Selecting a reliable padel racket manufacturer requires evaluating production capabilities, quality control measures, and customization options to ensure consistent performance and trust in your supply chain. This guide will help you compare manufacturers on essential criteria, providing actionable insights to support your sourcing decisions.

In today’s competitive sports equipment market, sourcing high-quality padel rackets is crucial for distinguishing your product offerings. Business owners and purchasing managers must look beyond price tags and focus on several key factors such as production quality1, customization capabilities, and reliability. As a leading manufacturer in the industry, we at NEX Padel understand the importance of a robust and transparent production process. Our in-house manufacturing combines advanced production techniques with a strong emphasis on quality control and rapid prototyping to meet diverse market needs.

This article outlines the core criteria to evaluate when choosing a reliable padel racket manufacturer and provides a detailed comparison of important factors. By understanding production techniques, material selection like carbon fiber2 and glass fiber, and the role of factory certifications, you can make an informed decision when building partnerships.

When comparing manufacturers, consider the following essential aspects:

- Production Quality & Techniques: Emphasis on advanced production processes, material consistency, and technical expertise.

- Customization Options: The ability to offer custom racket designs, personalized imprints, and color choices.

- Supply Chain Reliability: Capabilities in Rapid Prototyping3, timely delivery, and rigorous quality control.

- Industrial Certification & Expertise: Maintaining industry standards and obtaining factory audits for global certifications.

- Material Variety: Offering a range of materials from glass fiber to 3K, 12K, and 18K carbon fiber to accommodate various play levels.

Each of these factors plays a pivotal role in ensuring that the final product meets the demanding performance standards expected in the padel world.

Quality production is the backbone of any reliable padel racket manufacturer. Advanced production techniques guarantee that rackets not only perform well on the court but also maintain durability over time.

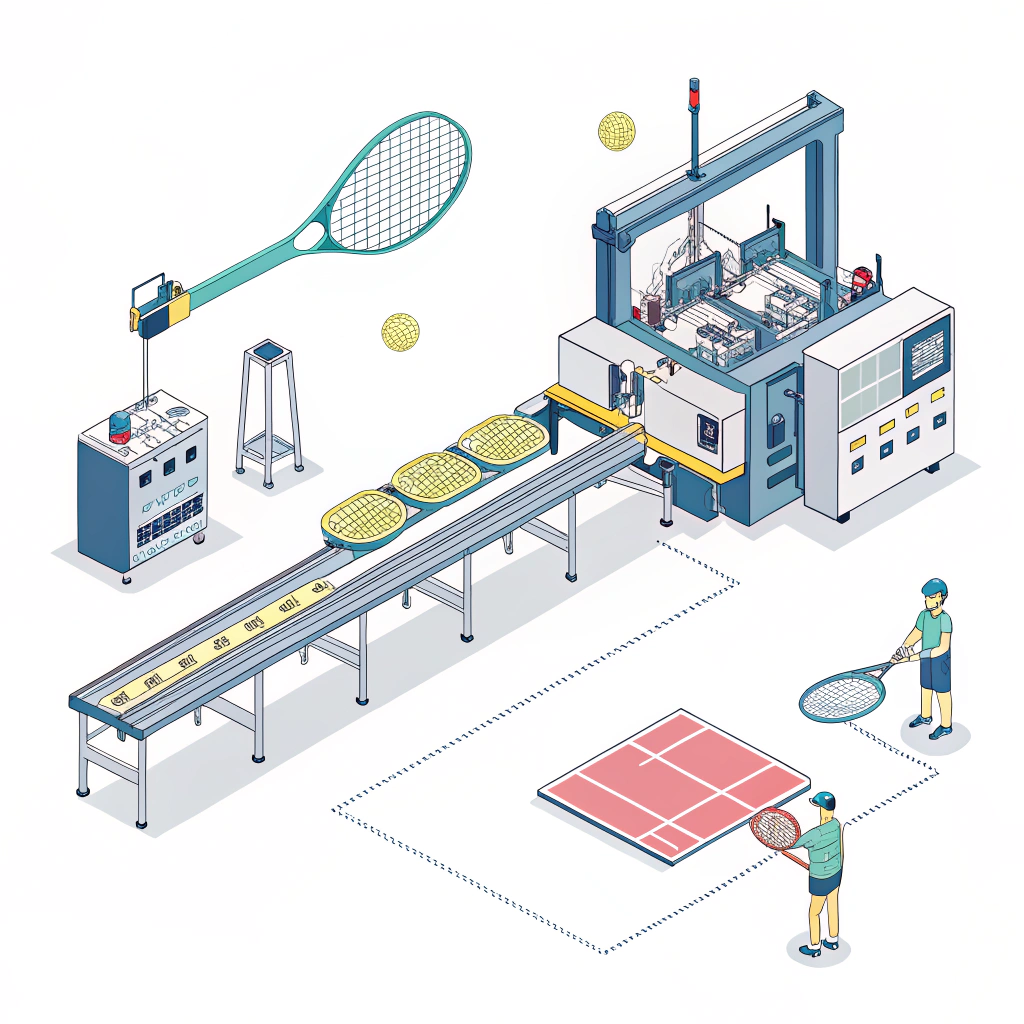

Manufacturers like NEX Padel use state-of-the-art production techniques to ensure precision in every racket. This includes automated processes that monitor temperature and pressure conditions during the layup process of carbon fiber and glass fiber materials. By employing these techniques, manufacturers can achieve a consistent balance and structural integrity in each product.

The material selection process is crucial. For instance, using different grades of carbon fiber such as 3K, 12K, and 18K provides varying degrees of stiffness and flexibility, catering to different play styles:

- 3K Carbon Fiber: Offers a balanced mix of durability and flexibility.

- 12K and 18K Carbon Fiber: Provide high stiffness for players needing greater control and power.

These technical choices ensure that every racket is optimized for competitive play and sustains high performance over continuous usage.

Strict quality control protocols are implemented at every step. During production, quality checks are performed to verify consistency in material layering and handle integration. Moreover, regular audits and industry certifications are maintained to ensure compliance with international standards, thereby minimizing the occurrence of defects and ensuring long-term reliability.

A crucial advantage of partnering with an established manufacturer is the flexibility in customization. This is particularly important in the B2B space, where retailers and distributors often look for unique selling propositions to differentiate their products in the market.

Leading manufacturers offer several customization options:

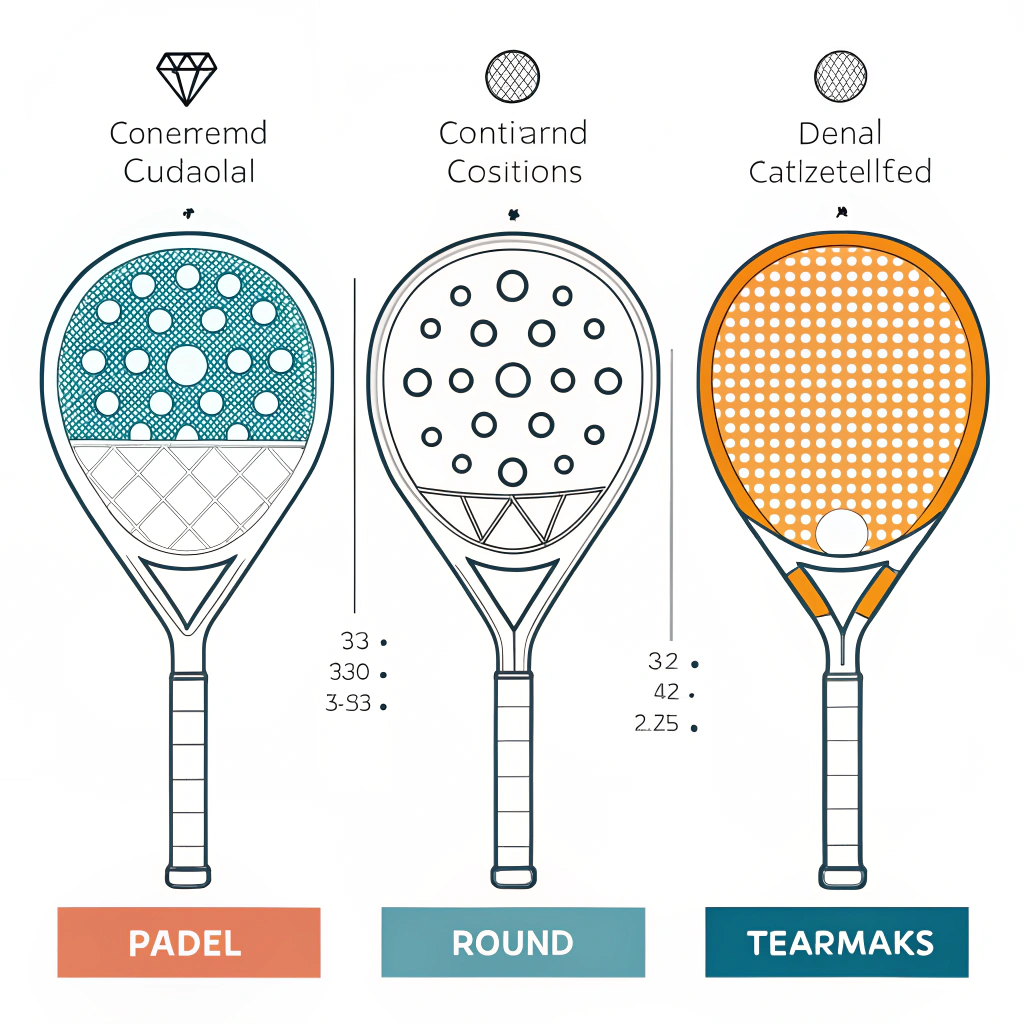

- Custom Shapes: Options such as Diamond, Round, and Teardrop designs, and even bespoke shapes tailored to customer specifications.

- Imprint Customization: Companies can request specific logos or inscriptions on the racket surface, ensuring brand visibility.

- Color Variants: A wide palette of color schemes allows for differentiation in the market while staying true to brand identity.

Beyond the core racket, additional elements such as hand grips and handle covers can also be customized with logos or signature patterns. This adds an extra layer of branding, appealing to niche markets or high-end clients who value exclusivity.

Customized products not only assure quality but also enhance the competitive edge in the market. Business partners can co-brand products with exclusive designs and implement features that align with the latest performance trends and customer preferences. Customization builds a direct link between the manufacturer’s expertise and the retailer's brand identity.

In the fast-paced world of sports equipment, delays or inconsistencies in supply can be detrimental. Reliable manufacturers optimize their processes to ensure that orders are met on time without compromising on quality.

A robust supply chain is built on several pillars:

- Rapid Prototyping3: Fast turnaround on prototype designs allows businesses to test and refine new models quickly.

- Timely Delivery: Efficient logistics and production schedules guarantee that products reach the market as planned.

- Consistent Quality Assurance: Regular factory audits and quality controls ensure that every batch is consistent.

Utilizing the latest in production software and machinery, manufacturers are now better equipped to handle large orders without errors. However, this is balanced with traditional craftsmanship where experienced technicians perform nuanced quality checks that machines may overlook. This combined approach ensures that every product benefits from both precision technology and human oversight.

The Role of OEM Partnerships4

For businesses that require extra assurance on part quality and technological integration, Original Equipment Manufacturer (OEM) partnerships can be a key differentiator. OEM companies, like NEX Padel, offer flexibility in designing products that adhere strictly to customer specifications while maintaining high standards of quality and performance.

Below is a table that summarizes and compares the critical evaluation criteria for padel racket manufacturers:

| Evaluation Criteria | Manufacturer A (Example) | Manufacturer B (Example) | NEX Padel |

|---|---|---|---|

| Production Techniques | Standard methods | Mixed automation | Advanced Automation with precision controls |

| Material Variety | Limited (mainly glass fiber) | Includes basic carbon fiber | Range: Glass Fiber, 3K, 12K, 18K Carbon Fiber |

| Customization Options | Minimal customization | Standard design options | Extensive customization (shapes, logos, colors) |

| Quality Control | Basic QC | Regular audits | Rigorous QC with industry certification audits |

| Supply Chain Reliability | Moderate | Good | High reliability with rapid prototyping and timely delivery |

| OEM Capabilities | Not available | Limited | Full OEM services and co-branding abilities |

This table provides a clear comparative view to help you weigh your options when choosing a manufacturing partner.

One significant aspect that can influence your decision is the adherence to industrial standards and successful factory audits. Certifications from recognized bodies serve as evidence of the manufacturer’s commitment to quality and safety.

- Industry Trust: Certifications signal a manufacturer’s compliance with international standards, building trust in the buyer-supplier relationship.

- Quality Assurance: Frequent factory audits and quality management processes help ensure consistent production quality.

- Risk Mitigation: Aligning with manufacturers who hold valid certifications reduces the risk associated with product recalls or quality issues.

At NEX Padel, we hold several industrial certifications5 that demonstrate our commitment to maintaining the highest standards. These include both local and international quality management credentials. Regular audits are performed internally and by third-party agencies to ensure our facilities meet rigorous production and safety requirements.

Examining real-world examples provides further reassurance in your decision-making process. Consider a case where a major sports distributor partnered with a manufacturer offering extensive customization and high-standard certifications.

A well-known retailer in the padel industry faced stiff competition and decided to upgrade its product line by incorporating custom-designed rackets. The key steps included:

- Evaluation of manufacturers based on production techniques and customization capabilities.

- Detailed assessments of material quality, with a focus on using various grades of carbon fiber.

- A successful trial phase involving rapid prototyping and iterative design adjustments.

- Final integration into the retailer's brand, resulting in increased market share and customer satisfaction.

Data from this case study indicated a 20% improvement in customer engagement and a notable decrease in product defects, thereby reinforcing the importance of partnering with a manufacturer that combines technical excellence with supply chain reliability.

- Production efficiency improved by 15% when switching to advanced automation systems.

- Customization options contributed to a 10-15% price premium in premium markets.

- Supply chain reliability and timely delivery were cited as major factors by over 80% of B2B partners in post-implementation surveys.

These insights underline that modern production technologies combined with strong customer service can significantly enhance your competitive edge.

Choosing the right padel racket manufacturer is not just about finding a supplier; it’s about building a long-term partnership that guarantees quality, innovation, and supply chain efficiency. Here are some final action steps for making an informed decision:

- Assess Production Capabilities: Evaluate potential partners based on their manufacturing techniques, material variety, and quality control processes.

- Review Customization Options: Ensure the manufacturer offers extensive customization to meet your brand’s needs.

- Verify Certifications and Audits: Look for evidence of consistent quality and compliance with industry standards.

- Consider OEM Relationships: Seek manufacturers who can offer OEM services, facilitating co-branding and design collaboration.

- Pilot and Test: Begin with rapid prototyping to test the responsiveness and consistency of the manufacturer before scaling up.

By following these recommendations, you can significantly reduce risks and secure a reliable supply chain partner. For those ready to move forward, take the next step by contacting a manufacturing specialist who can tailor solutions specifically to your business needs.

At NEX Padel, we pride ourselves on our ability to meet diverse market demands while ensuring top-notch quality and performance. Our advanced production techniques, rigorous quality control, and expansive customization options make us a trusted partner for businesses worldwide. Get in touch with our team to explore how our solutions can empower your product line and drive business growth.

Q: Which brand makes the best padel rackets?

A: The market features many top brands, each excelling in different areas. For instance, brands like HEAD, Bullpadel, and Babolat are known for advanced design and performance. However, the best choice depends on your specific play style and performance expectations.

Q: How to find a good padel racket?

A: Finding a good padel racket involves assessing production quality, evaluating materials such as various grades of carbon fiber, and considering customization options. It is also important to check quality control certifications and supply chain reliability to ensure consistent performance.

Q: Who manufactures padel rackets?

A: Padel rackets are manufactured by a range of companies, from established industry leaders to specialized OEM providers. For example, companies like Bullpadel and NEX Padel have built strong reputations by offering advanced production techniques, comprehensive customization, and rigorous quality control measures.

-

Production Quality: Read more to discover industry best practices for optimizing manufacturing processes, ensuring material consistency, and achieving superior product durability. ^Return ↩

-

Carbon Fiber: Click here to understand the properties, benefits, and applications of carbon fiber in enhancing product performance in sports equipment. ^Return ↩

-

Rapid Prototyping: Learn how rapid prototyping accelerates product development and enables quicker iterations for better quality control. ^Return ↩ ↩2

-

OEM Partnerships: Discover the advantages of OEM partnerships that allow for customized design solutions and streamline production for co-branded products. ^Return ↩

-

Industrial Certifications: Explore how industrial certifications and rigorous factory audits build trust, ensure compliance, and maintain high quality standards in manufacturing. ^Return ↩