Quick Answer: For B2B procurement managers, understanding the differences between mass-produced and professional padel rackets is crucial. Professional rackets use advanced materials like 3k, 12k, and 18k carbon fiber1 and custom design options to deliver superior performance and durability, while mass market rackets focus on cost efficiency and broad appeal.

In the sporting goods industry, selecting the right padel rackets for your clientele depends on balancing cost, performance, and customization capabilities. Mass market rackets are typically engineered for broad consumer segments, prioritizing affordability and standard performance. On the other hand, professional-grade rackets are crafted for high performance, using advanced composites and production techniques that translate into superior feel, power, and durability. This article details the distinguishing factors, production methodologies, and material comparisons that B2B procurement managers should understand before placing bulk orders.

One of the primary differentiators between mass-produced and professional padel rackets is the type and quality of materials used. Manufacturers like NEX Padel use several types of carbon fiber reinforcements for superior performance:

- 3k Carbon Fiber: Provides a balance between stiffness and weight, making it an economical choice for players who need moderate performance without sacrificing too much durability.

- 12k and 18k Carbon Fiber: These higher denier carbon fibers offer enhanced rigidity and power transmission, as well as improved durability and feel. They are favored for professional-grade rackets where performance is paramount.

Additionally, fiberglass is often blended with carbon fiber to help absorb vibrations and offer a softer yet controlled impact, which is critical for players who engage in high-frequency matches.

Advanced production techniques2

Professional padel rackets take full advantage of refined production techniques and quality assurance measures. Rapid prototyping and automated layering processes ensure that the final product is not only consistent but also tailored to performance metrics. The use of custom printing, shape modifications, and specialized hand grips further contributes to a customized, high-end product that suits professional needs.

In contrast, mass market rackets generally streamline these processes to maximize production speed and reduce costs. They leverage standard molds and pre-defined design parameters, and while they fulfill general performance requirements, they lack the customizable elements that professionals demand.

Below is a comparison table summarizing the key differences between mass-produced and professional padel rackets.

| Feature | Mass Market Rackets | Professional-Grade Rackets |

|---|---|---|

| Material Composition | Basic fiberglass and lower grade carbon | Advanced carbon fibers (3k, 12k, 18k) and fiberglass |

| Production Techniques | Standard molds; simplified layering | Customized molds; precision layering and rapid prototyping |

| Customization Options | Limited (basic colors and standard grips) | High (custom printing, shape, logo on hand grip & cover) |

| Design Versatility | One-size-fits-all design approach | Multiple models (Diamond, Round, Teardrop) and fully custom options |

| Durability and Performance | Adequate for casual play | Superior vibration control, targeted weight distribution, enhanced durability |

| Pricing | Lower production cost and price point | Higher cost reflecting superior materials and customization |

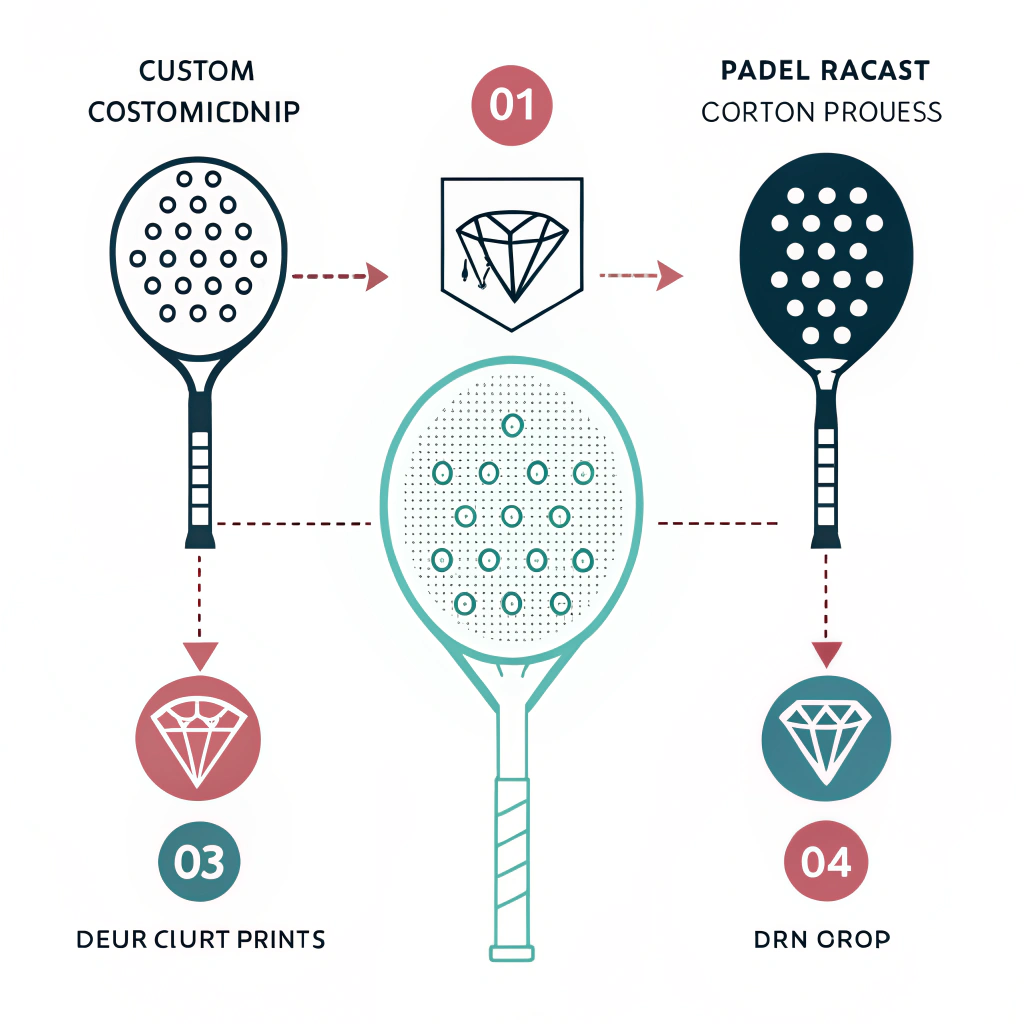

Customization3 Process

One of the cornerstones of professional padel racket production is the high level of customization. B2B procurement managers recognize that differentiation in the competitive sporting goods market requires offering products that can be tailored to specific customer preferences or branding needs. NEX Padel provides options such as:

- Customized Racket Shapes: Beyond standard shapes, we offer Diamond, Round, and Teardrop designs to cater to various playing styles.

- Custom Printing and Coloring: Customers can opt for personalized aesthetics. This means company logos or bespoke color schemes that not only enhance brand recognition but also meet marketing strategies.

- Hand Grip and Handle Customization: Including custom logos on hand grips and handle covers adds another layer of bespoke design, ensuring that the final product holds a unique identity.

Quality assurance4 and Control

For professional-grade products, quality assurance is a significant differentiator. At NEX Padel, quality control is applied during every stage of production:

- Material Inspection: Our supplier network is rigorously vetted to ensure that raw materials such as carbon fibers meet strict specifications.

- Layering Process: The construction process involves careful layering of carbon fiber variants and fiberglass to achieve the optimal combination of stiffness and vibration absorption.

- Rapid Prototyping and Testing: Prototypes are put through multiple rounds of testing to evaluate performance, durability, balance, and overall feel.

- Post-Production Analysis: Even after assembly, each racket passes a battery of tests to guarantee consistency and performance benchmarks.

These robust processes ensure that professional rackets meet the expectations of demanding players and provide clear benefits, even in highly competitive environments.

Balancing price and quality is at the heart of procurement decision-making. While mass market rackets are budget-friendly and cater to a wide array of novice players, professional-grade rackets command higher prices due to:

- Higher quality components and advanced manufacturing techniques.

- Increased labor and production time to allow for significant customization.

- Enhanced design elements that yield a superior performance and longer durability.

For distributors and sporting goods companies, investing in professional rackets can result in an enhanced market reputation and better customer satisfaction. However, the decision should factor in the targeted customer base. For example, an emerging brand may prefer an affordable range initially, while established entities aiming for premium market positioning might focus on high-performance, custom-built rackets.

Below is an illustrative breakdown of potential cost components:

| Cost Component | Mass Market Rackets | Professional-Grade Rackets |

|---|---|---|

| Material Costs | Lower grade fiberglass/carbon | Premium carbon fibers and additives |

| Production Process | Standardized, automated | Custom, precision engineering |

| Customization Features | Limited options | Extensive custom options |

| Quality Control Overhead | Basic certifications | Rigorous multi-stage testing |

| Final Retail Pricing | Economical pricing | Premium pricing based on performance and exclusivity |

When placing a bulk order, understanding your end customer’s needs is crucial. For sports equipment distributors, offering both mass market and professional options can cater to diverse segments:

- Mass Market: Targets budget-conscious consumers and amateur players. Emphasize durability for recreational use.

- Professional Market: Focuses on high-performance, tailored products for enthusiasts and competitive players. Highlight the advanced materials and customization features.

For B2B procurement managers, managing logistics is as important as the product itself. Professional-grade rackets may require more careful handling and extended lead times due to their complexity in production. An efficient supply chain includes:

- Accurate Forecasting: Use your sales data to predict demand trends for both mass market and professional products.

- Vendor Collaboration: Work closely with manufacturers like NEX Padel to ensure that production schedules align with your procurement timeline.

- Quality Documentation: Ensure that suppliers provide thorough quality control documentation. This is crucial for maintaining customer trust and supporting product warranties.

For companies focusing on professional-grade sports equipment, after-sales support becomes a significant decision factor. Offering value-added services such as extended warranties, technical support, and product customization consultations can differentiate your product in a crowded market.

- Extended Warranty Programs: Higher-end rackets are often accompanied by comprehensive warranties that speak to their durability and long-term performance.

- Training and Technical Support: Provide insights on product maintenance and customization benefits to educate retailers and end-users.

- Customer Feedback Integration: Use customer feedback for continuous improvements. This is especially important for products with highly customizable features.

- Conduct a Market Survey: Before finalizing bulk orders, analyze local market demand for both mass market and professional-grade rackets.

- Engage with Manufacturers: Initiate dialogue with manufacturers like NEX Padel. Understand their quality assurance protocols, customization possibilities, and production lead times.

- Evaluate Total Cost of Ownership (TCO)5: Factor in initial purchase costs, potential warranty claims, and after-sales support when calculating the TCO.

- Pilot Orders and Feedback Cycles: Consider placing pilot orders to gather real-world performance data. Use this feedback to refine the product lineup in subsequent bulk orders.

- Customization Integration: If targeting the professional market, focus on integrating high-level customization options to build brand differentiation.

- Risk Management: Develop a robust risk management framework to mitigate any supply chain or quality issues that may arise.

In summary, the decision between mass market and professional padel rackets involves a detailed comparison of material quality, production techniques, customization options, and pricing. For B2B procurement managers and product strategists, the superior performance of professional rackets can justify the higher investment—especially when serving discerning customers in competitive sports markets. With advanced materials like 3k, 12k, and 18k carbon fiber and versatile customization possibilities, professional rackets offer a distinct edge in terms of durability, performance, and brand differentiation. By carefully balancing cost, production capabilities, and market needs, sporting goods companies can effectively target diverse consumer segments and drive competitive advantage in the market.

Ultimately, aligning your procurement strategy with these detailed insights will ensure that you offer products that meet both consumer expectations and industry standards, creating a compelling mix that can drive long-term customer loyalty and brand strength.

People Also Ask

Q: Do expensive padel rackets make a difference?

A: Yes, expensive padel rackets are designed with superior materials, advanced manufacturing techniques, and custom options that enhance performance, comfort, and durability. They make a significant difference for players who frequently compete or require high-level performance, although beginners may not require such advanced features immediately.

Q: What padel rackets do professionals use?

A: Professional padel players often choose rackets that include advanced carbon fiber constructions, such as those incorporating 12k or 18k fibers, along with high-performance design elements. Top models from well-known brands are favored for their balance, customizability, and consistency, ensuring that they meet the exacting demands of professional play.

Q: Which brand makes the best padel rackets?

A: The best padel racket brands are those that consistently deliver top-tier performance, superior quality, and innovative design. In addition to widely recognized names, manufacturers like NEX Padel are known for their expertise in custom production and the use of advanced materials such as multiple grades of carbon fiber, ensuring reliability and performance for professional use.

-

3k, 12k, and 18k carbon fiber: Click to read more about the properties, manufacturing processes, and performance benefits of different carbon fiber grades used in high-performance sporting equipment. ↩ ↩

-

production techniques: Click to explore in detail how advanced production techniques, such as rapid prototyping and automated layering, contribute to product consistency and performance. ↩ ↩

-

customization: Click to learn how customization processes allow for tailored product features that can meet specific branding and performance requirements in competitive markets. ↩ ↩

-

quality assurance: Click to understand the critical importance of quality assurance in high-end manufacturing, ensuring reliability, performance, and customer satisfaction. ↩ ↩

-

Total Cost of Ownership (TCO): Click to discover how evaluating the total cost of ownership can help in making informed procurement decisions by considering long-term costs and benefits. ↩ ↩