High-performance OEM/ODM1 padel rackets are essential for distributors and retailers seeking products that merge technical precision with reliable durability. In short, whether you choose Fiberglass2 for its affordability and control or high-grade Carbon3 (3K, 12K, or 18K) for superior performance, each material offers unique benefits that can be customized to meet market demands and end-user expectations.

In the competitive world of padel sports equipment, making informed decisions about the materials used in racket manufacturing is crucial. As a decision-maker in sports equipment distribution, procurement, or product management, you require a supplier who not only delivers top-notch quality but also offers extensive Customization4 options. At NEX Padel, we understand these needs, and our advanced production techniques ensure every padel racket meets the highest standards of precision and durability.

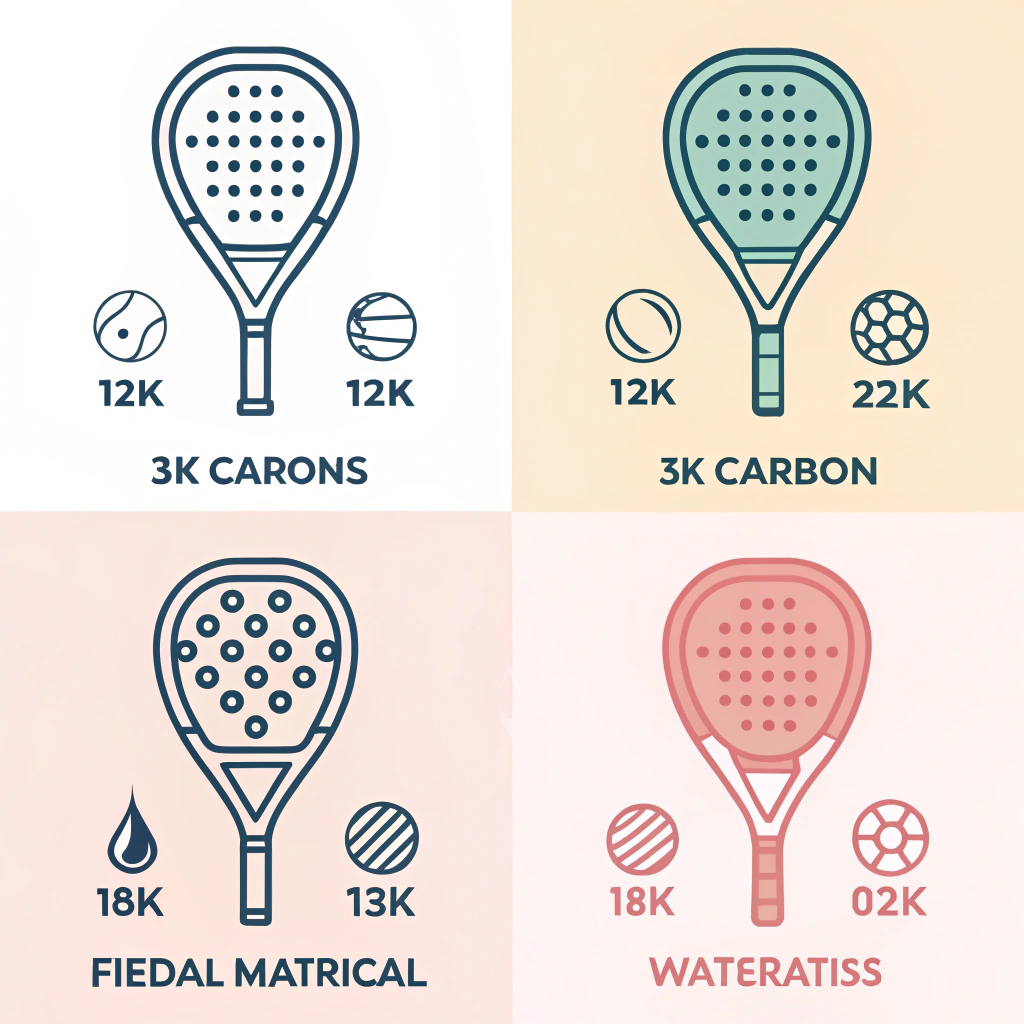

Manufacturers and distributors must compare various materials like Fiberglass, 3K Carbon, 12K Carbon, and 18K Carbon when choosing a production partner. Each of these materials is tailored to different play styles and consumer needs:

- Fiberglass: Known for its excellent control and comfort, making it ideal for new players or those focusing on technique.

- 3K Carbon: Offers a balanced blend of durability and stiffness. It features a quick ball release that suits intermediate players.

- 12K Carbon: Provides a softer feel compared to 3K. This material enhances ball release from the baseline, catering to players who need additional comfort and controlled power.

- 18K Carbon: The ultimate choice for professionals looking for enhanced rigidity and precise energy transfer on the court.

Below is a quick comparison table outlining these material options:

| Material Option | Key Characteristics | Ideal For |

|---|---|---|

| Fiberglass | Superior control, excellent comfort, affordable | Beginners, players focusing on technique |

| 3K Carbon | Balanced stiffness, quick ball release | Intermediate players needing versatility |

| 12K Carbon | Softer feel, improved ball release | Players seeking comfort with moderate power |

| 18K Carbon | Enhanced rigidity, precise energy transfer | Advanced and professional level players |

When evaluating padel rackets for OEM/ODM purposes, a deep dive into the technical specifications is essential. Here are some key aspects to consider:

-

Control vs. Power:

- Fiberglass offers superior control, making it easier for beginners to handle the racket and maintain consistency.

- Carbon variants (3K, 12K, 18K) provide varied levels of rigidity and energy transfer. For instance, 12K Carbon delivers a softer impact, which can aid in longer rallies and controlled shots, while 18K Carbon offers the crisp precision needed for powerful spikes.

-

Weight and Balance:

The weight distribution of the padel racket is significantly influenced by the material used. Lightweight materials like Fiberglass are typically easier for beginners, whereas heavier carbon frames provide stability during high-speed impacts. -

Durability:

Carbon fiber types, especially 18K, are revered for their durability and long-lasting performance even under rigorous play conditions. Manufacturers often customize the layering and density of carbon fiber to achieve the optimum balance between durability and playability.

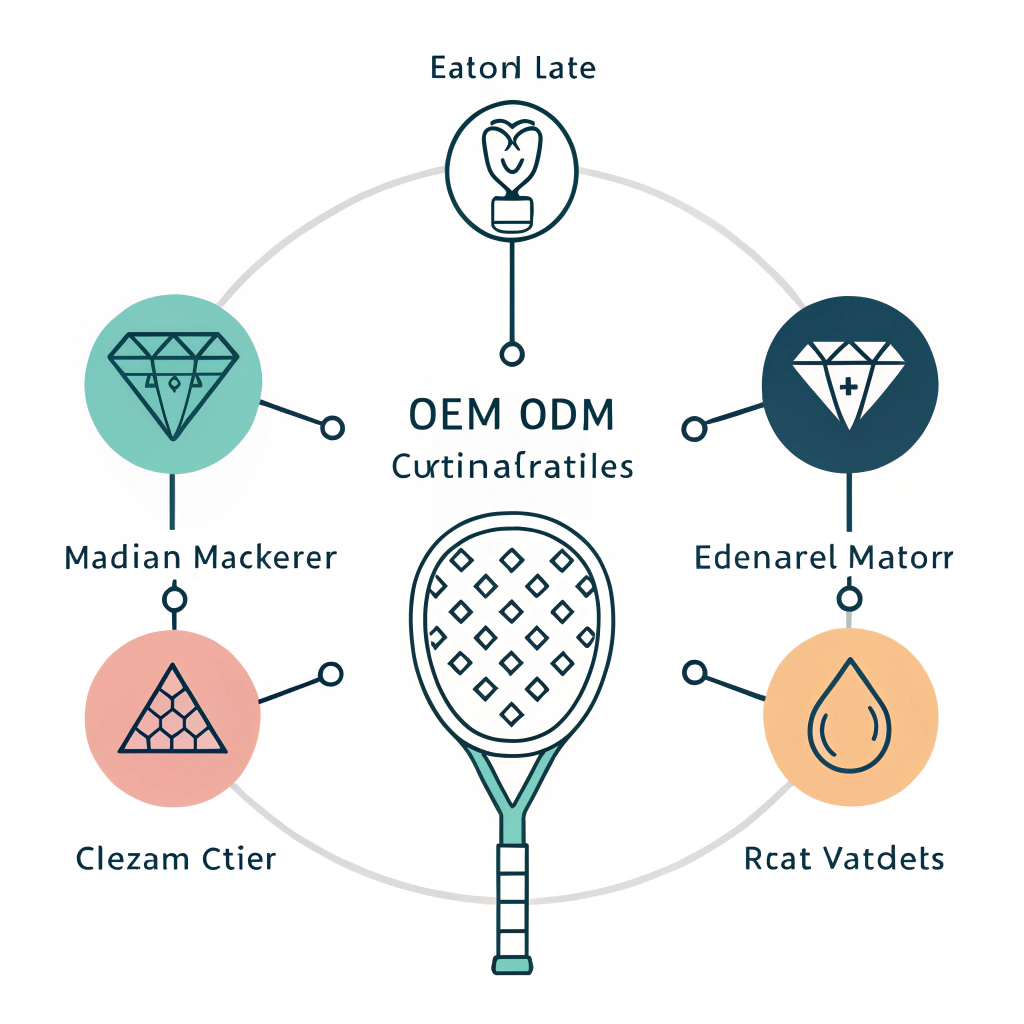

NEX Padel stands out by offering extensive customization options in the production process:

- Shape Customization: We design rackets in various shapes such as Diamond, Round, and Teardrop. These shapes can be tailored to meet both performance characteristics and aesthetic preferences.

- Material Customization: Clients can choose from different material combinations—ranging from Fiberglass to various grades of Carbon (3K, 12K, 18K)—to meet specific performance requirements.

- Customization Beyond the Racket: Additional elements like hand grips and handle covers may also be customized, including professional logo printing to maintain brand consistency.

- Rapid Prototyping5: Our advanced production lines facilitate rapid prototyping, allowing quick sampling and modifications based on market feedback.

- Quality Control: Rigorous testing and quality control are embedded in every production step to ensure each padel racket meets international standards.

A table summarizing the OEM/ODM customization process can help illustrate these points:

| Customization Aspect | Key Details | Benefits |

|---|---|---|

| Racket Shape | Diamond, Round, Teardrop, and custom shapes | Tailored performance and aesthetics |

| Material Selection | Fiberglass, 3K, 12K, 18K Carbon | Meets diverse technical needs |

| Additional Customization | Hand grip design, handle cover logo printing | Enhanced brand visibility |

| Production Speed | Rapid prototyping, swift sample approval | Shorter lead times, agile market response |

| Quality Assurance | Rigorous testing and quality control | Consistent high performance |

At NEX Padel, leveraging cutting-edge production techniques is not just about meeting industry benchmarks but about setting them. Here, we break down our approach into clear, actionable segments that benefit our B2B partners:

Every padel racket undergoes a strict quality control process. The use of advanced composite technologies and precise layering ensures that the final product is free from structural flaws. With controlled production parameters, our rackets offer reliable performance match after match.

In today’s fast-evolving sports equipment market, the ability to quickly adapt to changes in consumer preferences is crucial. Our rapid prototyping capabilities allow us to iterate designs swiftly. This ensures that our partners receive products that are both innovative and aligned with market trends.

Opting for OEM rackets produced by NEX Padel means you won’t have to compromise on quality for cost. Our streamlined production processes and economies of scale allow us to offer competitive pricing while ensuring superior durability and performance.

Innovation in sports equipment manufacturing is an ongoing process. We continually invest in research and development to integrate new materials and manufacturing techniques. This proactive approach ensures that our padel rackets stay ahead of the curve, offering innovations that resonate well with both amateur and professional players.

To further illustrate the benefits of material selection and customization, consider the following three real-world scenarios:

-

A major sports retailer required a padel racket that balanced affordability with high performance. We recommended our Fiberglass option, which provided the desired control for new players while keeping production costs low. Sales data showed a significant uptake among entry-level players, validating the material choice.

-

A leading distributor wanted to differentiate its product line by offering rackets that cater to varying player proficiencies. By incorporating 3K for intermediate players and 12K Carbon for those seeking a softer feel, the distributor successfully targeted a broader market segment. Comparative play tests revealed that the combination maximized player satisfaction and performance.

-

A top-tier brand approached us for a fully customized solution using 18K Carbon. Their goal was to serve professional athletes seeking maximum precision and power. Our production team tailored each aspect of the racket—from weight distribution to grip customization—resulting in a product that not only met but exceeded professional standards.

These scenarios underscore the importance of material variety, customization, and rapid response to market needs. Our discussions with clients reveal that strategic material selection can directly influence market performance, consumer satisfaction, and ultimately, the success of the product in a competitive field.

For procurement specialists and product managers evaluating padel racket suppliers, consider the following recommendations:

- Assess Your Target Market: Understand the specific needs of your customer base. For beginners, materials like Fiberglass may be more appealing, while advanced players might prefer the performance of 18K Carbon.

- Review Customization Capabilities: Ensure the manufacturer can support not only standard product specifications but also custom design requests. This flexibility can be a significant competitive advantage.

- Examine Quality Control Protocols: Look for production partners that adhere to rigorous quality assurance processes. Consistency in product quality is a non-negotiable aspect for reliable performance.

- Consider Lead Times and Prototyping Cycles: In a dynamic market, the ability to introduce new designs rapidly is crucial. Evaluate the supplier’s rapid prototyping and production turnaround times.

- Analyze Cost Versus Performance: Balance budget constraints with performance requirements. High-grade materials like 18K Carbon offer unmatched performance at a premium cost, while Fiberglass provides a cost-effective solution without compromising basic functionality.

In summary, selecting the right padel racket material is a balancing act between performance, cost, and market demands. By understanding the properties and benefits of materials like Fiberglass, 3K, 12K, and 18K Carbon, distributors and retailers can make informed decisions that align with their target audience’s needs.

At NEX Padel, our commitment to quality, customization, and rapid innovation ensures that our OEM/ODM solutions are not only competitive but also tailored to the evolving needs of the padel sports industry. With our extensive experience and advanced production technologies, we stand ready to support your journey towards market leadership with products that deliver both performance and reliability.

By considering the technical details discussed above and evaluating the specific needs of your target customers, you can confidently select the material composition that will drive your product’s success. Whether it’s through a versatile Fiberglass design for broad appeal or a specialized Carbon configuration for professional play, the right choice will enhance customer satisfaction and brand reputation in a competitive marketplace.

People Also Ask

Q: Is a fiberglass padel racket good?

A: Fiberglass padel rackets provide excellent control and comfort at an affordable price, making them ideal for beginners or players focused on technique. They offer a versatile playing experience that emphasizes maneuverability and ease of use, in contrast to the higher performance-oriented carbon rackets used by professionals.

Q: What is the difference between 3K and 12K padel racquets?

A: The key difference lies in the feel and performance on the court. 12K carbon offers a softer impact, contributing to greater ball release from the baseline and a less forceful spike. In contrast, 3K carbon provides a balanced stiffness and energy transfer suited for a broader range of players seeking a mix of control and power.

Q: Which brand makes the best padel rackets?

A: While several top-tier brands offer high-quality padel rackets, renowned names like Adidas, Bullpadel, Nox, Head, and Babolat have consistently delivered innovative and reliable products. The best choice will depend on a player’s individual requirements regarding performance, feel, and customization options.

-

OEM/ODM: Click to read more about the strategic benefits of Original Equipment Manufacturer (OEM) vs. Original Design Manufacturer (ODM) models for B2B partnerships in product development. ↩ ↩

-

Fiberglass: Click to explore how fiberglass is used in sporting goods manufacturing and its advantages in terms of cost and playability. ↩ ↩

-

Carbon: Click to understand the different grades of carbon fiber (3K, 12K, 18K) and their impact on durability and performance in racket production. ↩ ↩

-

Customization: Click to learn about customization in manufacturing, including product design flexibility that meets specific market needs. ↩ ↩

-

Rapid Prototyping: Click to discover how rapid prototyping accelerates product development and innovation in competitive B2B markets. ↩ ↩