The right padel racket choice hinges on balancing shape, material quality, weight, and customization options1. For instance, diamond rackets offer offensive power with a high balance point, while round rackets provide greater control and ease of use. Evaluating these factors is essential for informed B2B sourcing decisions2.

In the competitive world of padel equipment manufacturing, sourcing high-performance rackets tailored for specific playing styles and market segments is critical. Padel rackets come in various shapes—diamond, round, and teardrop—each with unique technical features and performance benefits. As a leading manufacturer with advanced production techniques3, we at NEX Padel ensure our products meet stringent industry standards, using materials ranging from fiberglass to premium carbon fiber like 3k, 12k, and 18k variants. This article provides an in-depth comparison of these racket types to aid procurement managers and category specialists in making the best decision for their portfolios.

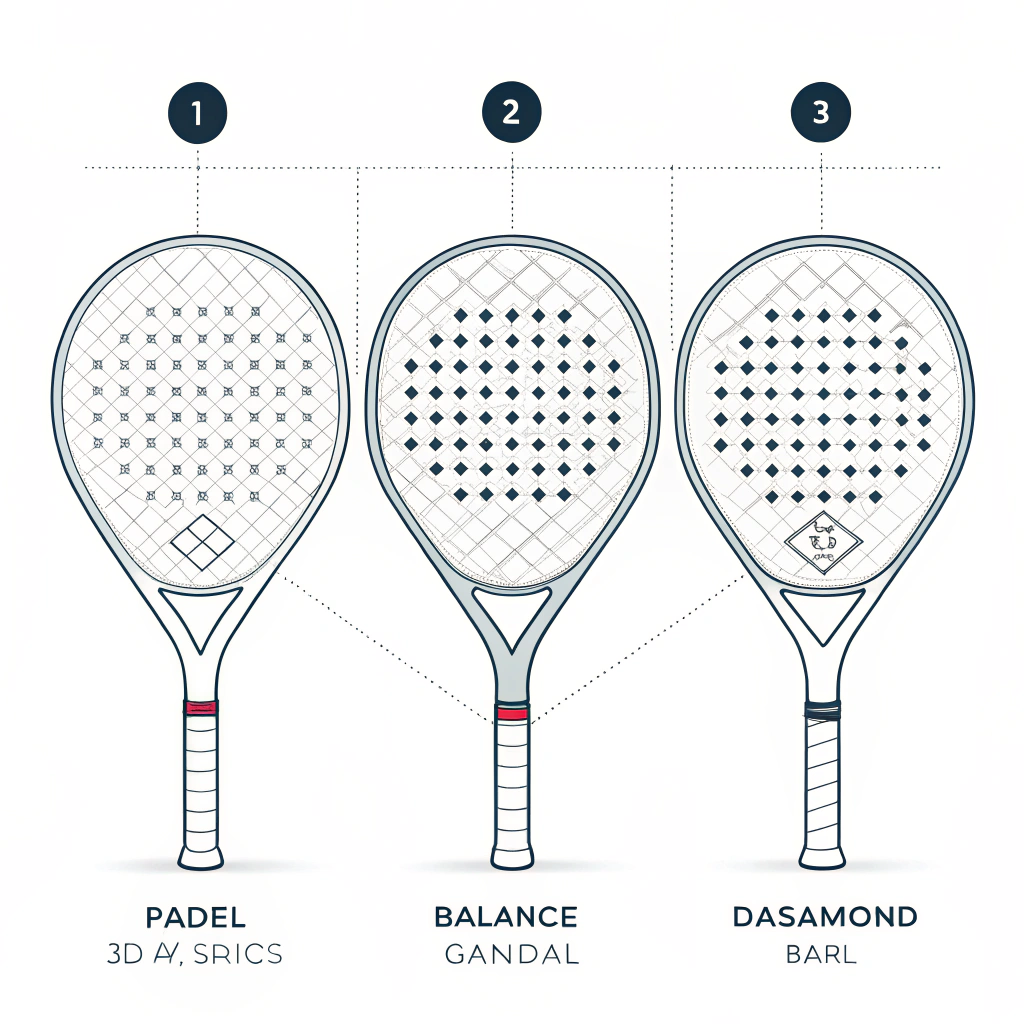

Padel rackets have traditionally evolved to optimize various game demands, leading to three key shapes:

-

Diamond Rackets

- Design and Balance: Diamond rackets feature a higher balance point, meaning the weight is more distributed at the top. This design supports powerful, offensive strokes.

- Performance Focus: Their design is ideal for high-tempo offensive plays, enabling players to generate dynamic shots.

- Market Application: Typically selected by advanced players looking for aggressive performance, these rackets are often referenced in competitive settings.

-

Round Rackets

- Design and Balance: Known for their lower center of gravity, round rackets boast a larger sweet spot, which offers greater comfort and control.

- Performance Focus: Their balanced nature minimizes errors, making them an attractive option for beginners and intermediates.

- Market Application: They cater to players prioritizing consistency and maneuverability, essential for markets emphasizing training and entry-level performance.

-

Teardrop Rackets

- Design and Balance: Teardrop rackets embody a blend of both worlds—they balance power and control, often landing in between diamond and round rackets.

- Performance Focus: With a mid-balance design, they suit a variety of playing styles, accommodating versatile needs.

- Market Application: These rackets are well-suited for players who require adaptability, making them a competitive choice for a broad consumer base.

Each shape responds to different playing styles, influencing the market segmentation strategies crucial for B2B sourcing decisions.

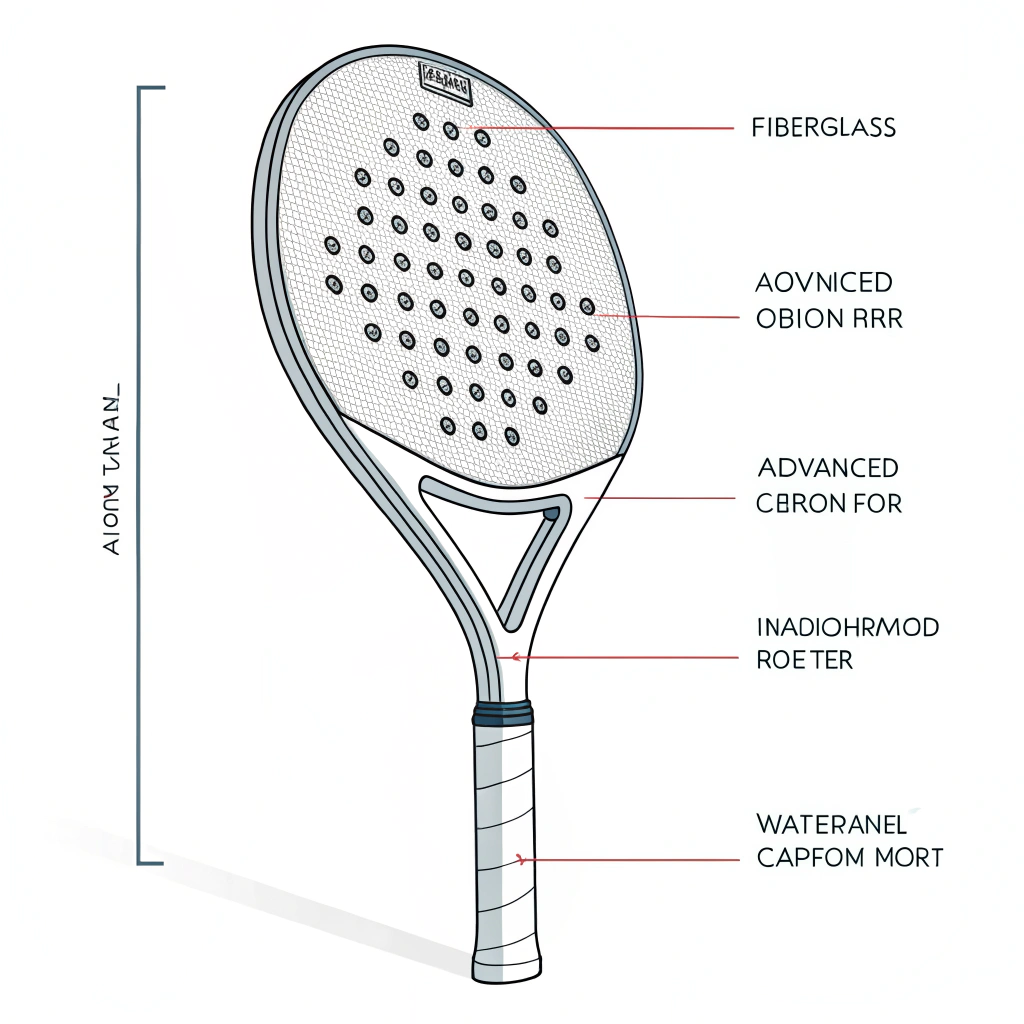

When comparing padel rackets, material composition and manufacturing techniques are essential factors. Our production process emphasizes precision and durability by using high-performance materials and innovative techniques.

-

Fiberglass vs. Carbon Fiber:

Fiberglass components are widely used for their flexibility and cost-effectiveness. However, advanced carbon fiber variants (3k, 12k, and 18k) offer greater rigidity and weight reduction, enhancing both power and durability. -

Manufacturing Precision:

Our advanced production techniques ensure strict adherence to quality standards. This precision in crafting rackets enables consistent performance, crucial when fulfilling OEM4 and branding requirements for reputed companies like Hirostar, Reebok, and Starvie. -

Customization Options:

Beyond the racket shapes, customization plays a vital role. Clients may require specific logo placements on the racket surfaces, handle grips, or even unique shapes tuned to their market demands. A comprehensive manufacturing guide must include:Feature Diamond Racket Round Racket Teardrop Racket Balance High, top-skewed Low, center-skewed Mid, balanced Material Use Advanced carbon fiber Fiberglass/carbon blend Mixed material blend Customization High, shape/print options Moderate, standard grips High, versatile options Preferred Usage Offensive play Control and ease Versatile play This table encapsulates the core differences from a technical specification standpoint, helping procurement managers align their product selection with market needs and consumer preferences.

- Weight Differences:

The overall weight of a padel racket significantly affects the game. A heavier racket might favor offensive players by providing extra power, whereas lighter rackets aid in better maneuverability and control. - Ergonomic Design:

The handle size, grip design, and balance point are crucial for player comfort. Our production ensures ergonomically sound designs that cater to long-term use without sacrificing performance. - Surface Texture:

The surface of the racket, including its texture, affects spin generation and ball control during high-speed plays. Advanced customization allows different surface finishes to enhance tactile feedback for varied playstyles.

Procurement managers must adapt their product portfolios to market segments:

-

For High-Performance Players:

Emphasizing features such as precision balance points, advanced carbon fiber materials, and aggressive racket shapes shows clear benefits. Diamond rackets, in this context, offer a tactical advantage in power-based play. -

For Training and Entry Markets:

Prioritizing ease of use and error reduction, round rackets become the ideal choice. With a larger sweet spot and lower weight, these rackets can assist beginners in developing proper techniques. -

For Versatile Use Cases:

Teardrop rackets provide a middle ground suitable for diverse player abilities. Their balanced characteristics appeal to a broader market, making them a strategic addition to product portfolios seeking both performance and flexibility.

Quality control processes are integral to our manufacturing. Each padel racket goes through rigorous testing phases:

-

Durability Testing:

Ensuring that high-performance materials maintain structural integrity under intense conditions is paramount. Stress and fatigue tests simulate real-match dynamics. -

Performance Validation:

Field testing with professional players helps to validate the design efficacy across different racket shapes. Feedback is incorporated into continuous improvement cycles. -

Compliance with Industry Standards:

Our products adhere to international quality guidelines, ensuring both reliability and performance in competitive environments.

Data gathered from these processes often guide the decision-making for B2B procurement. Managers can be confident that each product in our lineup meets the highest quality benchmarks.

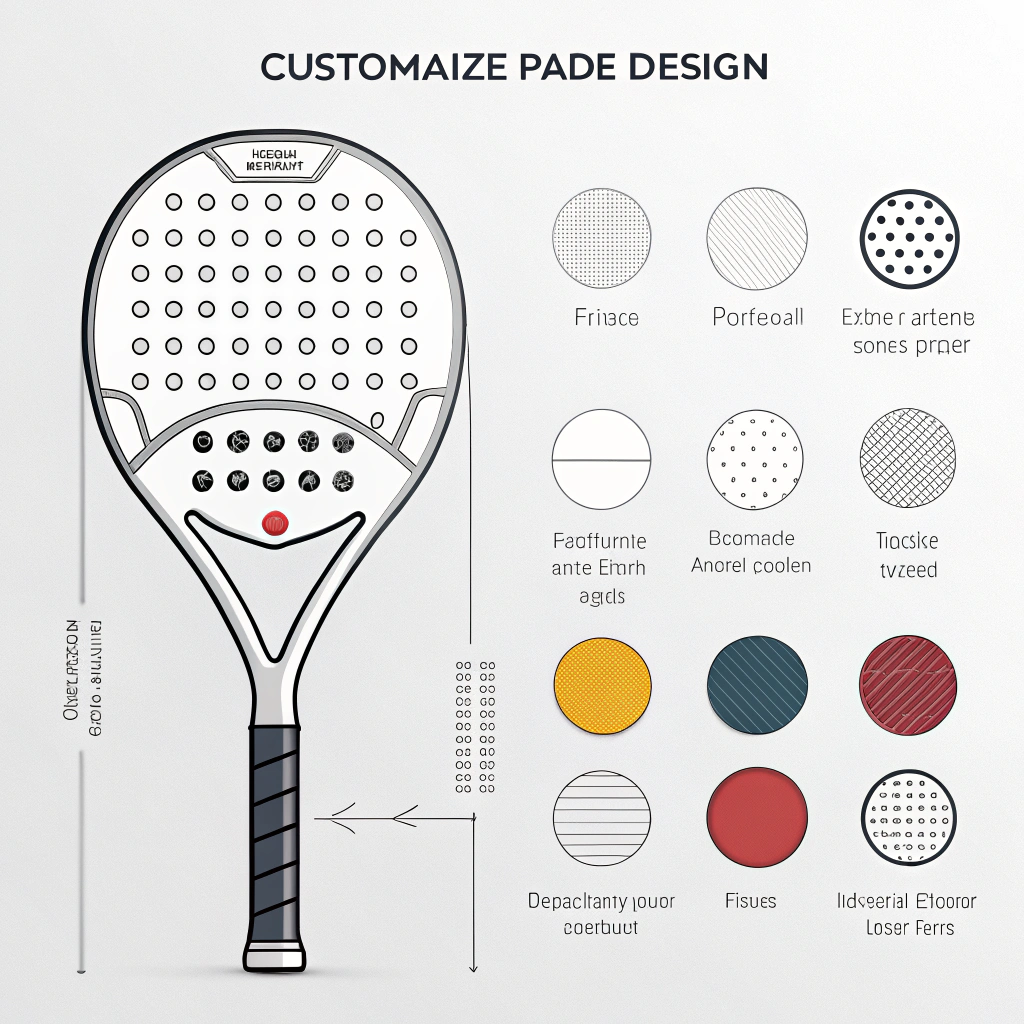

As sourcing decisions increasingly lean towards differentiation, customization stands out as a critical factor. Our full-order solutions include not only the standard racket composition but also bespoke adjustments to meet specific market demands.

-

Full-Shape Customization:

Clients have the flexibility to choose not only from the available shapes (diamond, round, teardrop) but also to request slight modifications to optimize performance for niche applications. -

Custom Printing and Colors:

Branding is a core element in B2B sourcing. Offering customization of color schemes and print logos directly on the racket surface adds to the overall product appeal. -

Tailored Grip Options:

Beyond the racket head, the grip and handle components can be customized to include logos or unique textures that cater to a brand’s identity. -

Integrated Product Solutions:

We also offer padel balls with two different material compositions (45% wool and 57% wool) and superior packaging technologies like the pressurized tube, ensuring the ball’s performance remains consistent.

This flexibility in customization not only enhances product differentiation but also strengthens the supplier-client relationship, making NEX Padel a preferred partner for many leading brands.

Another key aspect for B2B procurement is sustainable manufacturing:

-

Energy-efficient Processes:

Modern production techniques reduce energy consumption, contributing to lower overall environmental impacts without sacrificing product performance. -

sustainability5:

Sourcing high-quality yet sustainable raw materials is increasingly important. Our manufacturing strategies incorporate sustainable practices while still meeting performance benchmarks. -

Cost Efficiency:

Customizable production does not necessarily equate to higher costs. Our streamlined processes and robust supply chain management ensure competitive pricing, making high-performance padel rackets accessible to diverse market segments.

Choosing the right padel racket is a multi-faceted process requiring careful consideration of shape, material quality, ergonomics, and customization options. For B2B procurement managers, the following are key takeaways:

-

Understand Your Market:

Align the racket shape—diamond, round, or teardrop—with your target demographic’s performance needs. -

Focus on Material and Manufacturing Quality:

High-performance materials like advanced carbon fibers, combined with precise manufacturing processes, ensure product durability and competitive performance on the field. -

Leverage Customization:

Embrace opportunities to differentiate your product range with custom shapes, detailed branding, and ergonomic adjustments that appeal to diverse consumer groups. -

Ensure Quality Assurance:

Robust testing and adherence to international quality standards provide assurance that your products will perform as expected under competitive conditions. -

Consider Sustainability:

Assess the environmental impact and overall cost efficiency of your sourcing choices to ensure long-term viability.

At NEX Padel, we bring years of technical expertise and market understanding to help you navigate these decisions. Our comprehensive approach—from material selection to advanced production techniques and customization—ensures that our padel rackets are precisely what the market demands. We invite you to connect with our team for consultation and further insights into how we can tailor our products to meet your exact needs.

People Also Ask

Q: How to decide what padel racket to buy?

A: To decide on a padel racket, consider shape (e.g., diamond for offensive play, round for control), weight distribution, balance, handle size, material quality, and surface texture. These factors collectively determine performance and suitability for specific playstyles.

Q: What are the different types of padel tennis racquets?

A: Padel tennis racquets primarily come in diamond, round, and teardrop shapes. Diamond rackets suit offensive play with higher balance points, round rackets are favored for control with lower balance and a larger sweet spot, and teardrop rackets offer a versatile blend of power and control.

Q: What shape padel rackets are for me?

A: For beginners and intermediate players, a round racket with a large sweet spot and low balance is optimal as it enhances control and stability. Advanced players might opt for diamond or teardrop shapes based on their specific performance preferences.

-

customization options – Click here to understand how offering tailored product solutions can meet niche market demands and enhance brand differentiation for B2B customers. ↩

-

B2B sourcing decisions – Click here to learn about strategic procurement practices, market segmentation, and how B2B sourcing decisions can impact long-term business relationships and product success. ↩

-

advanced production techniques – Click here to explore the latest innovations in manufacturing, precision engineering, and quality control methods that drive competitive advantage in production. ↩

-

OEM – Click here to read about original equipment manufacturing, its role in branding, and why partnering with reliable OEMs is critical for maintaining product quality and consistency. ↩

-

sustainability – Click here to delve into sustainable manufacturing practices, environmental impact considerations, and strategies for sourcing eco-friendly raw materials while maintaining performance standards. ↩