This article explains how partnering with a specialized OEM1 can provide a significant competitive edge when developing private label padel rackets. In brief, choosing an experienced manufacturer like NEX Padel means harnessing advanced production techniques2, customizable design options, and rigorous quality assurance3—all of which are essential in today’s competitive sports equipment market.

Private labeling4 padel rackets is a strategic move for sports brands and distributors looking to expand their market presence with unique products. In today’s market, a specialized manufacturer offers more than just a product; it provides a partnership built on advanced manufacturing processes, customization, and quality control. By leveraging our proven expertise at NEX Padel, you can ensure your padel rackets not only meet industry standards but set new benchmarks for performance and design.

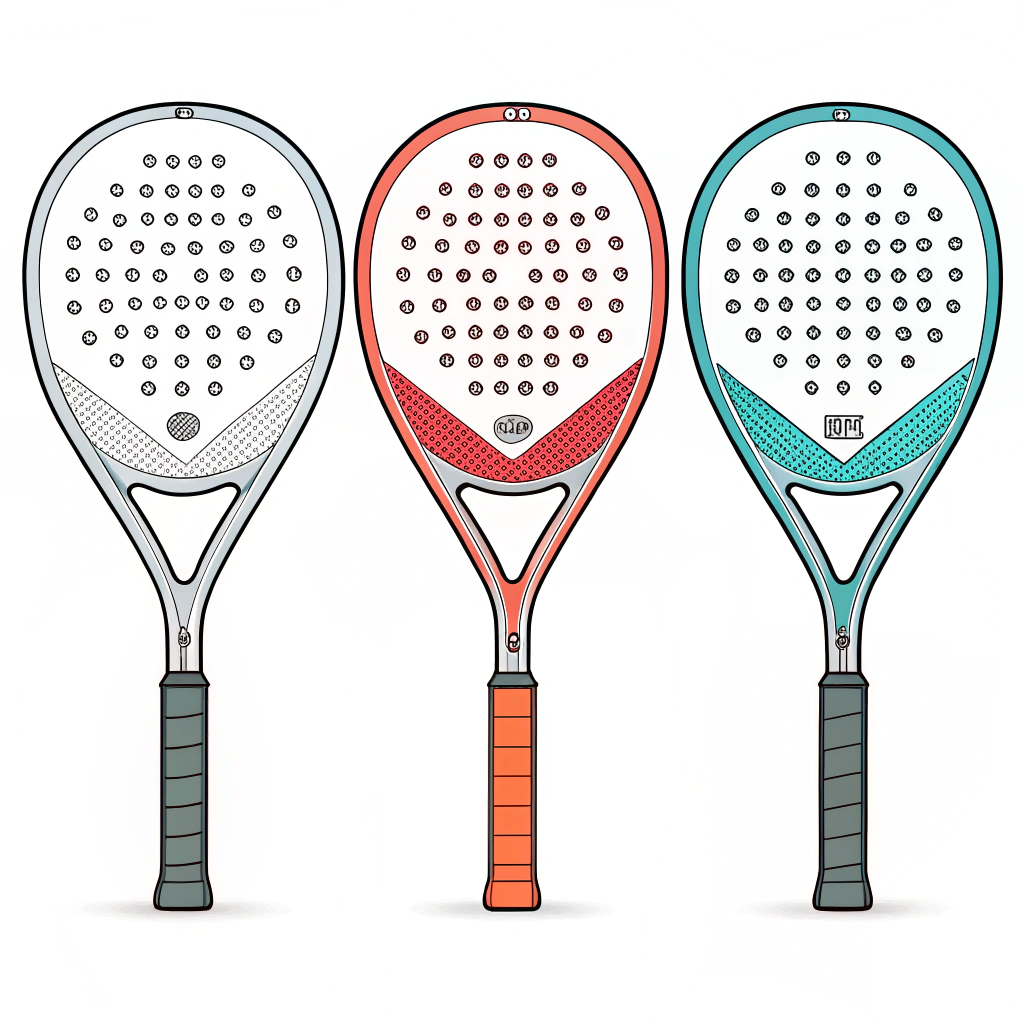

With our state-of-the-art facilities in Jiaxing, Zhejiang, China, and decades of accumulated production knowledge, our focus lies in delivering tailor-made solutions—from high-performance padel rackets with varied designs (Diamond, Round, or Teardrop) to customized ball production. This article compares the advantages of partnering with a specialized OEM versus conventional providers and provides detailed insights to support informed procurement decisions.

The padel racket market is rapidly evolving. Modern padel rackets incorporate high-tech materials such as various grades of carbon fiber5 (3k, 12k, 18k) that offer improved strength, reduced weight, and enhanced control. As product managers or procurement specialists, you face the challenge of not only sourcing high-quality equipment but also ensuring that the products carry unique brand identities and meet the growing demands of professional players.

Key industry factors include:

- Material Innovation: Transition from fiberglass to advanced carbon fiber composites.

- Customization: Bespoke designs, including shape, color, and branding options.

- Quality Assurance: Rigorous testing protocols ensure durability and performance.

- Production Efficiency: Rapid prototyping and short lead times enhance market responsiveness.

The need for a partner who can handle the intricate balance between customization and mass production is greater than ever.

When selecting an OEM to manufacture padel rackets, consider the following aspects:

-

Customization Capabilities:

- Options for different racket shapes (Diamond, Round, Teardrop)

- Custom branding including printing, logo placement, and hand grip design

- Flexibility in adapting to evolving market trends

-

Material Quality and Innovation:

- Use of high-grade materials including 3k, 12k, and 18k carbon fiber

- Expertise in integrating advanced composites and fiberglass

- Consistent quality control measures ensuring long-term durability

-

Production Efficiency and Scale:

- Proven lead times due to streamlined production processes

- Ability to handle both large-scale orders and limited bespoke manufacturing

- Coordination with supply chain partners for timely delivery

-

Quality Assurance and Testing:

- Detailed testing protocols for performance and safety

- Established relationships with key brand players (e.g., Hirostar, Reebok, Starvie)

- Regular quality audits and certifications adhering to international standards

To help you assess these points, the following table provides a comparison between a specialized OEM and a general manufacturing provider:

| Evaluation Criteria | Specialized OEM (e.g., NEX Padel) | General Provider |

|---|---|---|

| Customization Options | Extensive (shapes, prints, grips) | Limited |

| Material Quality | Advanced carbon composites | Standard materials |

| Production Efficiency | Rapid prototyping and quick delivery | Longer lead times |

| Quality Control | Rigorous, tested protocols | Basic quality checks |

| Industry Experience | Niche padel expertise | Broad, non-specific |

This detailed comparison highlights why a specialized OEM plays a vital role in enhancing product differentiation and market readiness.

NEX Padel employs state-of-the-art techniques that ensure every padel racket is crafted to meet exacting standards. Here’s a deeper look into our process:

- High-Quality Carbon Fiber: Utilizing grades from 3k to 18k, we ensure that each racket offers an optimal balance between durability and performance. This variety allows us to cater to various player levels and preferences.

- Innovative Molding Processes: Advanced molding techniques enable us to achieve precise shapes like Diamond, Round, and Teardrop. These methods play a crucial role in ensuring that every racket has consistent weight distribution and impact resistance.

- Bespoke Design Capabilities: Beyond the standard shapes, our manufacturing process allows complete customization. This includes custom printing, color schemes, and even personalized hand grips and covers.

- Design Prototyping: We offer rapid prototyping which facilitates faster design iterations. The ability to quickly adjust design and production factors means you are always ahead in the dynamic market.

- Integrated Branding: Customization extends to the small details—such as logo placements on the racket and hand grips—which are essential for private label products to maintain a unique brand identity.

Quality control stands as one of our strongest pillars. The entire production process is subject to strict quality checks at multiple stages:

- Material Inspection: Incoming materials are verified against our high standards.

- In-Process Testing: Rackets undergo performance testing during production to ensure that they meet the expected design parameters.

- Final Inspection: Every finished product is rigorously tested for durability, balance, and tensile strength before packaging.

Our agile production capacity means that whether you need a limited edition run or a large batch, we can adjust quickly:

- Quick Turnaround: Our efficient processes reduce lead times, enabling swift market launch.

- Adaptability: Customized manufacturing allows us to work on diverse order sizes without compromising quality.

Consider a scenario where a sports brand is looking to launch a new line of premium padel rackets under its private label. In their search for an OEM, they compare several suppliers based on customization, material integrity, and production efficiency. Here’s a simplified breakdown:

-

Challenge:

The brand wanted a product that would incorporate unique design elements, high performance, and rapid market entry. They also required a partner with proven expertise and flexibility in handling custom orders. -

Approach:

By partnering with a specialized provider like NEX Padel, the brand was able to:- Leverage advanced manufacturing techniques.

- Customize design elements extensively including print and grip designs.

- Benefit from quick turnaround times thanks to efficient production cycles.

-

Results:

The new product line not only met the desired quality benchmarks but also resonated with their target audience, leading to increased brand loyalty and market share. The collaboration emphasized that quality manufacturing coupled with customization is key to standing out in today's competitive market.

The advantages of partnering with us extend well beyond the production floor. Here’s why our expertise is vital:

-

Proven Track Record:

We have a history of manufacturing for world-renowned brands, ensuring that our processes and products meet global standards. Our experience with brands like Hirostar, Reebok, and Starvie is testament to our credibility. -

Full Customization:

For brands aiming to differentiate themselves, the ability to fully customize your padel rackets—from design to finish—is invaluable. This flexibility extends to padel balls as well, where we offer options tailored to performance needs (45% wool and 57% wool compositions). -

Advanced Production Processes:

We utilize precision techniques and rigorous quality checks that guarantee both speed and excellence. This means you never have to compromise quality for efficiency. -

Market Insight:

As a leading manufacturer in the sports equipment industry, we continuously monitor market trends and incorporate innovations that ensure your product remains competitive. -

End-to-End Solutions:

From initial design consultations to final product delivery, our services provide a comprehensive solution that covers every aspect of the manufacturing process—streamlining procurement decisions and reducing unforeseen risks.

When preparing to partner with an OEM, consider these actionable steps:

-

Evaluate Customization Options:

Ensure that your potential partner offers extensive options in design, branding, and materials to capture the unique essence of your brand. -

Assess Quality Assurance Practices:

Look for detailed quality control protocols at every stage of production. This minimizes the risk of product failures and ensures consistency. -

Examine Production Efficiency:

Confirm that the OEM has the capacity for rapid prototyping and fast delivery. Short lead times can be a critical factor in gaining market advantage. -

Request Case Studies and References:

Understanding the experiences of other brands can provide insight into the potential benefits and challenges of partnering with a specific manufacturer. -

Leverage Customized Solutions:

Use the opportunity to design a product that truly stands out in the market. A well-customized racket not only improves performance but also strengthens your brand identity.

By following these steps, you can confidently select a specialized OEM that aligns with your strategic goals, ensuring both product excellence and competitive market positioning.

In a competitive landscape where innovation and quality are paramount, partnering with a specialized OEM like NEX Padel can transform how your private label padel rackets perform in the market. Our commitment to advanced manufacturing techniques, full customization, and rigorous quality assurance makes us an ideal partner for sports brands seeking both differentiation and reliability.

The combination of superior materials, flexible design options, and efficient production processes not only drives down production risks but also builds long-term brand value. Whether you need a limited run or a full-scale production, our expertise helps accelerate your product launch, giving you the edge in a crowded market.

We invite you to contact us for a consultation and explore how NEX Padel can help elevate your private label offerings to new heights.

Q: What are the key advantages of partnering with a specialized OEM for padel racket manufacturing?

A: A specialized OEM offers extensive customization options, advanced materials like high-grade carbon fiber, rigorous quality control, and rapid production turnaround times—critical factors for producing high-performance, private label padel rackets.

Q: How does advanced manufacturing improve the quality of padel rackets?

A: Advanced manufacturing techniques ensure precise shaping, consistent weight distribution, and proper integration of materials, which together boost durability and performance, making the rackets competitive and reliable.

Q: Can specialized OEMs handle both large scale orders and bespoke design projects?

A: Yes, experienced specialized OEMs like NEX Padel are equipped for flexible production—from large-scale orders to fully customized designs—ensuring that every product meets specific client needs and market standards.

-

OEM: Click to read more about Original Equipment Manufacturers and how they serve as strategic production partners, offering expertise in manufacturing and supply chain management. ↩ ↩

-

Advanced production techniques: Click to learn about advanced production methods that improve product precision, efficiency, and innovation in manufacturing processes. ↩ ↩

-

Quality assurance: Click to discover quality assurance practices that ensure products meet rigorous performance standards through systematic testing and inspections. ↩ ↩

-

Private labeling: Click to explore how private labeling empowers brands to market customized products under their own brand name, enhancing differentiation and consumer trust. ↩ ↩

-

Carbon fiber: Click to understand the properties and benefits of carbon fiber, a high-performance material essential for lightweight and durable sports equipment. ↩ ↩