In an era where environmental compliance1 and sustainability are rising global priorities, manufacturers and procurement professionals in the sporting goods sector are under intense scrutiny. Companies must produce high-quality products while reducing waste, energy usage, and overall environmental impact. For padel rackets—an integral component for brands like ours at NEX Padel—adopting sustainable manufacturing2 practices not only enhances brand reputation but also drives operational efficiency and long-term cost savings.

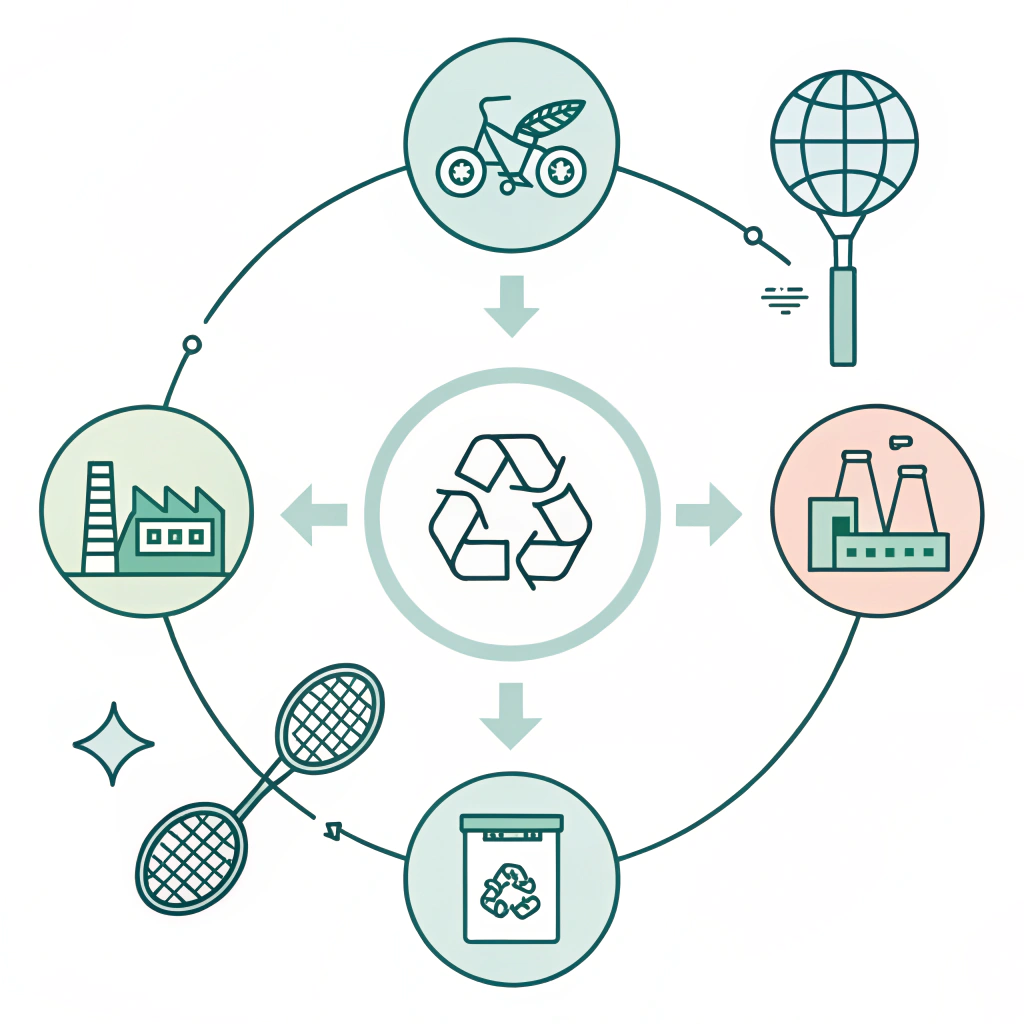

The sustainable approach involves careful selection of materials, like eco-friendly carbon fiber options3 (3k, 12k, and 18k), lean production methods4 , a circular economy5 mindset, and the implementation of advanced production techniques. With these strategies in place, companies can meet evolving regulatory standards, reduce their carbon footprint, and appeal to a market that increasingly values green innovation.

In an era where environmental compliance1 and sustainability are rising global priorities, manufacturers and procurement professionals in the sporting goods sector are under intense scrutiny. Companies must produce high-quality products while reducing waste, energy usage, and overall environmental impact. For padel rackets—an integral component for brands like ours at NEX Padel—adopting sustainable manufacturing2 practices not only enhances brand reputation but also drives operational efficiency and long-term cost savings.

The sustainable approach involves careful selection of materials, like eco-friendly carbon fiber options3 (3k, 12k, and 18k), lean production methods4 , a circular economy5 mindset, and the implementation of advanced production techniques. With these strategies in place, companies can meet evolving regulatory standards, reduce their carbon footprint, and appeal to a market that increasingly values green innovation.

Traditional manufacturing processes for padel rackets often rely on materials and methods that can be both energy-intensive and wasteful. Some of the key challenges include:

- High Energy Consumption: Conventional production lines typically require substantial energy, contributing to an elevated carbon footprint.

- Material Waste: Inefficient use of raw materials such as fibreglass and non-recyclable plastics leads to substantial waste generation.

- Environmental Compliance: Manufacturers constantly face pressure to meet stricter standards, and any non-compliance can result in penalties or brand damage.

- Quality Versus Sustainability Trade-off: Balancing high performance with eco-friendly practices can be challenging if only conventional techniques are used.

- Supply Chain Inefficiencies: When sustainability is not integrated throughout the supply chain, inefficiencies and increased costs often follow.

These challenges call for a paradigm shift toward eco-friendly practices that deliver both performance and environmental benefits.

A deep dive into the root causes reveals several factors contributing to unsustainable manufacturing:

- Outdated Production Techniques: Many factories still use legacy equipment which lacks energy-efficient features.

- Material Sourcing Concerns: Sourcing non-recycled, non-renewable resources increases environmental degradation.

- Lack of Process Integration: Sustainable practices require a holistic view of the production cycle—from raw material acquisition to final product packaging.

- Economic Pressures: The initial investment for greener technologies can seem prohibitive, even though the long-term benefits outweigh the costs.

- Regulatory Complexity: Navigating varying environmental regulations across regions adds layers of complexity to sustainable operations.

By understanding these issues, manufacturers can adopt targeted measures that address both performance and ecological impacts.

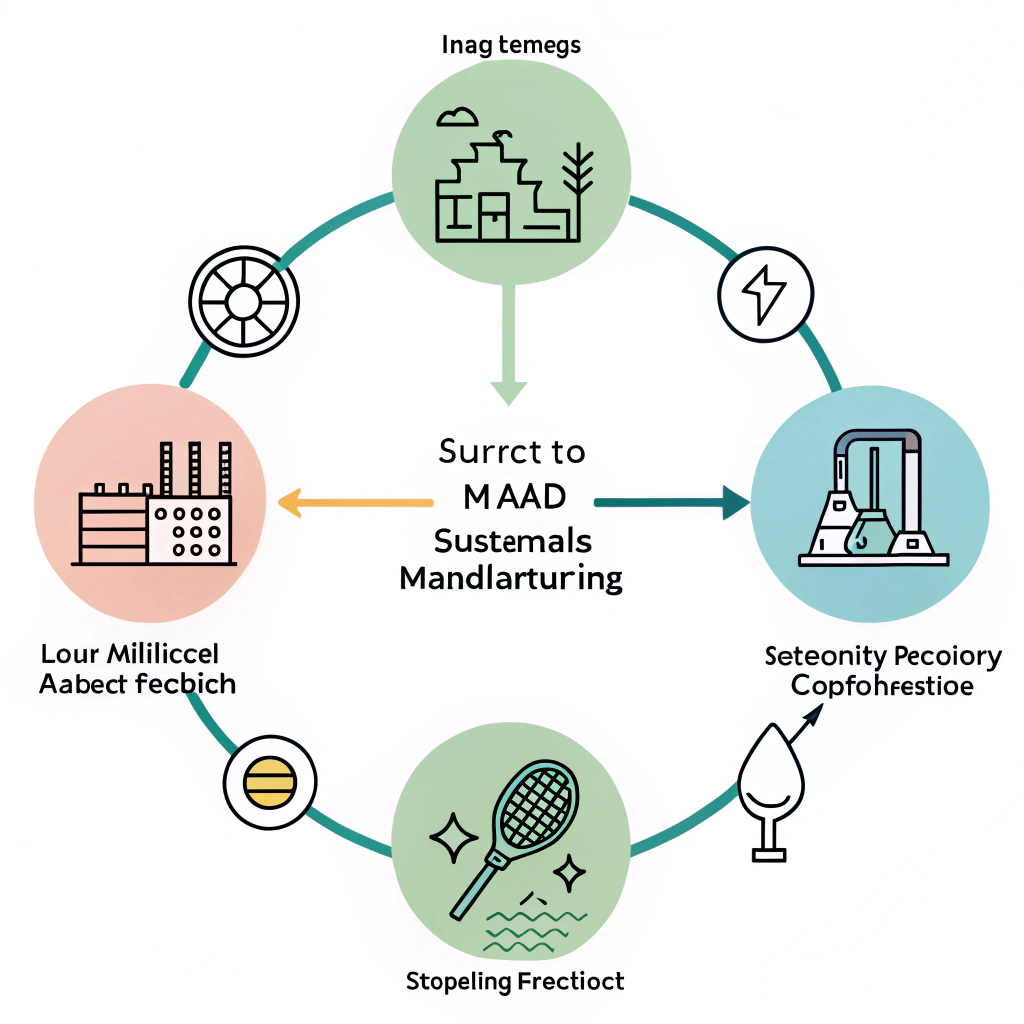

The path to sustainable padel racket production involves multiple strategies that span across material selection, process optimization, and supply chain management. Below is a comprehensive set of solutions designed to balance environmental responsibility with industrial performance.

Manufacturers can decrease environmental impact through smart material choices:

- Eco-friendly Carbon Fiber Options: Utilizing carbon fiber alternatives that are produced with environmentally responsible methods can reduce waste and energy use.

- Recycled Materials: Incorporating recycled components not only minimizes waste but also contributes to a circular economy.

- Customizable Materials: Leveraging options like Diamond, Round, and Teardrop designs with customizable shapes and colors can further enhance product appeal while being manufactured sustainably.

Improving manufacturing efficiency is crucial:

- Lean Production Techniques: Streamlined production reduces waste and minimizes resource consumption without compromising on product quality.

- Energy-Efficient Machinery: Upgrading to machinery that uses less energy can decrease operational costs and carbon footprint.

- Automation and Digital Monitoring: Integrating advanced production techniques ensures consistency in quality and adherence to eco-friendly practices.

Eco-friendly supply chain management plays a critical role:

- Optimized Supply Chain Efficiency: Collaborating closely with suppliers ensures that every element of production—from raw material acquisition to delivery—is sustainable.

- Waste Reduction Measures: Implementing systems for waste recycling and reusing production scraps supports environmental goals.

- Circular Economy Models: Embracing the concept of a circular economy means designing processes where waste materials are reintegrated into the production cycle.

The following table outlines a clear roadmap for transitioning to sustainable manufacturing practices for padel rackets:

| Step | Initiative | Benefits | Implementation Details |

|---|---|---|---|

| 1 | Material Audit | Identifies non-eco-friendly inputs | Conduct a comprehensive review of all raw materials and suppliers |

| 2 | Upgrade to Energy-Efficient Machinery | Lower energy consumption | Invest in modern production equipment with energy-saving features |

| 3 | Lean Production Integration | Reduced waste, optimized workflow | Adopt lean manufacturing principles and continuous improvement cycles |

| 4 | Enhanced Supply Chain Collaboration | End-to-end sustainability | Work with suppliers to ensure environmentally responsible practices |

| 5 | Recycling and Waste Reuse Programs | Minimized disposal needs | Establish internal recycling protocols and supplier take-back schemes |

| 6 | Certification and Compliance Auditing | Compliance with environmental regulations | Regular audits to ensure adherence to green production standards |

Implementing these initiatives will not only improve the ecological footprint but also enhance product quality and operational efficiency.

Consider a mid-to-large sporting goods brand that recently transitioned to sustainable production methods for their padel rackets. The company faced rising energy costs and increasing regulatory pressure regarding environmental impact.

Problem:

The brand was using traditional fibreglass for its rackets, which resulted in high energy consumption and significant waste. With emerging competition adopting eco-friendly practices, the company needed to adjust its manufacturing process to remain competitive.

Action Taken:

- Switched material sourcing from traditional fibreglass to eco-friendly carbon fiber alternatives that offer enhanced performance.

- Implemented lean production methodologies that reduced waste by 30%.

- Collaborated with suppliers to create a sustainable supply chain, ensuring that all materials met environmental standards.

- Invested in energy-efficient machinery that cut power consumption by 25%.

Results:

- The new technology improved the overall performance of the rackets, offering better power transfer and durability.

- The financial impact was significant; while there were initial costs, the long-term savings in energy and waste management led to improved margins.

- The environmentally friendly practices boosted the brand’s reputation, appealing to customers who prioritize sustainability.

This case illustrates that integrating sustainability in the production of padel rackets is not only feasible but also provides tangible benefits from both an operational and marketing standpoint.

Procurement managers must ensure that integrating sustainability does not compromise the performance expected by athletes and enthusiasts. Here are some critical aspects:

- Material Quality: Advanced carbon fibers, such as 3k, 12k, or 18k options, maintain the construction's integrity while being produced sustainably.

- Customization and Innovation: With the growing demand for customized products, sustainable manufacturing processes should also cater to design flexibility—from Diamond and Round to Teardrop shapes.

- Durability and Efficiency: High-performance padel rackets require precision engineering. By using lean production and quality monitoring, manufacturers can uphold quality while reducing environmental impact.

While the switch to sustainable practices might seem extensive initially, it offers significant returns in the long run:

- Reduced Waste Management Costs: Less material waste means lower disposal fees and a more efficient use of resources.

- Energy Savings: Modern, energy-efficient machinery reduces operational costs over time.

- Brand Value and Market Positioning: Today’s consumers and regulatory bodies value environmental responsibility, which can translate into enhanced market position and brand loyalty.

Manufacturers should view these changes as investments in the company’s future sustainability and competitiveness.

To successfully transition to a greener manufacturing process, consider the following best practices:

- Conduct a Full Environmental Audit: Identify areas in the production line where waste and inefficiency occur.

- Invest in Training and Technology: Equip your teams with the skills and tools necessary for lean production and energy-efficient operations.

- Engage Stakeholders: Involve employees, suppliers, and even customers in sustainability initiatives. Transparent communication about green practices can build trust and support.

- Monitor and Adjust: Use digital monitoring tools to track energy consumption and waste levels, ensuring continuous improvement.

- Certifications: Acquiring certifications for sustainability practices can enhance brand credibility and ensure compliance with international standards.

By following these guidelines, procurement and product development managers can successfully incorporate sustainability into their production cycles, contributing to long-term economic and environmental benefits.

Integrating sustainable manufacturing processes in the production of padel rackets is both a necessary and strategically beneficial shift for modern sporting goods companies. By carefully selecting eco-friendly materials, optimizing production processes with lean methods, and establishing a robust, green supply chain, manufacturers can achieve a balance between performance and environmental responsibility.

To summarize:

- Sustainable material choices like advanced carbon fibers ensure enhanced performance and lower environmental impact.

- Lean production methods reduce waste and energy consumption, resulting in cost efficiencies.

- Collaborative supply chains and waste management initiatives foster a circular economy that benefits both the environment and the bottom line.

- Real-world success stories reiterate that these changes lead to high performance, operational efficiency, and improved brand reputation.

Procurement managers are encouraged to begin with a detailed audit of current processes, followed by a phased implementation of sustainable measures. This proactive approach not only meets regulatory standards but also sets the stage for future innovations in padel racket manufacturing. Embrace the green revolution in production—your company, your clients, and the planet will all benefit.

What is the best material for padel racquets?

Carbon fibre is widely regarded as the best material for padel racquets because it is lightweight yet strong. High-performance carbon fibre enables rackets to maximize power and precision, providing advanced players with a significant performance edge.

What makes padel rackets so expensive?

Padel rackets can be expensive due to the high-quality materials like carbon fibre used in their construction. These materials not only deliver superior strength, lighter weight, and enhanced responsiveness but also involve advanced technology such as anti-vibration systems and customizable design features, all of which drive up costs.

Are tennis rackets sustainable?

The sustainability of tennis rackets largely depends on the materials and manufacturing processes used. Using recycled or eco-friendly alternatives can significantly reduce the carbon footprint, turning even traditional designs into more sustainable options.

-

Environmental compliance: Click to learn how understanding and meeting various environmental regulations can help companies reduce legal risks and enhance their reputation. ↩ ↩ ↩2

-

Sustainable manufacturing: Click to discover strategies and benefits of integrating eco-friendly practices into production processes for long-term efficiency and cost savings. ↩ ↩ ↩2

-

Eco-friendly carbon fiber options: Click to explore the advancements in carbon fiber production that reduce environmental impact while maintaining high performance. ↩ ↩ ↩2

-

Lean production methods: Click to understand how streamlining production processes can optimize resource usage and minimize waste. ↩ ↩ ↩2

-

Circular economy: Click to read about transforming waste into resources and the benefits of implementing circular economic models in manufacturing. ↩ ↩ ↩2