Padel rackets have evolved from simple wooden paddles to sophisticated, multi-layer composite structures using advanced materials like carbon fibre1 and fibreglass. This evolution is driven by continuous engineering innovation, rigorous quality control, and a deep understanding of player performance needs.

In today’s competitive market, procurement managers and product development specialists must navigate a complex manufacturing landscape when evaluating padel racket development2. Early designs were largely experimental, but over the decades, manufacturers have refined production processes, material choices, and design parameters. This article explores the evolution of padel racket manufacturing, outlines key innovations, and provides detailed insights into how advancements in production techniques have translated into improved durability, performance, and customization options.

Historically, padel rackets were constructed in a manner similar to wooden paddles. These early designs were:

- Basic in construction

- Lacking in consistency

- Susceptible to rapid wear and tear

The reliance on wood limited the performance capabilities due to inconsistencies in material density and durability. In addition, the designs did not support the evolving styles of play and the increasing demands for power, control, and precision. As competitive play grew, manufacturers began to seek alternatives that could offer enhanced properties.

Transition to composite materials3

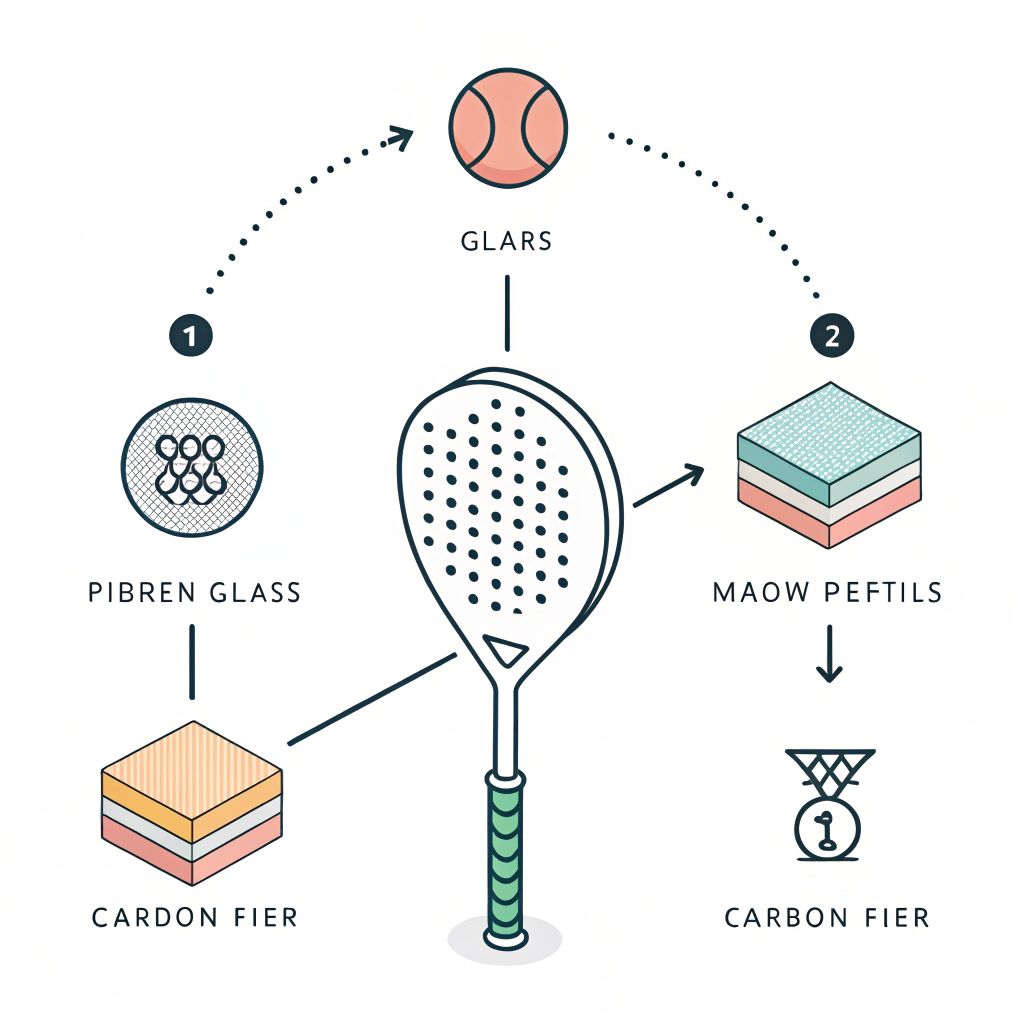

Fibreglass and Carbon Fibre Integration:

The introduction of composite materials marked a turning point in the evolution of padel rackets. Fibreglass was first adopted as it provided necessary elasticity and durability—attributes that were lacking in wooden designs. This material allowed for:

- Increased hardness on key impact surfaces

- Enhanced flexibility to absorb shock

- More consistent performance across batches

However, fibreglass alone was not enough to meet all performance expectations. Manufacturers then began integrating carbon fibre into the design. Carbon fibres, available in variants such as 3k, 12k, and 18k, provided superior structural strength and a lighter overall weight. The layered construction offered the following benefits:

- Precision engineering: Uniform distribution of weight and improved balance

- Extended durability: Withstand higher impact forces without deformation

- Enhanced customization: Ability to tailor characteristics based on player requirements

This phase of evolution solidified composite materials as indispensable in modern padel racket manufacturing.

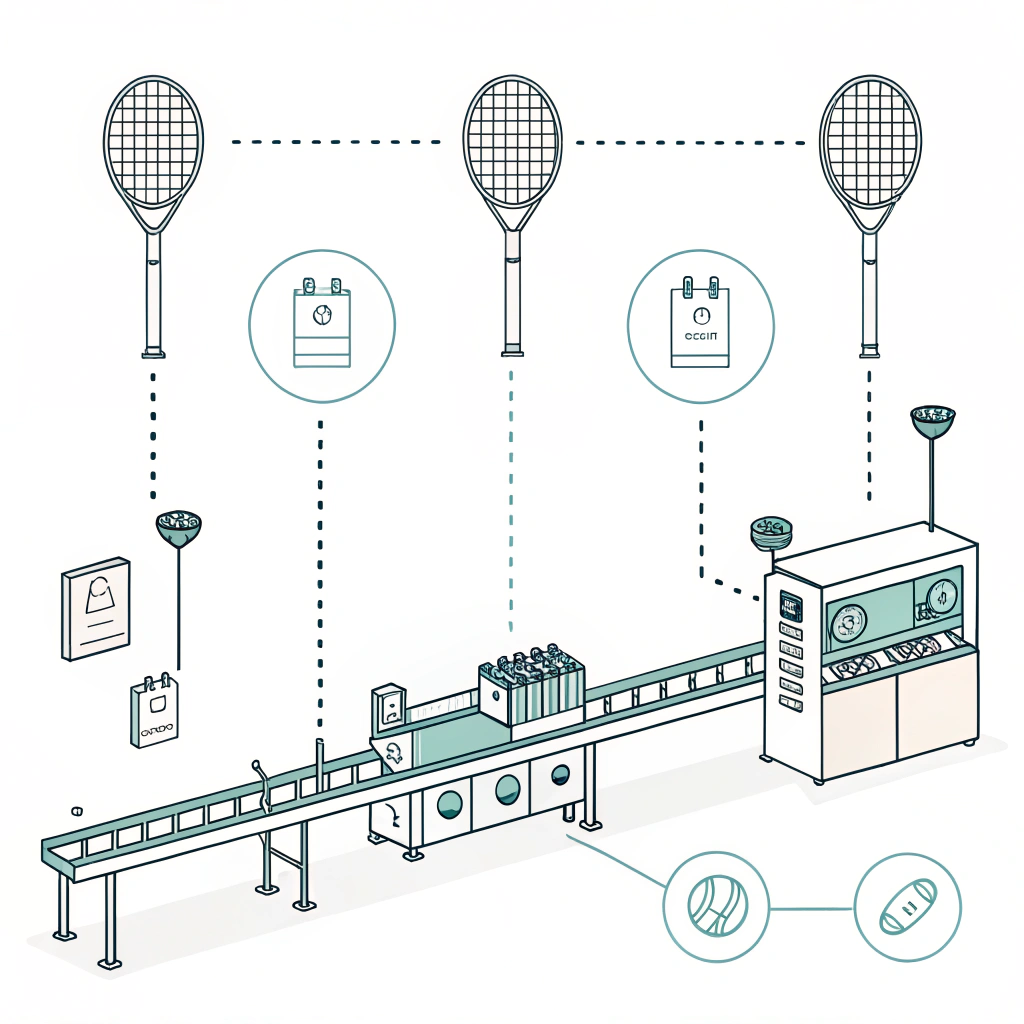

Advanced Production Processes and rapid prototyping4

One of the key areas where innovation has played a pivotal role is in the production process itself. Modern techniques emphasize:

-

Rapid Prototyping:

- The initial design phase now incorporates computer-aided design (CAD) which allows for fast iterations and testing of different structural configurations.

- Rapid prototyping techniques enable manufacturers to refine the shape — whether it is Diamond, Round, or Teardrop — early on, ensuring that design adjustments can be made quickly based on performance feedback.

-

Precision Manufacturing:

- Utilization of advanced production techniques ensures that every racket meets strict quality standards.

- The layering process is carefully controlled to distribute the specific properties of fibres such as elasticity and hardness exactly where needed.

- Our manufacturing process at NEX Padel leverages these techniques to ensure reliability in each batch and to offer full customization in shapes, colors, and printed logos.

-

Quality Control:

- Integrated quality control systems monitor each step of the production process.

- Sensors and automated inspection techniques are deployed to identify any anomalies in the composite layers.

- This rigorous approach reduces wastage and enhances the overall durability and performance of the final product.

Below is a table summarizing key milestones in the padel racket evolution:

| Evolution Stage | Materials Used | Key Developments | Impact on Performance |

|---|---|---|---|

| Wooden Paddle | Wood | Basic design, low durability | Limited performance, inconsistent |

| Early Composite Use | Fibreglass | Introduction of elasticity and impact resistance | Improved impact absorption |

| Advanced Composite Integration | Carbon Fibre + Fibreglass | Enhanced structural strength and lightweight design | Superior balance, durability, and customization |

The demands of modern padel players require equipment that can be fine-tuned to personal performance metrics and playing style. This need for customization has influenced entire production lines and design considerations:

-

Shape Customization:

Manufacturers now offer multiple shapes such as Diamond, Round, and Teardrop. Each shape has unique ergonomic and performance benefits. For instance:- Diamond: Typically provides more power due to a more concentrated striking zone.

- Round: Offers a balanced mix of power and control, making it ideal for versatile play.

- Teardrop: Balances the elements of control and power, appealing to intermediate players looking to improve.

-

Custom Graphics and Colour:

Beyond physical attributes, customization now extends to aesthetics. Companies can opt for bespoke prints, colours, and logos, ensuring that the equipment not only performs well but also aligns with brand identity and player preference. -

Accessory Integration:

Customization is not limited to the racket itself. Details like the hand grip (hand glue) and handle cover can also be customized with logos and specific materials. This broadens the scope for brands to strengthen their market presence through product differentiation.

This evolution in customization capability is not merely a design trend. It reflects technological advances that allow for rapid retooling and swift changes in production, ensuring that customer needs and emerging trends in padel play are adequately addressed.

For procurement managers, production transparency is critical. In recent years, increased scrutiny over manufacturing quality and sustainability has driven companies to provide greater insights into their production processes.

-

Traceability5:

Modern manufacturing lines ensure that every component, from carbon layers to fibreglass, is fully traceable. This traceability reassures customers that the materials used meet strict international standards and that the production process is both consistent and scalable. -

Supply Chain Reliability:

A reliable supply chain is integral to punctual deliveries. Our ability to conduct rapid prototyping and timely sampling has made us a preferred OEM for renowned brands such as Hirostar, Reebok, and Starvie. Our robust supply chain network reinforces our commitment to on-time delivery, ensuring our clients receive consistent quality with minimal delays. -

Engineering Innovations:

Continuous investments in research and development have led to the creation of state-of-the-art manufacturing facilities. These investments result in processes that are not only efficient but also adaptable to the evolving demands of both local and international markets.

At NEX Padel, our journey in padel racket manufacturing encapsulates decades of experience coupled with a forward-looking approach. Here are some of the highlights of our production evolution:

-

Material Expertise:

We utilize a range of materials—from high-quality fibreglass to various tiers of carbon fibre (3k, 12k, 18k)—ensuring that our rackets meet diverse player needs. The layering process is fine-tuned to provide optimal elasticity and resilience. -

Customization Capabilities:

Every design is an opportunity for innovation. Our production lines are equipped to handle full customizations not only in racket shape (Diamond, Round, Teardrop) but also in the aesthetics of the product, including custom prints and logo placements on accessories such as hand grips and handle covers. -

Rapid Prototyping and Testing:

The integration of CAD design and rapid prototyping methods allows us to iterate designs quickly. This capability significantly reduces the time from conceptualization to production, allowing our partners to test and roll out new designs on an accelerated timeline. -

Quality Assurance:

With stringent quality control at every production stage, our manufacturing processes guarantee that each product meets high performance standards before it reaches the market. We closely monitor the durability of our composite structures to ensure superior performance during high-intensity play.

The synthesis of these elements has allowed NEX Padel to establish a reputation for quality, precision, and innovation in the padel racket market.

For companies involved in sports equipment procurement and product development, understanding the evolution of padel racket manufacturing can inform better supplier selection and product strategy. Here are key recommendations:

-

Evaluate Material Specifications:

Look for suppliers who use a mix of fibreglass and carbon fibre to achieve both durability and performance. Verify that the materials used are consistent across production batches. -

Examine Customization Options:

Customizable options in both design (shape, weight balance) and aesthetics (color, logo placement) can differentiate a product in the market. Evaluate whether the supplier offers full customization support that aligns with your branding needs. -

Assess Production Timelines:

Rapid prototyping capabilities enable faster market response. Consider suppliers who demonstrate a strong track record of meeting deadlines and adapting quickly to market feedback. -

Confirm Quality Control Measures:

Ensure the production process includes comprehensive quality control measures, from material traceability to final product testing. Detailed inspection protocols help avoid inconsistencies that can affect product performance. -

Sustainability and Transparency:

With increased consumer and industry focus on sustainability, choosing a supplier that maintains transparency in its production process can be a competitive advantage. Confirm that the supplier's practices align with international standards and environmental regulations. -

Leverage Data and Case Studies:

Seek out documented cases where the supplier has successfully implemented engineering innovations to overcome production challenges. Industry trends and case studies provide additional confidence in the supplier's capability to innovate and deliver.

The evolution of padel racket manufacturing is a clear indicator of how technological advancements and process optimizations can transform traditional products into high-performance sports equipment. From the days of basic wooden paddles to today’s cutting-edge composite designs, each phase in the development process has aimed at enhancing playability, durability, and customization.

For procurement managers and product development specialists, understanding these innovations is critical. Not only does it help in selecting the right supplier, but it also empowers companies to adapt to market trends and customer demands more effectively. The detailed evolution outlined here illustrates that successful manufacturing in the sporting goods industry relies on a blend of advanced materials, rapid prototyping, and stringent quality controls—all of which are areas where NEX Padel excels.

By integrating these insights into your procurement strategy, you can make informed decisions that enhance product performance and align with emerging market trends. The story of padel racket development is not just about technological progress; it is about creating equipment that meets the high standards demanded by today’s athletes while also offering scalable and reliable manufacturing processes.

People Also Ask

Q: What is the evolution of the padel racket?

A: Padel rackets have evolved from simple wooden paddles to advanced composite structures incorporating materials like fibreglass and carbon fibre. This evolution has improved durability, control, and power while enabling customization in designs such as Diamond, Round, and Teardrop shapes.

Q: How are padel rackets made?

A: Modern padel rackets are manufactured using multiple layers of materials including fibreglass and various grades of carbon fibre. These layers are precisely assembled using advanced production techniques and rapid prototyping, ensuring a balance of elasticity, durability, and performance suitable for competitive play.

-

carbon fibre: Click to understand the role of carbon fibre in enhancing the strength-to-weight ratio of padel rackets and its impact on overall play performance. ↩ ↩

-

padel racket development: Click to learn how modern design and engineering innovations in padel racket development can optimize performance and meet evolving market standards. ↩ ↩

-

composite materials: Click to explore the benefits and technical specifications of composite materials used in high-performance sports equipment manufacturing. ↩ ↩

-

rapid prototyping: Click to discover how rapid prototyping techniques accelerate product development cycles and innovation in manufacturing processes. ↩ ↩

-

traceability: Click to learn about the importance of traceability in manufacturing, ensuring quality control and compliance with international standards. ↩ ↩