In short, padel rackets are produced using advanced composite techniques that involve layering glass fiber1 and various grades of carbon fiber2 (3K, 12K, 18K), precision molding, and extensive quality control to create high-performance, customizable rackets tailored for professional play.

The manufacturing journey begins with the careful selection and preparation of raw materials. A padel racket’s performance and durability are largely determined by its components. At NEX Padel, we source glass fiber and different grades of carbon fiber to meet diverse performance needs. The selection process includes verifying the quality of each material to ensure that every racket meets stringent international standards.

Before production, raw materials are cut and prepped to align with the design specifications. The carbon fiber options—3K, 12K, and 18K—offer varying levels of stiffness and durability. This diversity allows us to create rackets suited for a range of playing styles and market segments. Proper storage and handling of these materials are crucial, as even minor defects can compromise the structural integrity of a high-performance padel racket.

After material preparation, the next step is the layering process, where multiple layers of fibers are assembled to create a composite structure that balances strength, weight, and flexibility. Our highly skilled production teams and advanced machinery work together to achieve the ideal configuration for each racket shape. Whether it's a Diamond, Round, or Teardrop design, each configuration demands a unique layering sequence.

Below is a simplified table summarizing the key stages:

| Step | Description | Key Materials |

|---|---|---|

| Material Selection | Choosing high-quality glass fiber and carbon fiber (3K, 12K, 18K) based on design requirements | Glass Fiber, Carbon Fiber |

| Layering | Building up the composite by layering fibers in precise sequences | Carbon Fiber, Resin |

| Molding | Placing the layered material into precision molds and applying heat and pressure | Composite layers, Resin |

| Customization | Incorporating design elements, custom printing, and handle modifications | Custom Inks, Hand Grips |

| Finishing & Quality Control | Applying final touches, including handle assembly and quality checks | Hand Grip, Additional Trim |

This table represents the critical steps that ensure each padel racket not only performs at the highest level but also meets the unique customization needs of B2B clients.

During the molding stage, the expertly layered material is placed in molds that define the racket’s final shape. These molds apply consistent pressure and heat to achieve a perfect bond among the composite layers. This process is indispensable, as the precision of the molding directly influences the racket’s performance characteristics.

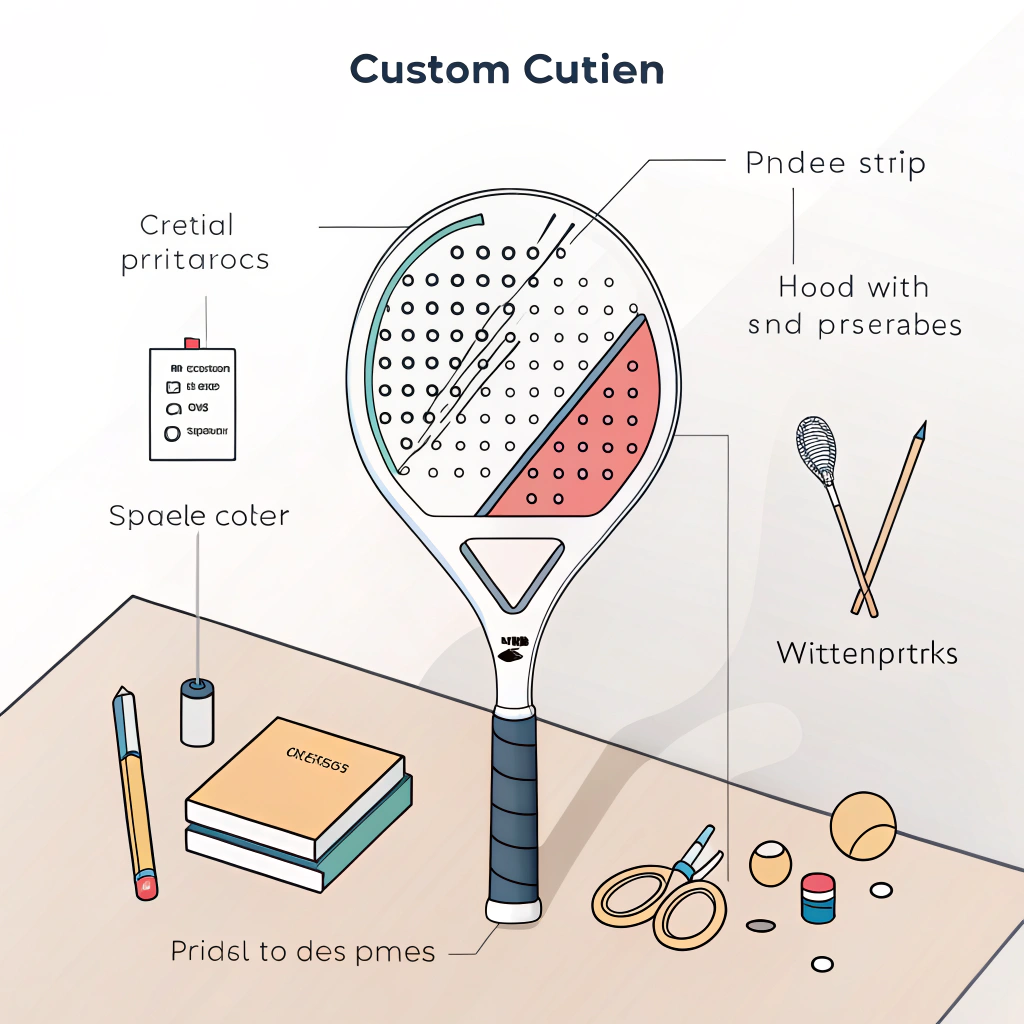

One of NEX Padel’s significant strengths lies in our customization abilities. B2B clients can specify not only the type of racket (Diamond, Round, or Teardrop) but also tailor intricate aspects like custom printing, color schemes, and even the design of hand grips and handle covers. Customization plays a pivotal role for companies looking to distinguish their brand in competitive markets.

To illustrate our customization process:

-

Customized Shapes:

Clients interested in shaping the racket to their brand ethos can opt for a fully customized racket form. Whether it is the aerodynamic advantages of a teardrop or the balanced power of a round configuration, the design is closely managed from start to finish. -

Printing and Branding:

Post-molding, our technicians ensure that custom logos and prints are applied using high-definition printing techniques. These marks not only boost brand visibility but also add an extra layer of authenticity and appeal to the final product. -

Hand Grip Personalization:

Alongside the racket’s body, additional components such as the hand grip and handle cover can also be customized. Companies often prefer to embed their logos or specific designs on these parts, ensuring consistency in branding across all equipment.

This level of customization requires precision and coordination. Our integrated production lines allow for rapid prototyping and evaluation, ensuring that every design aligns with our clients’ specifications. As production scales, our efficient design-to-delivery process reduces lead times without compromising on quality.

Quality assurance is a non-negotiable aspect of high-performance sports equipment manufacturing. At NEX Padel, each production phase incorporates strict testing and quality control measures. These checks include load testing, dimensional accuracy verification, and visual inspections to detect any anomalies in the composite structure.

Key points in our quality control process include:

- During Layering: Workers monitor the consistency and alignment of fibers, ensuring that no air bubbles or imperfections are trapped within the resin.

- Post-Molding Checks: Once the racket is molded, it undergoes several rounds of precision measurement to verify that the final dimensions adhere closely to design specifications.

- Customization Verification: After the application of logos and custom prints, quality control teams review the aesthetic details against the approved designs.

This systematic process helps eliminate errors and minimizes the risk of product defects. Moreover, our advanced production techniques allow us to continuously refine and improve our manufacturing methods, staying at the forefront of innovation in the sports equipment industry.

In today’s competitive market, B2B clients—especially those in the sports equipment sector—demand not only quality but also the adaptability to meet changing consumer preferences. At NEX Padel, we have honed our production techniques to support full customization while retaining consistent quality standards. This blend of efficiency and flexibility is particularly beneficial for companies engaging in private labeling3 or niche market targeting.

For instance, when working with international brands such as Hirostar, Reebok, and Starvie, our ability to switch from standard models to custom shapes and prints makes us a favored production partner. Our expertise in managing supply chain logistics4 further assures clients that production will meet deadlines in a timely manner, thus reducing downtime in marketing and distribution.

In practice, our production challenge is not simply about manufacturing padel rackets. It’s about delivering a product that meets high performance, aesthetic appeal, and durability—all while aligning with the client’s brand identity. The integration of technology with traditional craftsmanship positions us uniquely within the global market. Manufacturers can rely on our production processes to deliver consistent results, enabling them to focus on market expansion and customer relations.

In summary, high-performance padel racket manufacturing is a sophisticated process that involves critical stages from raw material selection and layering to precision molding, customization, and rigorous quality control. By leveraging advanced carbon fiber techniques along with modern production practices, NEX Padel creates rackets that not only enhance on-court performance but also offer extensive customization options for discerning B2B buyers.

For sourcing managers and product development specialists, the detailed understanding of these processes provides a clear roadmap for evaluating potential manufacturing partners. When choosing a manufacturer, consider production capabilities, customization flexibility, quality control standards, and supply chain efficiency. NEX Padel’s commitment to excellence and speed in production makes us a dependable partner in the sports equipment manufacturing industry.

To take the next step, consider reaching out to our technical support or scheduling a detailed consultation to see how our expertise can be aligned with your company’s needs. Let us partner with you to create sporting equipment that stands out in the global market.

• How are padel rackets made?

Padel rackets are constructed by layering composite materials such as carbon fiber (including 3K, 12K, and 18K options) and glass fiber. The layered structure is placed in precision molds and subjected to heat and pressure, resulting in the final racket shape. Once molded, additional components like the handle and custom branding elements are added to complete the product.

• Where are siux padel rackets made?

Siux padel rackets are noted for being handcrafted in Spain, with production located in facilities renowned for their expertise in manufacturing quality padel equipment. This contrasts with our operations at NEX Padel, where we combine advanced Chinese manufacturing techniques with high customization capabilities.

-

glass fiber: Click to read more about the properties and applications of glass fiber in high-performance composite manufacturing. Back to term ↩

-

carbon fiber: Click to understand the technical specifications, grading (3K, 12K, 18K), and benefits of using carbon fiber in sports equipment. Back to term ↩

-

private labeling: Click to explore how private labeling strategies can enhance brand visibility and market positioning for B2B companies. Back to term ↩

-

supply chain logistics: Click to learn about the management of supply chain logistics and its crucial role in ensuring timely production and delivery in the manufacturing industry. Back to term ↩