Padel rackets differ from pickleball paddles in several key ways. In essence, padel rackets are thicker, offer more power thanks to foam centers and perforated designs, and are engineered with high-performance composite materials1, while pickleball paddles tend to be lighter and aim for increased control and versatility.

In today’s competitive sports equipment market, it is essential for B2B procurement and product development managers to understand the intricate differences between products. At NEX Padel, we specialize in high-performance padel rackets that are built using advanced manufacturing techniques2 and top-tier materials. This article provides a detailed technical comparison between padel rackets and pickleball paddles, covering material composition, design architecture, and production considerations. Our analysis is aimed at helping you make informed sourcing decisions that best match your market demands and product portfolio.

When comparing padel rackets and pickleball paddles, it is crucial to note that while both products may appear similar at first glance, they serve distinct purposes and are engineered with different performance goals in mind.

-

Padel Rackets:

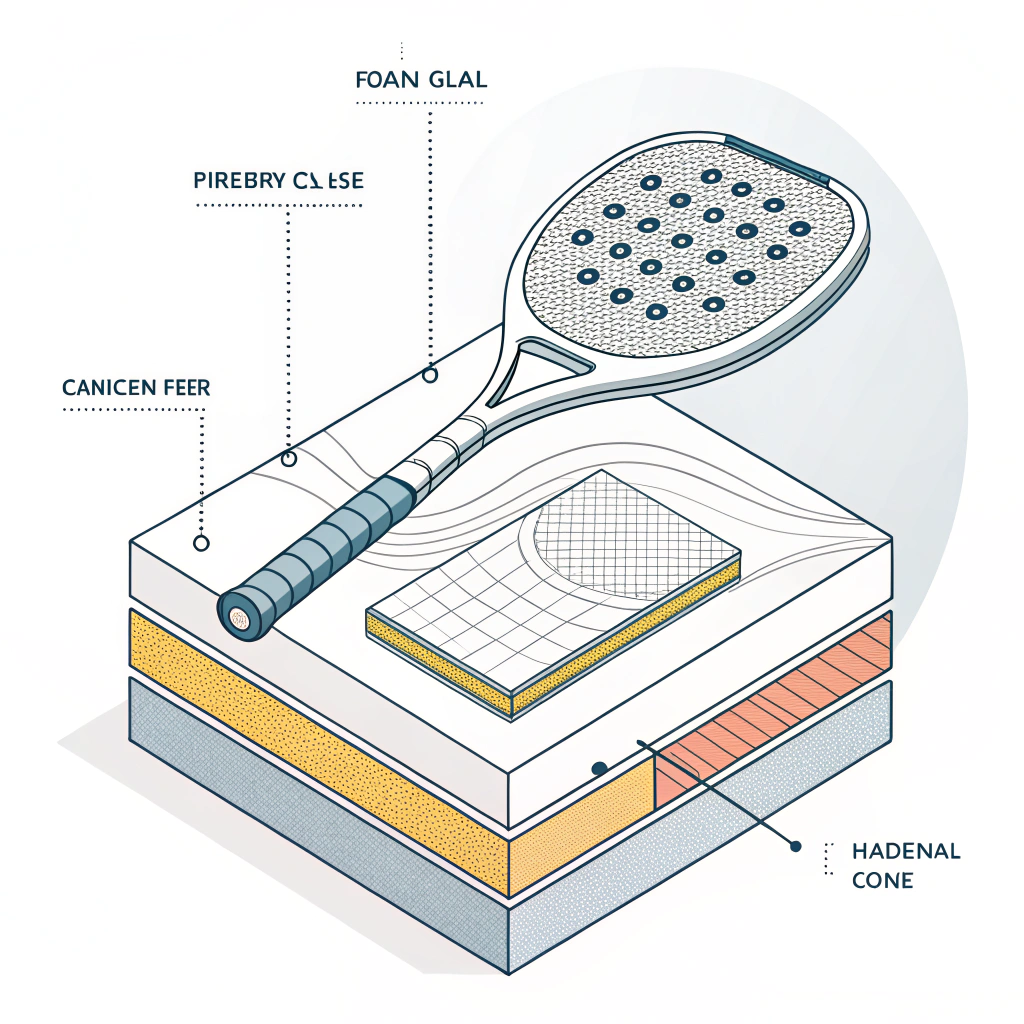

- Utilized in high-intensity play, padel rackets are designed for power and durability.

- They incorporate composite materials such as fiberglass and various grades of carbon fiber (3k, 12k, 18k)3 for optimal performance.

- Unique design features include thicker builds with rigid foam cores and perforated surfaces, which enhance ball control and impact absorption.

-

Pickleball Paddles:

- Typically lighter and more compact, these paddles are built to ensure nimble maneuverability and precision.

- Construction often involves polymer cores and composite faces, with an emphasis on control rather than explosive power.

Below is a comparison table summarizing the main differences between these two types of equipment:

| Feature | Padel Racket | Pickleball Paddle |

|---|---|---|

| Material Composition | Composite materials (fiberglass, carbon fiber variants) | Polymer cores with composite faces |

| Core Construction | Hard foam centers for added power | Lighter constructions for enhanced control |

| Thickness & Weight | Thicker and robust design for high-impact play | Thinner, lighter design aimed at maneuverability |

| Surface Design | Perforated holes to regulate pressure and enhance play | Smooth or lightly textured surfaces |

| Use Case | Suited for power and dynamic shot-making | Focused on control and precision in gameplay |

For B2B decision-makers, technical details play a vital role in product selection. Let’s break down some of the important technical aspects that differentiate padel rackets from pickleball paddles.

Padel Racket Materials:

- Fiberglass: Provides elasticity and shock absorption, enabling players to execute powerful shots.

- Carbon Fiber (3k, 12k, 18k): Each variant caters to different performance levels. The higher the grade, the more rigid and durable the racket becomes.

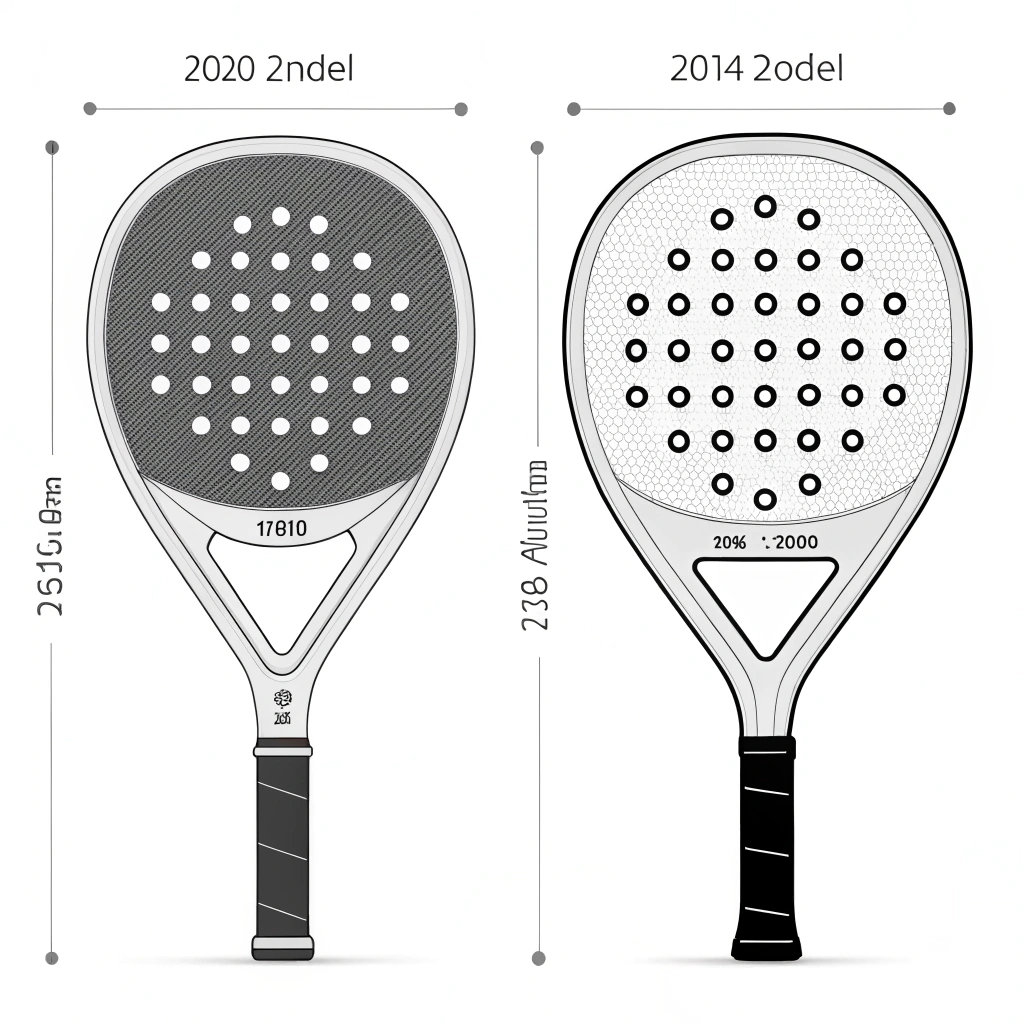

- Customization Options: Our rackets are highly customizable. Clients can choose from various core materials, shapes (Diamond, Round, Teardrop), custom print options, and even personalize hand grips and handle caps with unique logos.

Pickleball Paddle Materials:

- Designed with lighter materials which favor speed and control over raw power.

- The internal core typically utilizes a polymer or foam layer that balances between stiffness and light weight.

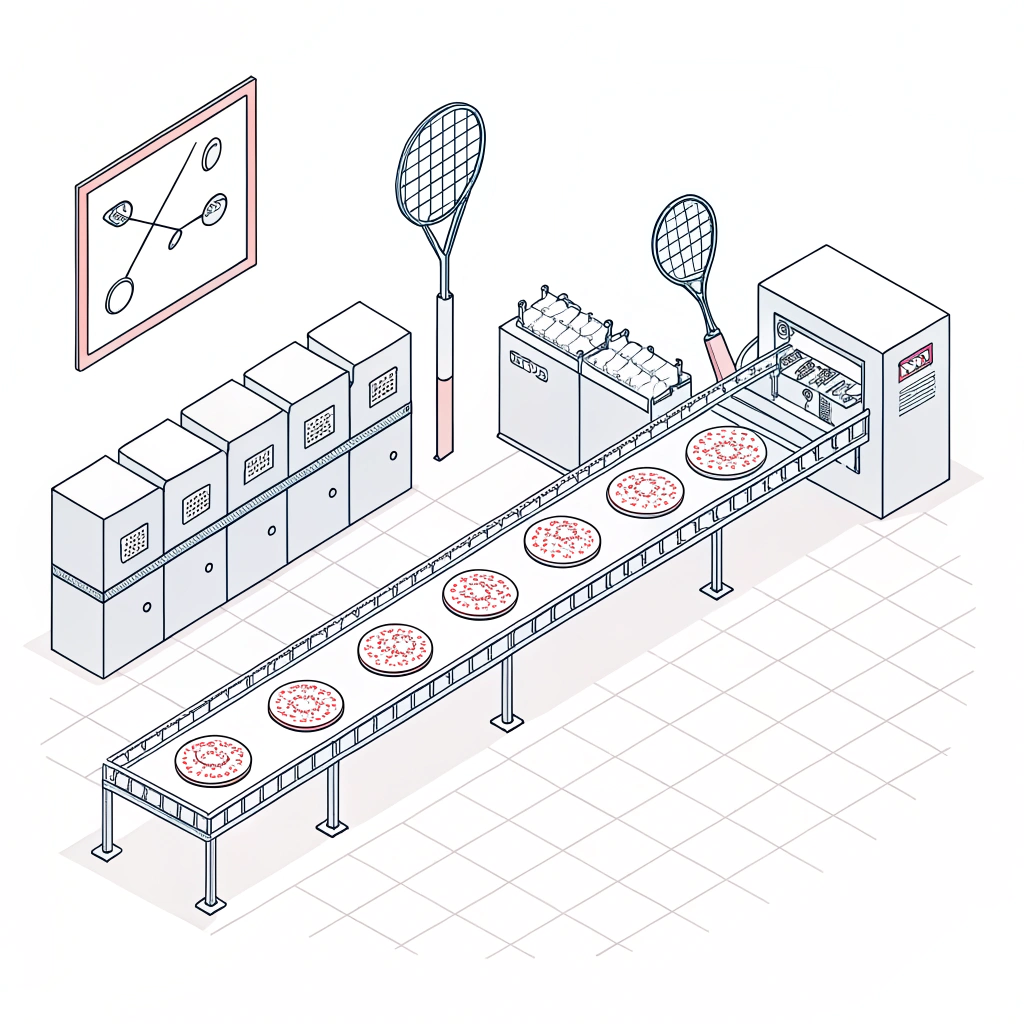

At NEX Padel, advanced manufacturing processes are leveraged to ensure each padel racket meets strict performance standards. Our production workflow includes rapid prototyping4 to expedite sample verification and timely delivery. This efficiency not only minimizes lead times but also ensures consistent quality control—key points when sourcing for global markets.

Key technical details include:

- Precision Molding5: Ensuring every racket shape is perfectly formed to deliver consistent performance.

- Advanced Composite Layering: Using multiple layers of carbon fiber and fiberglass for enhanced durability and strength.

- Customization Flexibility: Offering full customization in shape, color, printing, and additional components like hand grips and handle covers.

When procuring high-performance sporting goods, factory production expertise is a significant factor. Our collaboration with well-known brands such as Hirostar, Reebok, and Starvie is a testament to our effective manufacturing methods and capacity to scale production without compromising on quality.

- Rapid Sampling: We provide quick sampling turnaround times. This minimizes wait time and allows B2B partners to test quality and performance efficiently.

- Consistent Quality: With tight quality control measures in place, both padel rackets and padel balls (crafted under controlled conditions) meet rigorous safety and performance standards.

- Customization and Flexibility: Ability to adjust production runs based on market demand, including custom designs for specialized markets.

- Competitive Pricing: Our cost-efficient production model ensures competitive pricing without sacrificing material quality or performance.

Customization is a growing trend in the sports equipment industry. B2B buyers increasingly demand products tailored to their market needs. For padel rackets, customization options include:

- Shape: Choose between Diamond, Round, or Teardrop forms; even fully custom shapes are available.

- Materials: Select from various fiber types based on performance needs (e.g., 3k for flexibility or 18k for rigidity).

- Print and Color: Customized prints and colors cater to brand identity, helping distributors differentiate their product offerings in a crowded marketplace.

- Component Branding: Options to customize hand grips and handle covers with unique logos for enhanced brand visibility.

These factors provide an edge when sourcing premium equipment as they directly influence player performance and market appeal.

Globally, the sports equipment market is trending towards products that offer both performance and customization. The rising popularity of padel and pickleball as recreational and competitive sports is driving demand for specialized equipment. Here’s how the two products are positioned in the current market landscape:

- Growing Global Popularity: Padel is rapidly gaining popularity, particularly in regions like Europe and Latin America.

- High-Performance Demand: Players at various levels demand rackets that deliver both power and precision, leading to increased investment in quality rackets featuring advanced composites.

- Customization Trend: Modern consumers seek personalized products, boosting demand for customizable padel rackets that offer unique visual and performance traits.

- Expanding Market: Pickleball is one of the fastest-growing sports in North America, supported by an increasing number of recreational leagues and tournaments.

- Focus on Control: The market for pickleball paddles is driven by the need for control and lightweight designs, making them ideal for both recreational and competitive play.

- Cost-sensitive Demands: While performance is critical, there is also a significant demand for cost-effective solutions, especially in large-scale recreational markets.

- Product Differentiation: By understanding the technical and market differences between padel rackets and pickleball paddles, procurement managers can better align product offerings with target consumer preferences.

- Competitive Analysis: A thorough product comparison is essential. Evaluate factors such as material quality, customization options, production timelines, and pricing to make informed decisions.

- Supplier Collaboration: Co-developing or customizing equipment with a manufacturer that has advanced production expertise can lead to long-term business relationships and market success.

In summary, while both padel rackets and pickleball paddles share similarities in being composite sporting equipment, they cater to different performance needs and market segments. Padel rackets are designed for power, durability, and customization, making them a top choice for competitive play and market differentiation. On the other hand, pickleball paddles are engineered for control and speed, making them ideal for recreational and precision-based games.

For B2B procurement managers navigating product portfolios, consider the following actionable steps:

- Assess Market Demand: Analyze local and regional popularity trends for padel and pickleball to tailor your inventory.

- Evaluate Technical Specifications: Match your product needs with the specific technical attributes (material quality, weight, durability) offered by each product.

- Leverage Customization: Capitalize on the customization capabilities of padel rackets for brand differentiation and higher market value.

- Ensure Production Efficiency: Partner with manufacturers known for rapid sampling, consistent quality, and cost-efficient production methods.

- Conduct Comparative Analysis: Use decision matrices or comparison tables (see above) to balance performance metrics against cost considerations.

By following these recommendations, you can confidently select products that not only meet but exceed the expectations of your customers, positioning your organization as a leader in the competitive sports equipment market.

People Also Ask

Q: What is the difference between a padel paddle and a pickleball paddle?

A: Padel paddles (or rackets) are designed with thicker, more robust construction that incorporates hard foam centers and perforated surfaces, providing enhanced power and durability. In contrast, pickleball paddles are generally lighter and constructed from materials focused on control rather than high-impact performance.

-

Composite Materials: Click to explore detailed insights on the integration and benefits of composite materials in enhancing sports equipment performance and durability. ↩ ↩

-

Manufacturing Techniques: Click to learn how advanced manufacturing techniques drive efficiency and performance in sports equipment production. ↩ ↩

-

Carbon Fiber (3k, 12k, 18k): Click to understand the differences between carbon fiber grades and how they impact the strength and flexibility of padel rackets. ↩ ↩

-

Rapid Prototyping: Click to read about rapid prototyping practices that accelerate sample verification and production timelines in a competitive market. ↩ ↩

-

Precision Molding: Click to delve into precision molding processes that ensure consistent shape and performance in high-quality sporting goods. ↩ ↩