In today’s fast-paced sports equipment market, optimizing the padel racket production cycle is essential. Advanced production techniques1, from design to delivery, have become the backbone for creating high-performance padel rackets that meet market demands. This article provides a detailed look at the challenges and solutions in the production cycle, and how innovative manufacturers like NEX Padel lead the way in quality, efficiency, and customization.

A successful padel racket production cycle integrates cutting-edge technology, rigorous quality control, and flexible customization options. Business development managers and procurement specialists must understand each stage—from initial design and material selection to final delivery—to make well-informed decisions. Manufacturers that optimize these processes not only enhance product performance but also reduce time-to-market. In this article, we break down the challenges and pinpoint practical solutions using a solution-oriented approach.

The production of high-performance padel rackets involves multiple complex steps that influence both the performance and the aesthetics of the final product. As companies in the sports equipment industry seek to deliver innovative, durable, and customizable products, several challenges emerge:

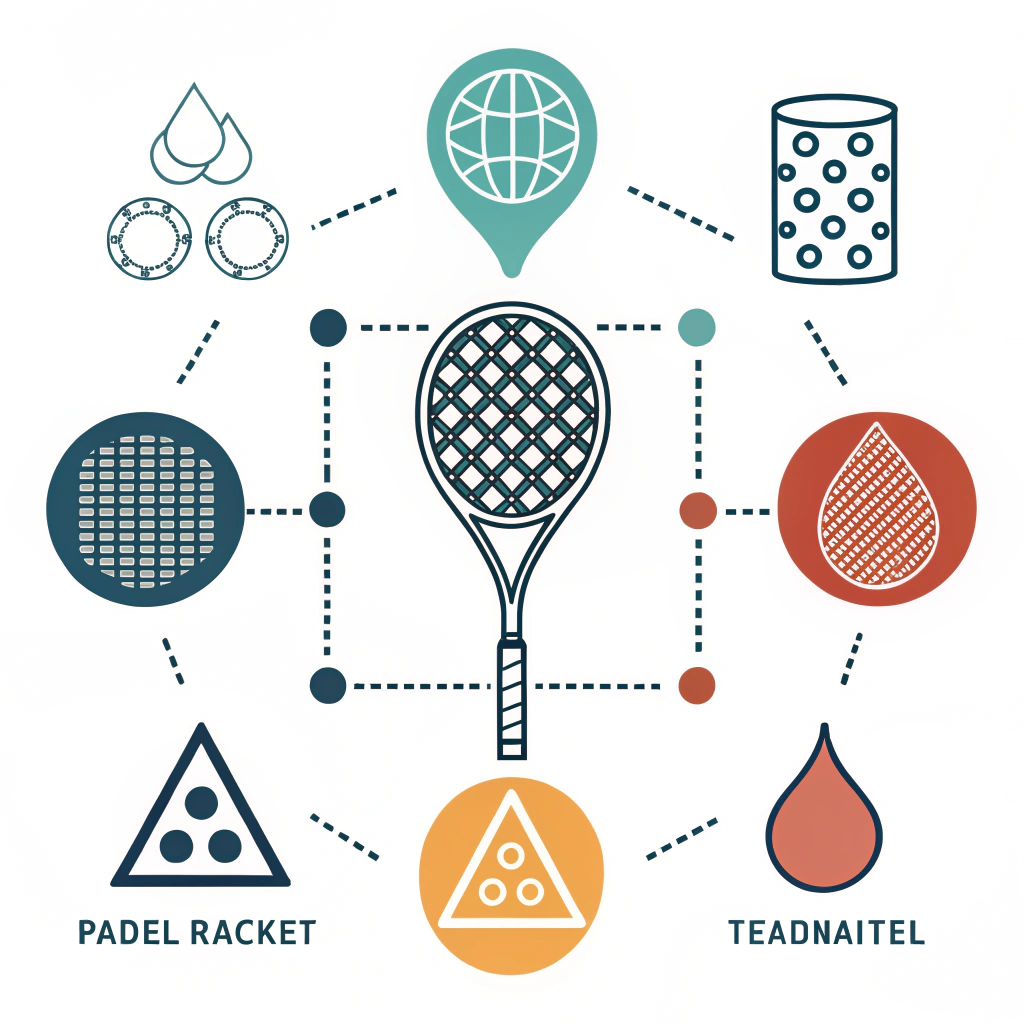

• Complex Material Requirements: With padel rackets, manufacturers work with various materials including carbon fibers2 (3k, 12k, and 18k) and fiberglass. Each material type contributes differently to the racket’s performance, affecting weight, flexibility, and durability.

• Customization Demands: The ability to produce rackets in diverse shapes—Diamond, Round, and Teardrop—and incorporate custom prints, logos, and hand grip designs adds layers to the production processes. These customization options are essential for companies looking to create a unique brand identity.

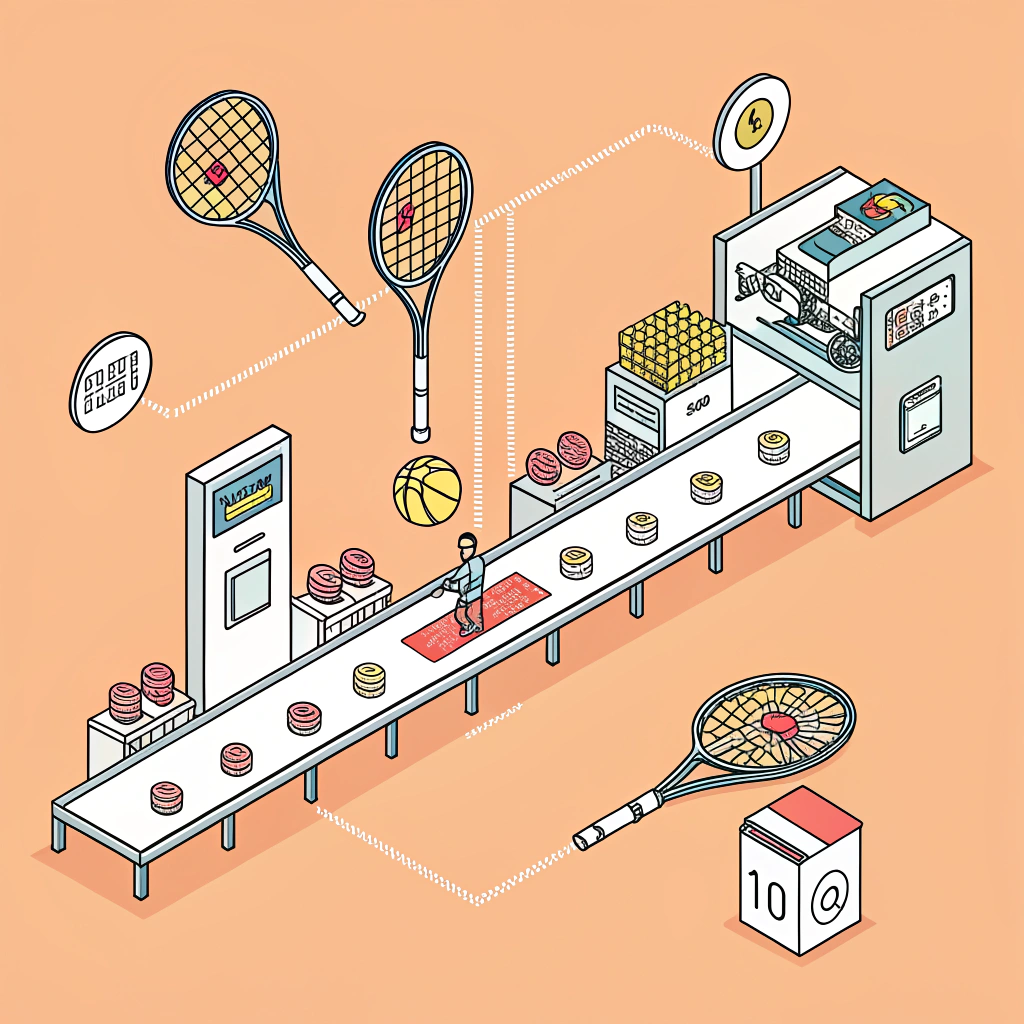

• Production Cycle Efficiency: Timely delivery and rapid prototyping are critical. Manufacturers need to balance high production speeds with rigorous quality control. Coordination across design, manufacturing, and logistics must be seamless to meet market expectations.

• Supply Chain Reliability3: A robust supply chain is crucial as delays or quality lapses in raw material sourcing can ripple through the production cycle, affecting both production and customer satisfaction.

Each of these areas shapes the overall production cycle and directly impacts procurement decisions and long-term business success.

Understanding the underlying reasons for these challenges is key. The complexity can be attributed to several factors:

• Material Diversity: Different layers and configurations of carbon fiber (3k, 12k, 18k) are used to cater to varying performance needs. Selecting the right mix involves balancing stiffness, weight reduction, and durability. This decision-making process often involves extensive R&D and testing before finalizing a production plan.

• Customization vs. Standardization: While customization opens up market opportunities, it complicates the standardization of production processes. Variations in shapes (Diamond, Round, Teardrop) and custom printing require manufacturers to adapt their production lines frequently. For instance, even small deviations in the design phase can necessitate adjustments in tool paths and material handling.

• Advanced Production Techniques: To ensure high precision and durability, padel racket manufacturing now relies on advanced production techniques. This includes automated systems, precision molding, and high-speed curing processes. Integrating these methods into traditional manufacturing while maintaining cost efficiency adds another layer of challenges.

• Quality Control Measures: Ensuring every racket meets rigorous quality standards means extensive testing at various stages. From the initial fabrication of the carbon fiber layers to the final assembly, quality checks are essential. Companies often implement multiple checkpoints, which can sometimes slow overall production if not managed efficiently.

By examining these core issues, manufacturers can begin to optimize production cycles and streamline processes, ultimately improving both product quality and operational efficiency.

To address and overcome these challenges, many leading manufacturers are adopting comprehensive strategies that integrate technology, process improvements, and continuous feedback. Below are some best practices:

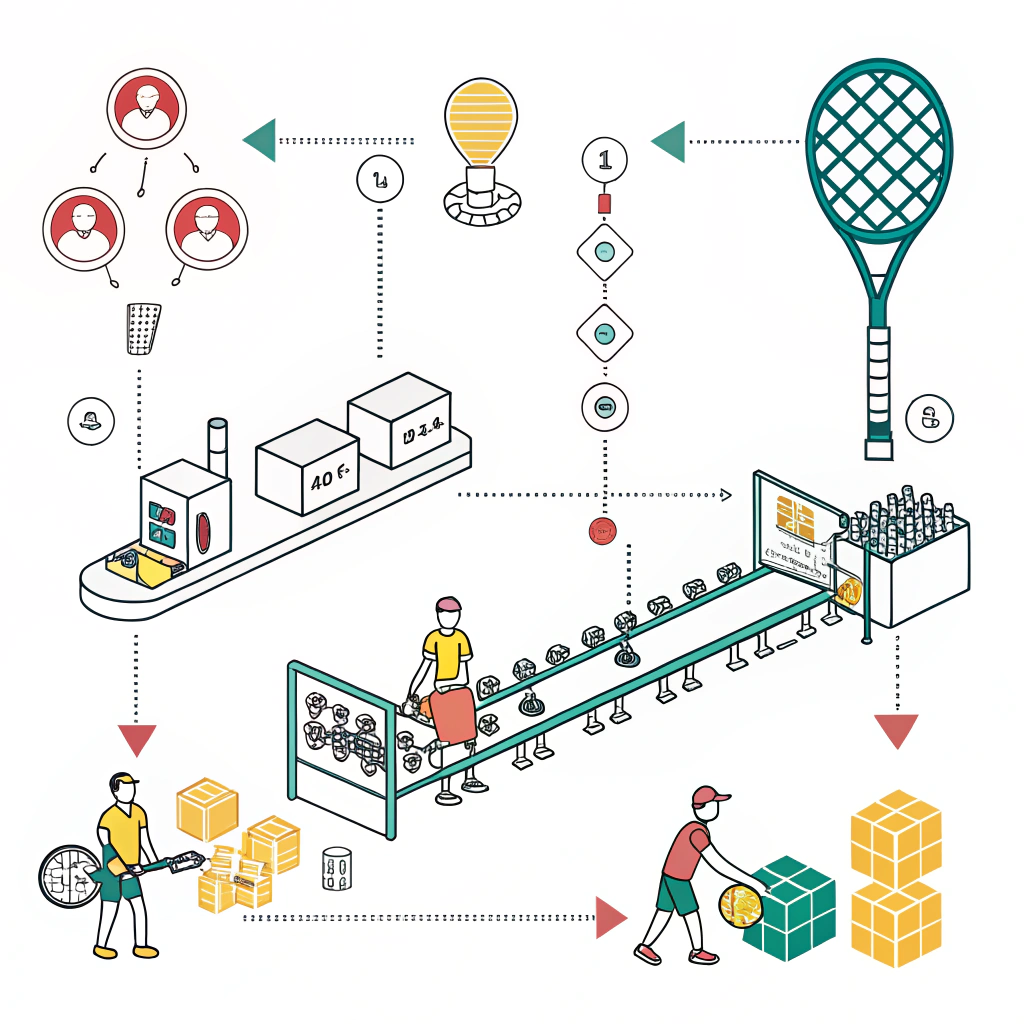

Optimizing the production cycle involves breaking down the process into manageable phases that can be continuously refined. A recommended approach is:

| Stage | Key Focus | Considerations |

|---|---|---|

| Design & Customization | Custom shapes, branding | Adapt designs for Diamond, Round, and Teardrop forms |

| Materials Selection | Carbon fiber types & quality | Evaluate 3k, 12k, and 18k options for performance |

| Fabrication & Assembly | Precision and rapid prototyping | Use advanced machinery and automation systems |

| Quality Control | Rigorous testing | Implement multi-stage inspections and compliance tests |

| Distribution & Logistics | Timely delivery & reliability | Synchronize supply chain operations for efficiency |

This table clearly maps out the production cycle, ensuring each stage meets the required performance and quality metrics.

Material selection is critical when specifying carbon fiber and other composites. Manufacturers need to balance technical performance with cost efficiency. Implementing automated material-handling systems and precision cutting technologies helps in exactly tailoring products to customer requirements. In our operations at NEX Padel, we maintain strict monitoring of material properties to ensure each racket meets performance standards and withstands rigorous use.

Customization is not simply about visual appeal but also about enhancing player performance through tailored racket properties. For example:

• Custom Shapes and Prints: We offer full customization where the racket can be fully tailored to customer specifications, whether it is a Diamond, Round, or Teardrop model. Such personalization extends to color schemes and custom prints that reinforce brand identity.

• Hand Grip Customization: Furthermore, customization extends to accessories like hand grips and hand grip covers. Incorporating company logos and specific tactile textures provides additional brand differentiation and improves user comfort.

The flexibility in design is crucial for staying competitive across various market segments, each having specific quality and performance expectations.

4.4. Integrating Quality Control & Rapid Prototyping4

Quality control is woven into every phase of production to catch issues early and reduce waste. Rapid prototyping methods can quickly validate designs, allowing adjustments before committing to full-scale production. This not only improves product reliability but also shortens production cycles. Adopting digital simulation and iterative testing methodologies can significantly reduce the time and cost associated with finalizing the design.

An impactful solution for many businesses is the tight integration of supply chain management with production scheduling. By partnering with reliable suppliers for raw materials and leveraging real-time production monitoring systems, manufacturers can achieve timely deliveries and ensure consistent product quality. Such integrated systems help minimize disruptions and maintain the steady production flows.

Let’s consider a practical example relevant to the current market dynamics. A leading sports equipment company recently revamped its production processes in response to increasing customization demands and tighter quality control benchmarks. By adopting a modular production strategy and integrating precision automation, the company achieved the following:

• A 20% reduction in production bottlenecks.

• Enhanced material consistency through automated quality checks.

• Significant improvement in turnaround time for prototypes due to rapid simulation and design validations.

Manufacturers were able to run multiple production lines in parallel, each fine-tuned to achieve specific design requirements. This modular approach not only increased adaptability but also allowed for better tracking of each stage, from material handling to final inspections, thereby improving overall efficiency.

Additionally, the integration of a robust OEM5 framework ensured that customization did not compromise product performance. The ability to quickly pivot and adopt new designs in reaction to market feedback was a substantial competitive advantage. Enhanced supply chain management further ensured that production remained steady despite market fluctuations.

This case study demonstrates that by carefully analyzing and refining each component of the production cycle, padel racket manufacturers can achieve optimal efficiency and remarkable product improvements. Such strategies are essential for staying ahead in an increasingly competitive market.

In summary, optimizing the padel racket production cycle requires a holistic approach that addresses every stage—from concept and design through material selection to final quality control and distribution. The advanced production techniques and customization options now available allow manufacturers to produce high-performance, tailored products that not only meet but exceed market expectations.

For procurement specialists and product managers, the key takeaways include:

• Recognizing the critical role of advanced material selection and precision fabrication.

• Emphasizing the importance of integrated quality control and rapid prototyping.

• Leveraging modular production and robust supply chain management to reduce turnaround times.

At NEX Padel, we consistently apply these principles to ensure that our products are at the forefront of innovation and reliability. By aligning production practices with market demands, we help our partners develop superior padel rackets that deliver both performance and value. We invite you to evaluate your current production strategies and consider how these innovations can address your unique challenges. Effective system upgrades and process optimizations are not only feasible but necessary for sustained success in today’s competitive sports equipment industry.

Seize the opportunity to enhance your production cycle and maintain a competitive edge. Reach out to us for further consultation and discover how our advanced production techniques can transform your business processes.

• How do advanced production techniques improve padel racket performance?

Advanced production techniques ensure precision in material handling and fabrication. By using automated systems and rigorous quality control, manufacturers achieve enhanced durability and exact performance characteristics, which directly contribute to better overall racket performance.

• What customization options are available for padel rackets?

Manufacturers offer a range of customization options including various racket shapes (Diamond, Round, Teardrop), personalized design prints, custom color schemes, and even tailored hand grip and grip cover branding to align with specific brand identities.

• How can supply chain management streamline padel racket production?

Robust supply chain management ensures timely delivery of high-quality raw materials and synchronizes production schedules. This integration helps to reduce bottlenecks, maintain quality consistency, and ultimately shorten the production cycle, resulting in more efficient operations.

-

Advanced production techniques: Read the article to discover how integrating cutting-edge manufacturing methods can enhance efficiency and product performance in the sports equipment industry. ↩ ↩

-

Carbon fibers: Learn more about the types, properties, and applications of carbon fibers, and understand how they improve the strength and durability of advanced sporting goods. ↩ ↩

-

Supply Chain Reliability: Read further on how maintaining a reliable supply chain is essential for minimizing production delays, ensuring quality, and improving overall operational efficiency. ↩ ↩

-

Rapid prototyping: Find out how rapid prototyping accelerates innovation by allowing fast validation of designs, reducing production risks, and shortening development cycles. ↩ ↩

-

OEM: Explore the concept of Original Equipment Manufacturers (OEM) and how a robust OEM framework supports customization while maintaining high performance standards in production. ↩ ↩