Feedback | Data collection from user feedback | Continuous product refinement |

To ensure precise optimization of the sweet spot, manufacturers should integrate the following best practices and technical data considerations:

A rigorous ballistics analysis evaluates how energy is transferred when the ball strikes the racket. This includes:

- Tracking energy dispersion across the racket frame.

- Measuring vibrations and rebound effects.

- Identifying the point of maximum energy return.

By leveraging advanced sensors and high-speed cameras during testing, engineers can accurately determine whether the sweet spot is performing optimally during impact.

Precision in manufacturing is paramount. Even slight deviations can alter the balance and reduce the effectiveness of the racket’s sweet spot. Key tactics include:

- Utilizing automated machinery for layering carbon fiber sheets.

- Calibrating curing processes to maintain dimensional accuracy.

- Ensuring tight production tolerances and regular quality audits.

NEX Padel’s experience as an original equipment manufacturer (OEM)4 for well-known brands such as Hirostar, Reebok, and Starvie speaks to our commitment to precision and quality. We incorporate industry best practices and continuously benchmark data from leading brands to refine our processes.

Consider a recent project where our technical team collaborated with a renowned padel brand to develop a racket optimized for control and ease of use. Initially, the sweet spot in early prototypes was inconsistent, leading to performance variability.

To address this, the team implemented the following changes:

-

Material Adjustment:

Switched a portion of the racket’s frame to a 12k carbon fiber blend to improve stiffness without sacrificing flexibility. This fine-tuning resulted in better energy transfer. -

Redesign of the Frame Geometry:

Minor modifications in the racket shape redistributed impact forces more evenly. Through finite element analysis, we redesigned the internal structure to expand the effective sweet spot without increasing weight. -

Enhanced Quality Control Measures:

Introduced additional sensor-based inspections to monitor real-time impact performance during production, ensuring each unit maintained the target sweet spot range.

The outcome was a padel racket that significantly reduced mis-hit rates in internal testing, with players reporting improved performance consistency across a variety of play styles. This case study exemplifies how combining material science with advanced engineering can effectively enhance product performance.

While the approach described offers a robust pathway to optimization, it is essential to consider potential limitations and constraints:

-

Economic Factors:

Advanced materials and high-precision manufacturing often come at a higher cost. Balancing cost efficiency with performance optimization is crucial. -

Customization Complexity:

Fully customizable products may encounter production scalability issues. It is important to standardize critical performance parameters, such as the sweet spot, even when other elements like shape and color vary. -

Quality Assurance:

Automated quality control systems must continually evolve based on emerging technologies and testing methodologies to adapt to new materials and design innovations.

By understanding these limitations, manufacturers can implement risk mitigation strategies, ensuring that product enhancements do not negatively impact overall production efficiency or cost-effectiveness.

Optimizing the padel racket sweet spot involves a multifaceted approach combining:

• Strategic material selection, especially among various carbon fiber types

• Advanced structural and ballistic analysis

• Precision engineering and rigorous quality controls

• Customization that maintains critical performance metrics

For product developers and technical managers evaluating a new supplier partnership, key action steps include:

- Reviewing the supplier’s technical data sheets and production quality controls.

- Assessing the balance between cost, performance, and production scalability.

- Prioritizing partnerships that embrace advanced engineering methodologies and continuous improvement protocols.

By implementing these actionable recommendations, decision-makers can ensure that their final products not only meet but exceed the performance expectations of today’s competitive padel arena.

People Also Ask

Q: What shape padel rackets are for me?

A: For beginner and intermediate players, a round padel racket that features a large sweet spot and low balance is highly recommended. This shape provides a more forgiving experience and ease of play by reducing the need to constantly focus on hitting the ball at the precise contact point, ultimately offering a balanced and user-friendly solution.

-

[3k, 12k, and 18k carbon fiber]: Click to read more about the different carbon fiber variants, their unique properties, and how they impact the performance and durability of padel rackets. ↩ ↩2

-

[ballistics analysis]: Click to explore an in-depth explanation of ballistics analysis, including its role in measuring energy transfer and optimizing the sweet spot in sports equipment. ↩ ↩2

-

[finite element analysis (FEA)]: Click to learn about finite element analysis (FEA), a computer-aided simulation technique used to predict how a product reacts to real-world forces, vibration, and other physical effects. ↩

-

[original equipment manufacturer (OEM)]: Click to understand the role of an original equipment manufacturer (OEM) in the sports equipment industry, including quality assurance processes and industry partnerships. ↩