In today’s fast-paced sports equipment market, decision-makers need manufacturers who not only deliver high-performance padel rackets but also offer superior customization and reliable production processes. NEX Padel answers that need with state-of-the-art OEM manufacturing1, backed by advanced production techniques, thorough quality control, and a versatile customization portfolio. This article guides you through the critical aspects of choosing NEX Padel as your strategic partner, comparing performance factors and highlighting why our factory remains the top choice for leading brands.

Manufacturing high-quality padel rackets requires precision and innovation. At NEX Padel, our production process leverages both fiberglass and advanced carbon fiber2 materials such as 3k, 12k, and 18k options. This diversity allows us to produce rackets that not only meet but often exceed industry performance standards.

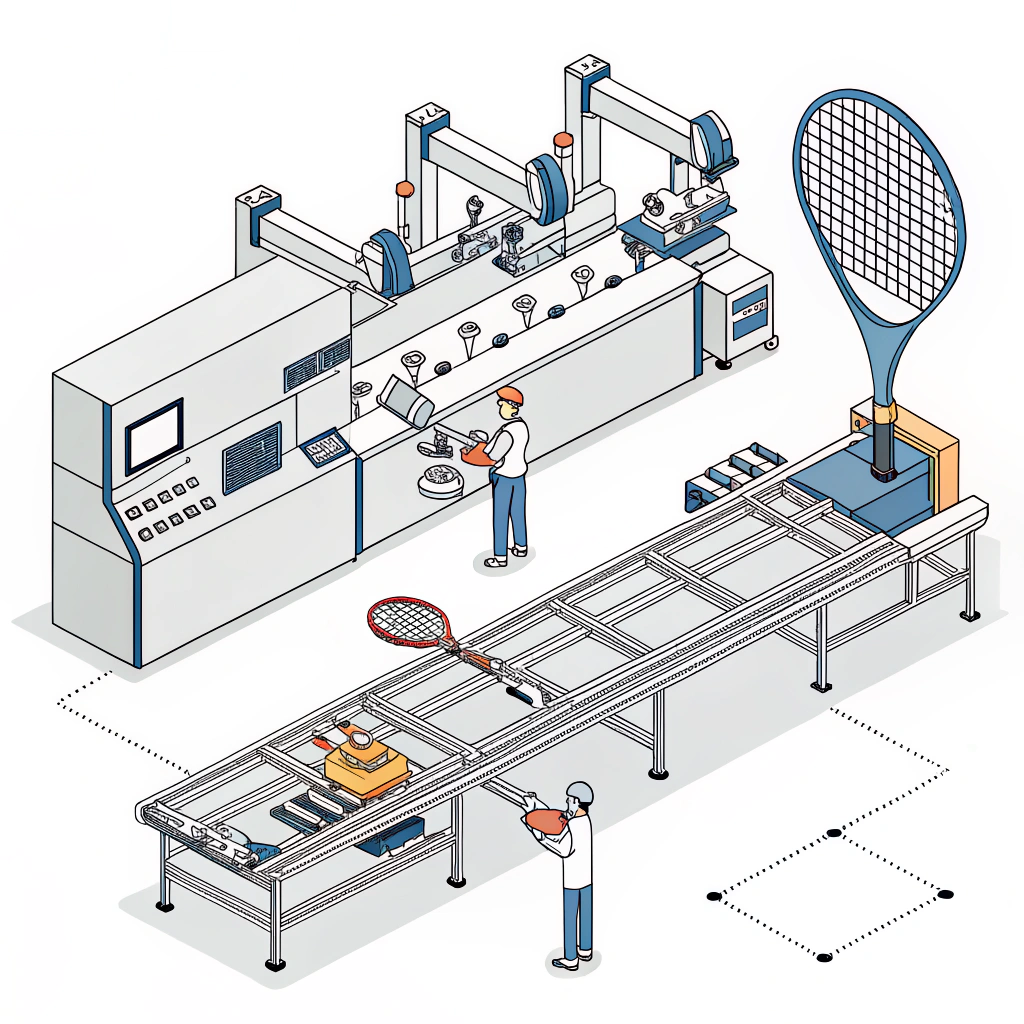

We design and produce three primary shapes—Diamond, Round, and Teardrop—to cater to varied play styles and power requirements. These shapes are not arbitrarily chosen; they result from extensive testing and iteration. Our production line employs highly automated processes that ensure a high level of precision. Through advanced CNC machining3 and quality inspections, every racket is crafted to maintain durability, weight balance, and optimal strength.

The specific benefits include:

• Consistent performance and durability through rigorous production controls.

• The ability to customize internal structures and weight distribution to improve playability.

• Rapid prototyping4 and sampling capabilities that drastically reduce time-to-market.

Each facet of our production process is continually optimized through feedback loops with top-tier brands such as Hirostar, Reebok, and Starvie. These partnerships underscore our commitment to innovation and quality control across every step.

In today’s market, sports equipment buyers require more than just a product—they need a solution that can be tailored for market differentiation. At NEX Padel, we provide extensive customization options that include not only racket shapes but also color schemes, printing, and even customizable elements like hand grips and handle covers with your logo.

Customization is integrated into our production from the design phase to the final quality check. This means that as you specify design details, our engineers work alongside your team to validate the proposed design through simulations and sample productions. This collaborative approach ensures that every detail is refined according to your brand’s needs while still meeting the exacting performance criteria of competitive padel play.

Here’s a quick view of our customization options:

| Customization Feature | Description | Benefit |

|---|---|---|

| Racket Shape | Diamond, Round, Teardrop, or fully custom designs | Tailor-made performance and aesthetics |

| Material Selection | Fiberglass, 3k, 12k, 18k carbon fiber options | Adjust weight, stiffness, and durability |

| Branding & Printing | Custom logos, color schemes, unique pattern designs | Enhanced brand identity and market appeal |

| Hand Grip and Handle Covers | Customizable with logo and tactile design optimization | Cohesiveness with overall product design |

This table shows how we match product features with end-user benefits, ensuring that our paddle rackets resonate with both performance athletes and brand-conscious consumers.

For any business development or procurement manager, quality control is non-negotiable. NEX Padel’s manufacturing process is designed with multiple quality checkpoints. We follow international industry standards to maintain our production excellence, which includes:

- Pre-production Quality Checks: Raw materials undergo rigorous testing to ensure they meet required industry standards before they are even incorporated into production.

- In-line Inspection: During production, automated systems and skilled technicians perform continuous inspections, ensuring that every stage is maintained at peak quality.

- Final Product Testing: After the final assembly, each padel racket is subjected to a battery of tests that simulate realistic playing conditions. This helps us evaluate performance metrics like weight distribution, balance, and overall durability.

By combining automated quality control with expert human oversight, we have consistently mitigated common issues such as material defects or production inconsistencies. Our commitment to quality control is further evidenced by the trust placed in us by internationally recognized brands.

Some additional steps we take include:

• Regular Audits: Internal and external quality audits ensure adherence to both regulatory standards and our high internal benchmarks.

• Data-Driven Improvements: Post-production analysis helps us continuously adapt and implement improvements in our production processes.

• Sustainability and Safety Compliance: We also focus on sustainable manufacturing practices, ensuring not only product quality but also environmental responsibility.

NEX Padel has built a robust reputation through partnerships with some of the most recognized names in the sports equipment market. Our collaboration with brands like Hirostar, Reebok, and Starvie speaks volumes about our manufacturing capabilities. These brands have specific requirements for their OEM padel manufacturing that go beyond standard production. They rely on our technology and expertise to create innovative designs that offer a competitive edge.

Working with a global network of suppliers and distributors, NEX Padel has honed a seamless supply chain management5 system that supports fast turnaround times. This reliability is crucial for business development executives who must ensure that premium products arrive on time and meet market expectations.

Key strategic advantages include:

• Rapid Prototyping and Sampling: Allowing quicker market tests and adjustments.

• Consistent Production Schedule: Timely and reliable production to meet seasonal demands.

• Customization Flexibility: Facilitating different tiers of products from entry-level to high-performance rackets.

These strengths make NEX Padel an ideal partner for companies looking to elevate their sporting goods portfolio and maintain a competitive market position.

When comparing potential suppliers, it is critical to consider several factors: advanced production capabilities, strict quality control, robust customization options, and a proven track record with industry leaders. NEX Padel covers all these aspects with precision and reliability.

Here’s a summary checklist to help guide your decision-making process:

- Evaluate the manufacturer’s material options (fiberglass versus various carbon fiber grades) and how they impact performance metrics.

- Ensure the supplier can offer diverse racket shapes (Diamond, Round, Teardrop, or custom) to suit your market's needs.

- Confirm that each step of the production—from raw material inspection to final product testing—meets international quality standards.

- Assess their customization abilities, from structural designs to branding elements such as hand grips and color schemes.

- Validate their supply chain reliability by reviewing partnerships with established brands and evidence of timely delivery.

By following these steps, you can confidently select a manufacturing partner who not only meets but exceeds your expectations in high-performance padel equipment.

Choosing the right OEM partner is more than a single decision—it's a strategic move that impacts market competitiveness and brand perception. With its advanced production techniques, extensive customization capabilities, and stringent quality control processes, NEX Padel stands out in the world of sports equipment suppliers. For procurement managers and business development executives, partnering with NEX Padel ensures that every padel racket is a blend of innovation, quality, and brand value. Embrace a collaboration that transforms your product lineup and elevates your brand’s market position.

People Also Ask

• What are the key features that differentiate NEX Padel’s manufacturing process?

NEX Padel’s process combines advanced materials like multiple carbon fiber grades with automated production techniques and rigorous quality controls, ensuring superior durability and performance across various racket shapes.

• How does NEX Padel ensure high-standard quality in padel racket production?

Quality is maintained through multi-stage inspections, from raw material testing and in-line automated checks to comprehensive final product performance tests, coupled with continuous audits and data-driven process improvements.

• What customization services does NEX Padel offer for OEM padel rackets?

NEX Padel provides a complete range of customization options including diverse racket shapes (Diamond, Round, Teardrop, or fully custom), personalized branding such as custom prints and logos on hand grips and handle covers, and tailored material selections to meet specific performance criteria.

-

OEM manufacturing: Click to learn how Original Equipment Manufacturer processes integrate design, production, and quality management to deliver tailored products that meet market-specific standards. ↩ ↩

-

Carbon fiber: Click to explore the properties and benefits of carbon fiber materials in high-performance sports equipment manufacturing. ↩ ↩

-

CNC machining: Click to understand how Computer Numerical Control machining enhances production precision and efficiency in manufacturing processes. ↩ ↩

-

Rapid prototyping: Click to discover the advantages of rapid prototyping for accelerating product development and reducing time-to-market. ↩ ↩

-

Supply chain management: Click to learn about effective supply chain management strategies that ensure timely delivery and operational efficiency in manufacturing. ↩ ↩