In our manufacturing process, every padel racket is the result of precise craftsmanship, advanced materials, and customization expertise that transform raw materials into high-performance sports equipment.

Our expertise in padel racket manufacturing stems from years of developing innovative production techniques. At NEX Padel, we integrate materials science with state-of-the-art production processes1 to address common industry challenges, including long lead times, limited customization options, and inconsistent quality control. In this article, we explore the detailed production process behind our padel rackets and demonstrate how our advanced manufacturing methods deliver superior performance and reliability.

■ Problem Description and Industry Challenges

Procurement managers and product development specialists face several challenges when selecting a manufacturing partner for padel rackets:

• The need for high-performance products that withstand rigorous gameplay.

• Demands for innovative customizations, including form, printing, and material variations.

• A reliance on suppliers who can consistently deliver fast turnaround times without sacrificing quality.

These challenges require a partner who not only understands technical details but also has the capability to integrate advanced materials and innovative design into every custom racket we produce.

■ Cause Analysis: Why Conventional Production Falls Short

Traditional manufacturing methods in sports equipment industries often struggle with:

- Inconsistent quality control, leading to variations in product performance.

- Limited customization options available for product differentiation in global markets.

- Slow prototyping and turnaround times that impede quick market entry for new models.

At NEX Padel, we have addressed these issues by adopting a rigorous process that combines high-end production techniques with a flexible customization system. Our manufacturing process is a blend of art and science, where each step is finely tuned to ensure the final product meets the highest standards.

■ Our Manufacturing Process: The Craft Behind Every Padel Racket

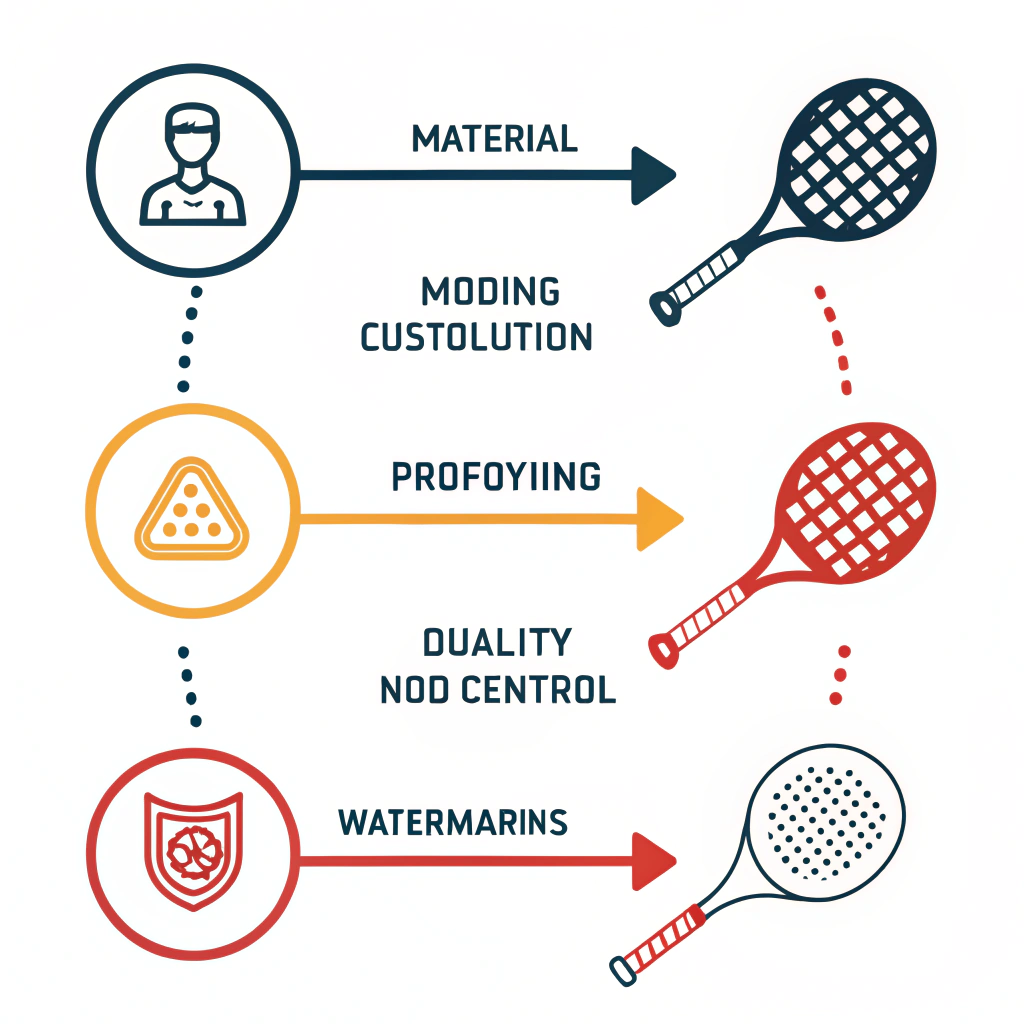

To tackle these issues head-on, we have developed a comprehensive manufacturing process. Below is an overview of our production flow:

| Stage | Description | Key Techniques & Materials |

|---|---|---|

| Material Selection | Choosing premium materials such as fiberglass and various grades of carbon fiber (3k, 12k, 18k). | Precision grading, material testing |

| Molding & Shaping | Crafting the core shapes (Diamond, Round, Teardrop) according to strict design specifications. | Computer-aided design (CAD) and CNC machining |

| Customization Options | Allowing full customization including logo printing, color schemes, and even customized handle grips. | digital printing2, custom-molding techniques |

| Prototyping & Testing | Rapid prototyping followed by rigorous testing to ensure performance, durability, and weight balance. | Accelerated lifecycle testing, performance analytics |

| Quality Assurance | Multi-layer quality control measures ensure every racket meets our high-performance standards. | ISO compliance3, in-house expert evaluations |

| Final Assembly & Packaging | Assembling final products and packaging them with pressurized tube ball technology to preserve quality. | Automated assembly lines, protective packaging design |

This table demonstrates our commitment to not only using advanced technology but also ensuring that every product detail is meticulously checked and validated.

■ Advanced Production Techniques: Material Innovation and Precision Engineering

Our production process starts with careful material selection. We source premium fiberglass as well as several grades of carbon fiber, including 3k, 12k, and 18k variants. This variety allows us to cater to different consumer needs, whether it's for high durability or enhanced performance characteristics.

In our molding phase, we leverage computer-aided design (CAD) and precision CNC machining. These techniques ensure that each racket, be it Diamond, Round, or Teardrop, maintains a perfect balance of weight and strength. The use of digital printing2 for customization is another significant advantage. We can imprint logos or texts on the racket surface swiftly and with great detail, ensuring brand consistency across every product.

The core advantage of employing such advanced carbon fiber technology4 lies in its high strength-to-weight ratio. This property directly translates into improved racket performance, providing players with the agility and control they require during fast-paced matches. Moreover, our production process allows for full customizations. Whether you need specific color combinations or unique handle designs like customized hand grips and handle covers, our techniques support it with no compromise on quality.

■ Quality Control and Assurance: Guaranteeing Excellence at Every Step

For a manufacturing partner, reliability in quality is paramount. At NEX Padel, quality control is woven into every stage of production. We employ a multi-layer inspection process that spans pre-production raw material assessment to final product testing. Key performance metrics such as durability, force distribution, and balance are rigorously monitored to ensure compliance with international sports equipment standards.

A detailed inspection checklist includes:

• Material composition verification to confirm the correct grade of fiberglass or carbon fiber is used.

• Structural integrity tests during and after molding to ensure there are no defects in bonding or shaping.

• Dimensional accuracy checks using high-precision measuring instruments.

• Aesthetic and printing inspections for custom designs to ensure consistency with client specifications.

This detailed process not only fortifies product integrity but also allows us to meet tight production schedules, making us an ideal partner for global brands like Hirostar, Reebok, and Starvie.

■ Customization Capabilities: A Tailored Experience for Elite Performance

A standout feature of our manufacturing approach is our ability to offer extensive customization. Modern padel players and brands alike demand products that reflect both performance and personal style. We provide options to tailor various elements of the racket, including:

- Frame structures (Diamond, Round, Teardrop designs)

- Customizable print and color schemes

- Specialized handle grips and covers where logos can be imprinted

- Material selection ranging from fiberglass to advanced carbon fibers

Below is a simple table summarizing the customization options available:

| Component | Customization Options | Benefits and Features |

|---|---|---|

| Frame Shape | Diamond, Round, Teardrop, Custom shapes | Optimizes balance and performance |

| Material Choices | Fiberglass, 3k/12k/18k Carbon Fiber | Tailors weight and strength to player needs |

| Aesthetic Customization | Custom prints, color schemes, logo placements | Enhances branding and individual style |

| Grip Customization | Custom hand grips and handle covers | Improves control and personalizes comfort |

These options empower brands to create exclusive products that resonate with their target markets, ensuring competitiveness in a saturated sports equipment market.

■ Fast prototyping5 and Turnaround Efficiency: Meeting Market Demands

Time-to-market is a critical consideration for product development. Our fast prototyping5 capabilities allow us to rapidly produce and test new designs. This not only shortens overall production cycles but also gives our clients a competitive edge in rapidly evolving markets. By leveraging efficient production planning and supply chain management, we minimize downtime and maintain high throughput without sacrificing quality or attention to detail.

Our streamlined process consists of:

• Digital design validation to quickly simulate product performance.

• Rapid prototyping using advanced 3D printing and molding techniques.

• Rigorous field testing with prototypes to capture real-world feedback.

• Iterative design enhancements before final mass production.

This efficient turnaround is a testament to our commitment to innovation, ensuring that design improvements and market trends are quickly incorporated into our production lines.

■ Robust Supply Chain and Manufacturing Excellence

At NEX Padel, we pride ourselves not only on advanced production techniques but also on our robust supply chain and excellent logistics management. The coordination between our in-house design teams, quality control units, and external suppliers ensures that every step of the production process is optimized for both speed and quality.

Our established relationships with reliable suppliers of raw materials and components guarantee that even customized orders are fulfilled on time. This integrated ecosystem benefits international brands that need consistency and reliability in production. Our advanced planning supports order scalability—from limited edition runs to large-volume orders—ensuring that procurement managers can source exactly what their brand requires at any given time.

■ Case Studies and Data Support: Real-World Impact

Our manufacturing approach has a proven track record with several industry-leading brands. For instance, during a collaboration with a notable sports brand, our commitment to rigorous testing and rapid prototyping resulted in a 20% reduction in time-to-market for a new padel racket line. Detailed post-production analyses showed that our products maintained consistent balance and durability over extended play periods, offering tangible benefits in player performance and brand reputation.

In another case, our customization capabilities allowed a global brand to design a padel racket that matched their unique aesthetics and functional specifications. The seamless integration of custom printing and unique handle designs not only boosted the product's visual appeal but also enhanced its ergonomic design to meet player demands.

These cases illustrate our ability to merge craftsmanship and modern production techniques to create high-performance, fully customizable padel rackets.

■ Summary and Actionable Recommendations

In summary, our advanced manufacturing process at NEX Padel exemplifies the perfect blend of tradition and innovation. We have overcome common industry challenges by implementing state-of-the-art production techniques, enforcing stringent quality control, and offering extensive customization capabilities. Whether you require a standard round racket or a uniquely designed Diamond model with custom printing, our process guarantees both performance and durability.

For procurement managers and product development specialists looking to partner with a reliable manufacturer, our approach ensures:

- High-quality and consistent product performance.

- Fast turnaround and rapid prototyping capabilities.

- Flexibility in customization that supports brand differentiation.

We invite you to explore a partnership with NEX Padel as your trusted industry partner, where every padel racket is crafted with precision, care, and an unwavering commitment to excellence. Contact us today to learn more about how our manufacturing prowess can power your brand’s next breakthrough.

People Also Ask

Q: What advanced technologies are used in padel racket manufacturing?

A: Our manufacturing process uses advanced materials like various grades of carbon fiber (3k, 12k, 18k) along with precision molding, computer-aided design, and digital printing technology to ensure high performance and consistent quality.

Q: How can customization lead to better performance in padel rackets?

A: Customization not only enhances the aesthetics of a padel racket but also optimizes its design for improved balance and control. Tailoring elements such as frame shape, grip designs, and material choices allows manufacturers to better meet player needs and brand requirements.

Q: What role does fast prototyping play in modern padel racket production?

A: Fast prototyping significantly reduces time-to-market by efficiently transforming design concepts into testable products. This allows for rapid refinements, ensuring that the final product meets high-performance standards while keeping production timelines short.

-

[state-of-the-art production processes]: Read more about integrating the latest production methods that leverage technology and innovation to optimize manufacturing efficiency and product quality. ↩ ↩

-

[digital printing]: Understand the role of digital printing in customization, offering high precision and visual consistency in product branding and design. ↩ ↩ ↩2

-

[ISO compliance]: Learn about the international standards that ensure quality management and consistency in manufacturing processes, critical for global certification and reliability. ↩ ↩

-

[advanced carbon fiber technology]: Discover how sophisticated carbon fiber techniques improve product performance with increased strength-to-weight ratios and durability in competitive sports equipment. ↩ ↩

-

[fast prototyping]: Explore how rapid prototyping methods accelerate product development cycles, allowing for swift iterations and market responsiveness. ↩ ↩ ↩2