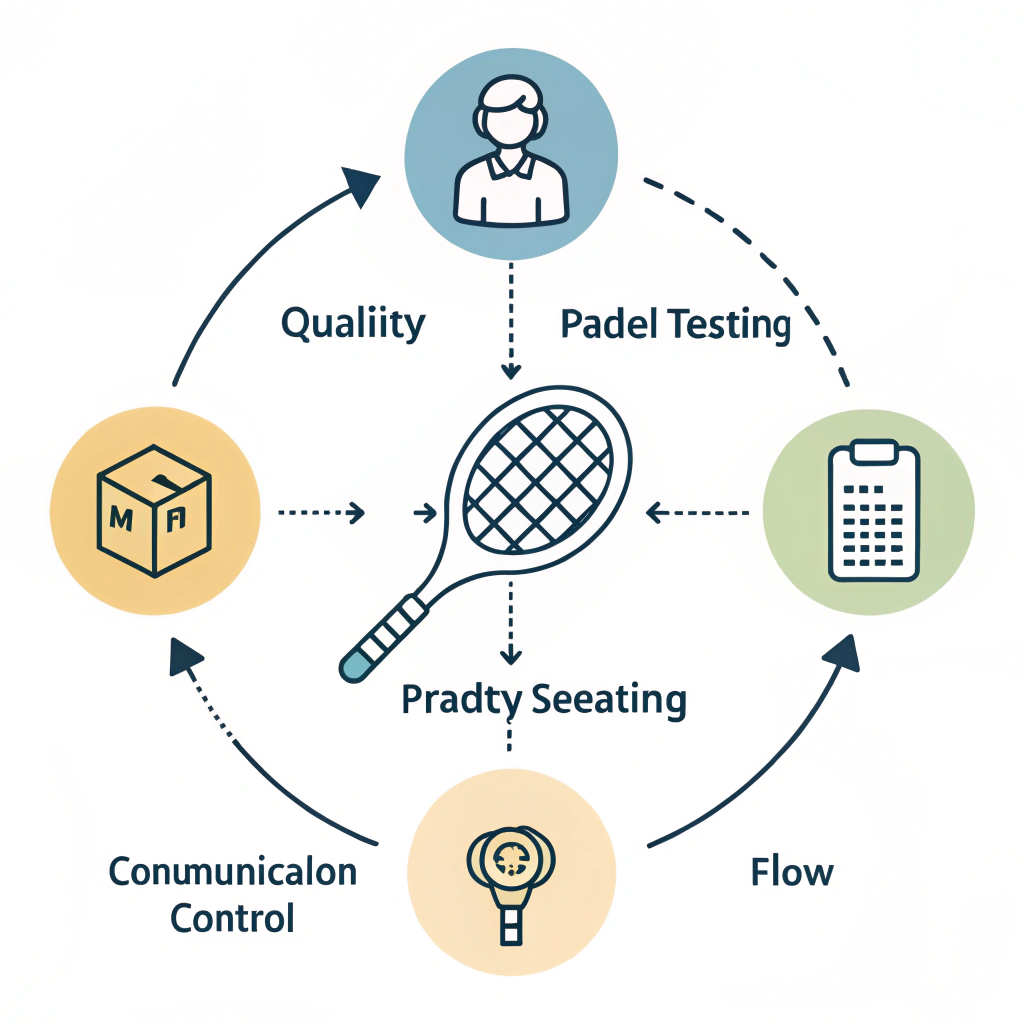

The most common design pitfalls in padel racket production involve material mismatches, improper customization processes, and insufficient quality control measures. By understanding these issues and implementing targeted solutions, manufacturers can improve performance, reduce costs, and enhance production efficiency.

In the competitive world of padel racket manufacturing, even slight design errors can impact product performance and lead to higher production waste or rework costs. Many OEM1 producers face issues such as selecting the wrong material combinations2 (e.g., confusing the performance characteristics of glass fiber versus carbon fiber grades like 3k, 12k, and 18k), improper design tolerances in Diamond, Round, or Teardrop shaped rackets, and misinterpretation of customization requirements like logo placement on hand grips and handle caps. These challenges are compounded during the refinement phase where product managers, design engineers, and quality assurance professionals must ensure that the final product meets both high-performance standards and OEM specifications.

A lack of clear communication early in the design phase can lead to expensive errors: prototypes might not accurately reflect the final product, and performance parameters such as weight distribution, balance, and overall durability may suffer. Particularly for companies that supply well-known brands like Hirostar, Reebok, and Starvie, maintaining consistent quality while meeting tight deadlines and customization demands becomes a delicate balancing act.

Several key factors contribute to these design pitfalls:

-

Material Misalignment: Manufacturers often choose between glass fiber and various carbon fiber grades without fully accounting for their distinct properties. For instance, using a lower grade carbon fiber in a high-performance Diamond racket may compromise both durability and performance. Understanding the exact requirements for power versus maneuverability3 is critical.

-

Customization Process Gaps: When implementing custom features such as special shapes or branded elements like logos on hand grips, the complexity of these tasks can lead to errors. Insufficient coordination with customers and imperfections during proofing stages often lead to mismatches between design intent and production outcome.

-

Inadequate Design Verification: Without a robust system for continuous testing and validation, minor design flaws can escalate. In many cases, initial designs do not undergo thorough simulation or physical prototyping, leaving room for issues related to balance and vibrational dynamics to persist.

-

Communication and Coordination Issues: In an OEM environment, miscommunication between design teams and production lines often becomes evident only in later production stages. This inefficiency can result in costly adjustments mid-production, leading to higher scrap rates and reduced production efficiency.

-

Lack of Standardized Protocols4: The absence of standardized design and verification protocols can lead to inconsistent quality across different product batches. This is especially true when multiple design iterations and customization levels are involved.

A detailed material selection process should be the backbone of any high-performance padel racket production line. This includes:

- Comprehensive Material Testing: Regular assessments of glass fiber and various carbon fiber grades to ensure they meet performance standards.

- Material Matching Protocols: Clear guidelines matching material properties to specific racket shapes and performance needs. For instance, using the superior stiffness of 18k carbon fiber for Diamond rackets where strength is key, versus using lighter materials for Round or Teardrop designs aimed at maneuverability.

Quality assurance starts with precise customization procedures. To avoid errors during the customization process, consider the following steps:

- Detailed Mockup and Proof Stages: Before full production, create high-fidelity prototypes that incorporate every customization element, including logo placements and unique design features.

- Customer Collaboration: Engage customers closely from the design phase to final approval, ensuring their preferences are consistently integrated into every iteration.

- Digital Simulation Tools5: Use advanced simulation tools to predict the behavior of the racket under stress, especially where custom shapes might affect vibrational performance.

A multi-step verification process can catch early errors:

- Prototype Testing: Implement both virtual simulations and physical prototypes to validate performance metrics such as balance, weight distribution, and shock absorption.

- Iterative Feedback Loops: Use iterative cycles that involve design tweaks based on test data, ensuring each production run is an improvement over the last.

- Cross-Functional Review Meetings: Regularly schedule meetings between design, production, and quality assurance teams to align expectations and troubleshoot emerging issues.

Efficient communication channels are essential:

- Collaborative Platforms: Utilize digital platforms where real-time updates and documentation ensure that everyone from the design engineers to production line managers is on the same page.

- Standard Operating Procedures (SOPs): Develop and enforce clear SOPs for every stage of the design and production processes to reduce the risk of miscommunication.

- Training Programs: Regular training can update teams on new processes, material technologies, and industry standards.

Developing and adhering to a set of standardized design criteria can streamline the production process, reduce errors, and ensure product consistency across various batches:

- Design Guidelines: Create detailed documentation on design specifications for each type of racket shape (Diamond, Round, Teardrop), outlining critical dimensions, material recommendations, and expected performance characteristics.

- Quality Checklists: Implement comprehensive checklists at each stage of production to ensure that every design element is accurately executed.

- Continuous Improvement Programs: Collect and analyze production data regularly to refine design protocols over time.

Below is a comparison table summarizing these solutions:

| Focus Area | Key Actions | Expected Benefits |

|---|---|---|

| Material Selection | Comprehensive testing, material matching guidelines | Improved performance and durability |

| Customization Process | Detailed prototypes, customer collaboration, digital simulation | Reduced errors and higher customer satisfaction |

| Design Verification & Validation | Prototype testing, iterative feedback, cross-functional reviews | Early error detection and better design reliability |

| Communication & Coordination | Collaborative platforms, SOPs, regular training | Fewer miscommunications and streamlined production |

| Standardized Protocols | Clear design guidelines, quality checklists, continuous improvements | Consistent quality and reduced production waste |

While the outlined strategies can greatly mitigate design pitfalls, it is important to note several limitations:

- Cost Implications: Implementing advanced testing and prototyping tools can increase initial costs. Companies must balance the benefits of these investments against budget constraints.

- Time-to-Market Pressure: Iterative testing and approvals may prolong the design cycle. In fast-paced industries, finding the right balance between thorough design verification and market demands is critical.

- Complexity in Customization: Increasing customization options may increase production complexity. It is vital to establish a scalable process to manage these variables efficiently.

- Reliance on Technological Tools: Advanced software and simulation tools require proper training and periodic updates to remain effective.

Understanding and carefully managing these constraints will be the key to transitioning from design pitfalls to a more streamlined, efficient production process.

Several companies in sports equipment manufacturing have successfully applied these solutions to overcome design challenges. For example:

- A manufacturer specializing in high-performance padel rackets identified that quality issues were primarily due to incorrect material combinations. By revising their material selection protocol and investing in material testing, they observed a 20% reduction in production errors.

- Another company enhanced customer satisfaction by integrating an advanced digital simulation tool into their design process. This tool allowed them to preempt potential issues in custom design elements, leading to a smoother production cycle and a 15% improvement in overall production efficiency.

- Companies with rigorous cross-functional communication protocols reported fewer instances of misaligned design updates, ultimately leading to lower rework rates and higher on-time delivery performance.

These examples highlight the importance of a systematic approach in overcoming common production pitfalls and demonstrate that investment in quality and communication pays back through improved product performance and reduced waste.

In conclusion, the key to avoiding design pitfalls in padel racket production lies in deliberate planning, rigorous testing, and enhanced communication. By embracing a solution-oriented strategy that focuses on robust material selection, meticulous customization, and standardized protocols, manufacturers can enhance product quality and production efficiency while maintaining competitive edge in the market.

We recommend the following actionable steps:

- Review and update current material selection protocols.

- Integrate advanced prototyping and simulation tools into the design process.

- Establish clear SOPs and communication platforms across departments.

- Collect and analyze production data continuously to refine designs over time.

- Balance customization flexibility with production complexity through scalable processes.

These steps empower OEM manufacturers to produce durable, high-performance padel rackets that meet the evolving demands of competitive sports and high-quality standards. Continuous improvement, customer collaboration, and proactive quality assurance will lead to products that not only satisfy but exceed market expectations.

People Also Ask

Q: What is the 40-40 rule in padel?

A: The 40-40 rule in padel is a crucial part of the game’s scoring system. When both teams reach 40 points, known as deuce, a tie-break condition initiates, where each team must secure a two-point lead to win the game.

Q: What to look for in a good padel racket?

A: Key factors include the racket's shape and weight, which determine power and maneuverability, balance for tailored playstyle, and handle size and length for optimal comfort and control. Additionally, the materials used, such as carbon fiber or glass fiber, have a significant impact on performance and durability.

Q: What is the 45 degree rule in padel?

A: The 45 degree rule in padel refers to the angle at which a ball bounces off a surface. If the ball hits the corner between the turf and the glass and bounces at an angle higher than 45 degrees, it remains in play; if the angle is lower than 45 degrees, it is considered a fault.

-

[OEM]: Click to understand the role of Original Equipment Manufacturers (OEMs) in the sports equipment industry and how they influence production standards and quality. Back to OEM ↩

-

[material combinations]: Click to learn about the different material combinations used in padel racket manufacturing, including how various fiber grades influence performance and durability. Back to material combinations ↩

-

[power versus maneuverability]: Click to explore the balance between power and maneuverability in racket design, detailing how material and design choices impact each aspect. Back to power versus maneuverability ↩

-

[Standardized Protocols]: Click to learn about standardized protocols in design and production, and how they promote consistency and quality across manufacturing batches. Back to Standardized Protocols ↩

-

[Digital Simulation Tools]: Click to delve into how digital simulation tools are applied in testing and refining padel racket designs, ensuring optimal performance under various conditions. Back to Digital Simulation Tools ↩