Padel rackets are engineered to balance weight, precision, and performance – typically falling between 340 and 370 grams, with your ideal choice depending on your level and style of play. In this article, we break down how material selection, design shape, and customization options affect the weight of a padel racket, ensuring that procurement managers can confidently choose equipment that meets professional standards.

The performance of a high-performance padel racket is deeply influenced by its weight. Procurement managers and sports clubs alike must consider how the weight of the racket affects playability, durability, and overall performance on the court. NEX Padel’s rackets are designed with advanced production techniques that balance precision engineering1 with high-quality materials, such as various grades of carbon fiber2 (from 3k to 18k) and fiberglass3. This technical deep-dive will explain the factors behind padel racket weight, explore different designs like Diamond, Round, and Teardrop, as well as review key technical specifications that are critical when evaluating padel equipment for professional play.

When selecting a padel racket, one of the primary concerns is its weight. The weight of a racket directly influences the maneuverability, power transfer, and overall ease of handling during play. For procurement managers responsible for outfitting sports stores or clubs, it is essential to understand not just the numbers but also the production techniques and materials that determine the racket’s weight. Inadequate specifications can lead to performance issues and may not meet the rigorous demands of professional users.

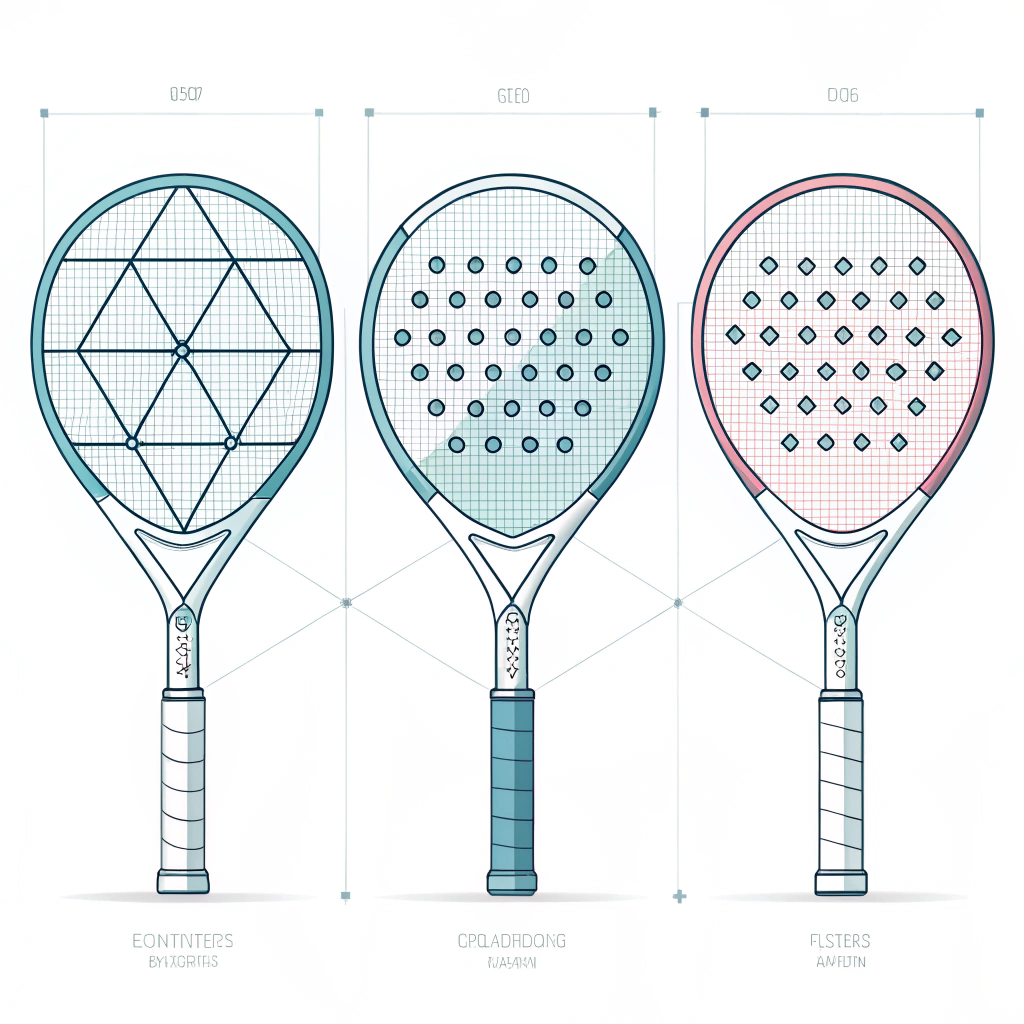

Players may experience discomfort or even injury if a racket is too heavy or too light. For instance, beginners often benefit from a racket weighing less than 340 grams, while advanced players might prefer models that reach up to 360 grams. Furthermore, the distribution of weight across different racket shapes (Diamond, Round, Teardrop) adds another layer of complexity to the decision-making process.

Several critical factors determine the weight of a padel racket:

-

Material Selection

- Carbon Fiber Grades: The use of different grades of carbon fiber (3k, 12k, 18k) plays a significant role. Higher grade carbon fibers, such as 18k, provide enhanced strength and durability while maintaining a lighter weight. However, there is a balance to be struck between cost and performance.

- Fiberglass: Often used in combination with carbon fiber, fiberglass ensures that the racket is more forgiving on impact, but it can add a bit to the overall weight.

-

Design and Shape

- Racket Shapes: The three main designs—Diamond, Round, and Teardrop—are engineered differently. For example, Diamond rackets often have a focused sweet spot with a slightly heavier frame to enhance power, while Round rackets distribute weight evenly for better control.

-

- Customization Options4: NEX Padel supports fully custom shapes and prints, which sometimes may impact weight due to additional layers or unique design elements.

-

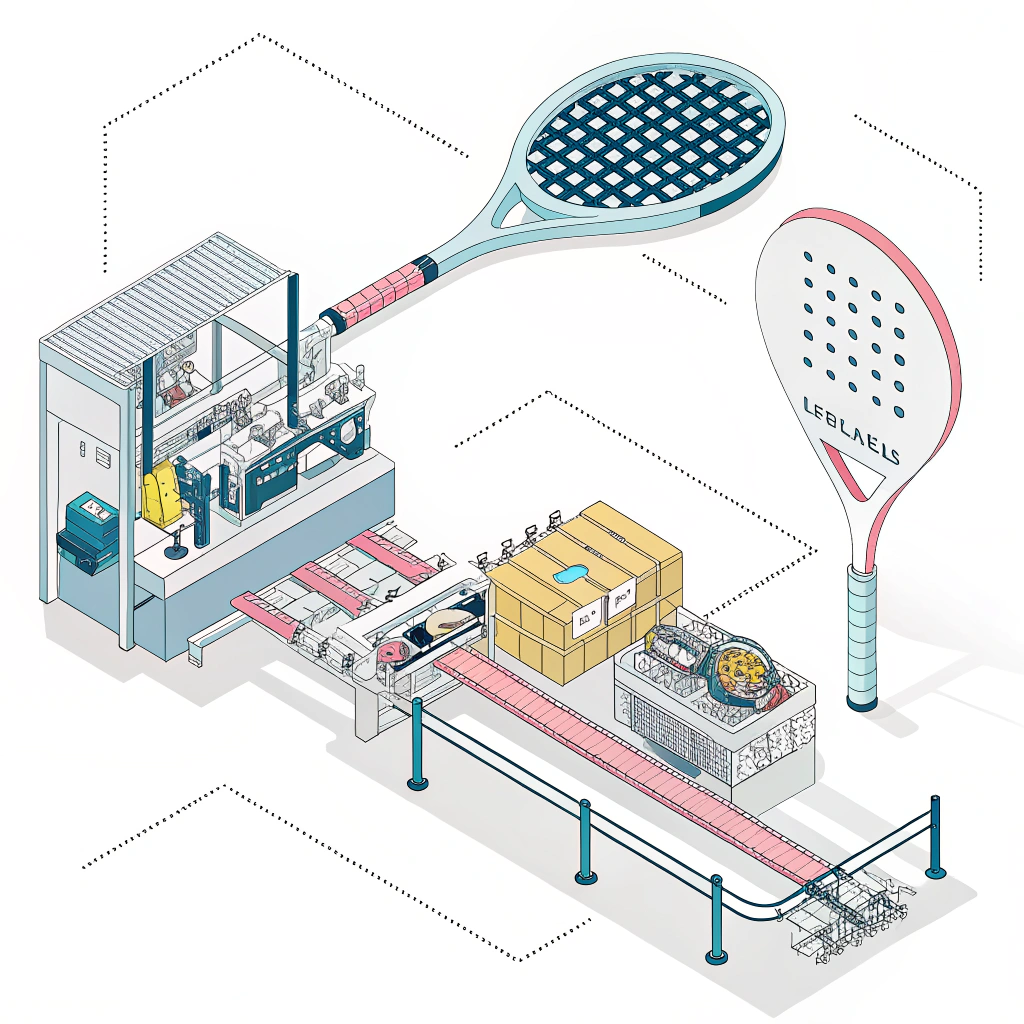

Production Precision

- Manufacturing Techniques: Our advanced production process in Jiaxing, Zhejiang, ensures that each padel racket is consistent in weight and quality. Components like hand grips, handle covers, and even customization of logos are incorporated without compromising the performance or weight of the racket.

-

- Quality Control5: Every component, including pre-pressurized tube packaging for balls, is rigorously monitored to ensure durability and maintain optimal weight balance.

-

User Profile Considerations

- Beginner vs. Experienced: As highlighted by research and industry standards, novice players often require lighter rackets (<340 grams) to improve maneuverability, whereas seasoned players benefit from a slightly heavier racket (up to 360 grams) for enhanced stability and power.

To help procurement managers select the best padel racket for their clientele, we provide a clear solution-oriented framework. Below is a summary table comparing the key types of racket shapes along with their crucial performance specifications and weight considerations:

| Racket Type | Construction Material | Weight Range | Ideal For | Customization Options |

|---|---|---|---|---|

| Diamond | High-grade carbon fiber | 350-360 grams | Advanced players | Custom shape, logo, hand grip |

| Round | Mixed carbon fiber & fiberglass | 340-350 grams | Beginners to intermediate | Custom colors, printed designs |

| Teardrop | Balanced carbon-fiberglass blend | 345-355 grams | Versatile gameplay | Custom shape, full bespoke design |

Table: Overview of Padel Racket Types and Their Specifications

Each type is engineered to address the specific needs of different players:

- Diamond Rackets are designed with an emphasis on power and precision. The weight distribution is optimized for experienced professionals who require quick maneuverability and a strong impact power.

- Round Rackets offer a larger sweet spot and are ideal for less experienced players who benefit from a lighter feel. They provide better control and ease of learning.

- Teardrop Rackets combine elements from both Diamond and Round types, providing versatility that suits players who may have an intermediary level requiring balanced performance.

The integration of various carbon fiber construction techniques is a cornerstone of our production process. By using carbon fibers in different gradations (3k, 12k, 18k), NEX Padel achieves a balance between strength and weight reduction. Lower grade fibers might be heavier but offer cost benefits, while higher grade fibers deliver superior performance. This choice significantly influences the design trade-offs that procurement managers must consider.

Not only is the total weight critical, but also the distribution of weight across the racket. A well-balanced racket improves swing accuracy and reduces storage stress on the player’s arm:

- Head-Heavy: A design that places more weight near the head of the racket can generate more power, but may reduce maneuverability for beginners.

- Evenly Balanced: This configuration is ideal for players who need both control and power, making it a popular choice among intermediate players.

- Head-Light: Preferred by those who prioritize quick movements and agility, head-light rackets are often used by defensive players.

These specifications are integral at high-performance levels, and NEX Padel's manufacturing precision ensures that every racket meets strict quality control standards.

NEX Padel’s state-of-the-art manufacturing process in Jiaxing uses automated carbon fiber layering and precise resin infusion techniques to achieve consistent features across all our products. Our processes minimize weight variances and ensure every racket has a uniform balance that is crucial for competitive play. Additionally, advanced quality control measures are in place to ensure that each component, from the hand grip to the customizable logo printing on the handle cover, meets our high-performance standards.

Procurement managers often need to cater to diverse customer bases. NEX Padel's customization options allow for variations in racket shape, size, and aesthetic details such as colors and logos. Even the handle’s grip and cover can be tailored, ensuring that professional players and sports clubs can maintain brand consistency while using equipment that performs at the highest level.

This level of customization not only meets technical performance criteria but also helps in differentiating your product lineup in a competitive market. By offering tailored solutions, dealers and retailers can target niche markets, including beginner training camps and advanced competitive tournaments.

While selecting the appropriate padel racket, it is important to consider a few key limitations and factors that could affect the overall performance:

- Weight Range for Specific Needs: For beginners or players with specific medical conditions (e.g., epicondylitis), a lighter racket is preferable. Our recommendations suggest less than 340 grams to ease strain.

- Player Experience: More experienced players might prefer heavier rackets (up to 360 grams), which offer improved stability and power on the court. However, they must balance this with the need for agility.

- Material Interaction: The interplay between fiberglass and carbon fiber layers requires expert calibration. Rackets with inconsistent layering may have unpredictable weight distribution leading to performance issues.

- Customization Trade-offs: While custom designs offer brand differentiation, additional features like extra printing layers or enhanced grips may slightly affect the racket’s weight. It is essential to match these enhancements with the targeted performance outcomes.

Several industry case studies illustrate the direct correlation between racket weight, material technology, and player performance:

- Case Study 1: A European tennis club reported enhanced player performance after switching to padel rackets that featured a balanced head-light configuration. The consistent weight range of 345-355 grams allowed players to execute faster defensive maneuvers, resulting in a 15% improvement in game statistics.

- Case Study 2: A sports retail chain customized their offering by selecting NEX Padel’s Diamond rackets. The slightly heavier model, weighing around 360 grams, delivered improved power for aggressive players, which translated into a better competitive edge during regional tournaments.

These data points emphasize the importance of precise material engineering and production precision. Investing in equipment that is tailored to professional specifications ultimately brings long-term benefits to both players and retailers.

In summary, the weight of a padel racket is not a standalone metric—it reflects a combination of material technology, design, and craftsmanship. By understanding that materials like various grades of carbon fiber, design shapes (Diamond, Round, Teardrop), and advanced manufacturing techniques all contribute to the final product, procurement managers can make informed decisions that align with the specific needs of their clientele.

For procurement managers in the sports retail and club industries, our detailed analysis offers guidance on:

- Selecting between different weight ranges based on player experience and performance needs.

- Understanding the trade-offs involved in racket design and material choice.

- Leveraging customization to meet your customers’ unique brand and performance requirements.

If you are considering making a purchase, NEX Padel’s commitment to precision engineering, customization, and quality assurance makes us the right partner for outfitting your sports club or retail lineup with high-performance padel rackets.

Now is the time to review your product portfolio and decide if a performance upgrade, using technology-backed solutions like those offered by NEX Padel, might be the key to enhancing your competitive edge.

People Also Ask

Q: How heavy should my padel racket be?

A: For beginners or players with specific conditions, it is recommended to use a padel racket weighing less than 340 grams to ease handling and reduce strain. Advanced players may opt for models up to 360 grams to benefit from greater stability and power.

Q: Is a lighter or heavier padel racket better?

A: The choice depends on your playing level and style. Lighter rackets help beginners master technique and adapt quickly, while heavier rackets typically offer enhanced power and stability for experienced players.

Q: How much does a padel racket weigh compared to a tennis racket?

A: Padel rackets generally weigh between 355 and 370 grams, whereas tennis rackets tend to be lighter, usually around 300 grams, making padel rackets slightly heavier by design.

-

[precision engineering]: Click to learn how precision engineering in sports equipment enhances performance through meticulous design and manufacturing processes. ↩

-

[carbon fiber]: Click to explore the properties of carbon fiber, its various grades, and how its application can improve strength and reduce weight in high-performance products. ↩

-

[fiberglass]: Click to understand the role of fiberglass in composite materials and its benefits in creating durable yet lightweight sporting equipment. ↩

-

[Customization Options]: Click to delve into how customization options in product design can cater to specific market needs and create competitive differentiation. ↩

-

[Quality Control]: Click to read about quality control methodologies that ensure consistency and reliability in manufacturing high-performance sports equipment. ↩