Quick Answer: Chinese factories like NEX Padel offer a full spectrum of padel racket customization1 options—ranging from unique shapes (Diamond, Round, Teardrop) to varied carbon fiber materials (3K, 12K, 18K)—using advanced production techniques, fast prototyping2 and strict quality control. This comprehensive approach ensures that your products not only stand out but also meet high-performance requirements with dependable delivery.

In today’s highly competitive sporting goods market, brands and procurement specialists face the challenge of differentiating their padel products. The need for customization is critical, particularly when it involves technical aspects such as material choices, detailed shapes for optimal performance, and personalized branding elements including custom printing and logo placement. However, navigating these technical requirements and selecting the right manufacturing partner can be daunting.

Manufacturers in China, especially leaders like NEX Padel, are uniquely positioned to provide tailored solutions through advanced production processes. Yet, knowing where to start, understanding the challenges, and effectively communicating your customization needs remain common hurdles for many B2B purchasers.

Several factors contribute to the challenges in custom padel racket production:

-

Technical Complexity: Producing a padel racket that meets high performance standards requires precision. From the selection of carbon fiber types3 (3K, 12K, 18K) to the design of the racket shape (Diamond, Round, Teardrop), each step has a significant impact on the final product.

-

Customization Requirements: Brands often desire unique shapes and specific material configurations to set their products apart. The process must also accommodate additional demands like custom printing on the frame or handle, and tailored placement of logos.

-

Quality Control: Ensuring that every customized element meets strict quality standards is vital. Challenges include maintaining material consistency, reliable bonding in carbon fiber layers, and ensuring rapid prototyping does not compromise durability.

-

Supply Chain Efficiency: Fast turnaround times and on-time delivery are crucial for B2B clients who operate on strict schedules. This requires robust project management, rigorous testing protocols, and adaptive production schedules.

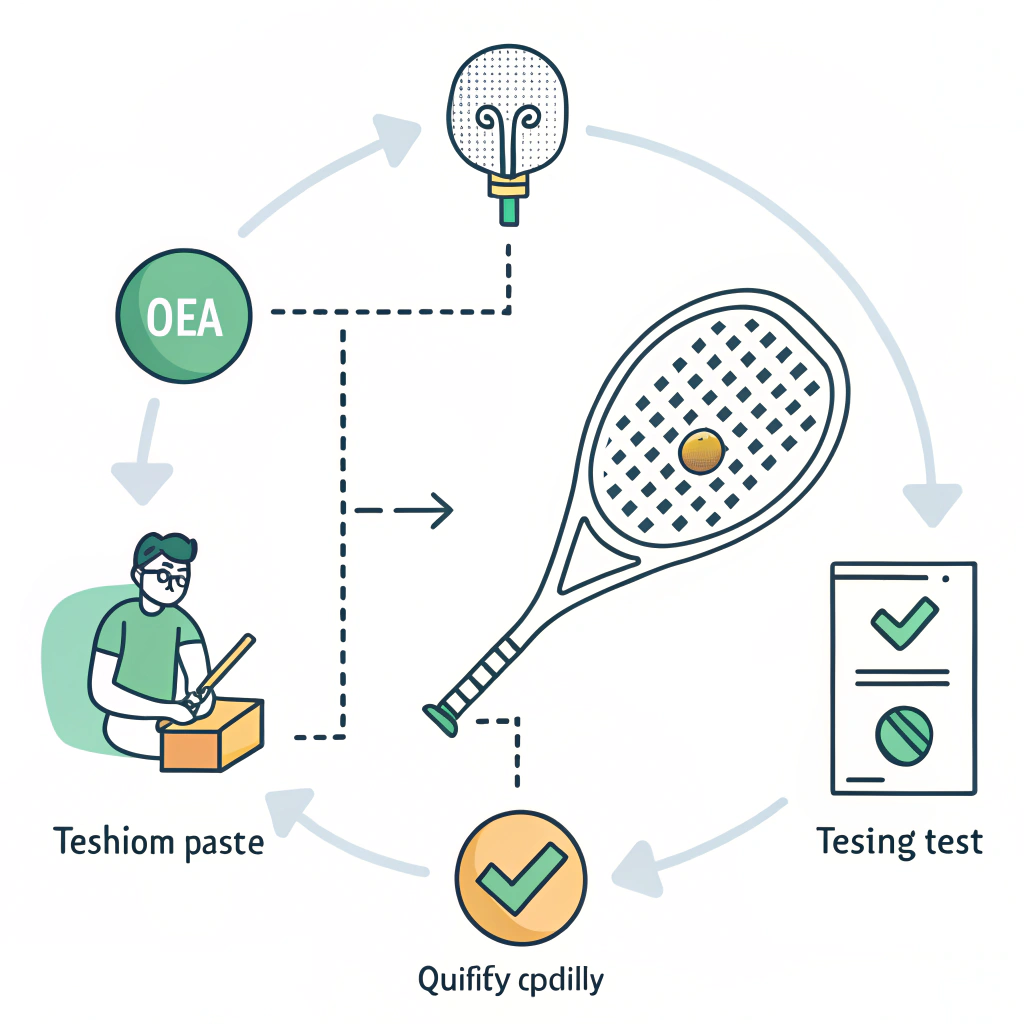

To address these challenges, manufacturers like NEX Padel adopt a systematic solution-oriented approach that includes the following steps:

-

Define Customization Objectives:

Clearly outline your design requirements and customization options. Determine the optimal shape for your product—whether it is Diamond, Round, or Teardrop—based on performance research and market trends. -

Select Material and Production Techniques:

Choose the carbon fiber material that best meets your performance and budget criteria. Options like 3K, 12K, and 18K carbon fibers each offer different balances of strength, stiffness, and cost. -

Implement Fast Prototyping:

Employ rapid prototyping techniques to quickly evaluate new designs. Rapid iterations help to refine the product without lengthy delays. -

Ensure Rigorous Quality Control:

Utilize advanced testing methods to validate each component of the racket. This includes stress tests on the materials, verification of custom printing quality, and overall consistency checks. -

Optimize Supply Chain Coordination:

Work closely with manufacturers to ensure alignment on production schedules and timely deliveries. Effective communication channels are crucial for adapting quickly to any design changes or production challenges.

Manufacturers often present these customization options in a clear, structured format. Below is a table summarizing key customization elements available through high-performance Chinese manufacturers like NEX Padel:

| Customization Aspect | Options Available | Benefits |

|---|---|---|

| Racket Shape | Diamond, Round, Teardrop, Fully Custom Shapes | Enhanced gameplay performance and brand distinction |

| Carbon Fiber Material | 3K, 12K, 18K | Tailored balance of weight, strength, and cost efficiency |

| Custom Printing/Logo | Frame, Backhand, Handle; Custom Colors | Unique brand identity and market differentiation |

| Handle Customization | Custom hand grip design, Logo printing, and Grip Covers | Improved ergonomics and personalized design elements |

| Prototyping Speed | Quick Sampling and Feedback Integration | Rapid market testing and iterative design improvements |

| Quality Assurance Measures | Stress Testing, Material Consistency Analysis, Final Inspections | Assurance of durability and high performance |

This table illustrates the multi-dimensional approach that manufacturers adopt to meet the stringent demands of the sporting goods market.

When partnering with a manufacturing firm for custom padel rackets, consider the following best practices:

Ensure that your product design details are fully communicated. Include sketches, technical specifications, and performance expectations. This minimizes misunderstandings and errors during the production phase.

Working with advanced materials like carbon fiber requires that the manufacturer have robust expertise in material handling. Ask for material certificates, process documents, and performance test reports to verify the quality.

A fast prototyping process allows you to test the design practically before committing to mass production. This step is invaluable as it provides insights into the effect of shape and material choices on overall performance.

Select a manufacturer that offers both design innovation and high production capability. Companies like NEX Padel not only manufacture but also share industry best practices on design optimization and quality control.

Maintain close communication with the manufacturing team. Regular updates and feedback loops ensure that any adjustments are promptly integrated into the production process, leading to fewer delays and higher quality outputs.

At NEX Padel, our process begins with understanding each client's unique needs. For instance, when a renowned sports brand required a custom padel racket that balanced innovative design with robustness, we implemented our solution-driven approach:

-

Step 1: Requirement Analysis

We organized detailed discussions to capture all essential design parameters including the preferred racket shape (teardrop was selected for its optimal weight distribution) and specific material features (using 12K carbon fiber for its ideal blend of stiffness and flexibility). -

Step 2: Rapid Prototyping Implementation

Our technological setup allowed us to produce prototype models quickly. This phase involved multiple iterations to fine-tune the racket’s geometry and stress endurance, ensuring the final product met rigorous performance standards. -

Step 3: Quality Assurance and Testing

Each prototype underwent comprehensive testing involving load stress, vibration dampening, and material fatigue assessments. This data-driven approach confirmed that our product design was robust enough for high-intensity play. -

Step 4: Customization of Branding Elements

Following the physical validations, we integrated custom printing techniques on the racket’s frame and handle. The result was a product that not only performed exceptionally but also embodied the brand’s visual identity.

This case encapsulates how a structured, solution-oriented approach can yield superior customization results. The blend of advanced production techniques, strong quality control measures, and strategic communication with clients all contribute to a successful outcome.

To recapitulate, if you are exploring padel racket customization1, consider the following key points:

- Identify your unique design needs: Decide on the perfect shape (Diamond, Round, Teardrop, or a fully customized option) and material choice based on both performance and branding targets.

- Choose an experienced manufacturing partner: A factory like NEX Padel, with an extensive track record in OEM production4 and custom design, is positioned to meet both technical and aesthetic requirements.

- Leverage fast prototyping: Rapid design iterations paired with rigorous testing ensure that any product adjustments are quickly validated.

- Maintain quality control as a priority: Your product must meet industry performance standards consistently. Request detailed quality assurance reports and sample testing phases.

- Communicate effectively: Establish transparent communication channels with your production partner to streamline the customization process from design inception through final production.

By following these recommendations, product managers, procurement specialists, and brand owners can confidently partner with manufacturers who offer both technical proficiency and innovative customization options. This strategic approach not only enhances product differentiation in the market but also leads to robust, performance-enhancing sporting goods that resonate with end-users.

-

What are the key customization options for padel racket production?

Manufacturers in the Chinese padel racket industry offer several key customization options including the choice of racket shapes (Diamond, Round, Teardrop), varied carbon fiber materials (e.g., 3K, 12K, 18K), and custom printing options on both the frame and hand grip, ensuring each product meets specific performance and branding requirements. -

How does fast prototyping improve padel racket customization?

Fast prototyping allows designers to rapidly test and adjust racket designs. This iterative process helps identify the optimal balance between shape, material properties, and overall playability, ultimately leading to high-performance products that meet both technical and aesthetic standards. -

Why is quality control crucial in OEM padel production?

Strict quality control in OEM padel production ensures that each customized feature—from material selection to custom printing—adheres to high performance standards. Rigorous testing such as stress and fatigue assessments guarantees the durability of the racket, which is essential for meeting the competitive demands of professional sport.

-

padel racket customization: Read the article to gain insights into the process of designing and tailoring padel rackets for optimized performance and brand differentiation. Back to term ↩ ↩2

-

fast prototyping: Click here to explore how fast prototyping accelerates design iterations and reduces time-to-market in customized sporting goods production. Back to term ↩

-

carbon fiber types: Discover the differences between various carbon fiber types (3K, 12K, 18K) and learn how each impacts strength, weight, and overall racket performance. Back to term ↩

-

OEM production: Learn about OEM production processes, including strategies for maintaining quality control and meeting large-scale manufacturing demands in the sporting goods industry. Back to term ↩